Beruflich Dokumente

Kultur Dokumente

Global Intel Manufacturing FactSheet

Hochgeladen von

UmarameshKOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Global Intel Manufacturing FactSheet

Hochgeladen von

UmarameshKCopyright:

Verfügbare Formate

Intel Global Manufacturing Facts

For Intel, manufacturing serves as the underpinning for our business and allows us to provide customers and consumers with leadingedge products in high volume. The unmatched scope and scale of our investments in manufacturing helps Intel maintain industry leadership and drive innovation. -- Intel Brian Krzanich, senior

vice president and general manager, Manufacturing and Supply Chain.

Operating 24 hours a day, seven days a week in plants around the world, Intel's factories are precision tuned to perform with maximum efficiency and quality to produce fast, smart, and more energy-efficient computer chips. With 9 wafer fabrication plants (fabs) in production and 7 assembly test facilities worldwide, Intel's manufacturing facilities employ exceptional flexibility on a global and virtual network. By design, these facilities are consistently sharing information to improve product performance while further fine tuning the manufacturing process. At the end of 2010, the majority of Intels microprocessors were manufactured on 300mm wafers. In addition, by the second half of 2011 we expect to begin manufacturing microprocessors using our 22nm process technology. Our manufacturing processes advance according to Moores law, delivering ever more functionality and performance, improved energy efficiency, and lower cost per transistor, with each generation.

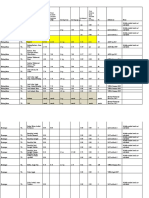

Fab

D1X D1D D1C Fab 68 Fab 42 Fab 32 Fab 28 Fab 24 Fab 17 Fab 12 Fab 11X

Location

Hillsboro, OR Hillsboro, OR Hillsboro, OR Dalian, China Chandler, AZ Chandler, AZ Qiryat Gat,Israel Leixlip, Ireland Hudson, MA Chandler, AZ Rio Rancho, NM

Products

Microprocessors Microprocessors Microprocessors Chipsets Microprocessors Microprocessors Microprocessors Microprocessors, Chipsets & Comm Chipsets and other Microprocessors & Chipsets Microprocessors

Process Technology

14nm and beyond 22nm* 32nm/22nm* 65nm 14nm and beyond 32nm/22nm* 45nm/22nm* 90nm/65nm 130nm 65nm/22nm* 45nm/32nm

Wafer Size Year Opened Comments

300mm 300mm 300mm 300mm 300mm 300mm 300mm 300mm 200mm 300mm 300mm 2013 projected Development Fab 2003 2001 2010 2013 projected 2007 2008 2004 1998 1996 2002 Development Fab Development Fab

*22nm upgrades projected to be completed 2011-12

Assembly Test Facility CD1 CD6 CRAT PG8

Location Chengdu, China Chengdu, China San Jose, Costa Rica Penang, Malaysia

Year Opened 2005 2007 1997 1977

Recent manufacturing Announcements:

D1X In Oct. 2010, Intel announced that it would build a new development fab D1X - in Oregon, with expected completion in 2013. Fab 42 In Feb. 2011, Intel announced that it would build a new chip fab fab 42 in Arizona, with completion expected in 2013. Fab 68 Intel opened its first China chip fab Fab 68 in Oct. 2010. Vietnam Intel opened its newest assembly and test facility in Vietnam in Oct. 2010.

KMO

KM5 VNAT

Kulim, Malaysia

Kulim, Malaysia Ho-Chi Min City, Vietnam

1996

2009 2010

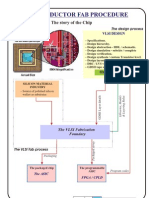

Manufacturing Tutorial

wafer and then removed in small areas to create transistors and interconnects. Together, they will form the active (on/off) part of the chips circuitry plus the connections Wafer fabrication or manufacturing of Intels between them, in a three-dimensional structure. The process microprocessors and chip sets is conducted in the U.S. is performed dozens of times on each wafer, with hundreds (Arizona, New Mexico, Oregon and Massachusetts). China, Ireland and Israel. Following manufacturing the majority of or thousands of chips placed grid-like on a wafer and our components are then assembled and tested at facilities processed simultaneously. After creating layers on the wafers, Intel performs wafer in Malaysia, China, Costa Rica and Vietnam. sort, and a computer completes a series of tests to ensure that chip circuits meet specifications to perform as designed. FABS The process of making computer chips is called fabrication. The factories where chips are made are called fabrication facilities or fabs. Intel fabs are among the most technically advanced manufacturing facilities in the world. When Intel first started making chips, the company used 2-inchdiameter wafers. Now the company uses primarily 12-inch or 300-millimeter (mm) wafers; larger wafers are more difficult to process, but the result is lower cost per chip. Intel uses a photolithographic printing process to build a chip layer by layer. Many layers are deposited across the ASSEMBLY TEST Intel sends the finished wafers to an Intel assembly facility where the manufacturing process is completed. The wafer is cut with a diamond saw, separating the microprocessors. Each functioning die is assembled into a package that protects the die. This package delivers critical power and electrical connections when placed directly on a computer circuit board, or other devices such as cell phones or personal digital assistants (PDAs).

Das könnte Ihnen auch gefallen

- Microprocessor Fabrication Trends and Prospects: (Cont'd)Dokument3 SeitenMicroprocessor Fabrication Trends and Prospects: (Cont'd)tesfu zewduNoch keine Bewertungen

- Intel - From Sand To Circuits PDFDokument16 SeitenIntel - From Sand To Circuits PDFspaulsNoch keine Bewertungen

- Wafer Production StepsDokument15 SeitenWafer Production StepsmehmetelmaliNoch keine Bewertungen

- Htaccess - Uniform Server Wiki SystemDokument12 SeitenHtaccess - Uniform Server Wiki SystemRodrigo TapiaNoch keine Bewertungen

- மாட்சியின் பெரியோரை வியத்தலும் இலமே,Dokument2 Seitenமாட்சியின் பெரியோரை வியத்தலும் இலமே,tabalpettyNoch keine Bewertungen

- Notes While Learning SaivamDokument3 SeitenNotes While Learning SaivamtabalpettyNoch keine Bewertungen

- 108 Nomi Di ShivaDokument3 Seiten108 Nomi Di Shiva33elefantiNoch keine Bewertungen

- RoadMap To Semiconductor Tech 1997Dokument239 SeitenRoadMap To Semiconductor Tech 1997pakukeras2Noch keine Bewertungen

- Fabrication of SemiconductorDokument12 SeitenFabrication of Semiconductorkrish2322100% (1)

- Globale Electronic IndustryDokument15 SeitenGlobale Electronic IndustryMehfooz AnsariNoch keine Bewertungen

- Vinayagar AgavalDokument3 SeitenVinayagar Agavalramaswamy1978Noch keine Bewertungen

- PDF LokDokument43 SeitenPDF LokSaroSureshNoch keine Bewertungen

- 88B09 382 Engl PDFDokument273 Seiten88B09 382 Engl PDFJaime HernandezNoch keine Bewertungen

- ELWB Read FirstDokument24 SeitenELWB Read FirstChris TanNoch keine Bewertungen

- Qualifications Handbook - ESSCIDokument49 SeitenQualifications Handbook - ESSCImass giridihNoch keine Bewertungen

- Internet of Things SensorsDokument25 SeitenInternet of Things SensorssenvimjagNoch keine Bewertungen

- Good Chemical Engineering BooksDokument2 SeitenGood Chemical Engineering BooksMad BhaNoch keine Bewertungen

- Department of Electrical and Systems Engineering: MOSFET Amplifier Mini ProjectDokument7 SeitenDepartment of Electrical and Systems Engineering: MOSFET Amplifier Mini ProjectsadfaNoch keine Bewertungen

- Stats eWLB OverviewFlyer PDFDokument4 SeitenStats eWLB OverviewFlyer PDFChris TanNoch keine Bewertungen

- A Guide To The Use of AgrochemicalsDokument86 SeitenA Guide To The Use of AgrochemicalsKissa R AlungaNoch keine Bewertungen

- Consolidated Oxalate Spreadsheet 15 Sep 2021Dokument269 SeitenConsolidated Oxalate Spreadsheet 15 Sep 2021Valentin QuinterosNoch keine Bewertungen

- Advanced Technologies For Next Generation Integrated CircuitsDokument321 SeitenAdvanced Technologies For Next Generation Integrated CircuitsIEC2020034Noch keine Bewertungen

- ScalingDokument32 SeitenScalingNK NKNoch keine Bewertungen

- Vision Ias SeptDokument27 SeitenVision Ias SeptAkash SarkarNoch keine Bewertungen

- Accenture Semiconductor Value Chain ReportzoomDokument103 SeitenAccenture Semiconductor Value Chain ReportzoomRicardo Jose Guerrero100% (1)

- SIA 2023 Factbook - 1Dokument27 SeitenSIA 2023 Factbook - 1cfsturmanNoch keine Bewertungen

- Vaishnava SongsDokument124 SeitenVaishnava SongsSai KrishnaNoch keine Bewertungen

- Osat Sector TaiwanDokument33 SeitenOsat Sector Taiwantalleyrand8Noch keine Bewertungen

- Product Selector GuideDokument36 SeitenProduct Selector Guidekarthik4096Noch keine Bewertungen

- P PotassiumDokument12 SeitenP PotassiumHeleneSmithNoch keine Bewertungen

- Biopestcides: Types and Applications: IJAPBC - Vol. 1 (4), Oct-Dec, 2012Dokument8 SeitenBiopestcides: Types and Applications: IJAPBC - Vol. 1 (4), Oct-Dec, 2012Balaji RajendranNoch keine Bewertungen

- 2d and 3d Array AntennaDokument5 Seiten2d and 3d Array AntennaKurtish VenkatiahNoch keine Bewertungen

- Lab Experiment 8Dokument8 SeitenLab Experiment 8Meredith Jensen0% (1)

- Design For PCB EMIEMC ComplianceDokument49 SeitenDesign For PCB EMIEMC ComplianceBen BeckerNoch keine Bewertungen

- Neepco Project Report-003Dokument59 SeitenNeepco Project Report-00321UPE093 gaurav KumarNoch keine Bewertungen

- Kaynes Technology India LTD - IPO Note - 11!11!2022Dokument8 SeitenKaynes Technology India LTD - IPO Note - 11!11!2022Manipal SinghNoch keine Bewertungen

- Proper PCB Layout Techniques Maximize Power Module PerformanceDokument4 SeitenProper PCB Layout Techniques Maximize Power Module PerformancesumalaglNoch keine Bewertungen

- SDVFSDGVSDDokument288 SeitenSDVFSDGVSDmahdimkh23Noch keine Bewertungen

- PhDGallet RobustControlSOFCCHPApplications FinalDokument262 SeitenPhDGallet RobustControlSOFCCHPApplications FinalibrahimutkuNoch keine Bewertungen

- Hydrogen Train Spec EoiDokument27 SeitenHydrogen Train Spec EoiAparajitaNoch keine Bewertungen

- ADIReferenceDesignsHDLUserGuide PDFDokument61 SeitenADIReferenceDesignsHDLUserGuide PDFKrishna Prasad100% (1)

- Long Term VisionDokument102 SeitenLong Term VisionGabriel DonovanNoch keine Bewertungen

- A Systematic Review On MEMS GyroscopeDokument6 SeitenA Systematic Review On MEMS GyroscopeArjun KapoorNoch keine Bewertungen

- PHD A Harris Fuels 05-02-12Dokument279 SeitenPHD A Harris Fuels 05-02-12David Jiménez MenaNoch keine Bewertungen

- Headphones Specifications Application: A Guide For AKG Pro Dealers and UsersDokument10 SeitenHeadphones Specifications Application: A Guide For AKG Pro Dealers and UsersAnonymous LJTck8PNoch keine Bewertungen

- EMC Design Guidelines For Microcontroller Board Layout: Never Stop ThinkingDokument63 SeitenEMC Design Guidelines For Microcontroller Board Layout: Never Stop ThinkingMr CdtNoch keine Bewertungen

- Industrial Iot Technologies and Applications: Jiafu Wan Iztok Humar Daqiang ZhangDokument276 SeitenIndustrial Iot Technologies and Applications: Jiafu Wan Iztok Humar Daqiang ZhangRaymundo PiresNoch keine Bewertungen

- R H Burgess (Editor) - Manufacture and Processing of PVC-CRC Press (1981)Dokument295 SeitenR H Burgess (Editor) - Manufacture and Processing of PVC-CRC Press (1981)Санжар Жумахан100% (1)

- Net AppDokument466 SeitenNet AppjagatheeNoch keine Bewertungen

- Global Semiconductors July 2021: Marketline Industry ProfileDokument52 SeitenGlobal Semiconductors July 2021: Marketline Industry Profileakin1219Noch keine Bewertungen

- The Dynamic Role of Big Data Analytics in Learning and Development and Its Impact On Risk Analysis in Stock MarketDokument574 SeitenThe Dynamic Role of Big Data Analytics in Learning and Development and Its Impact On Risk Analysis in Stock MarketBrightsideNoch keine Bewertungen

- 2 - Inflammation and Repair (Edited Ver)Dokument149 Seiten2 - Inflammation and Repair (Edited Ver)CristinaConcepcionNoch keine Bewertungen

- Semiconductors Top Markets Report PDFDokument63 SeitenSemiconductors Top Markets Report PDFMichaela PlatzerNoch keine Bewertungen

- Intel Case StudyDokument7 SeitenIntel Case StudyAjay_Hariyani_1985Noch keine Bewertungen

- From Sand To CircuitsDokument4 SeitenFrom Sand To CircuitsdkishoreNoch keine Bewertungen

- 1991 Intel 16-Bit Embedded Controller HandbookDokument624 Seiten1991 Intel 16-Bit Embedded Controller HandbookBayanaka TehnikNoch keine Bewertungen

- Group Project OSDDokument29 SeitenGroup Project OSDAdnin NaimNoch keine Bewertungen

- Intel Corporate B-Roll 2002-2003: Featuring The Pentium® 4 Processor With HT Technology November 14, 2002Dokument5 SeitenIntel Corporate B-Roll 2002-2003: Featuring The Pentium® 4 Processor With HT Technology November 14, 2002officeintrocarteNoch keine Bewertungen

- Fourth Industrial Revolution Conference by MoHEDokument16 SeitenFourth Industrial Revolution Conference by MoHEeriire79Noch keine Bewertungen

- The Super World of Mario: The Ultimate Unofficial Guide to Super Mario®Von EverandThe Super World of Mario: The Ultimate Unofficial Guide to Super Mario®Bewertung: 4 von 5 Sternen4/5 (11)

- Pojo's Unofficial Ultimate Pokemon Trainer's HandbookVon EverandPojo's Unofficial Ultimate Pokemon Trainer's HandbookNoch keine Bewertungen

- Big Book of Zelda: The Unofficial Guide to Breath of the Wild and The Legend of ZeldaVon EverandBig Book of Zelda: The Unofficial Guide to Breath of the Wild and The Legend of ZeldaBewertung: 4.5 von 5 Sternen4.5/5 (5)

- The SNES Encyclopedia: Every Game Released for the Super Nintendo Entertainment SystemVon EverandThe SNES Encyclopedia: Every Game Released for the Super Nintendo Entertainment SystemBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Sid Meier's Memoir!: A Life in Computer GamesVon EverandSid Meier's Memoir!: A Life in Computer GamesBewertung: 4.5 von 5 Sternen4.5/5 (37)

- The Ultimate RPG Game Master's Guide: Advice and Tools to Help You Run Your Best Game Ever!Von EverandThe Ultimate RPG Game Master's Guide: Advice and Tools to Help You Run Your Best Game Ever!Noch keine Bewertungen

- The Advanced Roblox Coding Book: An Unofficial Guide, Updated Edition: Learn How to Script Games, Code Objects and Settings, and Create Your Own World!Von EverandThe Advanced Roblox Coding Book: An Unofficial Guide, Updated Edition: Learn How to Script Games, Code Objects and Settings, and Create Your Own World!Bewertung: 4.5 von 5 Sternen4.5/5 (2)

- Beginning AutoCAD® 2022 Exercise Workbook: For Windows®Von EverandBeginning AutoCAD® 2022 Exercise Workbook: For Windows®Noch keine Bewertungen

- Diablo III: Heroes Rise, Darkness FallsVon EverandDiablo III: Heroes Rise, Darkness FallsBewertung: 4 von 5 Sternen4/5 (4)

- Master Builder Power Up! Level 1: Minecraft® Redstone for Beginning PlayersVon EverandMaster Builder Power Up! Level 1: Minecraft® Redstone for Beginning PlayersBewertung: 5 von 5 Sternen5/5 (6)

- Quest for the Golden Apple: An Unofficial Graphic Novel for MinecraftersVon EverandQuest for the Golden Apple: An Unofficial Graphic Novel for MinecraftersBewertung: 5 von 5 Sternen5/5 (28)

- The Big Book of Super Mario: The Unofficial Guide to Super Mario and the Mushroom KingdomVon EverandThe Big Book of Super Mario: The Unofficial Guide to Super Mario and the Mushroom KingdomNoch keine Bewertungen

- Lost in a Good Game: Why we play video games and what they can do for usVon EverandLost in a Good Game: Why we play video games and what they can do for usBewertung: 4.5 von 5 Sternen4.5/5 (31)

- The Ender Eye Prophecy: An Unofficial Graphic Novel for Minecrafters, #3Von EverandThe Ender Eye Prophecy: An Unofficial Graphic Novel for Minecrafters, #3Bewertung: 5 von 5 Sternen5/5 (17)

- A History of Video Games in 64 ObjectsVon EverandA History of Video Games in 64 ObjectsBewertung: 4.5 von 5 Sternen4.5/5 (26)

- The Unofficial Sims Cookbook: From Baked Alaska to Silly Gummy Bear Pancakes, 85+ Recipes to Satisfy the Hunger NeedVon EverandThe Unofficial Sims Cookbook: From Baked Alaska to Silly Gummy Bear Pancakes, 85+ Recipes to Satisfy the Hunger NeedBewertung: 5 von 5 Sternen5/5 (3)