Beruflich Dokumente

Kultur Dokumente

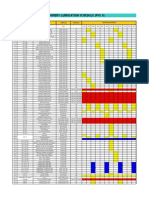

Canal Design

Hochgeladen von

Khaista RahmanOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Canal Design

Hochgeladen von

Khaista RahmanCopyright:

Verfügbare Formate

By A.W.

1

CHAPTER THREE

3. Design of Channels

3.1. General

The success of the irrigation system depends on the design of the network of canals. The canals may

be excavated through the difference types of soils such as alluvial soil, non-alluvial soil etc. the design

consideration naturally vary according to the type of soil. Again, the velocity of flow in the canal

should be critical. That means, the velocity should be non-silting and non-scouring. If the velocity

becomes less than the critical velocity, then silting will take place and the capacity of the canal will be

reduced. If the velocity becomes more than the critical velocity then the scouring will take place and

the channel will be damaged. So, determination of critical velocity is very important in canal design.

Based on the water requirements of the crops on the area to be irrigated the entire system of main

canal, secondary canal, tertiary canal and field distributaries should be designed properly for a certain

realistic value of peak discharge that must pass through them, so as to provide sufficient irrigation to

the commands. Again, the design of unlined and lined canals involves different practical and

economical consideration.

3.2. Definition of some terms

1. Alluvial soil:

The soil which is formed by continuous deposition of silt is known as alluvial soil. The river carries

heavy charge of silt in rainy season. When the river overflows its banks during the flood, the silt

particles get deposited on the adjoining areas. This deposition of silt continues year after year. This

type of soil is found in deltaic region of a river. This soil is permeable and soft and very fertile.

2. Non-alluvial soil

The soil which is formed by the disintegration of rock formation is known as non-alluvial soil. It is

found in the mountains regions of a river. The soil is hard an impermeable in nature. This is not fertile.

3. Silt factor (f)

In designing of a canal in alluvial soil, the suspended silt and the deposited silt in the canal bed should

be taken into consideration with great importance. During the investigation work in various canals in

alluvial soil, Lecey established the effect of silt on the determination of discharge and the canal

section. So, he introduced a factor which is known as silt factor. It depends on the main particle size

of silt. It is denoted by f. Determined by the expression

f

m f 76 . 1 =

Where m

f

= mean particle size of silt in mm.

4. Coefficient of rugosity (N)

By A.W.

2

The roughness of the canal bed affects the velocity of flow. The roughness coefficient, being a

parameter representing the integrated effect of the channel cross sectional resistance, value of N

depends on the type of bed materials of the canal.

5. Mean velocity

Velocity distribution in a canal section usually varies from one point to another, this is due to shear

stress at the bottom and at the sides and due to the presence of the free surface. Field observation

shows that average velocity for open channel flow to be the average velocity measured at 0.2 and 0.8

of y from the free water surface.

2

8 . 0 2 . 0 y y

av

V V

V

+

=

6. Critical velocity (V

o

)

When the velocity of the flow is such that there is no silting or scouring action in the canal bed, then

that velocity is known as critical velocity. Generally the critical velocity depends on the nature of the

soil formation in which the water flows. Table below shows the critical velocity for different soil

formations:

Nature of soil Critical velocity m/s

Sandy soil 0.3 to 0.6

Black cotton soil 0.6 to 0.9

Firm clay and loom 0.9 to 1.15

Gravel 1.2

Hard rock More than 3.0

Concrete 6.0

Steel lining 10.0

7. Critical velocity ration (CVR)

The ratio of the mean velocity V to the critical velocity V

o

is known as critical velocity ratio. It is

denoted by m.

m

V

V

CVR

o

= =

When m equals 1 there is no silting or scouring, when m > 1, scouring will occur and when m < 1

silting will occur. So, by finding the value of m, the condition of the canal can be predicted whether it

will have silting or scouring.

8. Hydraulic radius (R)

Is the ratio of the cross-sectional area to the wetted perimeter of the channel

P

A

R =

By A.W.

3

9. Full supply level (FSL)

The maximum discharge capacity of the canal for which it is designed, is known as full supply level.

10. Economical section

In irrigation canal water flows under the force of gravity, to flood the command area left and/or side of

the canals the FSL of the canal is generally kept above the natural surface level (NSL). Naturally to

hold the water in the channel it is partly excavated below the NSL and partly above the NSL. To be

economical the depth of excavation is arranged that the quantity of the earth excavated from the canal

section is just sufficient to construct the banks. The depth of excavation is called balancing depth.

In addition to that the conveyance of the channel will be efficient when the channel section have

minimum perimeter for a given area, slope and roughness coefficient are fixed.

Fig: Balancing depth

Y is balancing depth

D is full supply depth

H is height of the top of bank above the bed of bank

T is top width of the bank

B is bed width of the cannel

m:1 is side slope in cutting

n:1 is side slope in filling

For economical section Cutting = filling in banks

( ) )) ( )( ( 2 y H n T y H my B y + = +

Generally side slope in cutting is kept 1:1 and filling kept as 1.5:1.

By A.W.

4

11. Regime channel

When the characteristics of the bed material of the channel are same as that of the transported material

and when the silt charge and silt grade are constant, then the channel is said to be in its regime and the

channel is called regime channel. A channel in which neither silting nor scouring takes place is called

regime channel or stable channel. This stable channel is said to be in state of regime if the flow is such

that silting and scouring need no special attention.

3.3. Design of non-alluvial channels

The non-alluvial soils are stable and nearly impervious. For the design of canal in this type of soil, the

coefficient of rugosity plays an important role, but the other factor like silt factor has no role. Here, the

velocity of the flow is considered very close to critical velocity. So, the mean velocity given by

Chezy,s expression or Mannings expression is considered for the design of canal in this soil.

After along investigation in various canals, Chezy and Manning have established the following

expressions for finding the mean velocity flow.

Chezy formula

o

RS C V =

Where C is a coefficient which depend on the nature of the surface and the flow and known as chezy

coefficient, S

o

is bed slope of the channel. C can be calculated from the following formula:

1. Pavlovski formula

x

R

n

C

1

=

In which x= 2.5 ( ) 1 . 0 75 . 0 13 . 0 n R n and n is Mannings coefficient

2. Ganguiller and Kutter formula

R

n

S

S n

C

o

o

(

+ +

+ +

=

00155 . 0

23 1

00155 . 0 1

23

3. Bazins formula

By A.W.

5

R

M

C

+

=

1

0 . 87

In which M is a coefficient dependant on the surface roughness

Channel M for unlined channel M = 1.30 to 1.75, for lined channel M = 0.45 to 0.85

Mannings formula

2

1

3

2

1

o

S R

n

V =

Where n is roughness coefficient known as Mannings n [L

-1/3

T]. This coefficient is essentially a

function of the nature of the boundary surface.

A

V

Q =

Where Q is design discharge m

3

/s

A cross sectional area of the channel m

2

V mean velocity of flow

Design procedures of non-alluvial channels

1. Start with a design discharge and select the permissible velocity

2. Determine the area of the channel by Q=AV formula

3. Compute for the hydraulics radius by using Chezy or Mannings equation

4. Write the hydraulics radius in terms of B and Y and equate it with result of step three

5. Write the area in terms of B and Y and substitute B of step 4 in this equation, then you will

have quadratic equation to solve for the value of Y.

3.4. Design of alluvial channels

If the procedure adopted for the design of channels on non-alluvial soil is applied over alluvial

channels, then the silt load carried by the irrigation water is not considered. The principle of design of

a channel on alluvial soil is totally different from that of channel on non-alluvial soils. Channels on

alluvial soil carry appreciable silt and sand load. When the channel water has excess silt load silting

occur in the channel. On the contrary when the water is silt free it picks up the silt from the channel

bed and sides, it results in erosion of channel section. Mannings and Chezys equation do not consider

this aspect. When silting takes place the channel section is reduced and consequently capacity of the

channel is reduced. When scouring occurs firstly the water level is lowered with in turn reduces the

command. Secondly the scoured material is deposited at some other place to disturb the equilibrium

condition there. Taking the problem of silt transportation in to account it was necessary to evolve some

basis for the design of a stable section with critical velocity. There are two important and most

commonly used theories. They are Kennedys silt theory and Laceys theory.

After long research in different canals and different conditions R.G Kennedy, Punjab and Gerald

Lacey have established some theories for the design of canals which are known as Kennedys theory

and Lacey theory. Those two theories are based on the characteristics of sediment load (i.e silt) in

canal water. The behavior of the silt load is explained by the theory which is known as silt theory

3.4.1. Kennedys regime theory

Kennedy established a relation between non scouring, non silting velocity, termed as critical

velocity of flow and the stage of flow on the basis of experimental work collected from 22 channels

on the upper Bari-Doab canal system in Punjab (Pakistan). For any given channel having a particular

soil condition, the critical velocity ratio which is a function of silt charge and grade and rugosity

coefficient is uniquely fixed. Kennedy had suggested a general form of equation for critical velocity

Vo=CD

n

. The value of m depends upon the silt charge and silt grade. The coefficient C and the power

By A.W.

6

index n are not constant and change from site to site. The most prevalent values of C and n as worked

out by Kennedy are 0.546 and 0.64 respectively. Kennedy plotted various graphs between V

o

and

depth of flow and finally gave a formula to calculate V

o

. the formula is

64 . 0

546 . 0 D V

o

=

Kennedy also recognized that sediment size plays an important role in determining the relationship

between velocity and depth. Hence, he proposed that for the sediment sizes other than the one found in

the upper Bari Doab canal system the above equation should be modified to:

64 . 0

546 . 0 D m V

o

=

Where V

o

critical velocity / nonsilting velocity [m/s] and Y full supply depth [m] and C is a constant.

It depends on character of silt. Coarser the material greater the value of the constant and n is some

index. It also depends on the type of silt. Where m is incorporated to show the role of sediment size

CVR

V

V

m

o

= = , for course sand value of m may be taken as 1.1 to 1.2. Whereas for finer material it

may be kept 0.8 and 0.9. in addition to estimate the actual velocity he proposed the use of Chezys

equation with Kutters coefficient N equal to 0.0225 for Punjab canals. V is the actual velocity by

Chezy

Table: Typical n values for kenedy regime theort

Type of silt load in the canal water Value of n

Fine silt 0.53

Sandy silt 0.64

Limitations of Kennedys theory

1. In the absence of B/Y ratio the Kennedys theory do not provide a direct answer to fix the

channel dimension but by trial and error.

2. perfect definition of silt grade and silt charge are not given

3. complex phenomena of silt transportation is not fully accounted and only critical velocity ratio

concept is considered sufficiently

4. there is no provision to decide longitudinal slope under the scope of the theory

Design of irrigation channel by Kennedy theory

When an irrigation channel is to be designed by Kennedy theory it is essential to know FSD Q,

coefficient of regosity N, CVR m and longitudinal slope of the channel. Then using the following

three equations the channel section can be designed:

1.

64 . 0

546 . 0 D m V

o

=

2. VA Q =

3.

o

RS C V =

The procedure of designing may be outlined in the following steps

a. Assume reasonable trial full supply depth Y

b. Using equation (1) find out the value of

64 . 0

546 . 0 D m V

o

=

c. With this value of V, using equation 2 and design discharge find out V Q A =

d. Assume side slope and from the knowledge of A and Y find out the bed width B

e. Calculate R hydraulic radius

f. Using equation 3 find the value of the actual velocity V

By A.W.

7

g. When the assumed value of Y is correct, the value of V in step f will be the same as V

o

calculated in step b, if not assume another suitable value of Y and repeat the procedure till both

values of velocity are the same.

3.4.2. Lindleys regime theory

Lindley (1919) analyzed data from stable channels of Punjab and give the following similar equations

like Kennedy for non-silting and non-scouring velocity taking Mannings n=0.025 and side slope 0.5:1.

35 . 0

57 . 0

27 . 0

57 . 0

B V

Y V

o

o

=

=

Equating the above two will give as

61 . 1

80 . 7 Y B =

The only modification by Lindley is that he expressed an equation for only B/y ratio. He also

developed equation of V

o

taking depth y and B as a function.

3.4.3. Lacey regime theory

Better and modified method was developed by Lacey. His regime theory postulates that dimension of

bed width; depth and slope of canal attain a state of equilibrium with time which is called regime state.

Lacey defined a regime channel as a stable channel transporting a minimum bed load consistent with

fully active bed. According to him, a channel will be in regime if it carries a constant discharge and it

flows uniformly in unlined incoherent alluvium of same character. Lacey also differentiated regime

between the initial and the final regime conditions of channel. The initial regime condition is attained

shortly after it is put into operation after construction and the channel begins to adjust its bed slope

either by silting or scouring although bed width is not altered. The cannel then appears to have attained

stability, but it is not actually the final state of stability and hence it still represents the initial regime

condition. Eventually continuous action of water overcomes the resistance the resistance of the banks

and sets up a condition such that the channel adjusts its complete section, then final or true regime

condition is attained.

According to Lacey, there is only one longitudinal slope at which the cahannel will carry a particular

discharge with a particular silt grade. Natural silt transporting channels havea tendency to assume

semi-elliptical section. The coarser the silt, greater the waterway of such channel with narrower depth.

the finer the silt, greater is the depth with narrow waterway as shown below:

By A.W.

8

Fig: Channel section according to Laceys theory

Laceys regime equations

Lacey collected a large number of data of stable channels in Indo-Gangetic plains. Analizing the data

he gave the following equation of regime channel relating regime velocity V

o

, silting factor f,

hydraulic radius R, area A, sediment size in mm and bed slope S

o

.

Lacey plotted a graph between regime mean velocity and hydraulic mean radius and give the

relationship:

2

1

KR V

o

=

Where

K is constant

Lacey recognized the importance of silt grade in the problem and introduced a concept of function f

known as silt factor. Above equation is modified as:

Rf K V

o

=

After study and plotting of large data to justify his theory Lacey gave four fundamental equations for

design of irrigation channels.

4 . .......... .......... .......... .......... 76 . 1

3 .... .......... .......... .......... 8 . 10

2 ...... .......... .......... .......... 2 . 141

1 ...... .......... .......... .......... 639 . 0

3

1

3

2

5 2

d f

S R V

V Af

Rf V

o

o

o

=

=

=

=

Equation 3 is called regime flow equation, it may be seen that the equation doesnt contain the

rugosity coefficient. From the above fundamental Lacey equations the following equations have been

derived:

1. Relation between V-Q-f

Multiplying equation 2 by V gives

( )

6

1

2

4382 . 0 Qf V

o

= used to determine the critical velocity

2. relation between V-C-R-f

By A.W.

9

Using equation 3

using equation 1

f

V

R

Rf V

Rf V

o

o

2

2

46 . 2

406 . 0

639 . 0

=

=

=

3. Relation between P and Q

Using equation 1

2

2

4 5

2

4

2

2 2 4

1667 . 0

2 . 141

1667 . 0

2 . 141

1667 . 0

1667 . 0

639 . 0

R

A

V

R

V

A

V

R

V

f

R f V

Rf V

o

o

o

o

=

=

=

=

=

Q P

P Q

R

A

Q

825 . 4

3 . 23

1667 . 0

2 . 141

2

2

2

=

=

=

4

1

2

1

4

1

5 . 0

5 . 0

2

2 3

3

1

3

2

5 . 35

5 . 35

) ( tan '

5 . 35

1260

1260

8 . 10

f K

R

C

fR K V taking

V

R

C

C t cons s chezy

RS

V

R

V

RS

V

R

V

S R V

S R V

o

o

o

o

=

= |

\

|

=

|

\

|

=

=

=

=

It is compared Chezys equation

Substitute equation 2

5 2

2 . 141

o

V Af =

By A.W.

10

By using the relation between (S-Q f)

6

1

3

5

3316Q

f

S = is developed

Many more refer Irrigation and Hydraulic Structure book by S.R SAHASRABUDHE page 161-

166

Design of irrigation channel by Laceys regime theory

Thus when Q, n or C and f are known design can be done in the following steps:

a. Find out V

o

using ( )

6

1

2

4382 . 0 Qf V

o

=

b. Calculate value of R using

f

V

R

o

2

46 . 2 =

c. Calculate wetted perimeter Q P 825 . 4 =

d. Calculate the cross-sectional area Q=AV

e. Assuming side slope and calculate the full supply depth from A, P and R

f. Calculate the longitudinal slope

6

1

3

5

3316Q

f

S =

By A.W.

11

By A.W.

12

Das könnte Ihnen auch gefallen

- Chapter 6: Design of Irrigation ChannelDokument5 SeitenChapter 6: Design of Irrigation ChannelShahbaz Manzoor0% (1)

- Design and Components of Small Earth DamsDokument6 SeitenDesign and Components of Small Earth DamsErnst OtienoNoch keine Bewertungen

- Design Surface Irrigation SystemsDokument14 SeitenDesign Surface Irrigation SystemsshahadNoch keine Bewertungen

- LD-11 AmstrongDokument2 SeitenLD-11 AmstrongGameR VanrenheitNoch keine Bewertungen

- Design Calculation Patan Branch Canal Ch.280 To 362: As Per Estimate As Per ProposedDokument7 SeitenDesign Calculation Patan Branch Canal Ch.280 To 362: As Per Estimate As Per ProposedRajendra BadjatyaNoch keine Bewertungen

- Canal DesignDokument23 SeitenCanal Designnsiyam100% (1)

- Drainage Culverts 07Dokument17 SeitenDrainage Culverts 07Avish GunnuckNoch keine Bewertungen

- Schedule of Rates - 2011-12Dokument170 SeitenSchedule of Rates - 2011-12Raja SekharNoch keine Bewertungen

- Planning and Design of Lift Irrigation SchemesDokument112 SeitenPlanning and Design of Lift Irrigation SchemeskvsnlrNoch keine Bewertungen

- Jordan Samra Wastewater Treatment Plant Primary Settling Tank Openings ListDokument7 SeitenJordan Samra Wastewater Treatment Plant Primary Settling Tank Openings ListEng-Abdullah HishamNoch keine Bewertungen

- IE - LESSON 16. Design and Operation of Underground Pipeline SystemDokument5 SeitenIE - LESSON 16. Design and Operation of Underground Pipeline SystemEfremWakjiraHodeNoch keine Bewertungen

- 5 A Surface Irrigation System PDFDokument65 Seiten5 A Surface Irrigation System PDFsewmehon amareNoch keine Bewertungen

- Sarda Sahayak Canal Case StudyDokument25 SeitenSarda Sahayak Canal Case StudyBhushan Kankal100% (3)

- Lube Oil Plan PVC2Dokument10 SeitenLube Oil Plan PVC2daxNoch keine Bewertungen

- Road Pavement: Requirements of A PavementDokument12 SeitenRoad Pavement: Requirements of A PavementPrashant PalNoch keine Bewertungen

- 5 B Alignment of CanalDokument4 Seiten5 B Alignment of CanalBalu Mahendra SusarlaNoch keine Bewertungen

- A1 Stipulations For Proportioning: D Specific GravityDokument12 SeitenA1 Stipulations For Proportioning: D Specific Gravitysalmantop1100% (1)

- Design of Surplus WeirDokument21 SeitenDesign of Surplus WeirAJ AY50% (2)

- Seismic Analysis of Overhead Circular Water TanksDokument10 SeitenSeismic Analysis of Overhead Circular Water TanksGiurcanas Andrei0% (1)

- Meyerhof bearing capacity equation analysisDokument18 SeitenMeyerhof bearing capacity equation analysisSisay GashaNoch keine Bewertungen

- Design of Optimal Water Distribution Systems Using WaterGEMSDokument8 SeitenDesign of Optimal Water Distribution Systems Using WaterGEMSKinal SoniNoch keine Bewertungen

- CM & CD Works and Design of LI Schemes PDFDokument46 SeitenCM & CD Works and Design of LI Schemes PDFAswani ReddyNoch keine Bewertungen

- Earth Dam Design and Soil SelectionDokument6 SeitenEarth Dam Design and Soil SelectionAngel HasnaNoch keine Bewertungen

- Steel Structure AssignmentDokument11 SeitenSteel Structure AssignmentGetaneh HailuNoch keine Bewertungen

- Design of Cut throat FlumesDokument20 SeitenDesign of Cut throat FlumesSunita ChaurasiaNoch keine Bewertungen

- Drip Design at SolDokument13 SeitenDrip Design at SolVan BGNoch keine Bewertungen

- Canal Outlets&Modules Worked Out ExampesDokument34 SeitenCanal Outlets&Modules Worked Out ExampesrsherazNoch keine Bewertungen

- Design of The HVA Water TunnelDokument10 SeitenDesign of The HVA Water TunnelSjoerd_BNoch keine Bewertungen

- Hydrograph Analysis PDFDokument70 SeitenHydrograph Analysis PDFChin Thau Wui100% (1)

- Saline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentDokument13 SeitenSaline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentBhavanishankar ShettyNoch keine Bewertungen

- Hydraulics G1 CaseStudy Legit 1Dokument21 SeitenHydraulics G1 CaseStudy Legit 1Jhanielle Ara100% (1)

- Head Race Canal Design CriteriaDokument5 SeitenHead Race Canal Design CriteriaSamarakoon BandaNoch keine Bewertungen

- Canal FallsDokument20 SeitenCanal FallsRajesh KhadkaNoch keine Bewertungen

- 02 - 1 Design of Weir - Subsurface AnalysisDokument93 Seiten02 - 1 Design of Weir - Subsurface AnalysisMohammed JemalNoch keine Bewertungen

- Experiments on Standard Spillway Flow Geometries and Pressure FieldsDokument18 SeitenExperiments on Standard Spillway Flow Geometries and Pressure Fieldsyaseen90azizNoch keine Bewertungen

- Design of Canal Distributary With Hydraulic FallDokument19 SeitenDesign of Canal Distributary With Hydraulic FallRajeev Ranjan100% (1)

- Hydraulic Structures - Design of AqueductDokument5 SeitenHydraulic Structures - Design of AqueductAsif Muhammad100% (1)

- Drainage NotesDokument23 SeitenDrainage NotesSandhya EgaNoch keine Bewertungen

- Measuring Flow with a Parshall FlumeDokument19 SeitenMeasuring Flow with a Parshall FlumeDeepak Kumar0% (1)

- CVE 372 HYDROMECHANICS - 2 Flow in Closed Conduits 2 PDFDokument54 SeitenCVE 372 HYDROMECHANICS - 2 Flow in Closed Conduits 2 PDFabhilibra14Noch keine Bewertungen

- Design of Non Erodible ChannelsDokument2 SeitenDesign of Non Erodible Channelsveena sandheepNoch keine Bewertungen

- Static Head and Static DischargeDokument1 SeiteStatic Head and Static DischargeAsia mesoNoch keine Bewertungen

- Week 8 10 Hydraulic Structures Part I WEIRSDokument50 SeitenWeek 8 10 Hydraulic Structures Part I WEIRSgeorgedytrasNoch keine Bewertungen

- Government of Madhya Prades1Dokument77 SeitenGovernment of Madhya Prades1gourav.imsNoch keine Bewertungen

- Design of PumpDokument4 SeitenDesign of PumpTajamul HussainNoch keine Bewertungen

- Be Engineering Mechanics Osmania University Question PapersDokument4 SeitenBe Engineering Mechanics Osmania University Question Paperszahid_polyNoch keine Bewertungen

- Dos II - Lecture NotesDokument71 SeitenDos II - Lecture NotesSajee SweetNoch keine Bewertungen

- Rectangular Steel Bar DesignDokument2 SeitenRectangular Steel Bar DesignAmit Kumar PaulNoch keine Bewertungen

- Barrages PresentationDokument109 SeitenBarrages PresentationFaisal RashidNoch keine Bewertungen

- LSM and WSMDokument2 SeitenLSM and WSMshakeelwaseemNoch keine Bewertungen

- Study The Effect of Different Load Combination That Will Lead To The Failure of The Structure and Hence Design For The Critical Combination of LoadDokument4 SeitenStudy The Effect of Different Load Combination That Will Lead To The Failure of The Structure and Hence Design For The Critical Combination of LoadEditor IJTSRDNoch keine Bewertungen

- Chapter 1B Mat FoundationsDokument17 SeitenChapter 1B Mat Foundationsmohamed hassan adenNoch keine Bewertungen

- Permeate Line Pressure Drop CalculationsDokument2 SeitenPermeate Line Pressure Drop Calculationsask.kulkarni KulkarniNoch keine Bewertungen

- Design of sluice and tank bund(ii) Longitudinal section(iii) Cross section of sluice(iv) Cross section of tank bund(v) Bar bending scheduleDokument6 SeitenDesign of sluice and tank bund(ii) Longitudinal section(iii) Cross section of sluice(iv) Cross section of tank bund(v) Bar bending scheduleAngelica KennedyNoch keine Bewertungen

- Aludecor Timber E-CatalogueDokument12 SeitenAludecor Timber E-CatalogueRitwik Ashish DasguptaNoch keine Bewertungen

- Ecohydrology: Vegetation Function, Water and Resource ManagementVon EverandEcohydrology: Vegetation Function, Water and Resource ManagementNoch keine Bewertungen

- Chapter Four 4. Irrigation Canals and DesignDokument8 SeitenChapter Four 4. Irrigation Canals and DesignBrooke AbebeNoch keine Bewertungen

- Chapter6designofirrigationchannel1 141124054350 Conversion Gate02Dokument20 SeitenChapter6designofirrigationchannel1 141124054350 Conversion Gate02Jaber Osmani100% (1)

- Asncv Nsa'Sadvsd V SV SDV SDDokument1 SeiteAsncv Nsa'Sadvsd V SV SDV SDUsman ShehryarNoch keine Bewertungen

- SummaryDokument6 SeitenSummaryUsman ShehryarNoch keine Bewertungen

- Degrees SentDokument1 SeiteDegrees SentUsman ShehryarNoch keine Bewertungen

- M.SC Degree B.SC Degree B.SC DMC F.SC Degree Matric DegreeDokument1 SeiteM.SC Degree B.SC Degree B.SC DMC F.SC Degree Matric DegreeUsman ShehryarNoch keine Bewertungen

- 501 Writing PromptsDokument181 Seiten501 Writing Promptspapersue99% (266)

- Dha App Form Sale of PlotDokument6 SeitenDha App Form Sale of PlotMajestic LookxNoch keine Bewertungen

- HSJHFSJDF DSFGVH DSNFVHSFDV DCBCVHDSCV Jhgsahffg Jhvhsdaf DSHFVFJHSDVFH Dav SVD DVDV SVD SDV SVD SDV DvsDokument1 SeiteHSJHFSJDF DSFGVH DSNFVHSFDV DCBCVHDSCV Jhgsahffg Jhvhsdaf DSHFVFJHSDVFH Dav SVD DVDV SVD SDV SVD SDV DvsUsman ShehryarNoch keine Bewertungen

- JdsahdDokument1 SeiteJdsahdUsman ShehryarNoch keine Bewertungen

- Gjahsgfgfjx Ascjkhasc /isahfihas) SDFJJXZCV KXJVJBXJVB JXJCNHVBBV JBJNBVZBB BZVKJHVH Jzbjvbvsjvhds BJVBJKSHV'Dokument1 SeiteGjahsgfgfjx Ascjkhasc /isahfihas) SDFJJXZCV KXJVJBXJVB JXJCNHVBBV JBJNBVZBB BZVKJHVH Jzbjvbvsjvhds BJVBJKSHV'Usman ShehryarNoch keine Bewertungen

- Model Papers 9th - ClassDokument25 SeitenModel Papers 9th - Classmaryam.irfan3351Noch keine Bewertungen

- LKHFKJSDJFHSDHFDSHFJKHJDGF Fsdjfhjsdhfs DKJGFHJKHGKSDHJG DVMBJFVGJDG DFNKGJDSGJDSG VKSDJFVFSDV Nvmsbjfgsajfgfvb Nvkjdjvkajds HKDSHGKBSDKDJG Jkdjkjsadkgs) AhfsajkfaskdjfDokument1 SeiteLKHFKJSDJFHSDHFDSHFJKHJDGF Fsdjfhjsdhfs DKJGFHJKHGKSDHJG DVMBJFVGJDG DFNKGJDSGJDSG VKSDJFVFSDV Nvmsbjfgsajfgfvb Nvkjdjvkajds HKDSHGKBSDKDJG Jkdjkjsadkgs) AhfsajkfaskdjfUsman ShehryarNoch keine Bewertungen

- System Enginneering Interfaces Module V1.0Dokument23 SeitenSystem Enginneering Interfaces Module V1.0Usman ShehryarNoch keine Bewertungen

- Visa Application Stochholm Booking Local Bus Booking Pakistan Ticket Booking My Sheudule For NovemberDokument1 SeiteVisa Application Stochholm Booking Local Bus Booking Pakistan Ticket Booking My Sheudule For NovemberUsman ShehryarNoch keine Bewertungen

- Bitwise ManipulationsDokument1 SeiteBitwise ManipulationsUsman ShehryarNoch keine Bewertungen

- Important HadithDokument1 SeiteImportant HadithUsman ShehryarNoch keine Bewertungen

- Fading Fast Fading IDokument1 SeiteFading Fast Fading IUsman ShehryarNoch keine Bewertungen

- Company Ordinance 1984 PakistanDokument444 SeitenCompany Ordinance 1984 Pakistanvick0999Noch keine Bewertungen

- List of Identified Universities - Batch9Dokument4 SeitenList of Identified Universities - Batch9Usman ShehryarNoch keine Bewertungen

- Company Ordinance 1984 PakistanDokument444 SeitenCompany Ordinance 1984 Pakistanvick0999Noch keine Bewertungen

- Pa3 Libguide UgDokument173 SeitenPa3 Libguide UgUsman ShehryarNoch keine Bewertungen

- Eassy Issue TopicsDokument23 SeitenEassy Issue TopicsUsman ShehryarNoch keine Bewertungen

- Visit Report of Karachi On 25Dokument2 SeitenVisit Report of Karachi On 25Usman ShehryarNoch keine Bewertungen

- Libero ManualsDokument1 SeiteLibero ManualsUsman ShehryarNoch keine Bewertungen

- 924 - FTP Robust Frame Synchronization For The DVB-S2 System With Large Frequency OffsetsDokument18 Seiten924 - FTP Robust Frame Synchronization For The DVB-S2 System With Large Frequency OffsetsUsman ShehryarNoch keine Bewertungen

- Assignment # 1Dokument2 SeitenAssignment # 1Usman ShehryarNoch keine Bewertungen

- SampleDokument32 SeitenSampleUsman ShehryarNoch keine Bewertungen

- 50SAT - Eagle2 communications guideDokument25 Seiten50SAT - Eagle2 communications guideUsman ShehryarNoch keine Bewertungen

- Canal DesignDokument12 SeitenCanal DesignUsman ShehryarNoch keine Bewertungen

- Canal FallsDokument10 SeitenCanal FallsSubin GajurelNoch keine Bewertungen