Beruflich Dokumente

Kultur Dokumente

Sai Guru 10KL

Hochgeladen von

Rishi KathirOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sai Guru 10KL

Hochgeladen von

Rishi KathirCopyright:

Verfügbare Formate

Manufacturer of High Vacuum Transformer oil filter Plant, Vacuum Impregnation Plant, Epoxy Casting Plant, Capacitor Impregnation

Plant, Winding Machines Ref No. : SGE/01/78 Date: 26/12/11

MARY CONSTRUCTIONS

December 26, 2011

1

Works: - Sec:-10, plot no:-98, PCNTDA, Bhosari, Pune- 411026 Office: - Sec 27/A Plot 345 Pradhikaran, Nigdi, Pune-411044. Ph:-+91-9850572494,9970288900, 020-27653211 E-Mail saiguruengineers@rediffmail.com, madgonde@rediffmail.com

Website:- www.saiguruengineers.com

Manufacturer of High Vacuum Transformer oil filter Plant, Vacuum Impregnation Plant, Epoxy Casting Plant, Capacitor Impregnation Plant, Winding Machines Ref No. : SGE/01/78 Date: 26/12/11

December 26, 2011 Mary Constructions, Kind Atten: Mr. Dear Sir, As per your mail dated November 23, 2011, we are submitting our offer for High Vacuum Transformer oil filter machine 10,000LPH. The recommended system as outlined in the proposal is based on our understanding of your need obtained as per our discussion dated November 23, 2011. Every effort has been made to furnish you with a comprehensive proposal. Thank you for the opportunity to participate in this project. We are confident that this solution will not only meet your initial requirement but will also provide an excellent foundation to build upon and provide a significant advantage for years to come. Sai Guru Engineers look forward to working closely with Mary Constructions on successful implementation of this project. Please feel free to contact us for any additional information required. We will be pleased to respond immediately to your request. Sincerely, For Sai Guru Engineers,

Mr. Swapnil Madgonde (Manager-Sales & Application)

2

Works: - Sec:-10, plot no:-98, PCNTDA, Bhosari, Pune- 411026 Office: - Sec 27/A Plot 345 Pradhikaran, Nigdi, Pune-411044. Ph:-+91-9850572494,9970288900, 020-27653211 E-Mail saiguruengineers@rediffmail.com, madgonde@rediffmail.com

Website:- www.saiguruengineers.com

Manufacturer of High Vacuum Transformer oil filter Plant, Vacuum Impregnation Plant, Epoxy Casting Plant, Capacitor Impregnation Plant, Winding Machines Ref No. : SGE/01/78 Date: 26/12/11

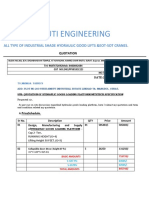

SCHEMATIC DIAGRAM OF 10,000LPH TRANSFORMER OIL FILTER PLANT (TWO STAGE):-

3

Works: - Sec:-10, plot no:-98, PCNTDA, Bhosari, Pune- 411026 Office: - Sec 27/A Plot 345 Pradhikaran, Nigdi, Pune-411044. Ph:-+91-9850572494,9970288900, 020-27653211 E-Mail saiguruengineers@rediffmail.com, madgonde@rediffmail.com

Website:- www.saiguruengineers.com

Manufacturer of High Vacuum Transformer oil filter Plant, Vacuum Impregnation Plant, Epoxy Casting Plant, Capacitor Impregnation Plant, Winding Machines Ref No. : SGE/01/78 Date: 26/12/11

1. TECHNICAL SPECIFICATION 10,000LPH (Two Stage). 1. Type of Design 2. Capacity of Plant 3. Maximum Power 4. Plant Operation 6. Mounting The whole plant with sturdy Channel Base will be fitted on TATA 909 Whether proof enclosure will be provided in 16 SGW Sheet. The plant will be provided with all side doors. At top portion a ventilator will be provided as the air temperature inside the plant will be above ambient temperature. A enclosure will be constructed such that even in heavy rain fall the enclosure will restrict the water to be entered into the plant. 7. Inlet Pump a) Capacity b) Model & Make c) Type d) Motor Power e) Motor Make f) Pressure g) Flow Control Valve h) Type of drive 8. Outlet Pump a) Make & Model b) Rating 4

Works: - Sec:-10, plot no:-98, PCNTDA, Bhosari, Pune- 411026 Office: - Sec 27/A Plot 345 Pradhikaran, Nigdi, Pune-411044. Ph:-+91-9850572494,9970288900, 020-27653211 E-Mail saiguruengineers@rediffmail.com, madgonde@rediffmail.com

: : : :

High Vacuum two stage plant 10,000LPH 180 KW. 440 V., 3 Phase, 50 Hz.

: : : : : : : : :

10,000LPH AL4195 (Imported) Positive displacement gear pump 3 H.P, 3 Ph. ISI Standard 5 Bar 20 NB each will provided across the pump. Coupled.

: :

Flow Engineering CM 18 5 HP, 3 ph.

Website:- www.saiguruengineers.com

Manufacturer of High Vacuum Transformer oil filter Plant, Vacuum Impregnation Plant, Epoxy Casting Plant, Capacitor Impregnation Plant, Winding Machines Ref No. : SGE/01/78 Date: 26/12/11

c) Seal d) Capacity of Pump e) Suction Head f)Delivery Head f) Non Return Valve

: : : : :

Glandless. More than 10,000LPH 0.6 Mtr. 15 mtr Will be provided for to prevent flooding

9. Vacuum Pumping System: 9a)

IMPORTED (Vane type / Piston type) Rotovac (Korean) RSVP 300 300 M3/hr 5 HP. ISI make. Will be mounted.

Vacuum Pump for First Stage : i) Make ii) Model ii) Pumping speed iii) Motor Rating iv) Motor Make v) NRV : : : : : :

9b)

Vacuum Pump for Second Stage (Roots Pump) i) Make ii) Model & stage iiI) Pumping speed iv) Motor Rating v) Motor Make : : : : : TuThill (Imported) MKB 890 890 M3/hr. 5 HP. ISI make.

10) Heaters a) Type b) Heating type c) No. of heaters d) Each Heater power e) Total heater power f) No. of group 5

Works: - Sec:-10, plot no:-98, PCNTDA, Bhosari, Pune- 411026 Office: - Sec 27/A Plot 345 Pradhikaran, Nigdi, Pune-411044. Ph:-+91-9850572494,9970288900, 020-27653211 E-Mail saiguruengineers@rediffmail.com, madgonde@rediffmail.com

: : : : : :

Refractory Type. Indirect 30 5 kw 150 KW Three (03)

Website:- www.saiguruengineers.com

Manufacturer of High Vacuum Transformer oil filter Plant, Vacuum Impregnation Plant, Epoxy Casting Plant, Capacitor Impregnation Plant, Winding Machines Ref No. : SGE/01/78 Date: 26/12/11

g) Watt Density

2 Watts/ Cm2.

11) Digital Temperature indicating controller a) Make b) Type c) Range d) Mounting 12) Dial type thermometer a) Make b) Range c) Type : : : National / RSB. 0-1500 C 100 mm dial, bimetallic stem type : : : : Selectron / equivalent Digital 0-250o C On control panel

13) Degassing Chamber The Degassing chamber is designed for Two stage for efficient degassing and dehumidification by siphon seal action and removing dissolved impurities. Rasching rings / degassers will be used in stages in the chamber for to expose the oil to the maximum surface area. The chamber will be designed for 3 Kg/Cm. and better than 0.2torr vacuum. Vision & indication glass windows will be provided on this tank accessibly. A float switch for high oil level control will be provided and it will be interlocked with inlet pump. Float Switch for low level control will be provided and it will be interlocked with outlet pump.

Number of Stage Vacuum achieved

: :

Two Stages Better than 0.2 torr

14) Coarse and magnetic filter

It will be provided at inlet side for to remove Ferrous & non ferrous particles.

15) 6

Micron Filter

Works: - Sec:-10, plot no:-98, PCNTDA, Bhosari, Pune- 411026 Office: - Sec 27/A Plot 345 Pradhikaran, Nigdi, Pune-411044. Ph:-+91-9850572494,9970288900, 020-27653211 E-Mail saiguruengineers@rediffmail.com, madgonde@rediffmail.com

Website:- www.saiguruengineers.com

Manufacturer of High Vacuum Transformer oil filter Plant, Vacuum Impregnation Plant, Epoxy Casting Plant, Capacitor Impregnation Plant, Winding Machines Ref No. : SGE/01/78 Date: 26/12/11

Model Rating 16) Bag filter Type of filter Rating Make Filter Chamber Filter Bag quality

: : : : : : : :

Cuno / Micro clean. 1 Micron

Bag filter 17 Micron Cuno Parker ( U.S.A) M.S Strainer Re usable after cleaning / drying.

17) Vacuum gauge / pressure gauge: Make Dial Pressure gauge Vacuum gauge 19) Oil Hoses for inlet and outlet Nitrile hoses 20) Ionic reaction column Catalyst to be used Capacity Type 21) Flow meter (Digital) Make Type Size : : : VATS Flow meter Turbine flow meter 40 NB : : : Activated alumina. Capacity suitable for 10,000L.P.H. Absorbent type : 20 Mtr (2 Nos) : : : : Feibig / Wika 100 mm. -1 to - 4.2 Kg./ Cm. Square 0-760 mm. Of Hg.

It will show the running flow rate with totalizer.

22) Mechanical non return valve will be provided for inlet and outlet to avoid flooding of oil into the system. 7

Works: - Sec:-10, plot no:-98, PCNTDA, Bhosari, Pune- 411026 Office: - Sec 27/A Plot 345 Pradhikaran, Nigdi, Pune-411044. Ph:-+91-9850572494,9970288900, 020-27653211 E-Mail saiguruengineers@rediffmail.com, madgonde@rediffmail.com

Website:- www.saiguruengineers.com

Manufacturer of High Vacuum Transformer oil filter Plant, Vacuum Impregnation Plant, Epoxy Casting Plant, Capacitor Impregnation Plant, Winding Machines Ref No. : SGE/01/78 Date: 26/12/11

23) Control Panel. A suitable control panel housed with isolator switch, DOL starters, contractors, pilot lamp, push buttons, back up protection fuses, over load relays, alarms indication lamps will be provided on control panel and all wiring will be neatly routed. All fuses will be of English Electric make and all contactors and relays will be L&T make or Siemens Make, Main switch will be STd. make.

Main Switch

filtrations:

300 Amps of GEC / L & T Siemens.

Mimic diagram will be provided with indicating various events during

Audio / Visual annunciation will be provided to indicate any manufacturing various events of processing during working of plant for following condition:-

1. 2. 3. 4. 5. 6.

High temperature of oil. Inlet Pump motor trip. Outlet pump motor trip. Rotary Vacuum pump motor trip. Roots Pump motor trip. High oil level in degassing chamber.

Three nos of Ammeters of AE make will be provided, 3phase, Voltmeter with selector switch will be provided. 15 amp plug pin socket will be provided for to connect BDV tester which will be mounted inside the plant. Flow meter Digital display will be fitted on control board.

SAFETY INTERLOCKS: 8

Works: - Sec:-10, plot no:-98, PCNTDA, Bhosari, Pune- 411026 Office: - Sec 27/A Plot 345 Pradhikaran, Nigdi, Pune-411044. Ph:-+91-9850572494,9970288900, 020-27653211 E-Mail saiguruengineers@rediffmail.com, madgonde@rediffmail.com

Website:- www.saiguruengineers.com

Manufacturer of High Vacuum Transformer oil filter Plant, Vacuum Impregnation Plant, Epoxy Casting Plant, Capacitor Impregnation Plant, Winding Machines Ref No. : SGE/01/78 Date: 26/12/11

1. Inlet pump is interlocked with high oil level float switch. 2. Inlet Pump is interlocked with Heater Groups. 3. Heater groups are interlocked with line thermostat. 4. Outlet pump interlocked with low level float switch. 5. Roots Pump interlocked with vacuum level by vacuum switch.

Overall Size of Plant: The whole equipment is mounted on stationary base frame with suitable lifting arrangement. The height of the whole unit will be less than or equal to 3200mm Dimension of the plant will be : Width : 2200mm Length : 4200mm Height : 3000mm

Note: 1. All valves used in the systems will be of VAAS / L & T 2. The plant be tested for its Vacuum Leak rate to the extent of 0.5 torr.lit / sec 3. Two sets of Instruction Manuals with electrical Circuit diagram will be provided along with the plant. 4. The plant will be fitted on your vehicle with 6 8 nos of U Type bolts for detachable purpose. 5. Whether proof enclosure will be provided in 16 SGW Sheet with suitable doors and top roof 6. Digital Vacuum gauge will be provided. 7. A scientific McLeod gauge will be supplied along with plant. 8. For Transformer Evacuation Purpose, a valve and nozzle arrangement will be provided.

9

Works: - Sec:-10, plot no:-98, PCNTDA, Bhosari, Pune- 411026 Office: - Sec 27/A Plot 345 Pradhikaran, Nigdi, Pune-411044. Ph:-+91-9850572494,9970288900, 020-27653211 E-Mail saiguruengineers@rediffmail.com, madgonde@rediffmail.com

Website:- www.saiguruengineers.com

Manufacturer of High Vacuum Transformer oil filter Plant, Vacuum Impregnation Plant, Epoxy Casting Plant, Capacitor Impregnation Plant, Winding Machines Ref No. : SGE/01/78 Date: 26/12/11

RESULTS OF OIL:Name of Test Break Down Voltage Moisture Content Neutralization Value Gas Content Particle Size

As per IS Standards. 40 KV 40 ppm 0.3mg KOH/g %Vol / Vol -

Before filtration 25 KV 100 ppm 0.5mg KOH/g 10% 100 Micron

After filtration More than 70 KV 5 ppm 0.05mg KOH/g <0.1% 1 Micron

10

Works: - Sec:-10, plot no:-98, PCNTDA, Bhosari, Pune- 411026 Office: - Sec 27/A Plot 345 Pradhikaran, Nigdi, Pune-411044. Ph:-+91-9850572494,9970288900, 020-27653211 E-Mail saiguruengineers@rediffmail.com, madgonde@rediffmail.com

Website:- www.saiguruengineers.com

Manufacturer of High Vacuum Transformer oil filter Plant, Vacuum Impregnation Plant, Epoxy Casting Plant, Capacitor Impregnation Plant, Winding Machines Ref No. : SGE/01/78 Date: 26/12/11

4. Price & Payment Terms: Sr.No Description 1. 10,000 LPH High Vacuum Two Stage Transformer oil Filter Machine along with all accessories as per technical specifications specified.

0 100 BDV Tester oil testing kit fitted into the plant. Optional

Amount 17,80,000/-

2.

49,000/-

The Machine will be mounted on your supplied Vehicle.

Payment Terms & Validity 40% advance along with the order or in stages 55% + Taxes & Duties etc after satisfactory testing of plant at our site. 5% balance after commissioning of plant at your site. This offer is valid for 45 days from the date of its submission. Transportation / Delivery Charges: Will be Extra at actuals CST: 2% Extra against C- Form. Octroi / Entry Tax: As Applicable Transit Insurance: Arranged by Sai Guru Engineers Delivery: 8 Weeks from receipt of P.O. Warranty SAI GURU ENGINEERS warrants the equipment and the work to be free from defects in materials and workmanship under normal use and service and when properly maintained for a period of One Year (12 Months) from date of delivery against faulty workmanship & defective material. workmanship & defective material. 11

Works: - Sec:-10, plot no:-98, PCNTDA, Bhosari, Pune- 411026 Office: - Sec 27/A Plot 345 Pradhikaran, Nigdi, Pune-411044. Ph:-+91-9850572494,9970288900, 020-27653211 E-Mail saiguruengineers@rediffmail.com, madgonde@rediffmail.com

Website:- www.saiguruengineers.com

Das könnte Ihnen auch gefallen

- Bhel (Transformer) Major TrainingDokument33 SeitenBhel (Transformer) Major TrainingArpitSinghNoch keine Bewertungen

- Cost Sheet For NPLDokument10 SeitenCost Sheet For NPLSachin MishraNoch keine Bewertungen

- Company Profile SimpleDokument7 SeitenCompany Profile SimpleAsif MemonNoch keine Bewertungen

- Krishna ElectronicsDokument10 SeitenKrishna Electronicsrishi070881100% (1)

- EAG2020-541 E575R 8000 LPH Paras Pakistan Revision ADokument3 SeitenEAG2020-541 E575R 8000 LPH Paras Pakistan Revision AArun BajajNoch keine Bewertungen

- 32687-1 The Light Cinema-BanburyDokument9 Seiten32687-1 The Light Cinema-Banburyamith_kmNoch keine Bewertungen

- Little Angel 500LPHDokument5 SeitenLittle Angel 500LPHMohamed HaneefaNoch keine Bewertungen

- 5 Offer For Vertical Pyrolysis Plant 10TDokument5 Seiten5 Offer For Vertical Pyrolysis Plant 10TGaurav BihaniNoch keine Bewertungen

- Turbine RAS - Back Pressure Turbine 4Dokument33 SeitenTurbine RAS - Back Pressure Turbine 4hemant visheNoch keine Bewertungen

- Ricardo 20kVADokument5 SeitenRicardo 20kVARashedul IslamNoch keine Bewertungen

- TBE Pumps CP 16Dokument21 SeitenTBE Pumps CP 16ivomNoch keine Bewertungen

- Supply, Installation & Testing and Commissioning of P.A. System, Tower AC & Water Cooler Cum Purifier For IHM & Different Panthanivas of OTDC LTDDokument9 SeitenSupply, Installation & Testing and Commissioning of P.A. System, Tower AC & Water Cooler Cum Purifier For IHM & Different Panthanivas of OTDC LTDgbaludbNoch keine Bewertungen

- MANUAL DezumidificatorDokument98 SeitenMANUAL DezumidificatorcivodulNoch keine Bewertungen

- R.K.Aircon Industries: An Iso 9001:2000 Certified CompanyDokument3 SeitenR.K.Aircon Industries: An Iso 9001:2000 Certified Companysri0403809235Noch keine Bewertungen

- 1 MW Quotation Documnets For Solar Panel Proudction Line 2014Dokument16 Seiten1 MW Quotation Documnets For Solar Panel Proudction Line 2014Madhu Babu JattiNoch keine Bewertungen

- Midea ChillerDokument37 SeitenMidea ChilleryayoteNoch keine Bewertungen

- 5 ประหยัดพลังงานในระบบอัดอากาศDokument5 Seiten5 ประหยัดพลังงานในระบบอัดอากาศTonmokNoch keine Bewertungen

- Janvik: Engineers and Tubes Pvt. LTDDokument6 SeitenJanvik: Engineers and Tubes Pvt. LTDshivNoch keine Bewertungen

- Meshak Control Room OperatorDokument7 SeitenMeshak Control Room Operatormsk649Noch keine Bewertungen

- Specif-Dust Extraction SystemDokument12 SeitenSpecif-Dust Extraction SystemChristopher LloydNoch keine Bewertungen

- Orden de Compra BarivenDokument25 SeitenOrden de Compra BarivenArmandoInfo100% (1)

- Further Product Details: Position Qty. Description CRE 64-2-2 A-F-A-E-HQQEDokument10 SeitenFurther Product Details: Position Qty. Description CRE 64-2-2 A-F-A-E-HQQEitsirc67Noch keine Bewertungen

- Berin Operator.Dokument7 SeitenBerin Operator.Godwin GodwinNoch keine Bewertungen

- M20CDokument79 SeitenM20CMuhammad AsifNoch keine Bewertungen

- Thermotech Manual-Section 1 To 5 PDFDokument100 SeitenThermotech Manual-Section 1 To 5 PDFNishadhraj Vasava67% (3)

- 502mva Transformer Installation ScheduleDokument4 Seiten502mva Transformer Installation ScheduleNaukhez A. KashifNoch keine Bewertungen

- Fw-Pump TbeDokument43 SeitenFw-Pump TbeTeguh Setiono100% (1)

- Technical OfferDokument32 SeitenTechnical OfferSupratik RoyNoch keine Bewertungen

- 751-Fainal-01-Qutetion For Haydrolic Lift 110MMDokument8 Seiten751-Fainal-01-Qutetion For Haydrolic Lift 110MMKush ThumarNoch keine Bewertungen

- Bis BFP Oil FlushingDokument19 SeitenBis BFP Oil FlushingShailenderNoch keine Bewertungen

- Gas Oil Processing Plant SimulatorDokument13 SeitenGas Oil Processing Plant SimulatorHanmant MalkapureNoch keine Bewertungen

- Triveni Offer - 17.1 MWDokument52 SeitenTriveni Offer - 17.1 MWPrasanna kumar subudhi100% (1)

- Simuwu Catalogo PDFDokument21 SeitenSimuwu Catalogo PDFFBSBNoch keine Bewertungen

- Catalogue of Industrial DehumidifierDokument8 SeitenCatalogue of Industrial Dehumidifierdaviko313Noch keine Bewertungen

- Baarga PDFDokument5 SeitenBaarga PDFDeepa SamiyappanNoch keine Bewertungen

- 1000-1500 1FNL Semi Automatic MWP Plant Offer STD EXPORTDokument16 Seiten1000-1500 1FNL Semi Automatic MWP Plant Offer STD EXPORTmimrusfanNoch keine Bewertungen

- Quotation 132kv CT PT 33kv PTDokument5 SeitenQuotation 132kv CT PT 33kv PTSharafat AliNoch keine Bewertungen

- 6 Fire Protection SystemDokument1.320 Seiten6 Fire Protection SystemedmondevangelistacorpuzNoch keine Bewertungen

- 4 Ad633Dokument6 Seiten4 Ad633Alcemir CampeloNoch keine Bewertungen

- 07 12 2021 Ric Incinerator Repair TechnicalDokument14 Seiten07 12 2021 Ric Incinerator Repair TechnicalMoosa QamarNoch keine Bewertungen

- 33 KV CT PTDokument20 Seiten33 KV CT PTHeather CarterNoch keine Bewertungen

- Madras CementDokument42 SeitenMadras CementAnonymous sfY8T3q0100% (1)

- Y2 Water Blasting Machine Manual 222Dokument7 SeitenY2 Water Blasting Machine Manual 222SAMUEL EDEHNoch keine Bewertungen

- TENDER ENQUIRY NO:ENQ/15-16/003652/MM25 (01) /DATE:18/12/2015 /page - 1Dokument7 SeitenTENDER ENQUIRY NO:ENQ/15-16/003652/MM25 (01) /DATE:18/12/2015 /page - 1Power MuruganNoch keine Bewertungen

- Revised Techno Commercial Offer of CSSD Equipment, Grand Port Hospital, Wadala, 08.02.2022Dokument20 SeitenRevised Techno Commercial Offer of CSSD Equipment, Grand Port Hospital, Wadala, 08.02.2022Pranali MhatreNoch keine Bewertungen

- Specifications and TenderinvitationDokument27 SeitenSpecifications and TenderinvitationAbhiram ReddyNoch keine Bewertungen

- PS3000 Refinery OperationsDokument23 SeitenPS3000 Refinery OperationsNguyễn Tiến DũngNoch keine Bewertungen

- 10P87-D0003-046-R0-WHRU by TEPLDokument23 Seiten10P87-D0003-046-R0-WHRU by TEPLjigarNoch keine Bewertungen

- Requisition Foster Wheeler Usa Corporation: FORM:116983 REV 0 7/8/97Dokument4 SeitenRequisition Foster Wheeler Usa Corporation: FORM:116983 REV 0 7/8/97jmcarvajal77Noch keine Bewertungen

- Quote 33kv CT PT Ddugjy DVVNLDokument4 SeitenQuote 33kv CT PT Ddugjy DVVNLeleconindiaNoch keine Bewertungen

- Nit Did3728l20Dokument8 SeitenNit Did3728l20Hossam AlzubairyNoch keine Bewertungen

- 237 Quotation 8 X 4 X 20 DL Press 1600 Tons Taj Ply Boards PVT LTDDokument3 Seiten237 Quotation 8 X 4 X 20 DL Press 1600 Tons Taj Ply Boards PVT LTDMONU YADAVNoch keine Bewertungen

- ASHOKADokument40 SeitenASHOKAManish PatilNoch keine Bewertungen

- Hvac Boq-07082014Dokument18 SeitenHvac Boq-07082014Kohilan NahivNoch keine Bewertungen

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentVon EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Machines, Tools and Methods of Automobile ManufactureVon EverandMachines, Tools and Methods of Automobile ManufactureBewertung: 4 von 5 Sternen4/5 (1)

- Keyboard Short CutsDokument5 SeitenKeyboard Short CutsRishi KathirNoch keine Bewertungen

- Overfluxing in TransformersDokument2 SeitenOverfluxing in TransformersRishi KathirNoch keine Bewertungen

- Model of Tender SpecificationDokument15 SeitenModel of Tender SpecificationRishi KathirNoch keine Bewertungen

- Electrika User GuideDokument56 SeitenElectrika User GuideRishi KathirNoch keine Bewertungen

- Tamil Nadu Electricity BoardDokument3 SeitenTamil Nadu Electricity BoardRishi KathirNoch keine Bewertungen

- Format For Application For TransferDokument1 SeiteFormat For Application For TransferRishi KathirNoch keine Bewertungen

- Joining Report: Yes No Yes No Yes No Yes No Yes No R.C. A.C. Yes NoDokument2 SeitenJoining Report: Yes No Yes No Yes No Yes No Yes No R.C. A.C. Yes NoRishi KathirNoch keine Bewertungen

- Sharp InverterDokument6 SeitenSharp InverterRishi KathirNoch keine Bewertungen

- Sudarshan CatelogueDokument16 SeitenSudarshan CatelogueRishi KathirNoch keine Bewertungen

- Drinking Water Treatment Unit Scheme Ver 2Dokument31 SeitenDrinking Water Treatment Unit Scheme Ver 2josephsedNoch keine Bewertungen

- KC CVDokument2 SeitenKC CVVishal KeshriNoch keine Bewertungen

- Lagundi/Dangla (Vitex Negundo)Dokument2 SeitenLagundi/Dangla (Vitex Negundo)Derrick Yson (Mangga Han)Noch keine Bewertungen

- A Simple and Reliable Submental Intubation.68Dokument4 SeitenA Simple and Reliable Submental Intubation.68Tîrban Pantelimon FlorinNoch keine Bewertungen

- Chapter 3 Rotation and Revolution NotesDokument12 SeitenChapter 3 Rotation and Revolution NotesMERLIN ANTHONYNoch keine Bewertungen

- Nava LunchDokument3 SeitenNava LuncheatlocalmenusNoch keine Bewertungen

- Stock Trak AssignmentDokument4 SeitenStock Trak AssignmentPat ParisiNoch keine Bewertungen

- TV ExplorerDokument2 SeitenTV Explorerdan r.Noch keine Bewertungen

- 2015.15009.fundamental Principles of Physical Chemistry - Text PDFDokument782 Seiten2015.15009.fundamental Principles of Physical Chemistry - Text PDFAnoif Naputo Aidnam100% (1)

- Anilkumar Surendran 3-AdDokument4 SeitenAnilkumar Surendran 3-AdAnil AmbalapuzhaNoch keine Bewertungen

- OXE Training - Complete (2011)Dokument94 SeitenOXE Training - Complete (2011)Dhexter Villa75% (4)

- Alma Matter SpeechDokument1 SeiteAlma Matter Speechlariza gallegoNoch keine Bewertungen

- Accessing Biodiversity and Sharing The BenefitsDokument332 SeitenAccessing Biodiversity and Sharing The BenefitsNelson MartínezNoch keine Bewertungen

- Honeymoon in Vegas Word FileDokument3 SeitenHoneymoon in Vegas Word FileElenaNoch keine Bewertungen

- Technik: RefraDokument54 SeitenTechnik: Reframustaf100% (1)

- State Magazine, May 2001Dokument38 SeitenState Magazine, May 2001State MagazineNoch keine Bewertungen

- Battle Group Builder + Commonwealth Infantry Roster - Wargames DesignDokument12 SeitenBattle Group Builder + Commonwealth Infantry Roster - Wargames DesignPete PoliNoch keine Bewertungen

- O RTIZDokument2 SeitenO RTIZKhimberly Xylem OrtizNoch keine Bewertungen

- Fruit Brearing CropsDokument177 SeitenFruit Brearing CropsJoshua G. Sapin100% (1)

- 2017 Lecture 3 Metal Carbonyls PDFDokument28 Seiten2017 Lecture 3 Metal Carbonyls PDFMahnoor FatimaNoch keine Bewertungen

- AC Hipots 15-200kVDokument4 SeitenAC Hipots 15-200kVfelipe.aounNoch keine Bewertungen

- 4612 4621 Vitamin D Supplementation For Osteoporosis in Older AdultsDokument10 Seiten4612 4621 Vitamin D Supplementation For Osteoporosis in Older AdultsMohammedNoch keine Bewertungen

- ECU MS 4 Sport ManualpdfDokument26 SeitenECU MS 4 Sport ManualpdfLucas DuarteNoch keine Bewertungen

- Ecological Pyramids WorksheetDokument3 SeitenEcological Pyramids Worksheetapi-26236818833% (3)

- AI LabDokument17 SeitenAI LabTripti JainNoch keine Bewertungen

- Graph 1: Temperature,° C of Mixture 1 (Naoh-Hcl) Against Time Taken, (Min)Dokument8 SeitenGraph 1: Temperature,° C of Mixture 1 (Naoh-Hcl) Against Time Taken, (Min)LeeshaaLenee Paramanantha KumarNoch keine Bewertungen

- Income Tax - MidtermDokument9 SeitenIncome Tax - MidtermThe Second OneNoch keine Bewertungen

- AEC 34 - ACB Assignment: Module 1: Problem 1-1.TRUE OR FALSEDokument5 SeitenAEC 34 - ACB Assignment: Module 1: Problem 1-1.TRUE OR FALSEDrew BanlutaNoch keine Bewertungen

- Hyperinflation of Zimbabwe and The Lesson For Zimbabwe: Foreign Trade University Faculty of Banking and FinanceDokument38 SeitenHyperinflation of Zimbabwe and The Lesson For Zimbabwe: Foreign Trade University Faculty of Banking and FinancePham Việt AnhNoch keine Bewertungen

- HGP Year End Report 2021-2022 NewDokument169 SeitenHGP Year End Report 2021-2022 Newangelica sungaNoch keine Bewertungen