Beruflich Dokumente

Kultur Dokumente

Case Study - S&D

Hochgeladen von

Sam AhujaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Case Study - S&D

Hochgeladen von

Sam AhujaCopyright:

Verfügbare Formate

Sales and Distribution for an Engineering Company Business Overview The client is a large manufacturer of L.V. AND H.

V electrical components like Switchgears, Contactors, Air Circuit Breakers and MCCBs. The direct sales to Stockists are handled through 20 branch offices across the country. Manufacturing of these products is done in 3 plants, which are also 3 separate legal entities. Each unit manufactures mutually exclusive items. Some products are also imported and sold without any value addition or modification. The customer or dealer places an order on to the branch office or regional office. The branches are well versed with the various products of the three group companies and segregate the orders with respect to the items manufactured by the three companies. If case they have not done so, the branch office separates the orders. The branch office generates an order number using a predefined serial number, which indicates the region, territory and the company on which the order is placed. The branch office forwards this order to the Marketing Office. The head office, after giving the order a techno commercial clearance prepares a dispatch advice for the plant and at the same time sends an order acknowledgement back to the branch office. The dispatch order is sent to the plant. The plant verifies the stock position and if they do not have the necessary items, send a requisition for manufacturing the required items. They are then dispatched with all necessary documents to the customer. A copy of the invoice is sent to the Head office and another copy to the branch office. The branch office follows up for the payment and forwards the same to the marketing office. On a regular basis the details of the invoices issued are sent by the plant on a floppy, to the marketing department, which is then uploaded into the system by the systems department. These details are then forwarded to the finance department. The finance department prepares the sales vouchers based upon these invoices into the FA system. These are now used to prepare the MIS reports.. Overall Setup implemented Reckoner was installed at the HO. A leased line to the internet with a fixed IP address was connected to this server. Using RF modems, the 3 plants and the Central Office was brought into a VPN. For the branches, a Branch kiosk was provided. Each branch would have its own unique id and password. Customers under its territory would be automatically linked to it. Branch was restricted from viewing details of any customers not under its territory. The branches would require a dial up internet connection to connect to the main server. Different order types were defined for each unit and further segregated on the basis of special invoicing requirements. Branches would connect and place their orders directly on the internet. Problems and Suggestions 1. Discrepancy in availability of goods and their dispatch: Branches do not have any idea of the current stock position of the finished goods. They are only able to give approximate delivery dates to the customer and these tentative dates may be really off the mark. As competition increased in this industry, customers were not willing to wait for too long and wanted firm commitments. If the order were not delivered on time, often they would refuse to accept the delivery and cancelled the order. Finished goods from production were required to be entered into Reckoner as a standard process. Since material issue is also a mandatory process, everytime a despatch document was posted, the stock would reduce. This meant that the current stock position was completely accurate. At the time of placing the order, a provision was made by which the branches would automatically be able to view the current stock position of each product for which they were placing the order. In addition the plants were asked to give

an estimated date for delivery of each product type. This date was a tentative date but would be reasonably accurate. When the branches placed the order, Reckoner based on the product type would automatically enter this date into the order. However, Reckoner did not restrict delivery against the order earlier than this date. 2. Discrepancy in the goods ordered and delivered: Despatch advices had to be manually created against each order. The problem in this data entry was that the wrong items would be entered at this time. Since the plant was only considering the despatch document, the wrong items would get delivered which the customer would refuse to accept. This was easily solved. Reckoner is a completely integrated system. For sales the only document that ever needs to be entered is the Sales Order. Reckoner prepares the delivery schedule for pending orders and partially despatched orders. These despatch advices would be generated from the order and do not allow removal or modification of any item within this document. The process control is established by ensuring that modifications can only be done in the Sales Order by means of Order revision. 3. Tracking the change in price of goods: The organisation had over 8000 products. Searching for these products on web pages was time consuming. Entering the prices for each product meant that they had to refer to the catalogue and enter the price. Sometimes the price had changed but the reference was still the old catalogue. This meant that for the same product, at the same time, the Marketing Office would be receiving orders at different prices. More often than not, these orders were executed since no one could remember the actual price of one product among 8000 products in any case. This also gave an incorrect picture of the average discount report in the MIS. A special entry screen was provided called the Entry Form method. Branch engineers were familiar with the codes of each product. They would enter the first few letters of each code for all products on the single screen. The branch kiosk screen would retrieve products, which match the typed letters. If it found a complete match, it would bring the product, else it would bring the nearest 20 matches and display them in a drop down. Prices for each product as well as the associated charges would be automatically picked up from the price list defined in Reckoner. Any changes in the price list would be entered at the Marketing Office or Plant and these would would again be reflected in the Sales order document at the branch level. Note: The entry form method was also provided for the Finished Goods Receipt from Production.

4. Production requirement for the plants: The plants had over a period of time moved from the Made to Stock strategy to Made to Order. For this they needed to know what to manufacture, by when and the quantities. Also since most of the products could be produced in a minimum economic quantity, they also wanted to know the projected sales quantities. A report was given which would take into account all orders (posted and pending). This report would list out the requirement for each product on a daily basis for the next 11 days and a consolidated figure over the 11 days. The report would also take into account the current Free Stock, calculate and indicate the shortfall in quantity. One problem that we did have was that this report was to run over a bandwidth of 64 KBPS (the RF link) and it was a complicated report bringing out a huge amount of data. However, this was successfully achieved. In addition to this report, a similar report was prepared to list out details of pending despatch advices.

5. Payment collection: The branches collected the payment from the customers and deposited in a local bank or sent it to the Marketing Office. They would enter the details of the cheque in a payment slip and send it to the Marketing Office. If the payment was made before the credit period expired, the branches were authorised to give a cash discount to the customer. The credit period would start from the date by which the customer was informed about the confirmed despatch of his order. There would always be a dispute on this date between the customer, the branch office and the marketing office. Also reconciliation of the payment advices, cheques and their credit to the bank was always a very problematic issue. A customer could make a consolidated payment, which would consist of part payments against various invoices. Branches knew about the adjustment but the accounts department did not and they would spend days in reconciling the accounts for a single customer. The despatch was authorised by the plant on Reckoner. The invoice was also generated from Reckoner. This information would be available online to the branches which meant that there was no delay in communicating the despatch details. The branch would take a printout of the invoice and give it to the customer as a proforma to indicate the start of the credit period. Customers were also given an additional credit period of 3 days to get their cooperation in accepting this process. Against the invoice, Reckoner automatically generates the sales vouchers. The Branches would enter their kiosk and select the customer. All outstanding sales vouchers for the customer would be displayed online. The branch would enter the amount against each voucher that the customer was paying and were also allowed to enter the Cash Discount, if any, against each voucher. This process automatically generated the bank Payment Voucher. Branches did not need to know any of the debit accounts and were relieved of any of the accounting problems. However, this voucher would still not be posted in the GL. When the cheque was credited to the account, the accounts department would post the Bank Payment Voucher. 6. Account statements for the customer: Branches did not have accounting details of any customer. If a dispute arose, or if the customer wanted his account statement, branch would have to follow up with the accounts department to get their customers account statement. This could take days. Also since information was all offline, virtually every account statement was disputed, even if it was correct. This was again easily solved. Account statements of each customer were available online with the branches. The branches would simply take a printout and send a copy to the Customer. The information would always be accurate. NOTE: 1. In this case study, although the customer is an engineering company, we have only discussed their Sales and Distribution Process, since this was the major bottleneck. 2. There were other issues related to Sales and other functional areas as well. However, we are mentioning only a few of the main issues. 3. Information in the system was kept confidential and secure. No branch would be able to view details of other branches or any other customer except the ones, which are attached with it. The organisation did not want its branches to compete with each other on the basis of special discounts given under some circumstances. 4. No implementation was required at the branches. The branch personnel were trained for a few hours when they came to the HO for their quarterly review meeting. They started entering their orders 2 days after their training. 5. Branches did not require to upgrade any hardware or software.

6. All reports required by the branches were also incorporated into the branch kiosk for their reference. For judging the branch performance, all information for the Marketing Office was available online in any case. 7. A special kiosk was also made which was called the Marketing Office Kiosk. This would make available online all orders placed by all branches against all units and the status of each order, despatch and invoice. 8. A tremendous amount of reports are available in Reckoner. However for specific reports and to do a What if Analysis, MIS was also made available through Pivot Tables in Microsoft Excel

Copyright 2003 Ascomp Technologies Pvt. Ltd. No part of this document may be reproduced in part or whole without the explicit written instructions of Ascomp Technologies Pvt. Ltd. All brand names and trademarks are property of their respective owners.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Amul TransportDokument2 SeitenAmul TransportCharles Wood83% (6)

- Solved in A Manufacturing Plant Workers Use A Specialized Machine ToDokument1 SeiteSolved in A Manufacturing Plant Workers Use A Specialized Machine ToM Bilal SaleemNoch keine Bewertungen

- Notices, Circulars and MemoDokument11 SeitenNotices, Circulars and MemoSaloni doshiNoch keine Bewertungen

- Case Study 1Dokument9 SeitenCase Study 1kalpana0210Noch keine Bewertungen

- G.R. No. 161759, July 02, 2014Dokument9 SeitenG.R. No. 161759, July 02, 2014Elaine Villafuerte AchayNoch keine Bewertungen

- Bakels Acquires Aromatic EngDokument2 SeitenBakels Acquires Aromatic EngMishtar MorpheneNoch keine Bewertungen

- Evolution of Supply Chain ManagementDokument7 SeitenEvolution of Supply Chain ManagementBryanNoch keine Bewertungen

- AgribusinessDokument6 SeitenAgribusinessshevadanzeNoch keine Bewertungen

- How industrial engineering can optimize mining operationsDokument6 SeitenHow industrial engineering can optimize mining operationsAlejandro SanchezNoch keine Bewertungen

- Fundamentals of Accounting 3- Segment Reporting and Responsibility AccountingDokument25 SeitenFundamentals of Accounting 3- Segment Reporting and Responsibility AccountingAndrew MirandaNoch keine Bewertungen

- IDA - MTCS X-Cert - Gap Analysis Report - MTCS To ISO270012013 - ReleaseDokument50 SeitenIDA - MTCS X-Cert - Gap Analysis Report - MTCS To ISO270012013 - ReleasekinzaNoch keine Bewertungen

- Accountancy Answer Key Class XII PreboardDokument8 SeitenAccountancy Answer Key Class XII PreboardGHOST FFNoch keine Bewertungen

- TCS Connected Universe Platform - 060918Dokument4 SeitenTCS Connected Universe Platform - 060918abhishek tripathyNoch keine Bewertungen

- Ministry of Transportation Audit Finding DetailsDokument6 SeitenMinistry of Transportation Audit Finding DetailsAmalia Resky100% (1)

- Surbhi Lohia - Vikash Kandoi - : Page - 1Dokument23 SeitenSurbhi Lohia - Vikash Kandoi - : Page - 1Neetesh DohareNoch keine Bewertungen

- Operations Management Syllabus for Kelas Reguler 60 BDokument4 SeitenOperations Management Syllabus for Kelas Reguler 60 BSeftian MuhardyNoch keine Bewertungen

- Prince2 - Sample Paper 1Dokument16 SeitenPrince2 - Sample Paper 1ikrudisNoch keine Bewertungen

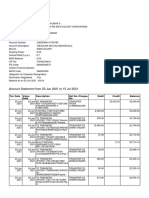

- Account Statement From 23 Jun 2021 To 15 Jul 2021Dokument8 SeitenAccount Statement From 23 Jun 2021 To 15 Jul 2021R S enterpriseNoch keine Bewertungen

- Marketing Quiz on Product Life Cycle, Pricing Strategies, Distribution Channels, Promotion ToolsDokument7 SeitenMarketing Quiz on Product Life Cycle, Pricing Strategies, Distribution Channels, Promotion ToolsDisha MathurNoch keine Bewertungen

- The Role of Business ResearchDokument23 SeitenThe Role of Business ResearchWaqas Ali BabarNoch keine Bewertungen

- MOTIVATION - Strategy For UPSC Mains and Tips For Answer Writing - Kumar Ashirwad, Rank 35 CSE - 2015 - InSIGHTSDokument28 SeitenMOTIVATION - Strategy For UPSC Mains and Tips For Answer Writing - Kumar Ashirwad, Rank 35 CSE - 2015 - InSIGHTSDhiraj Kumar PalNoch keine Bewertungen

- Zong Presentation1Dokument18 SeitenZong Presentation1shaddyxp2000Noch keine Bewertungen

- Jesd 48 BDokument10 SeitenJesd 48 BLina GanNoch keine Bewertungen

- Appendix - Structural Vetting ProjectsDokument37 SeitenAppendix - Structural Vetting Projectsqsultan100% (1)

- Chyna Benson-Receptionist 2014Dokument1 SeiteChyna Benson-Receptionist 2014api-245316866Noch keine Bewertungen

- Visa InterviewDokument1 SeiteVisa InterviewVivek ThoratNoch keine Bewertungen

- Lesson 6 EntrepreneurshipDokument13 SeitenLesson 6 EntrepreneurshipRomeo BalingaoNoch keine Bewertungen

- Suzuki Project NewDokument98 SeitenSuzuki Project NewRohan Somanna67% (3)

- Pandit Automotive Tax Recovery ProcessDokument6 SeitenPandit Automotive Tax Recovery ProcessJudicialNoch keine Bewertungen

- Stocks&Commodities S&C 03-2017Dokument64 SeitenStocks&Commodities S&C 03-2017Edgar Santiesteban Collado50% (2)