Beruflich Dokumente

Kultur Dokumente

370167

Hochgeladen von

maljugan1Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

370167

Hochgeladen von

maljugan1Copyright:

Verfügbare Formate

EVSIM A PC-based simulation tool for an electric vehicle technology course

K. T. Chau, Y. S. Wong and C. C. Chan Department of Electrical and Electronic Engineering, The University of Hong Kong, Hong Kong E-mail: ktchau@eee.hku.hk

Abstract A new software package, the EVSIM, is developed to perform electric vehicle (EV) simulation based on a PC. It can carry out performance analysis of different EVs in a visual, interactive and user-friendly way, hence serving as an experimental part of the Electric Vehicle Technology course for electrical engineering undergraduate students. Keywords electric vehicles; simulation tool

A timely course, Electric Vehicle Technology, has been newly introduced at the University of Hong Kong for electrical engineering undergraduate students.1 The course is to provide the students with up-to-date and comprehensive knowledge of electric vehicle (EV) technology. This optional course can be chosen by those students taking the Electrical Energy Systems Engineering (EESE) program (specialising in electrical and energy engineering) or the Electrical and Electronic Engineering (EEE) program (embracing electrical, electronic and computer engineering). Many positive comments have been received from the students. Most of them felt that they were acquiring knowledge of a technology that was leading edge, and the knowledge was likely to be an intellectual asset and of great use in the near future. Nevertheless, some constructive comments have indicated that the course should be supported by some laboratory sessions, even though eld demonstrations of various EVs have been arranged. In response to these comments, it was considered that some experiments should be purposely designed for this course. Since the technology involved in EVs is diversied and multidisciplinary,2 including electrical and electronic engineering, mechanical and automotive engineering, and chemical engineering, it is hardly possible to provide all the realistic experimental set-ups that are necessary to support the course. Rather than employing such bulky and expensive experimental set-ups, a simple and economical tool to emulate the function of realistic experiments is computer simulation.3 It is the purpose of this paper to present a new software package, namely the EVSIM, that has been developed specically for the Electric Vehicle Technology course. This package serves as a PC-based simulator to carry out performance analysis of dierent technological aspects of EVs. Programming environment MATLAB is a popular programming environment among researchers and engineers, so it is also commonly used for teaching and learning on undergradInternational Journal of Electrical Engineering Education 37/2

168

PC-based simulation tool for electric vehicle

uate courses. It consists of a series of built-in functions and advanced toolboxes which enable students to perform computer simulation eciently. As the m-les written for MATLAB are not compiled into binary form, students are able to visualise the inner structure of the simulation program and have the chance to realise how the program is implemented on a PC. The MATLAB version for WindowsTM (Ref. 4) also enables the use of graphical controls, facilitating interactive and user-friendly simulation. As the MATLAB program has been installed in the departmental network drive, and there are over 300 departmental PCs on this network, students can freely run the EVSIM in any departmental laboratory. Among the 300-plus PCs, there are about 60 Pentium PCs located in the PC Lab which opens 24 hours a day. Thus, students can also conduct the simulation work at any time. The EVSIM software package Based on the MATLAB for WindowsTM, the EVSIM has a modular programming structure and is programmed as m-les. As shown in Fig. 1, there are four hierarchical menus, namely the Main Menu, Input Menu, Specic Data Input Menu and Output Menu. The Main Menu consists of various subprograms which are graphically represented by pushbuttons. Hence, users can easily start the simulation with default values, modify the input values, evaluate the output results, and quit the simulation by clicking on those pushbuttons. From the Main Menu, users can enter into the Input Menu by simply

Fig. 1 EV SIM menus.

International Journal of Electrical Engineering Education 37/2

Chau, Wong and Chan

169

clicking a pushbutton. In this Input Menu, four major types of default models can be chosen interactively: Vehicle type. This includes three main types of EV, namely the passenger car, van and bus. These EVs have dierent default values of vehicle weight, aerodynamic coecient, frontal area, tyre rolling coecient, tyre pressure, wheel radius, motor-to-wheel transmission ratio and battery-to-vehicle (B/V) weight ratio. Driving cycle. This is a standard or user-specied driving prole for EVs. As shown in Fig. 2, the standard driving cycles include the European ECE cycle, US Federal Urban Driving Schedule (FUDS), US Federal Highway Driving Schedule (FHDS), and Japanese 10.15 Mode. On the other hand, the userspecied driving cycles can be freely designed to account for dierent driving habits in dierent countries. Motor type. This is the type of motor for electric propulsion in EVs. It can be the d.c. motor, induction motor, permanent-magnet (PM) brushless motor or switched reluctance (SR) motor.5 Dierent types of motor have dierent default values of the torque-speed characteristics and eciency maps. Battery type. This is the type of electrochemical battery for energy storage in EVs. It includes all viable EV battery types, namely valve-regulated leadacid ( VRLA), nickeliron (NiFe), nickelzinc (NiZn), nickelcadmium (NiCd), nickelmetal hydride (NiMH), zinc/chlorine (Zn/Cl ), zinc/bromine (Zn/Br ), 2 2 iron/air (Fe/Air), aluminium/air (Al/Air), zinc/air (Zn/Air), sodium/sulphur

Fig. 2 Standard EV driving cycles.

International Journal of Electrical Engineering Education 37/2

170

PC-based simulation tool for electric vehicle

(Na/S), sodium/nickel chloride (Na/NiCl ), lithiumaluminium/iron monosul2 phide (LiAl/FeS), lithium aluminium/iron disulphide (LiAl/FeS ), lithium 2 polymer (LiPo) and lithiumion (LiIon).6 Dierent types of battery have dierent default values of the discharging/charging characteristics, specic energies, specic powers and eciencies. Apart from using the default values, users can enter into the Specic Data Input Menu to alter the vehicle weight, frontal area, rolling coecient, wheel radius, transmission ratio and B/V weight ratio. In this Specic Data Input Menu, users can simply tune a particular parameter by altering the corresponding position of a slider, or type the desired value directly into the editable text box. Having set the input parameters, the EVSIM performs the simulation based on the owchart as shown in Fig. 3. The program consists of six major modules: Road load module. Based on the selected driving cycle, the road load can be calculated as the summation of aerodynamic force, rolling resistance force, climbing force and inertial force.7 Based on the wheel radius, the torque, speed and power requirements of the road load referred to, the vehicle wheels can be determined.

Fig. 3

Flowchart for EVSIM.

International Journal of Electrical Engineering Education 37/2

Chau, Wong and Chan

171

T ransmission module. According to the motor-to-wheel transmission ratio and the pre-dened transmission eciency map, the torque, speed and power requirements of the vehicle wheels can be referred to the motor shaft. Motor module. Based on the selected motor type and the corresponding eciency map, the motor parameters (speed, torque, current and power) that are necessary to satisfy the road load can be determined. Based on torquespeed operating points referred to the motor shaft, three torque-speed characteristics are generated for continuous, short-time and temporary torque demands. These are designed to embrace frequent, frequent-plus-sometimes and frequentplus-sometimes-plus-occasional operating points of the motor, respectively. Controller module. Although research on soft-switching power controllers for EV propulsion is being actively conducted, they are far from mature enough for practical application to EVs.8 Thus, the modelling of power controllers is focused only on conventional hard-switching PWM types (converters for d.c. and SR motors; inverters for induction and PM brushless motors). Based on the motor current, the d.c. input current of the appropriate controller can be determined. This d.c. input current is a positive value when the EV is in motoring operation, and becomes negative during regenerative braking. Battery module. Based on the selected battery type as well as the corresponding discharging/charging characteristics and eciencies, the battery current can be converted into eective energy discharge from the battery during motoring or eective energy recharge to the battery during regenerative braking. Moreover, in accordance with the pre-dened specic energy of the selected battery type, the remaining usable energy and hence the state-of-charge (SOC) of the battery can be calculated. It should be noted that the pre-dened specic power of the selected battery must be higher than the maximum power of the road load; otherwise, the EV cannot operate throughout a driving cycle. Performance module. This functions to calculate the top speed, acceleration rate, gradeability, range per charge and fuel economy of the EV. The acceleration rate is presented as the minimum time required to accelerate from zero to a particular speed (typically 50 km/h and 100 km/h) on the level road, whereas the gradeability is the maximum percentage gradient of the road that the EV can run on with a constant speed of 15 km/h. The range per charge is the achievable driving distance when the battery energy is exhausted, and the fuel economy is the achievable distance per unit of energy consumption. It should be noted that both range per charge and fuel economy are heavily dependent on the B/V weight ratio, battery type and driving cycle. After the simulation, users can enter the Output Menu to display the results graphically. Similar to the Input Menu, the Output Menu is also interactive and user-friendly. The following major parameters can be readily chosen for visual evaluation: Driving cycle. This displays the time-domain speed curve of the selected driving cycle (standard or user-specied) for the simulation.

International Journal of Electrical Engineering Education 37/2

172

PC-based simulation tool for electric vehicle

W heel output. This displays the time-domain speed, torque and power as well as the torque-speed operating points referred to the vehicle wheels. Motor output. This shows the time-domain speed, torque and power as well as the torque-speed operating points and characteristics referred to the motor shaft. Controller output. This shows the time-domain current, voltage and power, either d.c. or per-phase a.c., of the controller output. Battery output. This shows the time-domain current, voltage and SOC of the battery as well as the characteristic of SOC versus driving distance, during both discharging and regenerative charging. Performance output. This displays the individual data of top speed, acceleration rate, range per charge, gradeability and fuel economy, as well as the tabulation of all data. Simulations Based on the newly developed EVSIM, students can readily perform computer simulations relating to various key issues in EV technology. Before starting these simulations, the following typical EV system is selected as a reference for comparisons: the the the the default parameters of passenger car; standard ECE driving cycle; induction motor for propulsion; VRLA battery for energy storage.

First, students are requested to investigate the road load of various EV types. During the simulations, all default parameters corresponding to the passenger car, van and bus are adopted, while the driving cycle, motor and battery follow the reference. Figure 4 shows the desired torque-speed operating points referred to the wheels corresponding to the passenger car and bus. From the distribution of these operating points, students should realise that dierent EV types require dierent road loads, even under the same driving cycle. Secondly, students need to investigate the variation of road loads due to dierent driving cycles. In this study, the reference EV system is kept unchanged except for adopting various standard driving cycles, including the ECE, FUDS, FHDS and 10.15 Mode. Figure 5 shows the desired torque-speed operating points referred to the vehicle wheels corresponding to the FUDS and FHDS. Thus, students should realise that various driving cycles cause very dierent road loads, even under the same EV system. Consequently, they should be able to distinguish among various approaches to quote the driving range of EVs, such as the range of constant-speed operation at 40 km/h, FUDS range and ECE range. In fact, the FUDS range of 120 km is more demanding than the range of 200 km at 40 km/h.

International Journal of Electrical Engineering Education 37/2

Chau, Wong and Chan

173

Fig. 4 T orque-speed operating points of passenger car and bus.

Thirdly, students are asked to investigate the importance of motor-to-wheel transmission ratio on the design of EV motors. In this study, the reference EV system is adopted for exemplication, while the transmission ratio (the default value is 851) varies from 1051 to 551. Figure 6 shows the torque-speed operating points and characteristics referred to the motor shaft, corresponding to ratios of 1051 and 551. Students should observe that the use of various transmission ratios can eectively shift the operating points between low-torque high-speed and high-torque low-speed requirements, hence signicantly aecting the design of torque-speed characteristics of the motor. Thus, students realise the importance of devising an optimal transmission ratio (so-called

International Journal of Electrical Engineering Education 37/2

174

PC-based simulation tool for electric vehicle

Fig. 5 T orque-speed operating points of FUDS and FHDS.

single-speed transmission) for EVs. It should be noted that modern EVs have abandoned the use of variable transmission ratio (so-called multiple-speed transmission) due to the drawbacks of inecient transmission and bulky gearbox. Fourthly, students need to investigate the performance of various EV motor drives, incorporating the d.c., induction, PM brushless and SR motors and their associated power controllers. For comparison, the reference EV system is retained except for adopting various motor drives. Figure 7 shows that the battery discharging current of the induction motor drive is less than that of the d.c. motor drive, whereas the corresponding regenerative charging current

International Journal of Electrical Engineering Education 37/2

Chau, Wong and Chan

175

Fig. 6

T orque-speed operating points at transmission ratios of 10 : 1 and 5 : 1.

is higher than its counterpart. Thus, students should realise that the induction motor drive is preferable to the d.c. motor drive for modern EVs. Moreover, the results can induce the students to realise the importance of eciency maps for various EV motors, which are fundamentally dierent from the rated eciency points for industrial motors. Fifthly, students are requested to investigate the performance of various EV batteries, including the VRLA, NiFe, NiZn, NiCd, NiMH, Zn/Cl , Zn/Br , 2 2 Fe/Air, Al/Air, Zn/Air, Na/S, Na/NiCl , LiAl/FeS, LiAl/FeS , LiPo and 2 2 LiIon. Based on the reference EV system except for adopting various batteries, the corresponding driving ranges of the EV are determined. Figure 8 shows the relationships of SOC versus driving distance (the horizontal intercept

International Journal of Electrical Engineering Education 37/2

176

PC-based simulation tool for electric vehicle

Fig. 7 Battery currents of d.c. and induction motor drives.

represents the driving range) corresponding to the VRLA and NiMH batteries. Thus, instead of comparing those EV batteries roughly based on their specic energies, students can quantify the superiority of various batteries in terms of the driving range per charge. Finally, students are requested to realise the concept of tradeos in EV technology,2 particularly the selection of B/V weight ratio. Based on the reference EV system while varying the B/V weight ratio from 20% to 40% (in steps of 5%), students can calculate the corresponding acceleration rate, range per charge, gradeability and fuel economy. Figure 9 displays these performance output data when adopting a B/V weight ratio of 30%. As listed in Table 1, it

International Journal of Electrical Engineering Education 37/2

Chau, Wong and Chan

177

Fig. 8

Driving ranges of V RL A and NiMH batteries.

can be observed that the acceleration rate, gradeability and fuel economy are impaired, whereas the range per charge is improved, with an increase in B/V weight ratio. Thus, students can realise that a B/V weight ratio of about 30% is a tradeo for the passenger car. Conclusions A new software package, the EVSIM, has been developed specically for the Electric Vehicle Technology course. The package serves as a PC-based simulator to carry out performance analysis of EVs. This paper has discussed its programming environment, structure and modules. Simulations have been devised which

International Journal of Electrical Engineering Education 37/2

178

PC-based simulation tool for electric vehicle

Fig. 9 Performance output at a B/V weight ratio of 30%. TABLE 1 T radeoV for optimal B/V weight ratio

B/V weight ratio (%) 20 25 30 35 40 Acceleration rate (0100 km/h) (s) 9.10 9.52 9.94 10.36 10.78 Range per charge ( km) 53.15 68.89 86.30 103.04 120.43 Gradeability (%) 22.08 20.94 19.91 18.98 18.12 Fuel economy ( km/kWh) 4.74 4.73 4.68 4.60 4.52

can greatly facilitate the students in recognising some key issues in EV technology, namely the road load of various EV types and driving cycles, the importance of transmission ratio, the performance of various motor drives and batteries, as well as the tradeo for the selection of B/V weight ratio. This EVSIM is under continual development to enrich the system models and program functions. Acknowledgements This work was supported in part by the Committee on Research and Conference Grants of the University of Hong Kong, and the Hong Kong Research Grants Council. References

1 K. T. Chau and C. C. Chan, Electric vehicle technology, Int. J. Elect. Enging. Educ., 35(3) (1998), 212220. 2 C. C. Chan, An overview of electric vehicle technology, Proc. IEEE, 81(9) (1993), 12011213.

International Journal of Electrical Engineering Education 37/2

Chau, Wong and Chan

179

3 K. T. Chau, A software tool for learning the dynamic behaviour of power electronics circuits, IEEE T rans. Educ., 39(1) (1996), 5055. 4 MathWorks, Student Edition of MAT L AB Version 5 for W indows, 1/e (Prentice Hall, New Jersey, 1997). 5 K. T. Chau, C. C. Chan and Y. S. Wong, Advanced power electronic drives for electric vehicles, Electromotion, 5(2) (1998), 4253. 6 K. T. Chau, Y. S. Wong and C. C. Chan, An overview of energy sources for electric vehicles, Energy Conversion and Management, 40(10) (1999), 10211039. 7 L. E. Unnewehr and S. A. Nasar, Electric Vehicle T echnology (John Wiley & Sons, New York, 1982). 8 C. C. Chan, K. T. Chau, D. T. W. Chan and J. M. Yao, Soft switching inverters in electric vehicles, in Proc. 14th Int. Elec. Vehicle Symp., 1997, No. 2B-3, pp. 110.

International Journal of Electrical Engineering Education 37/2

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Portable hardness tester - Thiết bị đo độ cứng cầm tay- Liên hệ: 0989653832Dokument15 SeitenPortable hardness tester - Thiết bị đo độ cứng cầm tay- Liên hệ: 0989653832Đặng Đình TuấnNoch keine Bewertungen

- Computer Repair Business PlanDokument31 SeitenComputer Repair Business PlanBerihun Engda100% (1)

- GX Works2 Version 1 Operating Manual (Simple Project, Function Block)Dokument112 SeitenGX Works2 Version 1 Operating Manual (Simple Project, Function Block)Nhut Nguyen KeNoch keine Bewertungen

- ReWaRD User ManualDokument112 SeitenReWaRD User Manualfrog15Noch keine Bewertungen

- S7 400HDokument504 SeitenS7 400HSaverioCorNoch keine Bewertungen

- Manual 831Dokument102 SeitenManual 831Salvador LuisNoch keine Bewertungen

- FP-001 Programmer OverviewDokument4 SeitenFP-001 Programmer OverviewFlavio G MiguelNoch keine Bewertungen

- DUAL VIEW AND SINGLE VIEW 320kV Installation and Maintenance Manual 5 PDFDokument260 SeitenDUAL VIEW AND SINGLE VIEW 320kV Installation and Maintenance Manual 5 PDFRamilson43% (7)

- Leica FlexField v2.50 Software Release NotesDokument5 SeitenLeica FlexField v2.50 Software Release NotesMauricio RuizNoch keine Bewertungen

- HydroBat Product DescriptionDokument12 SeitenHydroBat Product DescriptionNur HabibNoch keine Bewertungen

- Simplified Datasheet For EX900 M.2 EN PDFDokument2 SeitenSimplified Datasheet For EX900 M.2 EN PDFWyler Gamarra LeonNoch keine Bewertungen

- Twenty Years of Measuring The Missing Link (Maitland+20)Dokument9 SeitenTwenty Years of Measuring The Missing Link (Maitland+20)ICTdocsNoch keine Bewertungen

- Business Startup Proposal for Sales RepresentativeDokument4 SeitenBusiness Startup Proposal for Sales RepresentativeBranson Kaution Peters II100% (9)

- Hardware NetworkingDokument2 SeitenHardware Networkingbca onlineclassNoch keine Bewertungen

- CX-Server Runtime 17 Manual PDFDokument109 SeitenCX-Server Runtime 17 Manual PDFSergio Eu CaNoch keine Bewertungen

- Results of A Case Study On Information Technology at A UniversityDokument24 SeitenResults of A Case Study On Information Technology at A UniversitypushmbaNoch keine Bewertungen

- Vodafone Station Complete User ManualDokument18 SeitenVodafone Station Complete User ManualFergus GardnerNoch keine Bewertungen

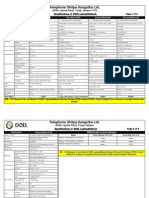

- Telephone Shilpa Sangstha LTD.: (DOEL Laptop Plant), Tongi, Gazipur-1710Dokument2 SeitenTelephone Shilpa Sangstha LTD.: (DOEL Laptop Plant), Tongi, Gazipur-1710krhaque2004Noch keine Bewertungen

- Thermal Take DH101 ManualDokument25 SeitenThermal Take DH101 Manualgrom381Noch keine Bewertungen

- Philips UpdateDokument3 SeitenPhilips UpdatesorintvrNoch keine Bewertungen

- G5vD E-Manual IDokument10 SeitenG5vD E-Manual Ijwvh25Noch keine Bewertungen

- Business Analysis HPDokument9 SeitenBusiness Analysis HPRizki Saputro0% (1)

- Software TiSwitchBoardDevice PDFDokument50 SeitenSoftware TiSwitchBoardDevice PDFAnthony VelezNoch keine Bewertungen

- Airnavx IT Prerequisites For Standalone v1Dokument7 SeitenAirnavx IT Prerequisites For Standalone v1Khalid DaghariNoch keine Bewertungen

- Lead Acid Battery Management System For Electrical VehiclesDokument11 SeitenLead Acid Battery Management System For Electrical VehiclesIAEME PublicationNoch keine Bewertungen

- PC Build NEW!! PDFDokument1 SeitePC Build NEW!! PDFAnonymous 1AEufxhKrNoch keine Bewertungen

- EB8000 Manual All in One PDFDokument702 SeitenEB8000 Manual All in One PDFgarm0704Noch keine Bewertungen

- Users Manual 154390 PDFDokument68 SeitenUsers Manual 154390 PDFhectorNoch keine Bewertungen

- Linux DownloadDokument6 SeitenLinux DownloadsaurabhNoch keine Bewertungen

- SDHmini-Ex: Intrinsically Safe Portable Dewpoint HygrometerDokument4 SeitenSDHmini-Ex: Intrinsically Safe Portable Dewpoint Hygrometerabdurahman143Noch keine Bewertungen