Beruflich Dokumente

Kultur Dokumente

Trex 01156

Hochgeladen von

OSDocs2012Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Trex 01156

Hochgeladen von

OSDocs2012Copyright:

Verfügbare Formate

Confidential

10

10.1

10.2

10.3

10.4

10.5

bp GoM Exploration Wells

.

#As,

...

-.

J'PTCI::t.o.::S - .J'

. ,,

v

MC 252 #1 BP01 - Macondo Prospect

11-7/8" Liner Interval

Table of Contents

11-7/8" LINER INTERVAL ....................................................................... ........ ...... 2

Introduction .................................................................................................................. 2

Objectives ................................................................................................ ................. .. .. 2

Concerns ....................................................................................................................... 3

General Drilling Operations Procedure ................... ............................................. ....... 4

11-7/8" Casing and Cementing Operations ................ ..................................... .. .... ..... 6

10. 5. 1 Casing and Cement Preparation ............. .. ............. .. ... ..... ... .. ... ........ .. ..... ...... ... .. ...... .. ......... 6

10. 5. 2 Casing Procedure ...... .... ..... ......... ..... .... .... ... .... ........ .. .. ........... .. .... ... .... .......... .. ... ........ ..... ... 7

10. 5. 3 Cementing Procedure ................ .... ... .... ....... ..... ............. ................... ... ......... .......... .... .. ... . 11

Attachments ... ............ ... .... .. ..... .. ........ ... ... .... .......................................................................... 14

Attachment 1: Drill String Design - Margin of Overpu/1 ... .... .... .. ... .... ........ ..... ...... ..... ..... ..... ......... ... 15

Attachment 2: BHA Schematic .. .... ..... .... ... .......... .. ..... ........... ..... ..... .... .. ........ ........... ... ................. 16

Attachment 3: Weathet1ord Plug DO Procedure .... .... .. .............. .. .............. ... ................................ . 17

Attachment 4: 11-718" Liner Diagram ......... .. .... ......... .. .......... ... .... ............. ... ........................ .......... 19

Attachment 5: Landing String Design - Margin of Overpu/1 .. ... .. .. .. .. ..... .. ... .... ..... .... ...... .... .... .... ...... 20

Bits

Underreamers

BHA

Special equipment

Liner equipment

Drillstring

Mud system

Casing

Landing string

Cementing

Anticipated LOT at 13-5/8" Shoe

EXHIBIT#

l\ 5lo

WIT: _ ____ _

Rev.2

12-1/4" Hughes 0 0507 (primary)

14-1/2" Hughes GaugePro XPR (primary)

Rotary Steerable, MWD/PWD/EWR, Sonic, GeoTap, Jars

Wear Sleeve, ATC Diverter Sub, ATC Diverter Test Devi ce, Blackhawk cement

head.

11-7/8" x 13-5/8" VersaFiex Liner Hanger, Running Tool, Weatherford Dual Plugs

6-5/8" 32 ppf S-135

Drillout MW = 12.5 ppg (surface), Drill ahead MW = 12.8 ppg (surface) Max

projected MW at Interval TO: 13.3 ppg (surface) (13.5 ppg DHE)

-2400' of 11-7/8", 71.8 ppf, HCQ-125, 0.582" wall. Hyd 513

6-518", 32 ppf, S-135 DP (- 12,800 ft)

Halliburton Class H Cement (see cement program)

13.86 ppg LOT

EXHIBIT# ____ _

WIT:. _____ _

Page 1 of 20 March 2010

BP-HZN-MBI 00113245

Confidential

bp GoM Exploration Wells

.M"aco:ndo

'

---.

v

MC 252 #1 BP01 - Macondo Prospect

4Jf

11-7/8" Liner Interval

10 11-7/8" Liner Interval

10.1 Introduction

The objective of this interval is to set the 11-7/8" liner as deep as hole conditions will allow

in a compete shale in order to achieve the maximum LOT possible. Currently based on the

seismic available, a shale exists between 15,080'- 15,230' TVD. If hole conditions allow,

the 11-7/8" casing shoe should be set at least 30' into this shale. It is planned to run the

11-7/8" liner into the pilot hole and set 1 0-15' off bottom. The hole size for this interval will

be 12-1/4" x 14-1/2".

10.2 Objectives

Maintain wellbore trajectory.

Set casing in competent shale.

Run and cement 11-7/8" casing with requirement for remedial operations.

Achieve sufficient LOT of 14.6 ppg at the 11-7/8" shoe.

Rev. 2 Page 2 of 20

March 2010

BP-HZN-MBI 001 13246

bp GoM Exploration Wells

:r .wiaco:n.do

#A!. -

M C::!6.:::-z

MC 252 #1 BP01 - Macondo Prospect

11-7 /8" Liner Interval

10.3 Concerns

Concern I Hazard Mitigation of Concern I Hazard

Utilize BP GoM procedures during 13-5/8' LOT to ensure accurate measurement.

Pore Pressures and Monitor pore pressure trends to ensure proper analysis of wellsite pore pressures.

Fracture Gradients Wellsite leaders, tool pushers, drillers, and crew are responsible for monitoring drilling

trends and will have an active role in ECD management.

GeoTap will be in the BHA to take pressures in any sands necessary, and help provide

a better understanding of the pressure predictions for the remainder of this wel l.

A 0.3 ppg margin will be required based on the current PP/FG margins and casing

point.

Well site leaders must ensure that personnel become familiar with wellbore

pressure/ECD management guidelines.

Vibration issues Utilize all previous lessons learned on 13-5/8" shoe track drilling. Vary drilling

parameters (WOB, RPM, etc) to minimize downhole and/or surface vibrations. Discuss

alternatives with Houston Team.

Lost Circulation Utilize all available tools and personnel for ECD management. Limit pump pressures

when a pack-off is detected or suspected. Have contingency LCM pills mixed and

ready.

Well Control Adhere to standard practices (finger printing flowbacks, pit volume monitoring, PWD,

ROP, etc ... ). Keep track of kick tol_erance. Take slow pump rates prior to 14" drillout.

Casing Wear Casing wear is a critical issue. Install and monitor ditch magnets. Clean ditch magnets

daily. Report daily metal recovery on morning reports. Watch for trends. Dogleg at

11,700' now exists.

Running 11-7/S' Iiner Optimize runni ng speeds to avoid sudden starts and stops. Have .AIIamon system in

place to minimize surge pressures.

Rev.2 Page 3 of 20 March 2010

Confidential

BP-HZN-MBI 0011324 7

Confidential

bp

GoM Exploration Wells

' JY.Ca.co:ndo

-

--

wrCDOu -.z

.,,

MC 252 #1 BP01 - Macondo Prospect

11-7/8" Liner Interval

10.4 General Drilling Operations Procedure

Rev. 2

1. Ensure BOP has been tested (per compliance with approved APD).

Initiate well control and emergency disconnect drills.

Ensure all personnel are in compliance with MMS Sub Part "0".

2. Ensure 13-5/8" casing and blind shear rams have been tested (per APD

requirements). Record pressure with volume pumped. This data will be compared

with planned 13-5/8" shoe LOT.

3. Pick-up and run-in-hole with 12-1/4" x 14-1/2" drilling assembly (per Sperry BHA):

Note:

Note:

Use lower 4 shear pins. (See Drii-Quip procedures.)

If Wear Sleeve is in well , post (with its I D) on rig floor .

If formation pressure tool is used, give special attention when picking up BHA

to ensure formation pressure probe is correctly oriented in relationship with

the MWD for downhole measurements. WSL I Drilling Engineer I Geologist to

discuss formation pressure objectives prior to running BHA in hole.

Confirm wear bushing 10 will allow running of 11-718" Liner Hanger. If wear

bushing must be pulled to run 11-718" hanger, set up Tool

to pull wear bushing on trip out (utilizing upper 8 shear pin position).

4. TIH to wiper plugs (Drill-out per Directional Drillers and Weatherford procedure)

5. Clean out rat hole and drill 1 0' of new hole.

Note:

Circulate until shaker screens are clean and mud is condit ioned .

Close annular or pipe ram .

Perform LOT per standard GOM procedure (anticipated LOT= 13.86 ppg EMW)

Compare surface value to pumped up downhole and send both to DE .

A minimum acceptable value for a successful LOT will be supplied to the rig. If

this is not reached contact Houston to discuss options prior to drilling ahead.

If LOT is successful- weight up system to at least a 12.8 ppg (surface)

Prior to LOT, obtain ESD value with MWD. However, if unable to get ESD value

after two attempts, continue LOT, and make one more attempt after the LOT.

Shape of LOT curve rather than an actual value will dictate whether a squeeze

job is required.

If surface mud weight is< 0.5 ppg margin from surface LOT, MMS approval i s

required.

Page 4 of 20 March 2010

BP-HZN-MBI 001 13248

Confidential

bp GoM Exploration Wells

, J.Yiaco.:ndo

v

MC 252 #1 BP01 - Macondo Prospect

4lf 11-7/8" Liner Interval

6. Drill12-1/4" x 14-1/2" hole using following parameters.

Rev. 2

Parameter Guideline

Inclination Limit DLS to 0.51100 ft and total inclination to 3.0or less to minimize subsequent

and DLS casing wear and mitigate for close casing tolerances.

ROP Control ROP to ensure adequate hole cleaning and ECD management (as

determined by WS Leader and Mud Engineer).

WOB 0-45 kips (limi ted by Vibration, Bit I BHA performance, and Wellbore Inclination)

RPM Planned range: 90-180 rpm. Optimize for ROP, vibration and DLS considerations.

Torque Monitor difference between on and off bottom torque. If surface torque begins to

approach makeup torque of weakest connection in hole, discuss options with

Houston Team (possible MOC with Transocean).

ECDI PWD Maintain ECD I PWD of at least 0.3 ppg < LOT value. (Remember to include any

mud compressibility in LOT number.) MMS approval is required_prior to drilling this

hole section for less than a 0.5 ppg margin. Drilling Engineer will obtain approval

once LOT is complete.

Close coordination between BP wellsite leaders, drilling crew, and L WD Engineers

will be required on ECD management to achieve maximum performance. Roles and

responsibilities of all parties should be discussed in interval planning meeting.

Pump viscous sweeps as needed to clean hole, and minimize ECD.

Pump Rates 750-850 is planned range. Optimize for ROP, hole-cleaning, and ECD limits.

Vibration Monitor vibration indicators to maintain in acceptable range. If vibrations are

encountered, immediately pick up off bottom, allow the energy to dissipate from the

string (may require a full stop), change a drilling parameter and go back to dri lling.

Continue the process until vibrations are improved or eliminated.

Casing Monitor and report daily metal recovery on morning reports. A caliper log may

Wear be uti lized at first logging opportunity (in lieu of a casing test and/or a USIT log).

Section TD 11-7/8" liner point between 15,080, - 15,230' MDnYD (Permit 16,000' TVD). If hole

conditions warrant, discuss alternative casing points with Houston team.

As always if Geo-Tap pressures change pressure prediction, a new section TO will

be determined by the drilling team, which uses these conditions.

7. Pump weighted/viscous sweeps, as needed, to clean hole and minimize ECD. As

this is a vertical wellbore with sufficient pump rate, sweeps should not be required.

8. At interval TD, pump a 100 bbl viscous sweep and circulate until shakers clean up.

9. While tripping out of hole, work through any questionable intervals. If significant

working was necessary, make a short trip prior to running casing.

10. Pull out of hole and rack back or lay down BHA.

Note:

It is not necessary to pull Wear Bushing. JD's should be confirmed with DQ

and Versaflex hands prior to making this decision.

Page 5 of 20 March 2010

BP-HZN-MBI 00113249

Confidential

bp GoM Exploration Wells

1,: {

0

--.

MC 252 #1 BP01 - Macondo Prospect

4tf

11-7 /8" Liner Interval

10.5 11-7/8" Casing and Cementing Operations

10.5.1 Casing and Cement Preparation

Prior to shipping, primary float equipment should have been bucked up and

thread-locked onto a joint of pipe. Inspect shoe and float collar joints for debris

prior to picking up.

Rev. 2

Ensure cement, additives, and fresh and seawater samples are sent to cement

company lab for final lab testing.

Use establ ished cement company procedures for BP Deepwater operations for

thickening time lab tests.

Prepare 11-7 /8" casing tally. Clean and inspect casing threads. Drift casing to

10.625 in. Liner has been drifted and callipered onshore prior to mobilization,

utilize the onshore caliper average for displacement calculations.

Calculate swab/surge pressures for various running speeds. Select an

acceptable running speed to ensure formation breakdown pressure is not

exceeded.

Surge calculations and compressibility calculations should be provided to the rig

by the Houston office.

Planned landing string is rig owned, 6-5/8", 32 ppf S-135 DP.

Prior to running casing. drift landing string to 2.875" drift 10 to ensure passage

of Halliburton's 2.750" contingency setting ball.

Ensure ALL crossovers required in landing string are rented, inspected and have

a specific request to provide material certifications to rig and engineer. These

certifications are to be used to verify proper load carrying capabilities.

Ensure all crossovers in string do NOT have internal square shoulders as these

have proven to hang up drill pipe darts. Minimum 30 degree internal tapers.

Long bails (22 ft) may be required to pick up a fill & circulate tool.

Rig up Blackhawk Cement Equipment and stand back in derrick (if desired):

Page 6 of 20

March 2010

BP-HZN-MBI 00113250

Confidential

bp GoM Exploration Wells

: li'Ca.co:n.d o

'

. ..,

MC 252 #1 BP01 - Macondo Prospect

11-7/8" Liner Interval

10.5.2 Casing Procedure

1. Pickup Fill and Circulate Tool.

2. Pickup and run 11-7/8" shoe track:

Apply a thin coating of API-modified thread dope to pin end only, as needed.

Check for proper thread make-up.

3. Run liner as follows:

Item Ftg Size Wall ppf Grade Connection

Shoe Jt centralized -44' 11-7/8 in 0.582 71.8 HCQ-125 Hyd 513

3 centralized Jts (w/ Centralizer -132' 11-7/8in 0.582 71.8 HCQ-125 Hyd 513

Subs)

Float Collar Jt with auto fill L45WP - 44' 11-718 in 0.582 71.8 HCQ-1 25 Hyd 513

Intermediate Jts - x,xxx' 11-7/8 in 0.582 71.8 HCQ-125 Hyd 513

11-7/8" P.up joint (for plugs) -10' 11-7/8 in 0.582 71. 8 HCQ-125 Hyd 513

11-7/8" x 14' Versaflex Liner Hanger - 16' Hyd 523 (MU to 513)

Liner hanger Running Assembly -5.4' N/A N/A N/A N/A 6-5/8" FH

Landing String (=>4 stands) -480' 6-5/8' 0.500" 32 S-135 FH

ATC OTD sub -6' 9" N/A N/A Q-125 FH

Landing String (=>4 stands) -480' 6-5/8' 0.500" 32 S-135 FH

ATC Oiverter Sub -6' 9-1/4' N/A N/A Q-1 25 FH

Landing Stri ng -'/.X,XXl 6-5/8' 0.500" 32 S-135 FH

"

Centralizer details: 4 Weatherford centralizer subs (MU onshore)

Casing ID: 10.711 in

Casing drift: 10.625 in

Casing collar OD: 11.875 in

Connection Size

Minimum Torque

Optimum Torque

Maximum

Required (Yield) Torque

11-7/8 in. 30,000 ft-lbs 36,000 ft-l bs 266,000 ft-l bs

Have Hydril thread representati ve on location to inspect casing threads and

connection make-up.

Thread lock entire shoe track. Apply thread locking compound to the pin thread

only.

Targeted MU torque for 11-7/8" liner should be 36,000 ft-lbs.

Run casing with blind shear rams OPEN.

Monitor well via choke and kill lines.

Rev. 2 Page 7 of 20 March 2010

BP-HZN-MBI 00113251

Confidential

bp GoM Exploration Wells

M"C::ZU:SZ#:.t

v

MC 252 #1 BP01 - Macondo Prospect

411f

11-7/8" Liner Interval

Rev. 2

Notes:

Recommended Well Control consideration while running this equipment and

liner:

If fill-ups are marginal:

Convert auto-fill FE and run liner conventionally.

4. Continue running 11-7/8" casing taking into account surge calculations.

Take returns to trip tank.

Verify casing is filling through auto-fill float equipment. If liner is not filling

automatically then fill up should be done at least every 10 joints. Note: circulation

at this point should not exceed 4bpm to prevent converting float equipment.

5. Run - x.xxx' of 11-7/8" liner w/ -300' of liner lap (above where top of cement is

encountered).

6. Once the 11-7/8" liner has been run, free-drop the 3-1 /2" closing ball for the float

collar.

7. Pick-up 11-7/8" x 13-5/8" Versaflex Liner Hanger assembly. Make-up per Versaflex

procedure to casing. Observe and record liner weight. Do not circulate.

Note:

Do not circulate the liner after it is picked up - float collar will be

converted.

Do not exceed 3500 psi at any time while circulating to avoid prematurely

setting liner hanger.

Do not exceed xxxx lbs while TIH. This could prematurely release the

running tool. This value to be determined once running loads are known.

8. Makeup A TC Oiverter Sub 6 stands above top of liner hanger setting tool, and

Diverter Test Device above liner hanger setting tool. Review surge pressure

calculations running speeds with Allaman rep to determine optimum dri ll pipe-running

speed. (For Allaman Tool pressure sequence, see Attachment 5).

A TC Diverter Sub

4 stands DP (may be adjusted in the field)

A TC Diverter Test Device

4 stands OP (may be adjusted in the field)

11-7/8" VersaFiex Liner Hanger Running Tool

9. Carefully lower liner hanger assembly through rotary table and also through BOP

stack.

Trip in hole with liner on drillpipe at speeds dictated by surge calculations and

hole conditions, taking returns to trip tank while liner is inside casing.

Fluid level inside DP and annulus should remain between 30-60' from drill floor

after drillpipe running string is inside riser.

Page 8 of 20 March 2010

BP-HZN-MBI 00113252

Confidential

bp

GoM Exploration Wells

lt'Iaco:n.do

JrrOad.Q-J

~

\ ..

MC 252 #1 BP01 - Macondo Prospect

~

11-7/8" Liner Interval

Rev.2

10. When 11-7/8" liner reaches 13-5/8" casing shoe, pickup Top Drive.

Get slow pump rates at 15- 25- 35 spm through open A TC diverter sub.

Record pickup and slack off weights (and rotating weights if requi red) at shoe.

11. Free drop Allaman's 2" (brass) closing ball 10 stands before landing out. Thi s can

also be done prior to going into open hole with casing depending on WSL discretion

and hole conditions.

12. The liner will be run into the pilot hole and should be set 1 0-15' off bottom.

13. After reaching one stand from TD with the liner, pick up the cement head stand and

make-up to the top drive and

Begin pumping slowly while keeping pipe moving.

The 2" ball wi ll be on the seat in the Diverter so pressure up to 1000 psi

slowly and hold same for 2 minutes.

Continue to increase the pump pressure until the ball yields the seat with

2400-2800 psi.

14. After blowing the ball through the Diverter seat let the 2" ball fall to the seat in the

DTD.

Pressure up to 1,000 psi for 2 min confirming the Diverter is closed

successfully.

Yield the seat w/2400-2800 psi.

Go back to circulating and record the pump pressure once returns have

stabilized.

Note: Max circulation rate through plug system BEFORE launching plugs is 12 bpm.

15. Circulate and condition the drilling fl uid for the cement job and position the liner for

the cement job. The float collar will activate during circulation but may not be seen

due to its low shear out pressure

Conversion will occur at 500-700 psi above circulation pressure at 5-8

bpm flow rate). If there are no returns, go directly to cement job.

16. Rig up and pressure test lines to 7,500 psi (6,500 psi may be needed if any

difficulties are encountered during the Versaflex liner hanger expansion process).

Note:

Do not circulate above 30 spm until thick mud is above liner assembly.

While running equipment and liner, consider the following:

Limit liner running speeds to avoid surging formations (no sl ower than

8 minutes per stand). Liner running schedule to be adjusted based on

actual hole conditions.

Page 9 of 20 March 2010

BP-HZN-MBI 00113253

bp

~ ~

v

~ j ~ l

Rev.2

Confidential

GaM Exploration Wells

IJII.aco:ndo

NIC::'US:ZN..l

MC 252 #1 BP01 - Macondo Prospect

~

11-7/8" Liner Interval

When attempting to wash-down, there is a greater chance of sticking

liner with additional ECD or creating a packing off problem due to

cuttings bed that is being pushed/circulated.

When closing diverter sub, pipe must be moving at all times. After

closing ATC Diverter tool, go back to circulating slowly (no more than

15 SPM) and immediately washing to bottom.

All pup joints and cross-overs must be free of " bore-backs" or square

shoulders (less than 1/8" transition) and must have high angle tapers

to ID from root thread in box. Tapers should be at least 30 degrees.

Give special attention to full open safety valve below Cement head to

prevent hanging-up DP dart during displacement. A Teflon bushing on

top of valve assembly will help transition dart cleanly.

Ensure Torque and Drag calculations have been performed to

determine the number of Emergency Release pins installed in the

Versaflex running tool.

Page 10 of 20 March 2010

BP-HZN-MBI 00113254

Confidential

bp GoM Exploration Wells

"t .zu--.aco.ndo

0

'- M'0 :36:l' -.l

MC 252 #1 BP01 - Macondo Prospect

~ ~ 11-7/8" Liner Interval

10.5.3 Cementing Procedure

Rev.2

1. Mix & displace the spacer and launch the bottom DP dart wi th 3-5 bbl of cement

ahead of dart.

When the dart leaves the cement head, the Blackhawk cement head indicator

should confi rm the dart has left the head. Position running tool for cement

operations.

2. Mix & pump the cement job per HES procedure.

After pumping the cement job, launch the top DP dart with 5-10 bbl of cement

behind dart. Indicators should be seen from the Blackhawk cement head

confirming the top dart left the head.

Line up rig pumps to take over cement di splacement after cement unit pushes

out top DP dart.

If DP dart is followed by cement, pump spacer to minimize contamination of

Note: slurry/drilling mud. This can J1revent the ball seating if contingency setting

process is needed. launching plugs is 12 bpm.

3. Continue with displacement (make sure to account for compressibility) .

Approximately 5 bbls before the bottom DP Dart reaches the diverter sub, slow

the pump rate to 3-4 bpm. The pressure required to yield the seat in the di verter

and DTD with the bottom DP dart should be 2500-3000 psi above the circulati ng

rate.

After yielding the seat, continue to pump the bottom DP Dart down to the

bottom plug at 3-4 bpm. The bottom plug with launch with 800-1200 psi. After

the plug is released, continue with the displacement of the cement at the

maximum rate.

App'roximately 5 bbls before the top DP Dart reaches the diverter sub, slow the

pump rate to 3-4 bpm. The pressure required to yield the seat in the Diverter and

DTD with the top DP dart should be 2500-3000 psi above the ci rculating rate.

After yielding the seat, continue to pump the top DP Dart down to the t op plug

at 3-4 bpm. The top plug should release with 2000-2500 psi. After the pl ug is

released, continue with the displacement of the cement at the maximum rate.

Just prior to the bottom plug reaching the float collar, slow down to 3-4 bpm to

witness the landing of the plug. The bottom plug burst tube should rupture with

900-1100 psi .

After bottom plug has landed, re-zero the stroke counter and pump calculated

cement volume to see the top plug land.

If bottom plug does not bump or top plug is late, do not exceed 1/2 shoe track

volume + compressibility. Bump top plug with 1000 psi over circulating pressure

(land/lock).

Page 11 of 20 March 2010

BP-HZN-MBI 001 13255

Rev. 2

Confidential

bp GoM Exploration Wells

..ln".:::o.cor.>tdo

M'O::US:::: #J

0

MC 252 #1 BP01 - Macondo Prospect

~

11-7/8" Liner Interval

Bleed off pressure and check floats are holding. Measure flow back .

Note:

If unable to bump plug or if floats do not hold, discuss wait on cement times

with Houston Team prior to setting Versa Flex liner hanger.

A 2-7/8" setting ball will be required if top plug does not bump or floats do not

hold.

4. Once confirmed the float is holding, prior to expanding the liner hanger, place the

setting tool in tension by picking up an additional 40,000 lbs over the neutral weight

of the workstring to the setting tool.

5. Pressure up to 5,500 psi to deploy the Versaflex fl apper. Record volume required to

reach 3,000 psi as reference to determine if flapper as functioned. Hold for 5

minutes. Release pressure. Record volume.

6. Expand Versa Flex liner hanger.

During expansion maintain a constant pumping rate of 1/2 bpm and observe

constant pressure increase.

Verify that the flapper has functioned by observing the volume required to build

3000psi compared to the recorded volume from the step above.

Pressure will drop off after the internal bypass is activated. This indicates

expansion is complete.

If flapper has not functioned repeat process. If unable to verify flapper function go

to contingency process.

Pressure will drop off after the internal bypass is activated indicating that the

expansion is complete. Stop pumping and bleed off pressure.

I Warning: Do not exceed 6,000 psi.

7. PU on setting tool 50,000-1 00,000 lbs over previous PU weight to confirm hanger is

set.

8. Slack off to neutral weight (Buoyed DP + Block Weight). Set down additional 30,000

lbs on setting tool to release from the liner setting sleeve.

9. PU on setting tool and pull out of hanger with 50,000-100,000 lbs overpull. Record

overpull through clad section.

10. Drop nerf ball and circulate a minimum of 1-1/2 times the DP volume - or until mud is

clean. Work pipe while circulating, but do not rotate (while circulating or

POOH) as this may damage the setting tool.

11 . Test casing and blind/ shear rams (per APD requirements).

Discuss changes in MW and/or test pressures wi th Dril ling Engineer.

Drilling Engineer will notify MMS on any APD variations.

Page 12 of 20 March 2010

BP-HZN-MBI 00113256

Confidential

bp

~ &

v

.... ...:&:.. .,.

GoM Exploration Wells

: JYI:aco:ndo

:n.ro ::;r.n:;:, - z

MC 252 #1 BP01 - Macondo Prospect

~ 11-7/8" Liner Interval

It is responsibility of Driller, Mud Engineer, and Mud Logger to closely monit or

and agree on amount of mud lost during liner job. Report mud losses f or

different phases of job as follows:

Bbls lost while PU and running liner.

Note: Bbls lost while TIH with liner on landing string.

Note:

Rev. 2

Bbls lost while washing liner to bottom, if required.

Bbls lost while circulating, after liner is landed.

Bbls lost while pumping and displacing cement.

Bbls left behind pipe.

If the wear sleeve was pulled prior to running the 11-7/8" liner, run the wear

sleeve on the BHA if that option is available.

Page 13 of 20

March 2010

BP-HZN-MBI 00113257

bp GoM Exploration Wells ..

.&.r .o:aco.ndo

-

MC 252 #1 BP01 - Macondo Prospect

11-7 /8" Liner Interval

Attachments

No. Title

1 Drill String Design - Margin of Overpull

2 BHA Schematic

3 Weatherford Plug Drill Out Procedure

4 11-7/8" Liner Diagram

5 Landing String Design - Margin of Overpull

Rev. 2 Page 14 of 20 March 2010

Confidential

BP-HZN-MBI 001 13258

Confidential

bp

GaM Exploration Wells

.M"aco.ndo

#.t!.

v

MC 252 #1 BP01 - Macondo Prospect

;

11-7/8" Liner Interval

Attachment 1:

Drill String Design- Margin of Overpu/1

5.625

32

67

37.71

NOTE: The air weight of spiraled drill pipe is cal culated as 96% of non-spiraled HY\/DP.

mes lowes1 planned mud weight. of 12.8 llll 9 for secti on

Rev.2 Page 15 of 20

o

439.364

525:1 29

670.1 29

March 2010

BP-HZN-MBI 00113259

Confidential

bp

Rev.2

0.0.

12.25"'

9.625"

8.5"

7.875"

s

8"

8"

8"

8"

8"

9"

8"

8.5"

8"

8"

8"

9.25"

6.625"

8"

6.625"

6.625"

Cont.

GoM Exploration Wells

:LV.Caco:ndo

.

-

MC 252 #1 BP01 - Macondo Prospect

4llf

11-7/8" Liner Interval

BHA Schematic

Bp Ameri ca Product ion

Macondo Prospect

BHA 10 it: 6

12 1/ 4" X 14 1/2" Gao-Pi lot

BHA Configuration

Longlh

1.9"

18.99"

2.93'

10"

25'

3.8"

21'

26.7"

3.8"

17"

6"

1"

Oescrtpllon

12 114" 0 0507 POC

9600 Sorlos GeoPjol

12 1/ 0'"IB Sc cr.lzor BFF

Flo< Collal w/ DM

a MS

12 1/9'"1n-LN SIAO

s OBAl Son

B"GooTnp

1::! 1/B'"lnUnil SID:> kz.i:H'

Filter Sl.b

12 1/0" 18 SlftlliUw BFF

Attachment 2:

BHA Schematic

20 x 6 518" HWDP

IS"

30'

14 1/2" XPR R""""'' Flool Volvo

I X 8 114" Drill CoiH<

7"

4"

270'

32'

600'

30'

12 1/0"18 Slftbii<v< 8FF

8 X 8 t/4" 0!111 Col!$

Cro33 O.Jot Sub

9 x 6 516" HWDP

HE DrdUnCJ Jar

20 x 6 5/Sw HWOP

65'8" OP

BHA Discussion

g , 6 S:8" HWDP

Ovor SUb

8 > 8 114" Dnll Collarc

Box 0-5-'0" R"9

12 118" 18 Sl>01lzr BFF

I a a 11.4" Otlll CoU.-v

So> a-YS" Rou

1 4 l/2" XPR Agamer FloaT :

VteiYO '

Page 16 of 20

12 118" IB Stabill:!or

OFF

Sex Rag

FIH>rSU:>

Pui!'IOr

12 1/B"liiLlns Srnbllr.zer

8" 08A T Sooc

12 1/B'" In-Uno Srablllzor

Box Q-<;8" Reg

8" MS

Flo:t Colll'll v:l OM

12 va 19 StaoU&Zet .

BFF

Be &SIS" R"'}

9600 S<xie< GooPIIo:

EkJx &510" R<H}

12 114" 00507 PDC

March 2010

BP-HZN-MBI 00113260

Confidential

bp GoM Exploration Wells

.lY.C.aco.ndo

tiJ

MC 252 #1 BP01 - Macondo Prospect

*

11-7/8" Liner Interval

Attachment 3:

Weatherford Plug DO Procedure

The drill out procedures presented below are a recommended guideline and does not cover all situations. Final dec1s1ons

on ho"' drillout should be controlled by the operator and within bit manufactures limits of operation.

GENERAL COMMENTS:

Apply Weatherford Tube Lok rM Compound to the bottom six thread connections and the float equipment threads. Apply to

the pin thread only. This helps prevent the shoe joint from backing off during drillout.

For standard plug sets the top cementing plug should be released while pumping cement Pump an additional 10 feet

(three meters) of cement on top of the plug. Non-rotating plugs do no! require cement to be pumped after !he top plug, but

cement lines can be flushed on top of top plug.

Make up BHA v.'ith a near bit stabilizer as close to the bit as possible.

Check the bit diameter with the Roat equipment drillout diameters to verify clearances.

A j unk basket may be used near the bit to catch large pieces of materials.

Do not use any type of automatic driller.

Do not "spud" or sit the b1t weight suddenly on the plugs or float equipment.

DRILL OUT PROCEDURE WITH PDC BIT ON DRILL STRING:

After tagg1ng the top of the cement or top plug. turn drill string at 60- 80 RPM and pump at a sufficient flow rate to remove

drilled cuttings. Some operators use 40- 50 GPM per inch of bit diameter as a starting point. Slowly apply 2.000 pounds

(909 kg) weight on bit (WOB) until the bit pattern is made. Slowly build WOB to 3.000 to 5,000 pounds (1,363 to 2.272

kg).

Maintain 3.000 to 5,000 pounds (1,363 to '2,272 kgj WOB while drilling the float equipment.

If the rate of penetration (ROP) slows or the torque increases. the bit should be raised while continuing to rotate and

circulate. Slowly lo..ver the bit and follow the above recommendations. This helps remove debris and cementing pl ug

wipers.

If the ROP stop,s or the torque declines. this could indicate that the bit is spinning without cutting.

: Stop rotating. reduce the flow rate to !'No or three BPM. and put 3,000 to 5.000 pounds (1.363 to 2.272 kg) WOB

(Note: High flow rates v.ill decrease the effective WOB).

: Pick-up and begin rotating to 40 - 60 RPM. Slowly set down increasing WOB to 5,000 to 6,000 pounds (2.272 to

2.726 kg).

-:- Resume drilling with original parameters once normal drilling characteristics are observed.

If the drillout characteristics change, i.e. drill pipe or rotary table star1s vibrating excessively, change ei ther the WOB,

RPM. or the circulation rate until the drillout characteristics normalize. Resume dnlling with the original parameters once

normal drillout characteristics are observed.

Convex bits tend to perform better when drilling out plugs and float equipment than do concave bits. since convex bits are

less likely to trap foreign materials under the bit

If the ROP stops and cannot be restarted using the above recommendations. then ret rieve the bit for inspect1on.

Rev.2 Page 17 of 20 March 2010

BP-HZN-MBI 00113261

Confidential

bp GoM Exploration Wells

, . ~ j :IIIIaco:n.do

0

' (,"- M<:!.:::u:I!J.#'J

MC 252 #1 BP01 - Macondo Prospect

~ 11-7 /8" Liner Interval

DRILL OUT PROCEDURE:

1. Start rotation above the wiper plugs/float collar. approximately 30 rpm while circulating.

2. Adjust pump rates to achieve a ratio of 1.5-2.0 hydraulic horsepower per sq. in. of bit area. Some operators use 40

gpm per inch of bit diameter as a starting point.

3. Ease into pl ugs, increasing rpm to 40 - 60 rpm.

4. Increase WOB (weight on bit) using 2.000- 3,000 lbs. per inch of bit diameter.

5. Monitor penetration rate and adjust WOB as required.

6. Raise the BHA and bit once through the plugs (approx. 2ft. ), again after drilling midway through the float collar. after

completing the float collar or as often as dictated by hole conditions.

Rev.2 Page 18 of 20

March 201 0

BP-HZN-MBI 00113262

Rev. 2

Confidential

bp

tf.l

r

l

r

Made up Onshore

l

i

Made up Onshore

1

r

Made up Onshore

l

GoM Exploration Wells

..ll!r .::o.co.r.z d o

MC 252 #1 BP01 - Macondo Prospect

11-7 /8" Liner Interval

Attachment 4:

11-718" Liner Diagram

1'1-718"

71.8 ppf

Hyd 513

0-125

11-718-

.8 pp(

Hyd 513

0-125

11-718"

718 pp

Hyd 513

0-125

11-7 18"

ns ppi

Hyd513

0-125

Versatlex

Hanger

11-7i8"

Pup Jt

11-71'8"

71.8 ppi

Hyd 513

0-125 /

/ 0,...--_/

-

Hydul 513 Conner.:tions on p1pe

Hydri l 523 on Versanex (MU to 513)

LA:S\11/P Float collar for sening

Versaftex w/oul dropping balD

design for better sealing area

11-718"

71. 8 ppi

H\'d 513

up Onsnore 0-

125

Move 4th centralizer as required

fot space on location

Backup equipment for all specialty

jts are provided

Page 19 of 20 March 2010

BP-HZN- MBI 00113263

Confidential

bp GoM Exploration Wells

i ....

MC 252 #1 BP01 - Macondo Prospect

11-7/8" Liner Interval

Rev. 2

10.711

71.8

71.8

Attachment 5:

Landing String Design - Margin of Overpu/1

es l owesT pi ,11Hl ed mud wei!Jill of 13.3 PII!J f or secri or1

: RT incllules runuintJ t ool. h.1nger . lrHI se<ll

Page 20 of 20

' ..li!C .aco.nd o

M"C:::':b.:! - .1

March 2010

BP-HZN-MBI 00113264

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- To's Post-Trial BriefDokument57 SeitenTo's Post-Trial BriefOSDocs2012Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- DOJ Pre-Trial Statement On QuantificationDokument14 SeitenDOJ Pre-Trial Statement On QuantificationwhitremerNoch keine Bewertungen

- BP Pre-Trial Statement On QuantificationDokument13 SeitenBP Pre-Trial Statement On Quantificationwhitremer100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- 2013-9-11 BPs Phase II PreTrial Reply Memo For Source Control Doc 11349Dokument13 Seiten2013-9-11 BPs Phase II PreTrial Reply Memo For Source Control Doc 11349OSDocs2012Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- 2013-09-05 BP Phase 2 Pre-Trial Memo - Source ControlDokument13 Seiten2013-09-05 BP Phase 2 Pre-Trial Memo - Source ControlOSDocs2012Noch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- 2013-9-18 Aligned Parties Pre-Trial Statement Doc 11411Dokument41 Seiten2013-9-18 Aligned Parties Pre-Trial Statement Doc 11411OSDocs2012Noch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- State of LAs Post Trial Brief Phase I (Doc. 10462 - 6.21.2013)Dokument23 SeitenState of LAs Post Trial Brief Phase I (Doc. 10462 - 6.21.2013)OSDocs2012Noch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- BP's Post-Trial BriefDokument72 SeitenBP's Post-Trial BriefOSDocs2012Noch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- To's Proposed FOF and COLDokument326 SeitenTo's Proposed FOF and COLOSDocs2012Noch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- HESI's Proposed FOF and COLDokument335 SeitenHESI's Proposed FOF and COLOSDocs2012Noch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- HESI's Post-Trial BriefDokument52 SeitenHESI's Post-Trial BriefOSDocs2012Noch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- DR Gene: CloggedDokument1 SeiteDR Gene: CloggedOSDocs2012Noch keine Bewertungen

- BP's Proposed Findings - Combined FileDokument1.303 SeitenBP's Proposed Findings - Combined FileOSDocs2012Noch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- USAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)Dokument121 SeitenUSAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)OSDocs2012Noch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Driller HITEC Display CCTV Camera System: Source: TREX 4248 8153Dokument1 SeiteDriller HITEC Display CCTV Camera System: Source: TREX 4248 8153OSDocs2012Noch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- State of ALs Post Trial Brief Phase I (Doc. 10451 - 6.21.2013)Dokument22 SeitenState of ALs Post Trial Brief Phase I (Doc. 10451 - 6.21.2013)OSDocs2012Noch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- USAs Post Trial Brief Phase I (Doc. 10461 - 6.21.2013)Dokument49 SeitenUSAs Post Trial Brief Phase I (Doc. 10461 - 6.21.2013)OSDocs2012Noch keine Bewertungen

- Foam Stability Testing: Request Date Slurry I.D. Result CommentsDokument1 SeiteFoam Stability Testing: Request Date Slurry I.D. Result CommentsOSDocs2012Noch keine Bewertungen

- Macondo Bod (Basis of Design)Dokument23 SeitenMacondo Bod (Basis of Design)OSDocs2012Noch keine Bewertungen

- Plaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013Dokument199 SeitenPlaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013OSDocs2012Noch keine Bewertungen

- Circa 2003Dokument1 SeiteCirca 2003OSDocs2012Noch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Circa 2003Dokument1 SeiteCirca 2003OSDocs2012Noch keine Bewertungen

- Arnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"Dokument5 SeitenArnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"OSDocs2012Noch keine Bewertungen

- PSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013Dokument72 SeitenPSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013OSDocs2012100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Exterior: Circa 2003Dokument1 SeiteExterior: Circa 2003OSDocs2012Noch keine Bewertungen

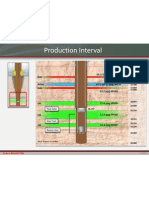

- Production Interval: 14.1-14.2 PPG M57B Gas Brine GasDokument1 SeiteProduction Interval: 14.1-14.2 PPG M57B Gas Brine GasOSDocs2012Noch keine Bewertungen

- April 20, BLOWOUT: BP Misreads Logs Does Not IdentifyDokument22 SeitenApril 20, BLOWOUT: BP Misreads Logs Does Not IdentifyOSDocs2012Noch keine Bewertungen

- Webster:: Trial Transcript at 3975:2-4Dokument1 SeiteWebster:: Trial Transcript at 3975:2-4OSDocs2012Noch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Laboratory Results Cement Program Material Transfer TicketDokument13 SeitenLaboratory Results Cement Program Material Transfer TicketOSDocs2012Noch keine Bewertungen

- End of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateDokument1 SeiteEnd of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateOSDocs2012Noch keine Bewertungen

- Instruction Manual Visotester VT-01 / VT-02Dokument17 SeitenInstruction Manual Visotester VT-01 / VT-02Guillermo Bianchi - Tikvatex S.A.Noch keine Bewertungen

- ALVAREZ Preboard Exam No. 2 - SolutionDokument8 SeitenALVAREZ Preboard Exam No. 2 - SolutionClark SibiNoch keine Bewertungen

- Maths SahodayaDokument9 SeitenMaths SahodayaSai Hari .R 10 312100% (3)

- Mutual Coupling in Antenna ArraysDokument48 SeitenMutual Coupling in Antenna ArrayshomeiraNoch keine Bewertungen

- Physics 17Dokument7 SeitenPhysics 17UPAHAR SWAPNASHISNoch keine Bewertungen

- Atomic Structure and The Periodic TableDokument3 SeitenAtomic Structure and The Periodic TableKhoer Ummah100% (1)

- Nicol PrismDokument22 SeitenNicol PrismVishwath Ram75% (8)

- (David Crolla - Behrooz Mashadi) Vehicle Powertrain Systems-Integration and Optimization - Solution ManualDokument256 Seiten(David Crolla - Behrooz Mashadi) Vehicle Powertrain Systems-Integration and Optimization - Solution Manualsadegh_199067% (3)

- Angular Wave Functions 11Dokument16 SeitenAngular Wave Functions 11Rajeev GangwarNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Training Module On Cow RearingDokument50 SeitenTraining Module On Cow RearingQuazi Moshrur-Ul-AlamNoch keine Bewertungen

- Lie Groups For 2D and 3D Transformations: Ethan EadeDokument24 SeitenLie Groups For 2D and 3D Transformations: Ethan EadeLe Dinh PhongNoch keine Bewertungen

- MT Level III Exam Bank AnswersDokument71 SeitenMT Level III Exam Bank AnswersEngr Agha Kabir100% (2)

- Periodic Table of ElementsDokument22 SeitenPeriodic Table of ElementsZennith Orions100% (1)

- Hadassa HidrociclonesDokument14 SeitenHadassa HidrociclonesHadassa Cabral Ribeiro GrippNoch keine Bewertungen

- Advances in Quantum TheoryDokument260 SeitenAdvances in Quantum Theorymbox1286593100% (1)

- ENITV31D: Intervention For Physics: Chapter 2B: FrictionDokument3 SeitenENITV31D: Intervention For Physics: Chapter 2B: FrictionHarvey MorosNoch keine Bewertungen

- COMEDK 2024 Preparation Guide EbookDokument966 SeitenCOMEDK 2024 Preparation Guide EbookVeerar ANoch keine Bewertungen

- Sample Question 2Dokument6 SeitenSample Question 2charleswcoleNoch keine Bewertungen

- CH 04Dokument20 SeitenCH 04msy83635Noch keine Bewertungen

- Unit 1 Honors PacketDokument8 SeitenUnit 1 Honors Packetapi-259040408Noch keine Bewertungen

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Dokument2 SeitenMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNoch keine Bewertungen

- Laplace TableDokument2 SeitenLaplace TableosmanfıratNoch keine Bewertungen

- Atoms PYQDokument8 SeitenAtoms PYQAyaanNoch keine Bewertungen

- Gr12 MCQDokument87 SeitenGr12 MCQkaaviya.mksasiNoch keine Bewertungen

- Khosla's LawDokument7 SeitenKhosla's LawAman sharmaNoch keine Bewertungen

- Lesson-Plan-2 ChemistryDokument7 SeitenLesson-Plan-2 ChemistryLeslayy CelizNoch keine Bewertungen

- Experiment V: FrictionDokument1 SeiteExperiment V: FrictionChristopherHiladoNoch keine Bewertungen

- Deformations and Theoretical NuclearDokument28 SeitenDeformations and Theoretical NuclearbinifsNoch keine Bewertungen

- Machine Design IIDokument11 SeitenMachine Design IIExequiel MedinaNoch keine Bewertungen

- JEE & NEET Material (All Coaching) Links - HTML PDFDokument6 SeitenJEE & NEET Material (All Coaching) Links - HTML PDFGaurav Mulodhia67% (6)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- A Place of My Own: The Architecture of DaydreamsVon EverandA Place of My Own: The Architecture of DaydreamsBewertung: 4 von 5 Sternen4/5 (242)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseVon EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseBewertung: 5 von 5 Sternen5/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionVon EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsVon EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNoch keine Bewertungen

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishVon EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishBewertung: 4 von 5 Sternen4/5 (3)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftVon EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftBewertung: 5 von 5 Sternen5/5 (5)