Beruflich Dokumente

Kultur Dokumente

List of Contents

Hochgeladen von

Abdalla Mohamed AbdallaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

List of Contents

Hochgeladen von

Abdalla Mohamed AbdallaCopyright:

Verfügbare Formate

List of Contents 1- General terms Oscillations Definitions Dimensions which describe the osclllatlon Phase Phase difference Undamped

ed and damped oscillations Waves Elastic waves, coupling 2- Propagation of sound waves Classification of sound waves Wave types Lamb waves Surface waves Comparison of sound velocities Calculatlon of practically usable wavelengths Behaviour of sound waves when normally incident on an Interface (boundary) Sound pressure Characteristic impedance Interfaces Reflection and transmission factors Continuous and pulsed waves 3- Ultrasonic testing techniques Through transmission technique, perpendicular incidence Pulse-echo technique, perpendicular incidence Introductory practice into the distance calibration for perpendicular Incidenc (pulse echo technique) Screen and important equipment controls Amplification control Pulse shift Time-base control Instructions for distance calibration 4- Configuration and functioning of ultrasonic test equipment and generation of ultrasound Equipment Configuration and functioning of ultrasonic test equipment Pulse generator Transmitter Operation node switch Receiver amplifier (vertical deflection) Horizontal deflection (sweep) Pulse shift Time-base calibration (sweep voltage generator)

Display screen (cathode ray tube) How oscilloscope functions Ultrasound generation Magnetostrictive effect Piezoelectric effect Transducer materials Transducer dimensions 5- Soundfield and probe configuration Interference Huygens principle Sound field dimensions Near field length Directional characteristics Graphic presentation Probe configuration Straight beam probe straight beam probe with plano-parallel delay block (stand-off) 6- Selecting the time-base rnge and the calibration distance Possible errors in calibrating the distance Read accuracy linearity deviations of the horizontal sweep Calibration distances 7- Logarithmic scale and sound attenuation Calculating with ratios Decay of sound pressure Causes Scattering Absorption Measuring the sound attenuation coefficient using perpendicular incidence 8- Sensitivity adjustment Echo height Reference reflectors Backwall Side drilled hole Diso shaped reflector (DSR) Adjustment of sensitivity and echo height comparison 9- Measurement of wall thickness Measurement techniques Simple length measurement Measurement using pulse shift Multiple echo methods

TR probe, transmitter/receiver probe for perpendicular incidence (twin probe) Applications Configuration Design dependent factors Sensitivity range Echo shapes Path errors Procedure for distance calibrations Factors influencing echo height and echo Position Testing surface Opposing surface 10- Scanning procedure Half value method, principle of sound measurement Sound field and other influences Step by Step procedure Limits of this method 11- Testing of sheet metal Types of defects found in sheet metal Typical scope indication Test techniques For thin sheet metals Automatic equipment Classification according to Iron and and Steel Supply Regulations 072 (12.77) 12- Testing of materials other than steel Sound velocity measurement Distance calibration for materials other than steel Influence of sound velocity on the echo Position Using reference block 1 or a calibration block of known dimensions and sound velocity Calculation of actual length when carrying out distance calibration for steel Testability of materials dependent upon sound attenuation 13- Properties of the testing system and its influence on the test results Influence on flaw location Depth resolution capacities Influence of the equipment on echo height Influence of probe on test conditions 14- Perpendicular (normal) incidence procedure Setting up the equipment Determining the time-base range and additional apparatus Checking the distance calibration Simple sensitivity calibration Defining flaw location

Depth of flaw Probe position on the test object Interpretation of form Indications Flaw scanning with echo height description Test report with evaluation according to test instructions 15- Principle of oblique incidence Interfaces and surface normals Phenomenon at Interfaces 16- Application of the laws of reflection and refraction with reference to mode conversion Oblique Incidence General case Critical angle Generation of surface waves Angle of Incidence Total mode conversion on reflection in steel Angle calculations on non-steel test items Conditions for total reflection of longitudinal waves 17- Partial mode conversion Grazing incidence (side wall ef Pfect) Radial perpendicular incidence in round stock Round stock testing Surface type transverse flaw Coaxial reflector (pipe) 18- Angled beam probes Principles of construction and function of angled beam probes Sonic field of an angled beam probe Determining probe data Checking probe Index and angle of Incidence 19- Principles and details of oblique incidence Reflection at parallel surfaces Reflections in corners (Corner Effect) Characteristic dimensions of oblique incidence Skip Sonic distance Sp Skip distance ap 20- Distance calibration for oblique incidence Selecting the test conditions Selecting the time-base Calibration with angled beam probes Calibration using a half-disc

Calibration on a half-disc with saw cut Calibration on calibration (reference) block 1 Calibration using calibration block 2 21- The Schlieren System Imaging arrangements Examples 22- Determination of reflector locations using oblique incidence The Flaw Triangle Calculatlon of unknown dimensions 23- Distance calibration using shortened Projection distances, sPD Determination of reflector location Rule for determining the time-base range Distance calibration using control blocks With precalibration using projection distances PD Without precalibration Calibration at edges Distance calibration Determination of x and a at corners 24- Form echoes Difference between form and flaw echoes Direction of incidence Perpendicular Incidence Oblique Incidence 25- Sensitivity adjustment for oblique incidence Adjustment reflectors Sensisitivity adjustment Checking the equipment calibration 26- Test reports (protocols) Preliminary remarks General section Test Instructions Coordinate Systems Test volumes, test techniques and Irradiation directions (directions of incidence, scanning directions) Registration details Test execution Test preparation Registering, locating and describing reflectors Longitudinal coordinates l1, 12, half value extensions

Transverse coordinate q Depth coordinate t Record sheet example 27- Mode conversion in steel Angle of impingement for complete mode conversion Almost complete mode conversion in test sample 60 angle probe, special features 28- Applications of reference block 1, as per DIN 54 120 and reference block 2 as per DIN 54 122 General Applications of the reference blocks Sensitivity adjustment Checking probe data and testing System properties 29- Examples of application of oblique incidence and notes on testing welded seams Testing shafts and bolts using oblique incidence Oblique incidence in pipes Faults in welded seams Location and differentiating between root flaws 30- Reference lines Recording reference lines Describing echo heights Registration level Sensitivity adjustment Echo height, exceeding registration level Prepared scales

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- OAFISjLOEeiP Qrke KVoA Setting A Sales Goal AOSDokument1 SeiteOAFISjLOEeiP Qrke KVoA Setting A Sales Goal AOSAbdalla Mohamed AbdallaNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Hydraulics and Conveyor Systems: TrainingDokument3 SeitenHydraulics and Conveyor Systems: TrainingAbdalla Mohamed AbdallaNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Engineering From Home: White PaperDokument7 SeitenEngineering From Home: White PaperAbdalla Mohamed AbdallaNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Optimization of Polysulfone / Graphene Oxide / Polyethylene Glycol / Triaminopyrimidine by Using Response Surface MethodologyDokument8 SeitenOptimization of Polysulfone / Graphene Oxide / Polyethylene Glycol / Triaminopyrimidine by Using Response Surface MethodologyAbdalla Mohamed AbdallaNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Dd422i Specification Sheet EnglishDokument4 SeitenDd422i Specification Sheet EnglishAbdalla Mohamed AbdallaNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Industrial Hydraulic CircuitsDokument16 SeitenIndustrial Hydraulic CircuitskingkakingNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Investigation On Tensile Properties of Epoxy/graphene Nano-Platelets/ Carboxylated Nitrile Butadiene Rubber Ternary Nanocomposites Using Response Surface MethodologyDokument12 SeitenInvestigation On Tensile Properties of Epoxy/graphene Nano-Platelets/ Carboxylated Nitrile Butadiene Rubber Ternary Nanocomposites Using Response Surface MethodologyAbdalla Mohamed AbdallaNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Optimization of UHMWPE/graphene Nanocomposite Preparation by Single Supported Ziegler Natta Catalytic System Via RSMDokument6 SeitenOptimization of UHMWPE/graphene Nanocomposite Preparation by Single Supported Ziegler Natta Catalytic System Via RSMAbdalla Mohamed AbdallaNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- PublicationDokument1 SeitePublicationAbdalla Mohamed AbdallaNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Trade MapDokument1 SeiteTrade MapAbdalla Mohamed AbdallaNoch keine Bewertungen

- #Aimenjobs: R&D Senior Researcher in Advanced Materials: Polymer and CompositesDokument2 Seiten#Aimenjobs: R&D Senior Researcher in Advanced Materials: Polymer and CompositesAbdalla Mohamed AbdallaNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Research Grant Donors: ItidaDokument5 SeitenResearch Grant Donors: ItidaAbdalla Mohamed AbdallaNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- RSC Advances: PaperDokument5 SeitenRSC Advances: PaperAbdalla Mohamed AbdallaNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Scrap Specification PDFDokument62 SeitenScrap Specification PDFr mohadiker0% (1)

- ErwgrwgwDokument5 SeitenErwgrwgwAbdalla Mohamed AbdallaNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- مركز لخدمات الكمبيوترDokument11 Seitenمركز لخدمات الكمبيوترmax_slamNoch keine Bewertungen

- W 4 Yte 54 SyDokument2 SeitenW 4 Yte 54 SyAbdalla Mohamed AbdallaNoch keine Bewertungen

- Course SpecificationDokument93 SeitenCourse SpecificationAbdalla Mohamed AbdallaNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- JHVJHVDokument5 SeitenJHVJHVAbdalla Mohamed AbdallaNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Teaching Statement: Roberto Silveira Silva FilhoDokument2 SeitenTeaching Statement: Roberto Silveira Silva FilhoAbdalla Mohamed AbdallaNoch keine Bewertungen

- Jin 2013Dokument9 SeitenJin 2013Abdalla Mohamed AbdallaNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Baba Yevsky 1973Dokument22 SeitenBaba Yevsky 1973Abdalla Mohamed AbdallaNoch keine Bewertungen

- TKT 2003Dokument2 SeitenTKT 2003Abdalla Mohamed AbdallaNoch keine Bewertungen

- Kurapati 2012Dokument3 SeitenKurapati 2012Abdalla Mohamed AbdallaNoch keine Bewertungen

- Schedule of Student Affairs Required Documents - Minutes #1Dokument2 SeitenSchedule of Student Affairs Required Documents - Minutes #1Abdalla Mohamed AbdallaNoch keine Bewertungen

- Creating Effective Scientific Figures For PublicationDokument24 SeitenCreating Effective Scientific Figures For PublicationAbdalla Mohamed AbdallaNoch keine Bewertungen

- Uspesna PrezentacijaDokument13 SeitenUspesna Prezentacijaboban72Noch keine Bewertungen

- ﻝﺎﻤﻟﺍ ﺓﺪﻳﺮﺟ ﺭﺎﺒﺧﺃ ﻢﻫﺃ (Alltopstories - 1.Aspx/) : ﻙﻮـــﻨﺑ (Section/12/1/بنـــوك/)Dokument9 Seitenﻝﺎﻤﻟﺍ ﺓﺪﻳﺮﺟ ﺭﺎﺒﺧﺃ ﻢﻫﺃ (Alltopstories - 1.Aspx/) : ﻙﻮـــﻨﺑ (Section/12/1/بنـــوك/)Abdalla Mohamed AbdallaNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Rwgtrygr 5Dokument5 SeitenRwgtrygr 5Abdalla Mohamed AbdallaNoch keine Bewertungen

- Japan VIsa Application SampleDokument2 SeitenJapan VIsa Application SampleBudi Utami Wibawani80% (5)

- GR No. 188213 - January 11, 2016 FACTS: Herein Petitioner, Natividad Cruz, Was The Punong Barangay or Chairperson of BarangayDokument6 SeitenGR No. 188213 - January 11, 2016 FACTS: Herein Petitioner, Natividad Cruz, Was The Punong Barangay or Chairperson of BarangayAilyn GaluraNoch keine Bewertungen

- Contract of EmploymentDokument5 SeitenContract of EmploymentFarisNoch keine Bewertungen

- A Thermoelectric Scanning Facility For The Study of Elemental Thermocouples Robin E Bentley - Meas. Sci. Technol. 11 (2000) 538-546Dokument10 SeitenA Thermoelectric Scanning Facility For The Study of Elemental Thermocouples Robin E Bentley - Meas. Sci. Technol. 11 (2000) 538-546Ver OnischNoch keine Bewertungen

- Yosys+Nextpnr: An Open Source Framework From Verilog To Bitstream For Commercial FpgasDokument4 SeitenYosys+Nextpnr: An Open Source Framework From Verilog To Bitstream For Commercial FpgasFutsal AlcoletgeNoch keine Bewertungen

- ACI 533.5R-20 Guide For Precast Concrete Tunnel SegmentsDokument84 SeitenACI 533.5R-20 Guide For Precast Concrete Tunnel SegmentsJULIE100% (3)

- Donor's Tax Post QuizDokument12 SeitenDonor's Tax Post QuizMichael Aquino0% (1)

- CHAPTER 2 Principles of MarketingDokument41 SeitenCHAPTER 2 Principles of MarketingASHIMA THAPANoch keine Bewertungen

- Qualifications and Disqualifications of CandidatesDokument3 SeitenQualifications and Disqualifications of CandidatesCARLO JOSE BACTOLNoch keine Bewertungen

- Policy 0000000001523360 PDFDokument15 SeitenPolicy 0000000001523360 PDFunique infraNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Shalina Healthcare JD - Business AnalyticsDokument2 SeitenShalina Healthcare JD - Business AnalyticsMeow bunNoch keine Bewertungen

- PR Status ReportDokument28 SeitenPR Status ReportMascheny ZaNoch keine Bewertungen

- Toyota PDFDokument3 SeitenToyota PDFPushp ToshniwalNoch keine Bewertungen

- General Milling Corp Vs CA (DIGEST)Dokument2 SeitenGeneral Milling Corp Vs CA (DIGEST)Raima Marjian Sucor100% (1)

- Mass Effect 5e - The HomebreweryDokument253 SeitenMass Effect 5e - The HomebreweryRony Do CarmoNoch keine Bewertungen

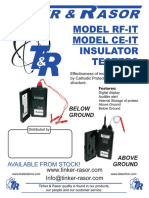

- R R O S A: Model Rf-It Model Ce-It Insulator TestersDokument2 SeitenR R O S A: Model Rf-It Model Ce-It Insulator Testersvictor raul sandoval martinezNoch keine Bewertungen

- 164 Dashboard Annotated Ver 2a W-InsertDokument1 Seite164 Dashboard Annotated Ver 2a W-Insertoleg164Noch keine Bewertungen

- Istqb Agile Tester Learning Objectives SingleDokument3 SeitenIstqb Agile Tester Learning Objectives SingleSundarNoch keine Bewertungen

- User Manual For FDC 2.1Dokument13 SeitenUser Manual For FDC 2.1Jeni FragaNoch keine Bewertungen

- Airbus Settles Fettling Dust With Clean Air SolutionDokument1 SeiteAirbus Settles Fettling Dust With Clean Air SolutionstephendixNoch keine Bewertungen

- Polaris Ranger 500 ManualDokument105 SeitenPolaris Ranger 500 ManualDennis aNoch keine Bewertungen

- CANVASS FORM MerchandiseDokument1 SeiteCANVASS FORM MerchandiseJuan VicenteNoch keine Bewertungen

- CN842 HBDokument15 SeitenCN842 HBElif SarıoğluNoch keine Bewertungen

- DSP QBDokument8 SeitenDSP QBNithya VijayaNoch keine Bewertungen

- Refill Brand Guidelines 2Dokument23 SeitenRefill Brand Guidelines 2Catalin MihailescuNoch keine Bewertungen

- OCES 1001 - Final Exam Instructions (Please Read BEFORE The Exam)Dokument16 SeitenOCES 1001 - Final Exam Instructions (Please Read BEFORE The Exam)Heihei ChengNoch keine Bewertungen

- MITSUBISHI I-MievDokument297 SeitenMITSUBISHI I-Mievtavaelromo84Noch keine Bewertungen

- Insular Bank of Asia vs. InciongDokument11 SeitenInsular Bank of Asia vs. InciongChristiane Marie BajadaNoch keine Bewertungen

- Intermediate Algebra Functions and Authentic Applications 5th Edition Jay Lehmann Solutions ManualDokument31 SeitenIntermediate Algebra Functions and Authentic Applications 5th Edition Jay Lehmann Solutions Manualchiliasmevenhandtzjz8j100% (32)

- 213-Article Text-620-1-10-20201118Dokument6 Seiten213-Article Text-620-1-10-20201118Arlin FebriantiNoch keine Bewertungen

- FPO Policy-1Dokument96 SeitenFPO Policy-1shashanksaranNoch keine Bewertungen

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookVon EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNoch keine Bewertungen

- Sodium Bicarbonate: Nature's Unique First Aid RemedyVon EverandSodium Bicarbonate: Nature's Unique First Aid RemedyBewertung: 5 von 5 Sternen5/5 (21)

- Guidelines for Chemical Process Quantitative Risk AnalysisVon EverandGuidelines for Chemical Process Quantitative Risk AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Water-Based Paint Formulations, Vol. 3Von EverandWater-Based Paint Formulations, Vol. 3Bewertung: 4.5 von 5 Sternen4.5/5 (6)

- Process Plant Equipment: Operation, Control, and ReliabilityVon EverandProcess Plant Equipment: Operation, Control, and ReliabilityBewertung: 5 von 5 Sternen5/5 (1)

- Phase Equilibria in Chemical EngineeringVon EverandPhase Equilibria in Chemical EngineeringBewertung: 4 von 5 Sternen4/5 (11)