Beruflich Dokumente

Kultur Dokumente

Turbine Meter

Hochgeladen von

amr bahyOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Turbine Meter

Hochgeladen von

amr bahyCopyright:

Verfügbare Formate

Turbine meters

Turbine flow meters measure the rate of flow in a pipe or process line via a rotor that spins as the media passes through its blades. The rotational speed is a direct function of flow rate and can be sensed by magnetic pick-up, photoelectric cell, or gears. Flow meters types can be either volumetric or velocity. Volumetric turbine flow meters measure flow rate in units of volumetric flow, for example, mL/min. Velocity turbine flow meters measure flow rate as in units of velocity, for example, ft./sec.

Turbine Flow Meter Media Applications

A turbine flow meter can be configured to measure either liquid or gas flow. Some types of liquid turbine flow meters can accommodate liquids with suspended solids (slurries), while some liquid and gas turbine flow meters can handle mixed phase materials such as steam.

Important Parameters for Turbine Flow Meters

Important parameters to consider when specifying turbine flow meters include velocity flow rate range, liquid volumetric flow rate, operating pressure, fluid temperature, material density, and material viscosity. Velocity flow rate range applies only to those turbine flow meters that are velocity flow sensors or meters. It is the range of flow in distance/time. Liquid volumetric flow rate applies only to those turbine flow meters that are liquid volumetric flow sensors or meters. It is expressed as the range of flow in volume/time. The operating pressure is the maximum head pressure of the process media the meter can withstand. The maximum temperature of the media that can be monitored is usually dependent on construction and liner materials. Depending on the flow meter technology used, material viscosity can be an important material factor to consider. The higher the viscosity, typically the higher the pressure drop. Pipe diameter is also important to consider, especially when specifying specific mounting options.

Turbine Flow Meter Mounting Options

Mounting options for turbine flow meters include insertion types, inline flanged, in-line threaded, and in-line clamp. Insertion turbine flow meters are inserted perpendicular to the flow path. Insertion type meters usually require a threaded hole in the process pipe or other means of access. In-line flanged flow meters are inserted parallel to the flow path,

usually inserted between two pieces of existing flanged process pipes. In-line threaded flow meters are inserted parallel to the flow path, and threaded into two existing process pipes. NPT is the most common thread type. In-line clamp flow meters are inserted parallel to the flow path, and clamped between two existing process pipes.

Turbine meters have found widespread use for accurate liquid measurement applications. The unit consists of a multiple-bladed rotor mounted with a pipe, perpendicular to the liquid flow. The rotor spins as the liquid passes through the blades. The rotational speed is a direct function of flow rate and can be sensed by magnetic pick-up, photoelectric cell, or gears. Electrical pulses can be counted and totalized The number of electrical pulses counted for a given period of time is directly proportional to flow volume. A tachometer can be added to measure the turbine's rotational speed and to determine the liquid flow rate. Turbine meters, when properly specified and installed, have good accuracy, particularly with low-viscosity liquids.

Das könnte Ihnen auch gefallen

- Types of Flow Meters For Different ApplicationsDokument8 SeitenTypes of Flow Meters For Different ApplicationsShahabNoch keine Bewertungen

- Types of Flow Measuring DevicesDokument19 SeitenTypes of Flow Measuring DevicesRafat ShaikhNoch keine Bewertungen

- Clamp-On Flow MeterDokument6 SeitenClamp-On Flow MeterHanan Khan100% (1)

- Flow Measurement: Calibration of Flow Meters How To Select A Flow MeterDokument4 SeitenFlow Measurement: Calibration of Flow Meters How To Select A Flow MeterVarunNoch keine Bewertungen

- Liquid Measurement Station Design 2017 ISHMDokument5 SeitenLiquid Measurement Station Design 2017 ISHMMalouk CheniouniNoch keine Bewertungen

- Lecture 310 - Fluid Flow MetersDokument41 SeitenLecture 310 - Fluid Flow Metersanonim 1178Noch keine Bewertungen

- AB502 ST U4 RotameterDokument9 SeitenAB502 ST U4 RotameterHARSH MALVIYANoch keine Bewertungen

- Me Lab 1 Draft Group ReportDokument12 SeitenMe Lab 1 Draft Group ReportAngelo PontivedraNoch keine Bewertungen

- Fundamentals of Liquid Measurement IIIBDokument10 SeitenFundamentals of Liquid Measurement IIIBmanuel_medcoNoch keine Bewertungen

- Gas Flow MeasurementDokument71 SeitenGas Flow MeasurementAnuranjan100% (1)

- Written ReportDokument18 SeitenWritten ReportAljun SarmientoNoch keine Bewertungen

- Measurement of Fluid FlowDokument10 SeitenMeasurement of Fluid FlowMd Ashikur RahmanNoch keine Bewertungen

- Practical Flow EssentialsDokument8 SeitenPractical Flow EssentialsAyman TermaniniNoch keine Bewertungen

- Flow Measurement - WikipediaDokument17 SeitenFlow Measurement - WikipediaJames JohnNoch keine Bewertungen

- Asme PTC 19.5 With ExplanationDokument4 SeitenAsme PTC 19.5 With ExplanationRoi OcoNoch keine Bewertungen

- Custody Transfer & Flow MeteringDokument4 SeitenCustody Transfer & Flow MeteringJoanna George - Joseph100% (1)

- ObjectiveDokument4 SeitenObjectiveAzwan BaharinNoch keine Bewertungen

- Flow Meter Flow Mesurement Definition Uses of Flow Meter A TypesDokument3 SeitenFlow Meter Flow Mesurement Definition Uses of Flow Meter A TypesMirza Zubair RazaNoch keine Bewertungen

- Basic of Flow Measurments TechniquesDokument34 SeitenBasic of Flow Measurments TechniquesShoaib DaharNoch keine Bewertungen

- Metering of GasDokument59 SeitenMetering of GasSHOBHIT KUMAR100% (2)

- Introduction To Magnetic Flow MetersDokument11 SeitenIntroduction To Magnetic Flow MetersNïkĦïl ДkДvØØrNoch keine Bewertungen

- Instrumentation Basics - 02 - Flow MeasurementDokument62 SeitenInstrumentation Basics - 02 - Flow MeasurementGhassan AL HaririNoch keine Bewertungen

- Flow MeasurementDokument16 SeitenFlow Measurementtaufiktm83Noch keine Bewertungen

- Fluid Flow and Fluid DynamicsDokument58 SeitenFluid Flow and Fluid DynamicsJeff Poi100% (4)

- Mem MicroDokument16 SeitenMem Micro119 HARSH SHIRKENoch keine Bewertungen

- A Brief Study of The Most Commonly Used Flow MetersDokument21 SeitenA Brief Study of The Most Commonly Used Flow MeterssumeghNoch keine Bewertungen

- Uba 2019Dokument21 SeitenUba 2019Isaac Honny JnrNoch keine Bewertungen

- FLOWDokument31 SeitenFLOWHassan HaiderNoch keine Bewertungen

- Flow InstrumentsDokument38 SeitenFlow InstrumentsTirado Melchor Angel Miguel100% (2)

- Assignment 4 - InstrumentationDokument10 SeitenAssignment 4 - InstrumentationAbdelrahman Mohamed ElshafeiNoch keine Bewertungen

- Flow MeasurementDokument16 SeitenFlow MeasurementNigel MagayaNoch keine Bewertungen

- Flow Measurement: Jump To Navigationjump To Search FluidDokument15 SeitenFlow Measurement: Jump To Navigationjump To Search FluidAtheerAlmosawiNoch keine Bewertungen

- CHE Facts 0709 PDFDokument1 SeiteCHE Facts 0709 PDFortegaroberNoch keine Bewertungen

- Flowmeter Types and Their PrinciplesDokument14 SeitenFlowmeter Types and Their PrincipleszaydFG100% (2)

- InstrumentationDokument104 SeitenInstrumentationAhmed Jebreel75% (4)

- How Laminar Flow Element Flowmeters WorkDokument1 SeiteHow Laminar Flow Element Flowmeters WorkMostafa AbdelalimNoch keine Bewertungen

- Flow MeasurementDokument37 SeitenFlow MeasurementVarad DateNoch keine Bewertungen

- Flow Measurement Is The Quantification of Bulk: FluidDokument5 SeitenFlow Measurement Is The Quantification of Bulk: FluidVIYANI JOSEPHNoch keine Bewertungen

- Fluid: Flow Measurement Is The Quantification of BulkDokument10 SeitenFluid: Flow Measurement Is The Quantification of BulkShubham SinghNoch keine Bewertungen

- Flow Meter TypesDokument11 SeitenFlow Meter TypesFaisal RafiqueNoch keine Bewertungen

- Flow MeasurementDokument118 SeitenFlow MeasurementVirag ParekhNoch keine Bewertungen

- Flow Measurement BasicDokument87 SeitenFlow Measurement BasicSri100% (2)

- Flow Measurement (Liquid)Dokument9 SeitenFlow Measurement (Liquid)İBRAHİM HAZAR AYTULUNNoch keine Bewertungen

- The Basics of Rotameters - SensorsDokument12 SeitenThe Basics of Rotameters - Sensorsnishanth132Noch keine Bewertungen

- Fundamentals of Liquid MEasurement III - DynamicDokument11 SeitenFundamentals of Liquid MEasurement III - DynamicCRT ServicesNoch keine Bewertungen

- Flow Measurement: Jitendra SurveDokument21 SeitenFlow Measurement: Jitendra Survedaman8448Noch keine Bewertungen

- Flow MeasurementDokument40 SeitenFlow MeasurementPradyumna Dhamangaonkar100% (2)

- Part C ReportDokument6 SeitenPart C Reportfathima camangianNoch keine Bewertungen

- Introduction To Fiscal MeteringDokument26 SeitenIntroduction To Fiscal MeteringmulkaNoch keine Bewertungen

- Introduction To Fiscal MeteringDokument24 SeitenIntroduction To Fiscal MeteringAliNoch keine Bewertungen

- Liquid Flow Sensors: Orifice Plate Turbine MeterDokument8 SeitenLiquid Flow Sensors: Orifice Plate Turbine MeterNileshNoch keine Bewertungen

- Flow Measurement BasicDokument87 SeitenFlow Measurement BasicSrinivasarao YenigallaNoch keine Bewertungen

- Liquid Engineering: Reynolds NumbersDokument12 SeitenLiquid Engineering: Reynolds NumbersajaymechengineerNoch keine Bewertungen

- FlowDokument62 SeitenFlowbapita roy100% (1)

- INSTRUMENTATIONfebDokument35 SeitenINSTRUMENTATIONfebBalli SinghNoch keine Bewertungen

- Impeller Diameter-Bioprocess EngineeringDokument20 SeitenImpeller Diameter-Bioprocess EngineeringKelmy Thomas MariaNoch keine Bewertungen

- Petroleum Engineering Department Flow Loop ExperimentDokument8 SeitenPetroleum Engineering Department Flow Loop ExperimentEbied Yousif AlyNoch keine Bewertungen

- Liquid Pipeline Hydraulics: Second EditionVon EverandLiquid Pipeline Hydraulics: Second EditionNoch keine Bewertungen

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingVon EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingBewertung: 5 von 5 Sternen5/5 (9)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesVon EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesBewertung: 5 von 5 Sternen5/5 (1)

- DCM-I&II Lab Equipments ListDokument2 SeitenDCM-I&II Lab Equipments ListPrashant ChinamalliNoch keine Bewertungen

- PythagorasDokument109 SeitenPythagorasaditya00012Noch keine Bewertungen

- Therapeutic EffectsofWhole-BodyDevices Applying Pulsed Electromagnetic Fields (PEMF)Dokument11 SeitenTherapeutic EffectsofWhole-BodyDevices Applying Pulsed Electromagnetic Fields (PEMF)Jeroan MonteiroNoch keine Bewertungen

- Tribology Module 01 NotesDokument19 SeitenTribology Module 01 NotesVinayaka G P89% (9)

- X-Plane Mobile ManualDokument66 SeitenX-Plane Mobile ManualRafael MunizNoch keine Bewertungen

- Creating Attachments To Work Items or To User Decisions in WorkflowsDokument20 SeitenCreating Attachments To Work Items or To User Decisions in Workflowselampe100% (1)

- Student - The Passive Voice Without AnswersDokument5 SeitenStudent - The Passive Voice Without AnswersMichelleNoch keine Bewertungen

- OIML R 137-1 & 2: Nternational EcommendationDokument76 SeitenOIML R 137-1 & 2: Nternational EcommendationAMY WEINoch keine Bewertungen

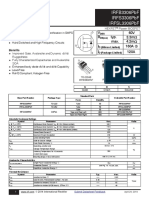

- Irfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADokument12 SeitenIrfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADirson Volmir WilligNoch keine Bewertungen

- Water Levels Forecast in Thailand: A Case Study of Chao Phraya RiverDokument6 SeitenWater Levels Forecast in Thailand: A Case Study of Chao Phraya RiverErna UtamiNoch keine Bewertungen

- Index Terms LinksDokument31 SeitenIndex Terms Linksdeeptiwagle5649Noch keine Bewertungen

- Che 410 ................... Transition Metal ChemistryDokument13 SeitenChe 410 ................... Transition Metal ChemistryElizabeth AnyangoNoch keine Bewertungen

- Solved - Which $1,000 Bond Has The Higher Yield To Maturity, A T...Dokument4 SeitenSolved - Which $1,000 Bond Has The Higher Yield To Maturity, A T...Sanjna ChimnaniNoch keine Bewertungen

- Wacker Neuson Light Towers LTN 6l Parts Manual 348628422Dokument23 SeitenWacker Neuson Light Towers LTN 6l Parts Manual 348628422kellyholland180884pnc100% (61)

- Fundamentals Writing Prompts: TechnicalDokument25 SeitenFundamentals Writing Prompts: TechnicalFjvhjvgNoch keine Bewertungen

- NumpyDokument23 SeitenNumpymuzammil jawedNoch keine Bewertungen

- MODULAR QUIZ - 57 - Steel DesignDokument9 SeitenMODULAR QUIZ - 57 - Steel DesignCornelio J. FernandezNoch keine Bewertungen

- Product Specifications: Handheld Termination AidDokument1 SeiteProduct Specifications: Handheld Termination AidnormNoch keine Bewertungen

- Synthesis of Glycerol Monooctadecanoate From Octadecanoic Acid and Glycerol. Influence of Solvent On The Catalytic Properties of Basic OxidesDokument6 SeitenSynthesis of Glycerol Monooctadecanoate From Octadecanoic Acid and Glycerol. Influence of Solvent On The Catalytic Properties of Basic OxidesAnonymous yNMZplPbVNoch keine Bewertungen

- Microporous and Mesoporous Materials: SciencedirectDokument8 SeitenMicroporous and Mesoporous Materials: SciencedirectAssyakurNoch keine Bewertungen

- Polya Problem Solving StrategiesDokument12 SeitenPolya Problem Solving StrategiesGwandaleana VwearsosaNoch keine Bewertungen

- Tutoriales Mastercam V8 6-11Dokument128 SeitenTutoriales Mastercam V8 6-11Eduardo Felix Ramirez PalaciosNoch keine Bewertungen

- Decision-Making Under Risk and Uncertainty: OutcomesDokument21 SeitenDecision-Making Under Risk and Uncertainty: OutcomesprabodhNoch keine Bewertungen

- Ampla's Technology ArchitectureDokument4 SeitenAmpla's Technology ArchitecturesyeadtalhaaliNoch keine Bewertungen

- Ticket Eater - User Manual 2006Dokument24 SeitenTicket Eater - User Manual 2006tokio2424Noch keine Bewertungen

- 10 2Dokument26 Seiten10 2cristinatubleNoch keine Bewertungen

- Fiber SyllabusDokument1 SeiteFiber SyllabusPaurav NayakNoch keine Bewertungen

- Chem 17 Exp 3 RDR Chemical KineticsDokument4 SeitenChem 17 Exp 3 RDR Chemical KineticscrazypatrishNoch keine Bewertungen

- CCNA2 Lab 7 3 8 enDokument6 SeitenCCNA2 Lab 7 3 8 enapi-3809703100% (1)