Beruflich Dokumente

Kultur Dokumente

Postharvest Ethylene: A Critical Factor in Quality Management

Hochgeladen von

German Antonio Aviles OrellanaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Postharvest Ethylene: A Critical Factor in Quality Management

Hochgeladen von

German Antonio Aviles OrellanaCopyright:

Verfügbare Formate

Sydney Postharvest Laboratory Information Sheet

Postharvest Ethylene: A critical factor in quality management.

By Jenny Jobling Ethylene plays a role in the postharvest life of many horticultural crops. Ethylene is a colourless gas with a faint sweetish smell that is the naturally produced ripening hormone of some fruit. It is also produced as an exhaust gas from petrol combustion engines. This article will outline some of the beneficial and negative effects of ethylene on the quality of fresh produce. The important role of ethylene as a plant growth regulator has only been established over the last 50 years but its effects have been known for centuries. Reid (1992) gives the example of how the flammable gas used for lighting street lamps in Europe contained added ethylene so the lamps burnt with a yellow flame. It was observed that plants growing near any leaky pipes showed some strange growth patterns such as premature leaf fall and death of their flowers. Observations like those spurred the research that continues today to determine the effects of ethylene on plant growth and development.

There are two classes of fresh produce in terms of ethylene production. There are climacteric products, mainly fruit that produce a burst of ethylene as they ripen, as well an increase in respiration and there are the non-climacteric products that do not increase ethylene production when they ripen. The more obvious way of establishing which class a product fits in to is whether or not the product ripens after harvest. Products that ripen after harvest are classed as climacteric and they typically ripen by softening significantly, by changing colour and become sweeter, examples are bananas and nectarines. Non-climacteric fruits do not change significantly after harvest. They will soften a little, lose green colour and develop rots as they become old but they do not change to improve their eating characteristics. Nonclimacteric crops include leafy vegetables, strawberries and grapes.

Table 1: Examples of climacteric and non-climacteric products. Climacteric Non-climacteric (Ethylene producing) (Non ethylene producing) Apples, pears, quince Cherry, blackberry, strawberry Apricot, nectarine, peach Eggplant, cucumber, pepper Mango, avocado, banana Lemon, orange, mandarin Tomato, sapodilla Water melon, honey dew melon Rock melon, passionfruit Grape, lychee, loquat * From Kader (1992). Postharvest Technology of Horticultural Crops. p.16.

www.postharvest.com.au

spl@postharvest.com.au

Sydney Postharvest Laboratory Information Sheet Beneficial Postharvest Applications Table 2: Ripening conditions for some fruit using ethylene. Fruit Temperature (oC) Ethylene (ppm) Avocado 18 - 21 10 Banana 15 - 21 10 Kiwifruit 18 - 21 10 Persimmon 18 - 21 10 Tomato 13 - 22 10 th *From Wills et al. (1998). Postharvest. 4 Edition. P. 209. The most commonly know use of ethylene is to trigger ripening is some crops, such as bananas and avocados. The application of ethylene at a controlled rate means that these products can be presented to the customer as ready to eat. For avocados this is a significant benefit as the consumer can now purchase an avocado to eat that night rather than buying a hard fruit that may take several days to ripen. Treatment time (hrs) 24 - 72 24 24 24 Continuous

and it can stimulate lateral branching in potted plants (azaleas and geraniums). All these responses are the result of the plant being exposed to fairly low concentrations of the plant growth regulator ethylene. Damaging Effect The presence of ethylene is not always beneficial, especially in terms of postharvest shelf life (Optimal Fresh, 2000). It seems that because it is a colourless gas that is not often measured in commercial situations its presence is over looked. A recent survey that included the wholesale markets, distribution centres and retail stores around Sydney showed that the concentration of ethylene present during the marketing of fresh produce was between 0.017 and 0.06 ppm. The main sources of ethylene during marketing and retail sale are from other ripening fruit in the market or storage room or from the exhaust gases of vehicles and forklift trucks. The levels reported had the potential to cause a 10 30% loss in shelf life of fresh produce (Wills et al., 2000). The effect of ethylene is accumulative so continuous exposure to a low concentration of ethylene throughout marketing can cause significant harm (Wills et al., 2000).

The concentration of ethylene required for the ripening of different products varies. The concentration applied is within the range of 1 and 100 ppm. The time and temperature of treatment also influences the rate of ripening with fruit being ripened at temperatures between 15 to 21 oC and relative humidity of 85 90 %. Although controlled ripening is the major postharvest use of ethylene it can also be applied pre-harvest to promote postharvest benefits. The chemical Ethephon produces ethylene and is applied in the field. Ethephon can promote several benefits such as fruit thinning (apples, cherries), fruit loosening prior to harvest (nuts), colour development (apples), degreening (citrus), flower induction (pineapples)

www.postharvest.com.au

spl@postharvest.com.au

Sydney Postharvest Laboratory Information Sheet However, the loss of shelf life will be most frustrating for the final consumer as the loss of quality will not be obvious during marketing and retail sale. The major reason for the loss of shelf life is that ethylene exposure increases the rate the product ages. In green tissue such leafy vegetables and cucumbers ethylene stimulates the loss of chlorophyll or green colour and also increases the susceptibility of the product to rots. For maximum shelf life and quality green leafy vegetables should not be stored or transported in trucks where there are mixed loads containing ripening fruit such as apples, pears, mangoes, tomatoes or bananas (Optimal Fresh, 2001). Lettuce is also susceptible to ethylene. It suffers from a distinctive disorder, called russet spotting as a result of exposure to ethylene. The symptoms of russet spotting are dark brown spotting of the mid-ribs of lettuce leaves. The quality of carrots can also be reduced as a result of ethylene exposure. In response to ethylene, carrots produce bitter tasting compounds called isocoumarins. It has been shown that concentrations of ethylene as low as 0.5 ppm can cause bitterness in carrots within 2 weeks of storage (Reid, 1992). Ethylene can also promote sprouting of potatoes and toughening of asparagus. A very obvious effect of ethylene is the loss of flowers or leaves from sensitive ornamental plants. Some common flowers that are ethylene sensitive include carnations, delphiniums, freesia, gypsophila and Geraldton wax. Sensitive plants should be treated with an ethylene inhibitor, such as silver thiosulfate or EthylBloc to prevent flower drop resulting from ethylene exposure and great care should be taken to avoid storage with ethylene producing produce. Reducing the Damaging Effects Preventing ethylene buildup around the product is often the simplest method of reducing the damaging effects of ethylene. For example products that are sensitive to ethylene are better handled with electric forklifts rather then gas powered ones. Trucks and forklifts should not be left idling in enclosed spaces or during loading or unloading of products. It is also important to remove over ripe or rotting fruit from the storage and handling area, as they are also sources of ethylene. For ethylene sensitive products it is important to avoid storing them with products that produce high levels of ethylene (Optimal Fresh, 2001). Increasing the ventilation rate of the storage area, assuming that the outside air is ethylene free is another way of reducing the level of ethylene around fresh produce. Ethylene can also be removed by using a number of chemical processes. The traditional method had been to use potassium permanganate or Purafil. Potassium permanganate reacts with ethylene to produce carbon dioxide and water. In order to scrub the air efficiently it is best to spread the potassium permanganate over as larger a surface area as possible either in trays or within highly permeable bags. For cut flowers it is possible to pulse the stems with a solution of silver thiosulfate. The flowers take the solution up through their stems and this protects them from the effects of ethylene. There is another relatively spl@postharvest.com.au

www.postharvest.com.au

Sydney Postharvest Laboratory Information Sheet new compound called EthylBloc that is distributed in Australia by Rohm and Hass. EthylBloc is a gaseous compound that inhibits the effects of ethylene. It is effective at very low concentrations, as low as 10 parts per billion (ppb). The active ingredient is 1MCP (1-methylcyclopropene). Recently there was an article in Good fruit and Vegetables (10:12), May 2000 reporting the potential benefit of using 1-MCP on bananas to prevent premature ripening. EthylBloc can be used for treatment of flowers but is currently not registered for use on food crops, however registration is in progress. Ethylene is a very important plant hormone and it plays a significant role in the postharvest life of fresh produce. Sometimes being positive and sometimes not. The damage resulting from ethylene exposure could easily be minimised if there was a greater awareness of the potential harm and the simple measures that can be used to prevent damage. References EthylBloc web site: www.ethylbloc.com Macnish, A., Joyce, D., Hofman, P. and Simons D. (2000). !-MCP gas can be used to control banana ripening. Good Fruit and Vegetables. 10(12): 56. Optimal Fresh (2001). The Fruit, Vegetable & Fresh Produce Storage Expert System. CSIRO Publishing, Collingwood Vic. Australia. Reid, M. (1992). Ethylene in Postharvest Technology. In. Postharvest Technology of Horticultural Crops. Publication 3311 University of California p. 97 108.

Wills, R.B.H., Warton, M.A. and Ku, V.V.V. (2000). Ethylene levels associated with fruit and vegetables during marketing. Australian Journal of Experimental Agriculture 40(3): 357 492. Wills, McGlasson, Graham and Joyce (1998). Postharvest. An introduction to the physiology and handling of fruit, vegetables and ornamentals. 4th Edition. UNSW Press, Sydney.

This article originally appeared in Good Fruit and Vegetables magazine 11. December 2000 (Melbourne, Australia)

Jenny Jobling is research manager at Sydney Postharvest Laboratory that is located at Food Science Australia and provides expert, independent postharvest horticultural research and advice. Sydney Postharvest Laboratory PO Box 52 North Ryde NSW 2113 Ph: 02 9490 8333, Fax: 02 9490 8499 Email: spl@postharvest.com.au

www.postharvest.com.au

spl@postharvest.com.au

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- House Health Reform BillDokument1.018 SeitenHouse Health Reform BillFOXBusiness.com100% (6)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Compost UseDokument2 SeitenCompost UseGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Ejercicios de Fortalecimiento (Musculación) Tomados de Muscle & Fitness - 102 Pags en PDFDokument102 SeitenEjercicios de Fortalecimiento (Musculación) Tomados de Muscle & Fitness - 102 Pags en PDFmapi_pv100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- House Health Reform BillDokument1.018 SeitenHouse Health Reform BillFOXBusiness.com100% (6)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Guidebook For The Preparation of HACCP PlansDokument74 SeitenGuidebook For The Preparation of HACCP Planslatog13Noch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Heard Health and Management Action PlanDokument2 SeitenHeard Health and Management Action PlanGerman Antonio Aviles OrellanaNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Broshure Oftof Post Harvest Technology Short CourseDokument2 SeitenBroshure Oftof Post Harvest Technology Short CourseGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Chlorine Use in Produce Packing LinesDokument5 SeitenChlorine Use in Produce Packing LinesGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Portable Demonstration Forced - Air CoolerDokument17 SeitenA Portable Demonstration Forced - Air CoolerGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Harvest and Field Satin at Ion Action PlanDokument2 SeitenHarvest and Field Satin at Ion Action PlanGerman Antonio Aviles OrellanaNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Handling, Cooling and Sanitation Techniques For Maintaining Post Harvest QualityDokument3 SeitenHandling, Cooling and Sanitation Techniques For Maintaining Post Harvest QualityGerman Antonio Aviles OrellanaNoch keine Bewertungen

- E (1) .Coli 0157 Via Product InformationDokument2 SeitenE (1) .Coli 0157 Via Product InformationGerman Antonio Aviles OrellanaNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Portable Demonstration Forced - Air CoolerDokument17 SeitenA Portable Demonstration Forced - Air CoolerGerman Antonio Aviles OrellanaNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Juice and Cider Production Action PlanDokument2 SeitenJuice and Cider Production Action PlanGerman Antonio Aviles OrellanaNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Farm BioDokument2 SeitenFarm BioGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Direct Marketing Action PlanDokument3 SeitenDirect Marketing Action PlanGerman Antonio Aviles OrellanaNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- U-Pick Operations Action PlanDokument2 SeitenU-Pick Operations Action PlanGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- Crisis MGMTDokument2 SeitenCrisis MGMTGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Record KeepingDokument3 SeitenRecord KeepingGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Toilets and Hand Washing Facilities Action PlanDokument2 SeitenToilets and Hand Washing Facilities Action PlanGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Worker Hygiene Trining Action PlanDokument2 SeitenWorker Hygiene Trining Action PlanGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Cert If ReportDokument4 SeitenCert If ReportGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Wild Animal Management Action PlanDokument1 SeiteWild Animal Management Action PlanGerman Antonio Aviles OrellanaNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Petting Zoos and Farm Animals Action PlanDokument3 SeitenPetting Zoos and Farm Animals Action PlanGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Packing House Satin at Ion and Safety Action PlanDokument6 SeitenPacking House Satin at Ion and Safety Action PlanGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Perticide Use and Storage Action PlanDokument3 SeitenPerticide Use and Storage Action PlanGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Manure Sources and Application Practices Action PlanDokument4 SeitenManure Sources and Application Practices Action PlanGerman Antonio Aviles OrellanaNoch keine Bewertungen

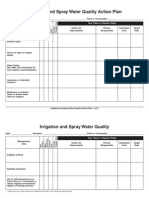

- Irriugation and Spray Water Quality Action PlanDokument4 SeitenIrriugation and Spray Water Quality Action PlanGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Juice and Cider Production Action PlanDokument2 SeitenJuice and Cider Production Action PlanGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Heard Health and Management Action PlanDokument2 SeitenHeard Health and Management Action PlanGerman Antonio Aviles OrellanaNoch keine Bewertungen

- Laboratory Tests for Hemostasis EvaluationDokument5 SeitenLaboratory Tests for Hemostasis EvaluationCMLNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Primer: Gastro-Oesophageal Reflux DiseaseDokument23 SeitenPrimer: Gastro-Oesophageal Reflux Diseasejcacia17Noch keine Bewertungen

- Krok 2 - 2021 - 26 JulyDokument19 SeitenKrok 2 - 2021 - 26 JulyNicole VinnikNoch keine Bewertungen

- Microbial GrowthDokument48 SeitenMicrobial Growthdreamrose100% (14)

- ICU One Pager Enteral NutritionDokument1 SeiteICU One Pager Enteral NutritionjalilNoch keine Bewertungen

- Irritablebowelsyndrome: What Treatments Really WorkDokument16 SeitenIrritablebowelsyndrome: What Treatments Really WorkTeodora RaindropNoch keine Bewertungen

- AIPG Paper CorrectedDokument42 SeitenAIPG Paper CorrectedbrihaspathiacademyNoch keine Bewertungen

- Choosing the Right PaediatricianDokument263 SeitenChoosing the Right PaediatricianSuneethaVangala100% (1)

- Philippine Primary Care Studies: Pilot Study at The UP Health ServiceDokument60 SeitenPhilippine Primary Care Studies: Pilot Study at The UP Health ServiceBryan SalvaNoch keine Bewertungen

- Epidemiology SlidesDokument30 SeitenEpidemiology SlidesHongMingNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Cannabis Phenolics and Their BioactivitiesDokument44 SeitenCannabis Phenolics and Their BioactivitiesTomislav ĆurićNoch keine Bewertungen

- United Home Whitfield's OintmentDokument5 SeitenUnited Home Whitfield's OintmentWalidur Rahman MridulNoch keine Bewertungen

- Test Bank For Introductory Maternity and Pediatric Nursing 2nd Edition by KlossnerDokument9 SeitenTest Bank For Introductory Maternity and Pediatric Nursing 2nd Edition by KlossnerJulieJacobsrkozw100% (84)

- Nume CNP Sex Varsta Dimensiune Pozitie PietreDokument12 SeitenNume CNP Sex Varsta Dimensiune Pozitie PietreGabriel BurteaNoch keine Bewertungen

- Everything You Need to Know About Prenatal CareDokument5 SeitenEverything You Need to Know About Prenatal Carelaura fernandiaNoch keine Bewertungen

- ABO Incompatible Platelets: Risks Versus Benefit: ReviewDokument5 SeitenABO Incompatible Platelets: Risks Versus Benefit: Reviewmy accountNoch keine Bewertungen

- Poultry ParasitesDokument164 SeitenPoultry ParasitesGiselle Castro Sabino100% (1)

- Ramadan Fasting and Infectious Diseases: A Systematic ReviewDokument9 SeitenRamadan Fasting and Infectious Diseases: A Systematic ReviewBasel SoudanNoch keine Bewertungen

- Surgical Hand WashDokument6 SeitenSurgical Hand WashAnn Mayie100% (2)

- Ms. Michelle Lau Sook Yee (First Speaker)Dokument5 SeitenMs. Michelle Lau Sook Yee (First Speaker)Nurhidayah MuhamadNoch keine Bewertungen

- Psychiatric Nursing Mastery Test Part 2Dokument16 SeitenPsychiatric Nursing Mastery Test Part 2Rika MaeNoch keine Bewertungen

- First Division (G.R. No. 217036, August 20, 2018)Dokument12 SeitenFirst Division (G.R. No. 217036, August 20, 2018)Emir MendozaNoch keine Bewertungen

- Biology 10Th Edition Raven Test Bank Full Chapter PDFDokument36 SeitenBiology 10Th Edition Raven Test Bank Full Chapter PDFlewis.barnes1000100% (12)

- MCQs 08Dokument39 SeitenMCQs 08api-3736493100% (2)

- Internet Book of Critical Care (IBCC) : Rapid ReferenceDokument1 SeiteInternet Book of Critical Care (IBCC) : Rapid Referenceian porterNoch keine Bewertungen

- Homeoapthy For InfantsDokument9 SeitenHomeoapthy For Infantspavani_upNoch keine Bewertungen

- How Can Women Make The RulesDokument0 SeitenHow Can Women Make The Ruleshme_s100% (2)

- Canine Disobedient, Unruly and ExcitableDokument5 SeitenCanine Disobedient, Unruly and ExcitableBrook Farm Veterinary CenterNoch keine Bewertungen

- Allele-specific expression of variant-specific surface proteins in Giardia lambliaDokument7 SeitenAllele-specific expression of variant-specific surface proteins in Giardia lambliawiwienNoch keine Bewertungen

- CucumberDokument25 SeitenCucumberDa Nie LNoch keine Bewertungen

- The Dragons of Eden: Speculations on the Evolution of Human IntelligenceVon EverandThe Dragons of Eden: Speculations on the Evolution of Human IntelligenceBewertung: 4 von 5 Sternen4/5 (632)

- Why We Die: The New Science of Aging and the Quest for ImmortalityVon EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityBewertung: 3.5 von 5 Sternen3.5/5 (2)

- When the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisVon EverandWhen the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisBewertung: 3.5 von 5 Sternen3.5/5 (2)

- The Consciousness Instinct: Unraveling the Mystery of How the Brain Makes the MindVon EverandThe Consciousness Instinct: Unraveling the Mystery of How the Brain Makes the MindBewertung: 4.5 von 5 Sternen4.5/5 (93)

- Crypt: Life, Death and Disease in the Middle Ages and BeyondVon EverandCrypt: Life, Death and Disease in the Middle Ages and BeyondBewertung: 4 von 5 Sternen4/5 (3)

- Masterminds: Genius, DNA, and the Quest to Rewrite LifeVon EverandMasterminds: Genius, DNA, and the Quest to Rewrite LifeNoch keine Bewertungen

- The Lives of Bees: The Untold Story of the Honey Bee in the WildVon EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildBewertung: 4.5 von 5 Sternen4.5/5 (44)