Beruflich Dokumente

Kultur Dokumente

Flexovit Abrasives - Troubleshooting Diamond Abrasives

Hochgeladen von

Flexovit AbrasivesCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Flexovit Abrasives - Troubleshooting Diamond Abrasives

Hochgeladen von

Flexovit AbrasivesCopyright:

Verfügbare Formate

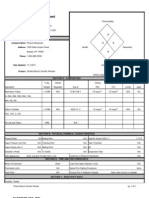

Diamond Abrasives Information Troubleshooting

Core or Segment Cracks

Cause - Blade is too hard for

material being cut. blade.

Undercutting

Cause - Steel

core wears faster than diamond segments. Highly abrasive fines grind against blade during cutting.

Solution - Use a softer bonded Cause - Blade mounted improperly;

Saw is in need of repair.

Solution - Check if saw is in good

condition and make sure the blade is the correct diameter and has the proper RPM rating for the equipment used. Check all bearings, belts, shaft, and flanges. Check direction of blade travel.

Solution - Use a

blade with wearretardant cores. Increase water flow to flush out cut.

Uneven Segment Wear

Cause - Insufficient water flow on

one side of the blade.

Arbor Hole Out-of-Round

Cause - Blade collar not properly Solution - Tighten arbor nut with

tightened, allowing blade to rotate or vibrate on shaft. wrench making sure blade is properly secured.

Solution - Flush water system and Cause - Equipment defect which

worn arbor shaft, or misaligned spindle.

check for adequate and equal water flow/distribution. causes segment to wear unevenly.

Solution - Replace bad bearings,

Cause - Blade not properly mounted. Solution - Check to make sure

blade is mounted on proper diameter of shaft before tightening arbor nut. Make sure pin hole slides over drive pin.

Wobbling / Warped Blade

Causes - Blade collar mounted improperly.

Incorrect collar size. Blade used improper RPM.

Segment Loss

Cause - Blade is too hard for material being cut. Solution - Use blade with

proper specification for material being cut.

Solution - Check RPM rating for blade and saw.

Make sure equipment is operating at rated RPM. Use correct sized blade collars. Check flanges for smoothness and tightness.

Cause - Steel core is not straight as a result of

dropping or twisting.

Cause - Steel Center is

worn due to undercutting.

Solution - Discard blade, it is unsafe to use.

Solution - Use sufficient

water to flush out cut.

Short Blade Life

Cause - Blade is too soft for material. Solution - Choose blade with a more wear-resistant bond

appropriate for the application. Check water flow and make sure blade is rated for the equipment used.

Slow Cutting Speed

Cause - Material being cut is too hard for the blade. The hard

material wears too slowly, no new diamonds are exposed.

Solution - Cut a soft abrasive material until new diamonds as

well exposed. Try asphalt block, sandstone, or dried mortar. Choose proper blade for the application.

Overheating

Cause - Inadequate coolant. Solution - Follow guidelines for proper blade operation and

cooling procedures. Check water flow. Make sure blade is rated for the equipment used.

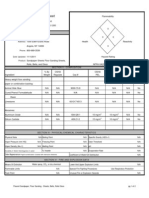

Safety & Equipment

Diamond Blade Safety

Personal protective equipment: Operator and bystanders must always wear ANSI Z87.1 eye protection, hearing protection, and protective clothing. Dust: Use of this product can generate dust containing chemicals known to cause cancer, birth defects, reproductive harm, and other respiratory injury. The operator and bystanders must use OSHA/ANSI-approved respiratory protection suitable for the specific application. -Read and understand these warnings and instructions before operating and the tool. -Always keep all parts of your body away from the wheel and other moving parts. -Always let the wheel come to a complete stop before setting the tool down. -Do not operate in combustible environments sparks could cause a fire or explosion. -Do not touch or try to stop a moving wheel with your hand. -Do not apply side pressure to the wheel, such as side grinding or twisting or wedging the wheel in a cut. -Do not touch a dry cutting wheel immediately after use, it may be hot.

WARNING

Comply with ANSI B7.1. Failure to comply could result in bodily injury. ANSI refers to the American National Standards Institute, Inc. 430 Broadway, NY 10018

Safety Precautions

Use Ear Protection

Use Eye Protection

Use Face Mask

Read Instructions

Use Gloves

Types of Equipment

Type of Use

Stone Saw

Masonry Saw

Angle Grinder

Tile Saw

Wall Saw

Wet Use

Circular Saw

Trowel Machine

Riding Trowel Machine

Tuck Pointer

High Speed Gas Saw

Dry Use

Flat Saw

Floor Grinder

Hand Drill

Core Drilling Machine

Dry / Wet Use

Cutting Depths & Operating Speeds

C utting Depths

Diameter T ile S a ws Wa lk Ma s onr y B ehind S a ws C onc r ete S a ws A ngle G r inder s , C ir c ula r S a ws & Dr ills 1" 1-1/4" 1-1/2" 2" 1-1/2" 2" 2-1/2" 3" Wa ll S a ws H igh S peed S a ws R ec ommended R PM MA XIMU M R PM

4" 4-1/2" 5" 6" 7" 8" 9" 10" 12" 12" - High Speed Saw 14" 14" High Speed Saw 16" 16"- High Speed Saw 18" 20" 24" 26" 30" 36" 42" 48"

3/4" 1" 1-1/4" 1-3/4" 2-1/4" 2-3/4" 3-1/4" 3-3/4" 3-5/8"

9, 072 8, 063 7, 257 6, 048 5, 184 4, 536 4, 032 3, 629 3, 024 4"

15, 000 13, 300 12, 000 10, 185 8, 730 7, 640 6, 790 6, 115 5, 095 6, 300

4-5/8"

5"

4-5/8" 5"

2, 592

4, 365 5, 460

5-5/8" 6" 6-5/8" 7-5/8" 9-5/8" 10-5/8" 11-3/4" 14-3/4" 17-1/2" 19-3/4" 11-1/2" 14-1/2" 17-1/2" 20-3/4" 7" 8" 9-1/2" 6-1/2"

2, 268

3, 820 4, 725

2, 016 1, 814 1, 512 1, 396 1, 120 1, 008 864 756

3, 395 3, 055 2, 550 2, 350 2, 040 1, 700 1, 455 1, 275

1-800-689-FLEX (3539) NOTES:

flexovitabrasives.com

Das könnte Ihnen auch gefallen

- Flexovit Abrasives - Label Specification ChartDokument1 SeiteFlexovit Abrasives - Label Specification ChartFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Bench Grinder WheelsDokument2 SeitenFlexovit Abrasives - Bench Grinder WheelsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Cartridge Rolls Spiral Bands PadsDokument2 SeitenFlexovit Abrasives - Cartridge Rolls Spiral Bands PadsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Mounted Flap WheelsDokument2 SeitenFlexovit Abrasives - Mounted Flap WheelsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Grinding Cutoff Wheels Reinforced ResinoidDokument2 SeitenFlexovit Abrasives - Grinding Cutoff Wheels Reinforced ResinoidFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Nylon Pads and Mesh ScreensDokument2 SeitenFlexovit Abrasives - Nylon Pads and Mesh ScreensFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Vitrified Mounted PointsDokument2 SeitenFlexovit Abrasives - Vitrified Mounted PointsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Cupstone Hand Rubs Floor StonesDokument2 SeitenFlexovit Abrasives - Cupstone Hand Rubs Floor StonesFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Resinoid Bonded Plugs and ConesDokument2 SeitenFlexovit Abrasives - Resinoid Bonded Plugs and ConesFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Carbide BursDokument4 SeitenFlexovit Abrasives - Carbide BursFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Floor Sanding Sheets Rolls Belts DiscsDokument3 SeitenFlexovit Abrasives - Floor Sanding Sheets Rolls Belts DiscsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Flap DiscsDokument2 SeitenFlexovit Abrasives - Flap DiscsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Quick Change Sanding DiscsDokument1 SeiteFlexovit Abrasives - Quick Change Sanding DiscsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - PSA Sanding DiscsDokument2 SeitenFlexovit Abrasives - PSA Sanding DiscsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Sanding BeltsDokument1 SeiteFlexovit Abrasives - Sanding BeltsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Resin Fiber Discs Ceramic GrainDokument2 SeitenFlexovit Abrasives - Resin Fiber Discs Ceramic GrainFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Sandpaper and Floor Sanding Sheets Rolls Belts DiscsDokument2 SeitenFlexovit Abrasives - Sandpaper and Floor Sanding Sheets Rolls Belts DiscsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Resin Fiber Sanding DiscsDokument2 SeitenFlexovit Abrasives - Resin Fiber Sanding DiscsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Shop and Plumber RollsDokument1 SeiteFlexovit Abrasives - Shop and Plumber RollsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Steel Wool PadsDokument1 SeiteFlexovit Abrasives - Steel Wool PadsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Hand-PadsDokument1 SeiteFlexovit Abrasives - Hand-PadsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Trim Kut Sanding DiscsDokument1 SeiteFlexovit Abrasives - Trim Kut Sanding DiscsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Surface Conditioning Discs BeltsDokument2 SeitenFlexovit Abrasives - Surface Conditioning Discs BeltsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Unmounted Flap WheelsDokument1 SeiteFlexovit Abrasives - Unmounted Flap WheelsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Nylon Floor PadsDokument2 SeitenFlexovit Abrasives - Nylon Floor PadsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives CatalogDokument92 SeitenFlexovit Abrasives CatalogFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Clean Strip DiscsDokument2 SeitenFlexovit Abrasives - Clean Strip DiscsFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives - Diamond BladesDokument3 SeitenFlexovit Abrasives - Diamond BladesFlexovit AbrasivesNoch keine Bewertungen

- Flexovit Abrasives Overview (English)Dokument6 SeitenFlexovit Abrasives Overview (English)Flexovit AbrasivesNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Lexicon Edition 6 - Chapter 5 RoutingDokument80 SeitenLexicon Edition 6 - Chapter 5 RoutingJović J.Noch keine Bewertungen

- ISO 1302 DIN 4768 Comparison of Surface Roughness Values Stainless Steel T PDFDokument2 SeitenISO 1302 DIN 4768 Comparison of Surface Roughness Values Stainless Steel T PDFYohanes Wahyu TdNoch keine Bewertungen

- Welding History Sheet: TTCL Vietnam Corporation LimitedDokument1 SeiteWelding History Sheet: TTCL Vietnam Corporation LimitedĐỗ Thị HuyềnNoch keine Bewertungen

- DTI Installation and Inspection GuideDokument2 SeitenDTI Installation and Inspection GuideGonzalo ContrerasNoch keine Bewertungen

- Data Sheet For BRASS SPECIFICATIONS PDFDokument5 SeitenData Sheet For BRASS SPECIFICATIONS PDFvkmsNoch keine Bewertungen

- Operation Management Objective QuestionsDokument22 SeitenOperation Management Objective QuestionsAnonymous LFgO4WbIDNoch keine Bewertungen

- Pilger Production Improvement PlanDokument10 SeitenPilger Production Improvement PlanTushar PachlangiaNoch keine Bewertungen

- Electron Resistance WeldingDokument20 SeitenElectron Resistance Weldingsai prasadNoch keine Bewertungen

- Reducing Gear Distortion with Simple FixtureDokument7 SeitenReducing Gear Distortion with Simple FixtureVireshVerma100% (1)

- PEN TURNING 101: Getting Started GuideDokument2 SeitenPEN TURNING 101: Getting Started GuidedevheadbotNoch keine Bewertungen

- Quotation For Kirnath FabricatorDokument2 SeitenQuotation For Kirnath Fabricatorvinkumar_hbti100% (1)

- Keystone Better Mann CatalogDokument12 SeitenKeystone Better Mann CatalogSpencer100% (1)

- WPS LIST Revson GuncelDokument1 SeiteWPS LIST Revson GuncelHAKANNoch keine Bewertungen

- Asme II Part A (A 36) - 2010Dokument6 SeitenAsme II Part A (A 36) - 2010Nila GamaNoch keine Bewertungen

- Unit 3. Components and AssembliesDokument10 SeitenUnit 3. Components and AssembliesFiqhi Fahrizal HaffidNoch keine Bewertungen

- Welding AutomationDokument15 SeitenWelding AutomationRajesh Kumar RNoch keine Bewertungen

- Avesta Welding: How To Weld Fully Austenitic Stainless SteelsDokument0 SeitenAvesta Welding: How To Weld Fully Austenitic Stainless SteelsMoosewanger01Noch keine Bewertungen

- Aluminium Wheel RepairDokument26 SeitenAluminium Wheel RepairAndrew MatsovkinNoch keine Bewertungen

- Frank T. Sargent The Key To Metall BumpingDokument69 SeitenFrank T. Sargent The Key To Metall BumpingPeter OlyschlägerNoch keine Bewertungen

- Fine BlankingDokument26 SeitenFine BlankingHarish Ks100% (1)

- Cataleg PSCDokument151 SeitenCataleg PSCAntônio Cesar de OliveiraNoch keine Bewertungen

- Annex A (Normative) - AWS D1.1 - 2015Dokument4 SeitenAnnex A (Normative) - AWS D1.1 - 2015AngelTinocoNoch keine Bewertungen

- 14 Bernardo Soustruhy deDokument40 Seiten14 Bernardo Soustruhy deTanase Constantin0% (1)

- Shaper Mechanism Its One of The Applications of The Quick Return Mechanism Its Converts The Rotating Motion (Input) To Reciprocating Motion (Out Put)Dokument4 SeitenShaper Mechanism Its One of The Applications of The Quick Return Mechanism Its Converts The Rotating Motion (Input) To Reciprocating Motion (Out Put)Shady YehiaNoch keine Bewertungen

- Summary of Cutting Data For Profile Surface - Ball Nose: Material DetailsDokument5 SeitenSummary of Cutting Data For Profile Surface - Ball Nose: Material DetailsPalade LucianNoch keine Bewertungen

- Drilling Hole Opener WebDokument2 SeitenDrilling Hole Opener WebBehrangNoch keine Bewertungen

- Alform 620-1100 Grobblech TLB EN 1401Dokument16 SeitenAlform 620-1100 Grobblech TLB EN 1401Bui Chi TamNoch keine Bewertungen

- Grinding MachineDokument4 SeitenGrinding MachineSridhar BhagavatullaNoch keine Bewertungen

- Truing Commutators and Slip-RingsDokument4 SeitenTruing Commutators and Slip-RingsTariq AhmedNoch keine Bewertungen