Beruflich Dokumente

Kultur Dokumente

Piping Engineering - Iit

Hochgeladen von

prajmen0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

314 Ansichten202 SeitenCopyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

314 Ansichten202 SeitenPiping Engineering - Iit

Hochgeladen von

prajmenCopyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 202

|

Bt

a

Certificate Course

on

PIPING ENGINEERING

June 12 - 25, 2006

Organized by

Piping Engineering Cell

Computer Aided Design Centre

Indian Institute of Technology, Bombay

Powai, Mumbai - 400 076

40"

Certificate Course on Piping Engineering

June 12-25, 2006

ig Engineering Cell, CAD Centre, IT Bombay

At

Dr. Babasaheb Ambedkar Technological University, Lonere

‘Monday, June 12, 2006

1030:1100 Inauguration

1100:1130 Tea

Introduction to Piping Engineering

1300:1400 Lunch

1400:1600 Introduction to Piping Engineering,

1600:1630 Tea

1630:1730 Introduction to Piping Engineering

Tuesday, June 13 to Saturday, June 24, 2006

There will be four sessions every day (except on June 21 which is a rest day in the

course).

0930:1100, 1130:1330, 1430:1600, 1630:1730

The tentative topics on these days are as follows.

Tuesday, June 13, 2006 Pipe Sizing

Wednesday, June 14, 2006 Mechanical Design Fundamentals —

Thursday, June 15, 2006 ‘Tutorials and Practical on Pipe Design

Friday, June 16, 2006 Codes & Standards, Piping Elements

Saturday, June 17, 2006 Valves, Basics of Drawing

Sunday, June 18, 2006 Plot Plan, Equipment & Piping Layout

Monday, June 19, 2006 Transient Flow, Pipe Under Stress, Tutorials

Tuesday, June 20, 2006 Nozzle Reinforcement, Cross-country Pipeline

Wednesday, June 21, 2006 Excursion/Rest Day

Thursday, June 22, 2006 Flexibility Analysis

Friday, June 23, 2006 Flexibility Analysis

Saturday, June 24, 2006 Support Selection & Design, Expansion Joints,

Jacketed Piping Design

Sunday, June 25, 2006

0930:1130 Quiz and Feedback

1200:1300 Closing Remarks

1300:1330 Certificate Distribution

PIPING ENGINEERING CELL.

INTRODUCTION

About two decades ago, in India, the

design procedure for piping systems for

Refineries, Petrochemicals and Fertilizer

Plants, in magnitude, depth and

complexities were not fully evolved. Only

in the recent past, we were exposed in

detail to this field. Now we are self:

sufficient in the field of piping technology

and design.

Piping systems in a chemical plant are

comparable to the vanes and arteries

through which fluids, vapors, slurries,

solids, ete. flow under various conditions,

as imposed by the process design of the

plant. Piping network is subjected to

almost all the severest conditions of the

plant such as high temperature, pressure,

flow and combination of these. In

addition to the above, corrosion, erosion,

toxic conditions and radioactivity add to

more problems and difficulties in piping

design, With the process conditions

becoming more and more severe by the

advancement in process development, a

continuous effort is required to be carried

on simultaneously to cope up with the

demands of process. This makes the job of

a piping engineer more complex and

responsible.

Piping, because of its nature, requires a

number of day to day decisions on matters

of detail, which, in some ways are often

more difficult to solve than major issues

connected with the project. It is this same

detail which can cause expensive delays in

design and construction and consequently

in commissioning. All too often in the

past, piping has been regarded as an

unimportant job in the overall project

engineering instead of being treated as a

function requiring as wide a knowledge,

experience and variety skills as any other

branch of engineering.

In almost all chemical industries, the

installed capital cost of piping is a major

factor in plant investment. Figs. 1 and

2 show a chart based on oil refineries,

chemical and petrochemical complexes.

Fig. 1 shows that, excluding major

equipment costs, piping is the largest plant

cost component. It exceeds the next

largest component by a factor of two. It is

also observed from Fig. 3 that piping

exceeds all other field costs by a

substantial amount. Fig. 2 indicates that

design engineering utilizes approximately

45% of engineering man-hours and 50%

of these hours are used in piping design.

In addition to the above, the lost time in

piping has an effect, which goes well

beyond its direct cost, as it involves

financial loss in some proportion to the

total plant investment. The delay in and

during start up means idle capital and

losses in plant earning capacity.

In the recent years, the trend is to develop

better techniques so as to save time in

piping activities. Computer is being used

extensively to obtain rapid solutions to the

more complex problems of plant design

and, in so for as piping is concemed, to

the solving of problems of pipe stressing.

More recently, itis being employed for

production of piping detail drawings,

piping isometrics, bill of materials, cost

estimation and control. Piping engineer

has therefore a further responsibility in

understanding and application of

continually growing techniques of this

ature.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Whats Different in B31.1 PDFDokument30 SeitenWhats Different in B31.1 PDFhirenkumar patel100% (2)

- Process Plant Layout and Piping DesignDokument460 SeitenProcess Plant Layout and Piping Design~E~97% (32)

- Piping Drawings Basics: Mr. T. N. GopinathDokument39 SeitenPiping Drawings Basics: Mr. T. N. Gopinathhirenkumar patel100% (1)

- Flexibility and Weight Analysis For Piping SystemsDokument16 SeitenFlexibility and Weight Analysis For Piping Systemshirenkumar patelNoch keine Bewertungen

- EJMA Standard 9th Ed. 2008 - Standards of The Expansion JoinDokument238 SeitenEJMA Standard 9th Ed. 2008 - Standards of The Expansion Joinmichski4488% (8)

- Pipingflexibilityanalysis PDFDokument762 SeitenPipingflexibilityanalysis PDFhirenkumar patel100% (1)

- Pipeline BendsDokument18 SeitenPipeline Bendshirenkumar patelNoch keine Bewertungen

- Pipeline Pigging (Visit http://Piping-Info - Blogspot.com)Dokument33 SeitenPipeline Pigging (Visit http://Piping-Info - Blogspot.com)Antoshal100% (7)

- Equipment & Piping Layout T.N. GopinathDokument88 SeitenEquipment & Piping Layout T.N. Gopinathhirenkumar patelNoch keine Bewertungen

- Piping Layout PresentationDokument56 SeitenPiping Layout Presentationhirenkumar patel89% (9)

- TTI Catalogue PDFDokument1 SeiteTTI Catalogue PDF24horas2Noch keine Bewertungen

- Process Plant LayoutDokument2 SeitenProcess Plant LayoutvijeyimusNoch keine Bewertungen

- Pipe Cost #Dokument5 SeitenPipe Cost #processpipingdesignNoch keine Bewertungen

- Seamless VS Welded TubesDokument1 SeiteSeamless VS Welded Tubeshirenkumar patelNoch keine Bewertungen

- Pipe Marker RegulationsDokument5 SeitenPipe Marker Regulationshirenkumar patelNoch keine Bewertungen

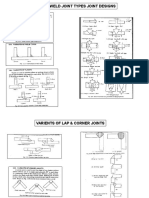

- Weld Training JointsDokument12 SeitenWeld Training Jointshirenkumar patel100% (1)

- Piping Manual For Stainless Steel Pipe For BuildingDokument246 SeitenPiping Manual For Stainless Steel Pipe For Buildinghirenkumar patel100% (1)

- Equipmentand Piping 1Dokument39 SeitenEquipmentand Piping 1hirenkumar patelNoch keine Bewertungen

- Carbon SteelDokument15 SeitenCarbon Steelhirenkumar patelNoch keine Bewertungen

- Piping Isometric by Sateesh LeleDokument46 SeitenPiping Isometric by Sateesh Lelehirenkumar patelNoch keine Bewertungen

- Piping FittingsDokument21 SeitenPiping Fittingshirenkumar patelNoch keine Bewertungen

- Pipe Tapping ComponentsDokument11 SeitenPipe Tapping Componentshirenkumar patelNoch keine Bewertungen

- Equipmentand Piping 2Dokument55 SeitenEquipmentand Piping 2hirenkumar patelNoch keine Bewertungen

- 04 ExtrusionDokument57 Seiten04 Extrusion9811923100% (1)

- Design Guidelines For The Selection & Use of Stainless Steel PDFDokument55 SeitenDesign Guidelines For The Selection & Use of Stainless Steel PDFhirenkumar patelNoch keine Bewertungen

- Piping Engineering-Iit Material PDFDokument202 SeitenPiping Engineering-Iit Material PDFhirenkumar patelNoch keine Bewertungen

- Piping Vibration & Stress by J.c.wachel PDFDokument9 SeitenPiping Vibration & Stress by J.c.wachel PDFhirenkumar patel100% (1)

- General Piping DesignDokument32 SeitenGeneral Piping DesignS_hassan_16Noch keine Bewertungen

- Welded Tube PDFDokument17 SeitenWelded Tube PDFhirenkumar patelNoch keine Bewertungen