Beruflich Dokumente

Kultur Dokumente

Trex 00074

Hochgeladen von

OSDocs20120 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

71 Ansichten16 SeitenPerform major service of the complete BOP hydraulic operating system. Pressure test the unlocking brake clutches on the ST locking system. Calibrate the transducers on the choke manifold Hitech system. Ensure the electronic meter readout is accurate for well control operations.

Originalbeschreibung:

Originaltitel

TREX-00074

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenPerform major service of the complete BOP hydraulic operating system. Pressure test the unlocking brake clutches on the ST locking system. Calibrate the transducers on the choke manifold Hitech system. Ensure the electronic meter readout is accurate for well control operations.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

71 Ansichten16 SeitenTrex 00074

Hochgeladen von

OSDocs2012Perform major service of the complete BOP hydraulic operating system. Pressure test the unlocking brake clutches on the ST locking system. Calibrate the transducers on the choke manifold Hitech system. Ensure the electronic meter readout is accurate for well control operations.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 16

Number I Criticality

7.0 Well Control Equipment

Ram-Type Preventers (General):

7.1.1.1.1 Minor

7.1.1.1 .2 Minor

Cameron ST Locking System:

7.1.2.1.1. 1 Major

Pressure Testing:

7.1.5.1.1 Minor

Mud/Gas Separator:

7.4.2.1.1 Minor

Remote Choke Control Unit General:

7.4.4.1.1 Major

7.4.4.1.2 Major

ModuSpec List of

Recommendations

Rig Name: DEEPWATER HORIZON

Recommendation

Perform major service of the complete BOP hydraulic operating

system. Disassemble and inspect BOP ram operators and ram

bodies.

Update certificate of compliance for the rams valid for five

I years.

Pressure test the unlocking brake clutches on. the ST locking

system. The unlocking pressure should be recorded. The

rams should be closed, locked and then the ST unlock clutch

pressure recorded. Trends should be recorded in the

maintenance history.

Calibrate and maintain up to date certification of the test pump

I gauges and chart recorder.

Include the wall thickness testing of the piping to the mud gas

separator and the tank body in the HP piping suivey.

Calibrate the transducers on the choke manifold Hitech system.

Ensure the electronic meter readout is accurate for well control

operations.

Calibrate the Hitech readouts from the Cameron BOP controls

to reflect actual pressure at the BOP sensors.

Type of Report - Survey

References: US1328.2

CONFIDENTIAL

Status

MODUSI 01 2 009952

EXHIBIT #_J_,_Cf +---

WIT: ______ _

!ModuS pee

Number Criticality

Cameron-Style Hub Clamps:

7.5.1.1 Minor

BOP-Handling Equipment:

7.6.1.1 Minor

Bridge Crane:

7.6.1.1.1 Minor

Hydraulic Pumps:

7.7.2.1.1 Minor

7.7.2.1.21 Minor

Hydraulic Control Manifold:

7.7.3. 1.1 Minor

7.7.3 .. 1.2 Minor

Diverter Valves:

ModuSpec List of

Recommendations

Rig Name: DEEPWATER HORIZON

Recommendation

Inspect all clamps, studs, nuts and spherical washers on the

five year certificate of compliance survey.

Repair the starboard bulkhead guidance stop that had been

damaged previously. This could fall off if struck again. A

safety sling would also prevent the part from falling if struck.

Paint the safe working load on each of the blocks for the

overhead bridoe crane.

Hydrates! and re-certify the HP relief valves on each of the

three BOP hydraulic skid 5,00b psi pumps. Add the relief

valves to the maintenance registry.

nstall safety signs warning PUMPS START AUTOMATICALLY

in the proximity of the three HPU pumps.

Test and certify the relief valves on the hydraulic control skid.

Include the relief valves in the maintenance registry.

Reduce the test pressure and re-certify the relief valve for the

telescopic joint hydraulic packer. The maximum test pressure

of the packer assembly is 500 _psi.

Type of Report Survey.

References: US1328.2

CONFIDENTIAL

Status

2.

MODUSI 01 2 009953

!aModuSpec

Number Criticality

7.8.3.1.1 Minor

Pods on the LMRP:

7.9.1..1 .1 Minor

7.9.1.1.2 Minor

Mini Reel :

7.9.3.1.1 .1 Minor

Emergency Back-Up Control.

Systems:

7.9.5.1.1 Minor

UPS Check:

7.9.73.1 Major

7.9.7.3.2 Minor

Subsea BOP Control System

Accumulator Charging Testing:

ModuSpec List of

Recommendations

Rig Name: DEEPWATER HORIZON

Recommendation

Test the diverter control system to ensure that the two hole fill

isolation valves will close when the diverter element was

closed. Consider installing check valves on the lines if control

software is not a solution.

Tilt test the LMRP to confi rm that the internal pod angle data is

similar in trends to the riser angle sensors on the riser adapter.

Correct Cameron readout gain confidence in the readout on the

drillers and tool pusher's panels.

Remove and inspect all valves control valves on the pods for

ceramic seal plates. Replace with 440C as required.

Install safety signs on the hot line hose reel that it can start

turning automatically and that there is high pressure in the

hose.

Surface test the BOP autoshear system in arm and disarm

modes.

Replace battery banks on the Cameron controls UPS banks A

and 8 36 batteries each.

Perform the API UPS tests per API Spec 160 2.2.3 for two hour

depletion with system in drilling mode.

Type of Report - Swvey

References: US1328.2

CONFIDENTIAL

Status

3

MODUSI 01 2 009954

Number Criticality

7.9.7.11.1 .1 Minor

Interlocks:

7.9.7.14.1.1 Major

Pod Function Tests:

7.9.7.16.1.1 Minor

Annular Regulator Function Test:

7.9.7.18.1.1 Minor

Pod Function Tests:

7.9.7.20.1. 1 Minor

Stack Function Tests:

ModuSpec List of

Recommendations

Rig Name: DEEPWATER HORIZON

Recommendation

Consider changing subsea regulator pilot regulator pre-charges

to 1/3 working pressure plus hydrostatic compensation 500 psi

for a 1,500 psi normal setting on the regulator.

Upgrade the software to include interlocks that will prevent the

accidental unlocking of the riser connector - primary arid

secondary, without ensuring the mini-collets are unlocked

primary or secondary, and that the BOP stingers were

retracted. One additional feature would be to also have an

interlock that the blind shear rams were closed to ensure the

well is secure prior to unlatching the LMRP manually.

Calibrate the pod readout pressures. Apply a calibrated gauge

and pump to each subsea transducer and adjust the readout

meter accordingly.

Ccnsider changing the precharge of the pilot accumulators to

be 500 psi plus hydrostatic compensation to allow regulators to

operate more reliably at pressures less than 1,000 psi.

Function test the pilot system by actuating the solenoid valves

and ensuring the pilot pressure is to the correct pod and stack

mounted component. Purge the air out of the lines.

Type of Report- Survey

References: US1328.2

CONFIDENTIAL

Status

4

MODUSI 01 2 009955

Number Criticality

7.9.7.21 .1.1 Minor

Portable Electronic Unit (PETU) Dead

Man Sequence:

7.9.7.32.1 .. 1 Major

Marine Riser System:

7.10..1-1 Minor

Telescopic Joints:

7.10.7.1.1 Minor

7.10.7.1.2 Minor

Spider and Gimbals:

7.10.8.1.1 Major

ModuSpec List of

Recommendations

Rig Name: DEEPWATER HORIZON

Recommendation

Incorporate testing the autoshear system and EDS sequence

timing into the function test check list prior to running the BOP.

Upgrade the deadman sequence description to reflect actual

software logic. As described, it is assumed the stinger seals

were de-energized prior to extending the stinger to close the

shear rams. If the sequence did not de-energize the stinger

seals first prior to extending the stinger, the software should be

changed. This will ensure pod integrity and the closure of th.e

shear rams.

Obtain additional riser torque tools to minimize downtime due

to wear and tear.

Repair I replace the rotating goosenecks and use them to avoid

inducing torque in the auxiliary line hoses when changing rig

headinq.

Re-set the telescopic joint hydraulic packer relief valve to be at

or less than the working pressure of the packer. The relief

valve needed re-calibration as it is past its two year service.

Write a procedure to maintain the gimbal prior to each use.

Include the procedure in the stack job preparation list Check

pre-charge., fill with fluid and hydrates! to. full rated working

!pressure prior to each use.

Type of Report - Survey

References: US1328.2

CONFIDENTIAL

Status

5

MODUSI 01 2 009956

lfloduSpec

Number Criticality

Test Tools:

7.1 0.8.3.1 Minor

7.10.8.3.2 Minor

Cameron Choke and Kill Connectors

(Mini Connectors):

7.12.2.1.1 Minor

Flexible High-Pressure Hoses

[(Coflexip):

7.13.1.1 Minor

Wellhead/Riser Connector:

7.14.1 .1 Minor

Connectors General:

7.14.1.1.1 Major

General Tensioner:

7.15.1.1.1 Major

ModuSpec List of

Recommendations

Rig Name: DEEPWATER HORIZON

Recommendation

Modify choke and kill test caps to be 1" autoclave to speed up

pressure testing times.

Modify hydraulic line test caps to be SAE or NPT threads to

avoid the potential of over-pressurizing the hydraulic lines when

testing.

Obtain a fleet spare connector and swap out the choke side

connector as it has symptoms of not operating correctly.

The hoses should be removed from service and tested per the

OEM requirements for re-certification.

Replace the riser connector with a rebuilt one as the piston

stroke is at its maximum limit.

Modify the BOP and LMRP frames to include the reaction pads

to prevent damage to the mini collet assemblies or pod stinger

receptacles in the event of a high angle disconnect.

Install a drain valve on the stand by APV tensioner bottles.

There are eiQht each bottles without a drain.

Type of Report- Survey

References: US1328.2

CONFIDENTIAL

Status

6

MODUSI 01 2 009957

Number Criticality

7.15.1.1.2 Minor

Riser Tensioner Panel:

7.15.2.1.1 Minor

ModuSpec List of

Recommendations

Rig Name: DEEPWATER HORIZON

Recommendation

Paint identification marking on each high pressure bottle of the

tensioner system the working pressure. This includes the

tensioner bottles and standby APVs.

Calibrate the tensioner system transducers to allow accurate

control of the riser tension.

Type of Report - Survey

References: US1328.2

CONFIDENTIAL

Status

7

MODUS! 01 2 009958

Comments

Type of Report - Survey

References: US1328.2

CONFIDENTIAL

8

MODUS! 01 2 009959

- --- - - - - - - ~ - - - - - - - - - - - ~ - - - - - - --- -------

Comments

Type of Report - Survey

References: US1328.2

9

CONFIDENTIAL MODUSI 01 2 009960

Comments

Type of Report - Survey.

References: US1328.2

CONFIDENTIAL

10

MODUSI 01 2 009961

;-

Comments

Type of Report - Survey

References: US1328.2

CONFIDENTIAL

11

MODUS! 01 2 009962

Comments

Type of Report - Survey

References: US1328.2

CONFIDENTIAL

12

MODUSI 01 2 009963

Comments

Type of Report - Survey

References: US1328.2

CONFIDENTIAL

13

MODUSI 01 2 009964

Comments

Type of Report - Suriey

References: US1328.2

CONFIDENTIAL

14

MODUSI 01 2 009965

The recommendations in this report are defined as follows:

Critical recommendations

Critical recommendations are based on shortcomings which may lead to loss

of life, a serious injury or environmental damage as a result of inadequate

use and/or failure of equipment.

Major recommendations

Major recommendations are based on shortcomings which may lead to

damage to essential equipment or have a detrimental effect on the drilling

operation. as a result of inadequate use and/or failure of equipment.

Minor recommendations

Minor recommendations are based on shortcomings which may lead to a

situation that contributes to an incident or to circumstances in which the

required standards of operation are not met.

Type of Report- [SUBJECT]

References: Contract No. I Project No ..

CONFIDENTIAL MODUSI 01 2 009966

Type of Report- (SUBJECT]

References: Contract No. l Project No.

CONFIDENTIAL MODUSI 01 2 009967

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- B694 PDFDokument8 SeitenB694 PDFEslam ElsayedNoch keine Bewertungen

- Fibre Repair ManualDokument2 SeitenFibre Repair ManualsaravanaNoch keine Bewertungen

- BP Pre-Trial Statement On QuantificationDokument13 SeitenBP Pre-Trial Statement On Quantificationwhitremer100% (1)

- 2013-9-18 Aligned Parties Pre-Trial Statement Doc 11411Dokument41 Seiten2013-9-18 Aligned Parties Pre-Trial Statement Doc 11411OSDocs2012Noch keine Bewertungen

- DOJ Pre-Trial Statement On QuantificationDokument14 SeitenDOJ Pre-Trial Statement On QuantificationwhitremerNoch keine Bewertungen

- 2013-9-11 BPs Phase II PreTrial Reply Memo For Source Control Doc 11349Dokument13 Seiten2013-9-11 BPs Phase II PreTrial Reply Memo For Source Control Doc 11349OSDocs2012Noch keine Bewertungen

- To's Post-Trial BriefDokument57 SeitenTo's Post-Trial BriefOSDocs2012Noch keine Bewertungen

- To's Proposed FOF and COLDokument326 SeitenTo's Proposed FOF and COLOSDocs2012Noch keine Bewertungen

- 2013-09-05 BP Phase 2 Pre-Trial Memo - Source ControlDokument13 Seiten2013-09-05 BP Phase 2 Pre-Trial Memo - Source ControlOSDocs2012Noch keine Bewertungen

- USAs Post Trial Brief Phase I (Doc. 10461 - 6.21.2013)Dokument49 SeitenUSAs Post Trial Brief Phase I (Doc. 10461 - 6.21.2013)OSDocs2012Noch keine Bewertungen

- Driller HITEC Display CCTV Camera System: Source: TREX 4248 8153Dokument1 SeiteDriller HITEC Display CCTV Camera System: Source: TREX 4248 8153OSDocs2012Noch keine Bewertungen

- BP's Post-Trial BriefDokument72 SeitenBP's Post-Trial BriefOSDocs2012Noch keine Bewertungen

- HESI's Proposed FOF and COLDokument335 SeitenHESI's Proposed FOF and COLOSDocs2012Noch keine Bewertungen

- HESI's Post-Trial BriefDokument52 SeitenHESI's Post-Trial BriefOSDocs2012Noch keine Bewertungen

- BP's Proposed Findings - Combined FileDokument1.303 SeitenBP's Proposed Findings - Combined FileOSDocs2012Noch keine Bewertungen

- State of LAs Post Trial Brief Phase I (Doc. 10462 - 6.21.2013)Dokument23 SeitenState of LAs Post Trial Brief Phase I (Doc. 10462 - 6.21.2013)OSDocs2012Noch keine Bewertungen

- USAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)Dokument121 SeitenUSAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)OSDocs2012Noch keine Bewertungen

- PSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013Dokument72 SeitenPSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013OSDocs2012100% (1)

- State of ALs Post Trial Brief Phase I (Doc. 10451 - 6.21.2013)Dokument22 SeitenState of ALs Post Trial Brief Phase I (Doc. 10451 - 6.21.2013)OSDocs2012Noch keine Bewertungen

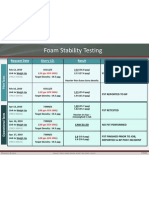

- Foam Stability Testing: Request Date Slurry I.D. Result CommentsDokument1 SeiteFoam Stability Testing: Request Date Slurry I.D. Result CommentsOSDocs2012Noch keine Bewertungen

- Plaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013Dokument199 SeitenPlaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013OSDocs2012Noch keine Bewertungen

- Circa 2003Dokument1 SeiteCirca 2003OSDocs2012Noch keine Bewertungen

- Exterior: Circa 2003Dokument1 SeiteExterior: Circa 2003OSDocs2012Noch keine Bewertungen

- Macondo Bod (Basis of Design)Dokument23 SeitenMacondo Bod (Basis of Design)OSDocs2012Noch keine Bewertungen

- Circa 2003Dokument1 SeiteCirca 2003OSDocs2012Noch keine Bewertungen

- Laboratory Results Cement Program Material Transfer TicketDokument13 SeitenLaboratory Results Cement Program Material Transfer TicketOSDocs2012Noch keine Bewertungen

- End of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateDokument1 SeiteEnd of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateOSDocs2012Noch keine Bewertungen

- DR Gene: CloggedDokument1 SeiteDR Gene: CloggedOSDocs2012Noch keine Bewertungen

- Arnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"Dokument5 SeitenArnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"OSDocs2012Noch keine Bewertungen

- April 20, BLOWOUT: BP Misreads Logs Does Not IdentifyDokument22 SeitenApril 20, BLOWOUT: BP Misreads Logs Does Not IdentifyOSDocs2012Noch keine Bewertungen

- Production Interval: 14.1-14.2 PPG M57B Gas Brine GasDokument1 SeiteProduction Interval: 14.1-14.2 PPG M57B Gas Brine GasOSDocs2012Noch keine Bewertungen

- Webster:: Trial Transcript at 3975:2-4Dokument1 SeiteWebster:: Trial Transcript at 3975:2-4OSDocs2012Noch keine Bewertungen

- Microwave-Induced Pyrolysis of Plastic WastesDokument8 SeitenMicrowave-Induced Pyrolysis of Plastic WastesSelim RejaNoch keine Bewertungen

- Malic Acid FermentationDokument55 SeitenMalic Acid FermentationElenaTrofimNoch keine Bewertungen

- Jack WelchDokument5 SeitenJack Welchapi-314805892Noch keine Bewertungen

- ANTSE Class 6 Previous Year Paper (2008-2013)Dokument81 SeitenANTSE Class 6 Previous Year Paper (2008-2013)Mota ChashmaNoch keine Bewertungen

- 2020.04.16 - FinalDokument32 Seiten2020.04.16 - Final韩龙Noch keine Bewertungen

- Sect 8 - Ref GalvadermDokument19 SeitenSect 8 - Ref GalvadermamymonuskinNoch keine Bewertungen

- Using Reverse Osmosis For Boiler PretreatmentDokument3 SeitenUsing Reverse Osmosis For Boiler Pretreatmentنيرمين احمدNoch keine Bewertungen

- Quadrajet Service Manual 1981Dokument46 SeitenQuadrajet Service Manual 1981Garrett Ross100% (4)

- SOP For Sampling and Testing Schedule of Water For Injection and Clean Steam - Pharmaceutical GuidelinesDokument2 SeitenSOP For Sampling and Testing Schedule of Water For Injection and Clean Steam - Pharmaceutical GuidelinesASHOK KUMAR LENKA100% (1)

- TSADokument44 SeitenTSAdraj1875977Noch keine Bewertungen

- Soil PH and Soil Acidity PDFDokument16 SeitenSoil PH and Soil Acidity PDFManuel EscobarNoch keine Bewertungen

- ISO14001 Step by Step Guide APMM VesselsDokument36 SeitenISO14001 Step by Step Guide APMM Vesselsnasol100% (3)

- Chemical Resistance GuideDokument20 SeitenChemical Resistance GuideDarien EdwardsNoch keine Bewertungen

- T 217Dokument4 SeitenT 217macc13Noch keine Bewertungen

- 2015-08-20 St. Mary's County TimesDokument32 Seiten2015-08-20 St. Mary's County TimesSouthern Maryland OnlineNoch keine Bewertungen

- PO - Lapox P 62Dokument2 SeitenPO - Lapox P 62alpesh.samruddhigroupNoch keine Bewertungen

- Unit 11 Fundamentals Org ChemDokument35 SeitenUnit 11 Fundamentals Org ChemKavisha AshaNoch keine Bewertungen

- Fruits150058 PDFDokument21 SeitenFruits150058 PDFJimantolo AjiNoch keine Bewertungen

- Chemical MachiningDokument5 SeitenChemical MachiningomenNoch keine Bewertungen

- WAEC Chemistry Syllabus 2022 PDF Download AvailableDokument26 SeitenWAEC Chemistry Syllabus 2022 PDF Download AvailableSamuel AikinsNoch keine Bewertungen

- CNG Price List 2010Dokument17 SeitenCNG Price List 2010Swastik MahapatraNoch keine Bewertungen

- PumpsDokument33 SeitenPumpsSamson HaykonNoch keine Bewertungen

- Smaw 12 Module 1Dokument7 SeitenSmaw 12 Module 1Francis Rico Mutia RufonNoch keine Bewertungen

- University of Santo Tomas: Williamson Ether Synthesis: Preparation of PhenacetinDokument4 SeitenUniversity of Santo Tomas: Williamson Ether Synthesis: Preparation of PhenacetinMarilou MagdalagaNoch keine Bewertungen

- Spray Nine Heavy DutyDokument7 SeitenSpray Nine Heavy DutyPubcrawlNoch keine Bewertungen

- Chemical Symbols and Valences of Elements and RadicalsDokument1 SeiteChemical Symbols and Valences of Elements and RadicalsproodootNoch keine Bewertungen

- Honda BayDokument16 SeitenHonda BayVicente Jr. BallonoNoch keine Bewertungen

- Magnum CV and Magnum IT Valves Installation InstructionsDokument86 SeitenMagnum CV and Magnum IT Valves Installation InstructionsWattsNoch keine Bewertungen