Beruflich Dokumente

Kultur Dokumente

Steam Traps

Hochgeladen von

Muhammad SajidOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Steam Traps

Hochgeladen von

Muhammad SajidCopyright:

Verfügbare Formate

MUHAMMAD SAJID

Steam Traps

A steam trap is a specialized type of valve that has the basic task of discharging condensate and non-condensable gases from a steam containing enclosure while retaining live steam. The removal of condensate and inert gases from steam lines ensures the best possible heat transfer rates in heat transfer equipment and eliminates the potentially disastrous effects of water hammer. Steam traps operate under one of three basic principles: density, temperature, or velocity. From these three basic operating principles, four common types of steam traps have been developed. The four common types are distinguished by their mechanism of closure: inverted bucket, float and thermostatic, thermostatic, and thermodynamic or disk steam traps. Inverted Bucket Steam Traps Inverted bucket steam traps are the most robust type of mechanical trap and resist water hammer. The design works on the principle of differentiating between the density of steam and water condensate. Steam entering under the submerged, inverted bucket causes it to float, which closes the discharge valve located at the top of the trap. Condensate entering the trap causes the bucket to sink, opening the valve to remove condensate. Normally there is a small vent in the top of the bucket, which allows non-condensable gases to pass through for discharge with the condensate. Inverted bucket steam traps are often found on higher-pressure steam systems, but they have also found use in lower-pressure service, where one might normally find float and thermostatic traps, because of their low maintenance and long lasting characteristics. With the addition of a check valve at the trap inlet, the inverted bucket can also be used to remove condensate from superheated steam lines. They must be installed in a vertical position and are used for a wide variety of service applications.

SAJIDAARL.BLOGSPOT.COM

MUHAMMAD SAJID Float and

Thermostatic Steam TrapsFloat and thermostatic steam traps use the principles of density and temperature to discharge condensate and non-condensable gases. A levered ball float (left) or free-floating ball (right) opens the primary valve when sufficient condensates enter the trap to lift the float, discharging condensate. As condensate is removed, the ball drops and the valve close. A separate thermostatic element at the top of the trap controls the discharge of air or other non-condensable gases from the trap. The thermostatic valve uses the temperature difference between the air and steam to causes a bimetallic valve actuator to open and close the air discharge valve (see the discussion of thermostatic steam traps for a more complete discussion of the mode of operation of the thermostatic air discharge). The primary discharge valve opening in float traps is proportional to the condensate flow rate entering the trap. Hence, float steam traps with thermostatic air vents are often used where prompt and continuous discharge of condensate is necessary. Some typical applications where these traps are used include: heat exchangers, ovens, drying cylinders or pans, and tank heaters. These designs are normally used for lowpressure, modulating service and must be installed so that the float rises and falls vertically in the trap body. Thermostatic Steam Traps Thermostatic steam traps open and close with the movement of a temperature sensitive element. As steam condenses, the newly formed condensate is at steam temperature, but as it flows to the steam trap, it cools. When the temperature inside the steam trap has dropped to a specified value below the steam temperature, the thermostatic valve will open, and line pressure will force condensate and noncondensable gases out of the trap. Once entering steam reheats the trap to the desired temperature, the thermostatic valve will close preventing the discharge of live steam.

SAJIDAARL.BLOGSPOT.COM

MUHAMMAD SAJID

There are two basic designs for a thermostatic steam trap, a bimetallic and a balanced pressure design. Both use the difference in temperature between live steam and condensate or air to control the release of water and noncondensable gases from the steam line. Bimetallic Thermostatic Steam Trap One type of thermostatic steam trap uses bimetallic elements to accuate a ball (left) or needle (right) valve assembly that discharges condensate and noncondensable gases. The ball valve design uses a multi-segment bimetallic element to actuate a free-floating ball valve on the downstream side of the trap. The element deflects against the line pressure with a variable increasing force in relation to rising steam pressure and temperature. The force exerted by the bimetallic element against line pressure closely parallels the steam curve, which permits the trap to operate throughout a wide pressure range without adjustment. The heart of this design is the bimetallic elements that consists of two dissimilar metals bonded together to form a composite strip. Due to the differing coefficients of expansion of the two metals, the strip will bend or deflect when subjected to a change in temperature. Most designs have the ball valve wide open when the trap is cold. This allows air and condensate to discharge rapidly during initial pressurization of the steam line. As warmer condensate enters the trap, the bimetallic element deflects slowly to close the valve. By the time live steam reaches the trap, the element has deflected so as to completly close the ball valve on the exit side of the trap. When condensate or air enters the trap, their temperature is below that of saturated steam and the consequent reaction of the element is insufficient to keep the valve tightly closed allowing line pressure on the valve to overcome the pull of the element and open the valve. When live steam again enters the trap, the element deflects to once again tightly close the exit side ball valve preventing the loss of live steam.

Balanced Pressure Thermostatic Steam Trap Balanced pressure thermostatic steam traps open and close via the expansion and contraction of a temperature sensitive element that responds to the lower temperatures created by condensate and noncondensable gases in the trap. The operating unit within the trap, a pressure-balanced disc or bellows, is filled with a liquid having a

SAJIDAARL.BLOGSPOT.COM

MUHAMMAD SAJID

saturation temperature slightly below that of water. With rising temperatures in the trap, the liquid contained in the active element evaporates. The resulting internal pressure causes the bellows or disc to expand and close the valve. As condensate or air enter the trap, the temperature within the trap decreases allowing some of the liquid in the bellows to condense, which reduces the pressure inside the bellows. This reduction in pressure causes the bellows to contract. and open the valve.

Balanced pressure thermostatic steam traps are ideal for superheated steam line applications and can readily be installed in any position. The traps are often used in low-pressure applications such as: radiators, convectors, and radiant heat heat units. Thermodynamic or Disk Steam Traps Thermodynamic steam traps are a time cycle device for discharging condensate from steam lines. This trap responds to imbalances of pressure applied to a valving device, usually a disc (right). These variations in pressure are generated from the difference between the flow of steam over a surface compared to the flow of condensate. Steam flowing over a surface creates a low pressure area. It is this phenomenon that moves the valve disc towards the seat causing the eventual closure of the valve. Condensate and noncondensable gases enter the trap and pass through an inlet orifice, heating chamber, and control chamber. As steam reaches the inlet orifice, velocity of flow increases, pulling the disc toward the valve seat. Increasing pressure in the control chamber snaps the disc closed. The contolled bleed-off of steam pressure across the sealing face of the disc permits the trap to open again, and regulates the cycling rate. Thermodynamic steam traps are preferably installed with the controlling disc in a horizontal position. The traps are used in applications where there will be no adverse effects from a temporary accumulation of condensate due to the intermittent operation

SAJIDAARL.BLOGSPOT.COM

MUHAMMAD SAJID of the trap. These applications include: pressing units, drying units, and steam jacket pipelines.

SAJIDAARL.BLOGSPOT.COM

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Medicinal Power of Some Products (English)Dokument50 SeitenMedicinal Power of Some Products (English)Muhammad SajidNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Kashf Ul MahjoobDokument480 SeitenKashf Ul Mahjoobhavocdx100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Tafseer Ibn e Kaseer 1Dokument807 SeitenTafseer Ibn e Kaseer 1Muhammad Sajid100% (1)

- Mardon Ke 300 Faqhi MasailDokument99 SeitenMardon Ke 300 Faqhi MasailMr UKNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Darhi Aur Balon Ke Shari Ahkam by Sheikh Mufti Ehsanullah ShaiqDokument63 SeitenDarhi Aur Balon Ke Shari Ahkam by Sheikh Mufti Ehsanullah ShaiqMusalman BhaiNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Asan Fiqh - Volume 1Dokument464 SeitenAsan Fiqh - Volume 1RahbarTv67% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Qasas Ul Anbiya in Urdu PDFDokument33 SeitenQasas Ul Anbiya in Urdu PDFMuhammad Sajid78% (23)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Compressor Manual (KAESER) 1 9964-0-00 8-5barDokument96 SeitenCompressor Manual (KAESER) 1 9964-0-00 8-5barMuhammad Sajid100% (8)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Kaeser Compressor and Valve (Of) - 11Dokument30 SeitenKaeser Compressor and Valve (Of) - 11Muhammad Sajid67% (3)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- ARL Boiler House ReportDokument21 SeitenARL Boiler House ReportMuhammad SajidNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Special Issue Honoring Don Mackay: Oil Spill Impact Modeling: Development and ValidationDokument16 SeitenSpecial Issue Honoring Don Mackay: Oil Spill Impact Modeling: Development and Validationbrice mouadjeNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Sample Questions For Anaphy and PhysiologyDokument90 SeitenSample Questions For Anaphy and PhysiologyMaria Jeorgia SalinasNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Influence of Methanol Concentration To Biodiesel Yield and QualityDokument5 SeitenThe Influence of Methanol Concentration To Biodiesel Yield and QualityOniNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Pulp Mill Odor ControlDokument6 SeitenPulp Mill Odor Controlalakazum28Noch keine Bewertungen

- SRU UnitDokument33 SeitenSRU UnitCenk Yağız ÖzçelikNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- SM3 9Dokument17 SeitenSM3 9Steven TaylorNoch keine Bewertungen

- Numerical Investigation On Freezing in Ballast Tank of Ship Navigating in Ice-Bound SeaDokument8 SeitenNumerical Investigation On Freezing in Ballast Tank of Ship Navigating in Ice-Bound SeaAlexander ProkhorenkoNoch keine Bewertungen

- Assign Chap 2 Version 2Dokument4 SeitenAssign Chap 2 Version 2Rashiqah RazlanNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elvaloy 4170 Research PaperDokument4 SeitenElvaloy 4170 Research PaperGolam MasudNoch keine Bewertungen

- Plastics PDFDokument18 SeitenPlastics PDFV Phanindra BoguNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- REHS2346 - Weld Repair Procedure For The Rear Axle A-Frame and Rear Axle Housing On 785, 789, and 793 Off-Highway TrucksDokument34 SeitenREHS2346 - Weld Repair Procedure For The Rear Axle A-Frame and Rear Axle Housing On 785, 789, and 793 Off-Highway TrucksrubenNoch keine Bewertungen

- Nutron Transport EquationDokument41 SeitenNutron Transport Equationmuti_khan20006003Noch keine Bewertungen

- Analysis Synthesis and Design of Chemical Processes Third Edition T LDokument5 SeitenAnalysis Synthesis and Design of Chemical Processes Third Edition T LUzair Wahid0% (1)

- MOSFET Round 1 (Done)Dokument12 SeitenMOSFET Round 1 (Done)Inimai SubramanianNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Extintor CO2 B10V-1 - BADGER PDFDokument2 SeitenExtintor CO2 B10V-1 - BADGER PDFCoordinador TecnicoNoch keine Bewertungen

- Maxlife 10W-40 SN PlusDokument1 SeiteMaxlife 10W-40 SN PlusOcto Adhi W PryhantoNoch keine Bewertungen

- Medium Voltage Cables: Refineries & Petrochemical - OnshoreDokument2 SeitenMedium Voltage Cables: Refineries & Petrochemical - OnshoreSriniNoch keine Bewertungen

- Chemistry Project - A Comparison of The Solubilities of Carbon Dioxide in Water at Various TemperaturesDokument4 SeitenChemistry Project - A Comparison of The Solubilities of Carbon Dioxide in Water at Various Temperatureszaid mansuri100% (3)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- MasterEmaco S 466 PDFDokument145 SeitenMasterEmaco S 466 PDFSri KanthNoch keine Bewertungen

- Used Oil AnalysisDokument44 SeitenUsed Oil AnalysisRiyadh Saleh100% (1)

- Chemistry Project: Organic PreparationDokument12 SeitenChemistry Project: Organic PreparationAthul Oscar RonaldoNoch keine Bewertungen

- Leaf Spring AnalysisDokument9 SeitenLeaf Spring AnalysisThilli KaniNoch keine Bewertungen

- Gasgroup Data HexeneDokument28 SeitenGasgroup Data HexeneTon Blok100% (1)

- Crystex HD OT 20 PDFDokument2 SeitenCrystex HD OT 20 PDFmeidyNoch keine Bewertungen

- NT Mat 003 - Assessment of Corrosion Protection Classes For Inorganic Coatings On Steel - Nordtest MethodDokument7 SeitenNT Mat 003 - Assessment of Corrosion Protection Classes For Inorganic Coatings On Steel - Nordtest MethodCorina StanculescuNoch keine Bewertungen

- UV VIS CaffeineDokument15 SeitenUV VIS CaffeineTinuviele EsguerraNoch keine Bewertungen

- Assignment 1 - Mass and Energy Balance March 2020Dokument2 SeitenAssignment 1 - Mass and Energy Balance March 2020Porkkodi SugumaranNoch keine Bewertungen

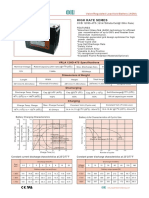

- High Rate Series: CCB 12HD-475Dokument1 SeiteHigh Rate Series: CCB 12HD-475orunmila123Noch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- A Report On Fire Extinguisher OperationDokument3 SeitenA Report On Fire Extinguisher OperationrajkotbpNoch keine Bewertungen

- Ultra-Violet Coatings Tricks and TipsDokument1 SeiteUltra-Violet Coatings Tricks and TipsAdriano AraujoNoch keine Bewertungen