Beruflich Dokumente

Kultur Dokumente

Example Simply Supported IPE Profile Purlin

Hochgeladen von

Ajay GargOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Example Simply Supported IPE Profile Purlin

Hochgeladen von

Ajay GargCopyright:

Verfügbare Formate

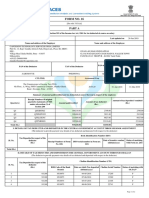

Example: Simply supported IPE profile purlin

CALCULATION SHEET

Document Ref: Title

SX021a-EN-EU

Sheet

of

10

Example: Simply supported IPE profile purlin EN 1993-1-1 Mladen Lukic Alain Bureau

Date Date

Eurocode Ref Made by Checked by

Jan 2006 Jan 2006

Example: Simply supported IPE profile purlin

This example gives the details of the verification according to EN 1993-1-1 of a simply supported purlin under a uniform loading. The purlin is an Isection rolled profile which is laterally restrained by the steel sheeting. Scope The example covers the design of a hot rolled profile beam used as purlin, under bending about the strong axis. The purlin is laterally restrained by the steel sheeting. The example includes:

Created on Monday, March 12, 2012 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

the classification of the cross-section, the calculation of the bending resistance, including the exact calculation of the elastic critical moment for lateral torsional buckling, the calculation of the shear resistance, the calculation of the deflections at serviceability limit state.

The verification of the steel sheeting is out of the scope of this worked example. Partial safety factors

Gmax = 1,35 Gmin = 1,00 Q M0 M1

= 1,50 = 1,0 = 1,0

(permanent loads) (permanent loads) (variable loads)

EN 1990

EN 1993-1-1 6.1 (1)

Loading The uniformly distributed loading includes: self-weight of the beam roofing Snow load : Wind load (uplift) : 0,240 kN/m2 0,618 kN/m2 0,730 kN/m2

Example: Simply supported IPE profile purlin

CALCULATION SHEET

Document Ref: Title

SX021a-EN-EU

Sheet

of

10

Example: Simply supported IPE profile purlin EN 1993-1-1 Mladen Lukic Alain Bureau

Date Date

Eurocode Ref Made by Checked by

Jan 2006 Jan 2006

Basic geometrical data Purlin Span length: Spacing: L = 7,20 m s = 3,00 m

tf z

Try IPE 180 Steel grade S275 Depth Width Web thickness Flange thickness Fillet

Created on Monday, March 12, 2012 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Euronorm 19-57

tw

h = 180 mm b = 91 mm tw = 5,3 mm tf = 8 mm r = 9 mm 18,8 kg/m A = 23,9 cm2

z b y

y h

Mass Section area

Second moment of area /yy Iy = 1317 cm4 Second moment of area /zz Iz = 100,9 cm4 Torsion constant Warping constant Elastic modulus /yy Plastic modulus /yy Sheeting Steel grade S350

25 100 50 25 1000 40

It = 4,79 cm4 Iw = 7430 cm6 Wel,y = 146,3 cm3 Wpl.y = 166,4 cm3

Thickness of the sheeting t = 0,7 mm

Example: Simply supported IPE profile purlin

CALCULATION SHEET

Document Ref: Title

SX021a-EN-EU

Sheet

of

10

Example: Simply supported IPE profile purlin EN 1993-1-1 Mladen Lukic Alain Bureau

Date Date

Eurocode Ref Made by Checked by

Jan 2006 Jan 2006

It is possible to calculate the shear stiffness of trapezoidal sheeting connected EN 1993-1-3 to the purlin at each rib and connected in every side overlap according to the 10.1.1(10) EN 1993-1-3. The formula is:

S = 1000 t 3 50 + 103 broof

) hs

The following expressions are calculated:

t 3 = 0,7 3 = 0,586 mm 3 2

50 + 103 broof = 50 + 10 3 7200 = 243 mm 2 3

s 3000 = = 75 hw 40

Created on Monday, March 12, 2012 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Then the shear stiffness is:

S = 1000 0,586 243 75 10-3 = 10680 kNm / m

Capacity of the sheeting to restrain the purlin Continuous lateral restraint If the following requirement is met, the purlin may be regarded as being laterally restrained in the plane of the sheeting:

EN 1993-1-1 BB.2.1 EN 1993-1-3 10.1.1 (6)

2 EI w 2 EI z (h 2)2 70 2 + GI t + S S min = L2 h L2 One calculates:

2 E Iw

L2

2 210000 7430 106

7200 2

10-9 = 0,2971 kNm 2

GI t = 80770 4,79 10 4 10 -9 = 3,869 kNm 2

2 E I z (h 2)2

L2

2 210000 100,9 10 4 902

7200 2

10-9 = 0,3268 kNm 2

Then the minimum stiffness is:

S min = (0,2971 + 3,869 + 0,3265) 70 = 9706 kNm/m 0,182

Example: Simply supported IPE profile purlin

CALCULATION SHEET

Document Ref: Title

SX021a-EN-EU

Sheet

of

10

Example: Simply supported IPE profile purlin EN 1993-1-1 Mladen Lukic Alain Bureau

Date Date

Eurocode Ref Made by Checked by

Jan 2006 Jan 2006

Therefore: S = 10680 kNm/m > Smin = 9706 kNm/m The condition is thus met and the steel sheeting can be considered as sufficiently stiff to restrain the purlin. Note that requirements regarding the resistance and the stability of the steel sheeting are given in the EN 1993-1-3, these verifications are out of the scope of this worked example.

Loads

Created on Monday, March 12, 2012 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Purlins: Roofing: Permanent load: Snow: Wind (uplift):

G1 = (18,8 9,81) 10-3 = 0,184 kN/m G2 = 0,240 3,00 G = G1 + G2 QS = 0,618 3,00 QW = 0,730 3,00 = 0,720 kN/m = 0,904 kN/m = 1,854 kN/m = 2,190 kN/m

Note:

It is assumed that the roof slope is so low that the decomposition of the vertical loads into two components, one parallel to the web and the other one parallel to the plane of the roof, is not needed here.

ULS Combinations:

Sagging:

Gmax G + Q QS = 1,35 0,904 + 1,50 1,854 = 4,00 kN/m

Hogging:

EN 1990 6.4.3.2

Gmin G + Q QS = 1,00 0,904 1,50 2,190 = -2,38 kN/m

Moment diagram

Maximum sagging moment at mid span: My,Ed = 0,125 4,00 7,202 = 25,92 kNm

M My,Ed

Maximum hogging moment at mid span: My,Ed = 0,125 (2,38) 7,202 = 15,42 kNm

My,Ed M

Example: Simply supported IPE profile purlin

CALCULATION SHEET

Document Ref: Title

SX021a-EN-EU

Sheet

of

10

Example: Simply supported IPE profile purlin EN 1993-1-1 Mladen Lukic Alain Bureau

Date Date

Eurocode Ref Made by Checked by

Jan 2006 Jan 2006

Shear force diagram

Maximum shear force at supports for sagging: Vz,Ed = 0,5 4,00 7,20 = 14,4 kN Maximum shear force at supports for hogging: Vz,Ed = 0,5 2,38 7,20 = 8,57 kN

SLS Combination

Sagging: G + Q = 0,905 + 1,854 = 2,759 kN/m Hogging: G + Q = 0,905 2,190 = 1,285 kN/m

EN 1990 6.5.3

Created on Monday, March 12, 2012 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Yield strength

Steel grade S275 The maximum thickness is 8 mm < 40 mm, so: fy = 275 N/mm2

Note:

The National Annex may impose either the values of fy from the Table 3.1 or the values from the product standard.

EN 1993-1-1 Table 3.1

Section classification:

The parameter is derived from the yield strength: =

Outstand flange: flange under uniform compression

235 = 0,92 f y [N/mm 2 ]

EN 1993-1-1 Table 5.2 (sheet 2 of 3)

c = (b tw 2 r) / 2 = (91 5,3 2 9)/2 = 33,85 mm c/tf = 33,85 / 8,0 = 4,23 9 = 8,28 Class 1 EN 1993-1-1 Table 5.2 (sheet 1 of 3)

Internal compression part: web under pure bending

c = h 2 tf 2 r = 180 2 8 2 9 = 146 mm c / tw = 146 / 5,3 = 27,5 < 72 = 66,24 Class 1

The class of the cross-section is the least favourable class between the flange and the web, here: Class 1

So the ULS verifications should be based on the plastic resistance of the cross-section.

Example: Simply supported IPE profile purlin

CALCULATION SHEET

Document Ref: Title

SX021a-EN-EU

Sheet

of

10

Example: Simply supported IPE profile purlin EN 1993-1-1 Mladen Lukic Alain Bureau

Date Date

Eurocode Ref Made by Checked by

Jan 2006 Jan 2006

Moment resistance Sagging

The design resistance for bending of a cross section is given by: Mc,Rd = Mpl,Rd = Wpl,y fy / M0 = (166,4 275 / 1,0) 10-3 Mc.Rd = 45,76 kNm My,Ed / Mc,Rd = 25,92 / 45,76 = 0,566 < 1 OK No verification against lateral torsional buckling is needed since the compressed flange is considered as fully restrained laterally.

Moment resistance Hogging

EN 1993-1-1 6.2.5

The bending resistance criterion is: My,Ed / Mc,Rd = 15,42 / 45,76 = 0,337 < 1 OK

Created on Monday, March 12, 2012 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

EN 1993-1-1 6.2.5

However, resistance to lateral torsional buckling should be checked since the compressed flange is now unrestrained laterally.

Reduction factor for lateral torsional buckling

To determine the design buckling resistance moment of the purlin, the reduction factor for lateral torsional buckling is determined on the basis of the elastic critical moment for lateral torsional buckling taking into account the lateral restraint of the tension flange.

Note:

The torsional restraint due to sheeting is also physically present and could be taken into account. In this spreadsheet, it will be supposed as insignificant and wont be considered.

Critical moment for lateral torsional buckling

The critical moment may be calculated using the software LTBeam developed SN011 by the CTICM. This software allows the designer to take into account special restraint conditions such as a continuous lateral restraint along the tension flange and its position from the shear centre. Note : LTBeam is free and can be downloaded on the web site www.cticm.com

Example: Simply supported IPE profile purlin

CALCULATION SHEET

Document Ref: Title

SX021a-EN-EU

Sheet

of

10

Example: Simply supported IPE profile purlin EN 1993-1-1 Mladen Lukic Alain Bureau

Date Date

Eurocode Ref Made by Checked by

Jan 2006 Jan 2006

The continuous lateral restraint is assumed to be located at 90 mm above the shear centre. The critical moment calculated by LTBeam is: Mcr = 27,20 kNm

Non-dimensional slenderness

The non-dimensional slenderness is obtained from: LT = Wpl,y f y M cr = 166400 275 10-6 = 1,297 27,20

EN 1993-1-1 6.3.2.2 (1)

For rolled profiles, LT,0 = 0,4

Note:

Created on Monday, March 12, 2012 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

the value of LT,0 may be given in the National Annex. The recommended value is 0,4.

LT = 1,297 > LT,0

EN 1993-1-1 6.3.2.3(1)

So

Reduction factor

For rolled sections, the reduction factor for lateral torsional buckling is calculated by:

LT =

LT +

2 LT

2 LT

but

LT 1.0 1 LT 2 LT

2 where: LT = 0,5 1 + LT LT LT,0 + LT

EN 1993-1-1 the method for rolled profiles, the LTB curve has to be selected from the table Table 6.5 6.5: Table 6.3 For h/b = 180 / 91 = 1,97 2

Curve b (LT = 0,34)

LT is the imperfection factor for lateral torsional buckling. When applying

LT,0 = 0,4 and = 0,75

Note: the values of LT,0 and may be given in the National Annex. The recommended values are 0,4 and 0,75 respectively.

Example: Simply supported IPE profile purlin

CALCULATION SHEET

Document Ref: Title

SX021a-EN-EU

Sheet

of

10

Example: Simply supported IPE profile purlin EN 1993-1-1 Mladen Lukic Alain Bureau

Date Date

Eurocode Ref Made by Checked by

Jan 2006 Jan 2006

We obtain: and:

LT = 0,5 1 + 0,34 (1,297 0,4 ) + 0,75 1,297 2 = 1,283

LT = 1 1,283 + 1,2832 0,75 1,297 2 = 0,525

Then, we check: LT = 0,525 < 1,0 OK and:

LT = 0,525 < 1 / LT = 0,594

Design buckling resistance moment

Mb,Rd = LT Wpl,y fy / M1 Mb,Rd = (0,525 166400 275 / 1,0) 10-6 = 24,02 kNm My,Ed / Mb,Rd = 15,42 / 24,02 = 0,642 < 1 OK

Created on Monday, March 12, 2012 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

EN 1993-1-1 6.3.2.1

Shear Resistance

In the absence of torsion, the shear plastic resistance depends on the shear area, which is given by: Av,z = A 2 b tf + (tw + 2 r) tf Av,z = 2390 2 91 8 + (5,3 + 2 9) 8 = 1120 mm2

Shear plastic resistance

EN 1993-1-1 6.2.6 (3)

Vpl,z,Rd =

Av,z ( f y / 3 )

M0

1120 (275 / 3 ) 10-3 = 177,8 kN 1,0

EN 1993-1-1 6.2.6 (2)

Vz,Ed / Vpl,z,Rd = 14,4 / 177,8 = 0,081 < 1 OK

Note:

No M-V interaction has to be considered since the maximum moment EN1993-1-1 is obtained at mid-span and the maximum shear force is obtained at 6.2.8 supports.

Note that the verification to shear buckling is not required when: hw / tw 72 /

may be conservatively taken as 1.0

hw / tw = (180 2 8) / 5,3 = 30,9 < 72 0,92 / 1,0 = 66,24

EN 1993-1-1 6.2.6 (6)

CALCULATION SHEET

i r

Document Ref: Title

SX021a-EN-EU

Sheet

of

10

Example: Simply supported IPE profile purlin EN 1993-1-1 Mladen Lukic Alain Bureau

Date Date

Eurocode Ref Made by

Jan 2006 Jan 2006

Checked by

Deflection Sagging

Deflection under G

w=

5 G L4 5 0,904 (7200) 4 = = 11,4 mm = L/632 384 E I y 384 210000 1317 10 4

EN 1993-1-1 7.2.1

Deflection under Q

w= 5 1,854 (7200) 4 5 Q L4 = 23,5 mm = L/306 = 384 E I y 384 210000 1317 104

a s

The deflection under (G+Q) is L/206

d i

Deflection Hogging

Deflection under G w=

l

5 0,904 (7200) 4 5 G L4 = 11,4 mm = L/632 = 384 E I y 384 210000 1317 10 4

EN 1993-1-1 7.2.1

Deflection under Q w= 5 ( 2,190 ) (7200) 4 5 Q L4 = 27,7 mm = L/260 = 384 E I y 384 210000 1317 10 4

M a

The deflection under (G+Q) is L/442

Note:

n r

the limits of deflection should be specified by the client. The National Annex may specify some limits. Here the result may be considered as satisfactory.

C T

r h

e i

a s

e m

d a

o e

Example: Simply supported IPE profile purlin

Example: Simply supported IPE profile purlin SX021a-EN-EU

Quality Record

RESOURCE TITLE Reference(s) ORIGINAL DOCUMENT Name Created by Technical content checked by Editorial content checked by Technical content endorsed by the following STEEL Partners: 1. UK 2. France 3. Sweden

Created on Monday, March 12, 2012 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Example: Simply supported IPE profile purlin

Company CTICM CTICM

Date 08/12/05 08/12/05

Mladen Lukic Alain Bureau

G W Owens A Bureau B Uppfeldt C Mller J Chica G W Owens

SCI CTICM SBI RWTH Labein SCI

7/04/06 7/04/06 7/04/06 7/04/06 7/04/06 17/07/06

4. Germany 5. Spain Resource approved by Technical Coordinator TRANSLATED DOCUMENT This Translation made and checked by: Translated resource approved by:

Das könnte Ihnen auch gefallen

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionVon EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNoch keine Bewertungen

- Ec3 Kolon HesabıDokument5 SeitenEc3 Kolon HesabınaimalimliNoch keine Bewertungen

- Simply Supported Primary Composite BeamDokument17 SeitenSimply Supported Primary Composite BeamPaul Marceti100% (2)

- Example - Buckling Resistance of A Pinned Column With Intermediate RestraintsDokument5 SeitenExample - Buckling Resistance of A Pinned Column With Intermediate RestraintsAndreea NanNoch keine Bewertungen

- SX019a-En-EU-Example - Column Base Connection Under Axial CompressionDokument5 SeitenSX019a-En-EU-Example - Column Base Connection Under Axial CompressionWNoch keine Bewertungen

- 07 Sx007a en Eu BeamDokument11 Seiten07 Sx007a en Eu BeamMic PaulaNoch keine Bewertungen

- 05 - Example Sway StabilityDokument10 Seiten05 - Example Sway StabilityAlex TimocNoch keine Bewertungen

- SX033b-En-EU-Example - Truss or Post End ConnectionDokument8 SeitenSX033b-En-EU-Example - Truss or Post End ConnectionWNoch keine Bewertungen

- LT Buckling Beam Design - Simple Method - 2upDokument5 SeitenLT Buckling Beam Design - Simple Method - 2upberto2008Noch keine Bewertungen

- Fin Plate ConnectionDokument70 SeitenFin Plate Connectionfloi dNoch keine Bewertungen

- Example Calculation of Alpha-Cr PDFDokument9 SeitenExample Calculation of Alpha-Cr PDFHerdean RemusNoch keine Bewertungen

- End Plates - Worked Examples With Partial Depth End Plate - Example 5Dokument1 SeiteEnd Plates - Worked Examples With Partial Depth End Plate - Example 5Kimutai Kirui AlphonceNoch keine Bewertungen

- Sway Frame Steel Column DesignDokument1 SeiteSway Frame Steel Column DesignChirianu MarianNoch keine Bewertungen

- Plate Girders 2008Dokument20 SeitenPlate Girders 2008Tharmalingam VijayNoch keine Bewertungen

- ComFlor® ManualDokument132 SeitenComFlor® ManualAhmedNoch keine Bewertungen

- SX010a-En-EU-Example - Continuous Column in A Multi-Storey Building Using An H-Section or RHSDokument9 SeitenSX010a-En-EU-Example - Continuous Column in A Multi-Storey Building Using An H-Section or RHSWNoch keine Bewertungen

- 1.0 Early Thermal CheckDokument7 Seiten1.0 Early Thermal CheckklynchelleNoch keine Bewertungen

- Reinforced Concrete Column by Zinab EC2Dokument15 SeitenReinforced Concrete Column by Zinab EC2berto2008Noch keine Bewertungen

- EC7 Fundamental Issues and Its Implications On Users PDFDokument24 SeitenEC7 Fundamental Issues and Its Implications On Users PDFVardhanNoch keine Bewertungen

- Access Steel Data Sheets BindedDokument154 SeitenAccess Steel Data Sheets BindedblueswanNoch keine Bewertungen

- Advantages CFSTDokument14 SeitenAdvantages CFSTprajjwal patidarNoch keine Bewertungen

- Circular Column Design - MPA-ECDokument1 SeiteCircular Column Design - MPA-ECmayphyoNoch keine Bewertungen

- Member Design - Prestressed Concrete Beam and Slab BS8110 (EC2), ACI318, AS3600 v2021.03 PDFDokument98 SeitenMember Design - Prestressed Concrete Beam and Slab BS8110 (EC2), ACI318, AS3600 v2021.03 PDFlau lauNoch keine Bewertungen

- Tying Resistance of A Fin Plate ConnectionDokument9 SeitenTying Resistance of A Fin Plate ConnectionSam Samoura0% (1)

- Bracing Design To Eurocode 3Dokument13 SeitenBracing Design To Eurocode 3B.A H100% (1)

- Eurocode Steel Calc CompareDokument2 SeitenEurocode Steel Calc Compareali_irvNoch keine Bewertungen

- Example: Determination of Loads On A Building EnvelopeDokument8 SeitenExample: Determination of Loads On A Building EnvelopeZarko KrusarevNoch keine Bewertungen

- Access Steel - Data To Eurocodes PDFDokument74 SeitenAccess Steel - Data To Eurocodes PDFsgtan_associatesNoch keine Bewertungen

- Bolted Bracket DesignDokument2 SeitenBolted Bracket Designharoub_nasNoch keine Bewertungen

- TEDDS Calculation Version 1.0.09Dokument7 SeitenTEDDS Calculation Version 1.0.09Shakil Akhter100% (1)

- Load Combination (STEEL AND TIMBER DESIGN)Dokument11 SeitenLoad Combination (STEEL AND TIMBER DESIGN)Mahmuddin AminNoch keine Bewertungen

- Shear KeyDokument14 SeitenShear KeyMbalekelwa MpembeNoch keine Bewertungen

- Column Splices Not Requiring Full Continuity of StiffnessDokument6 SeitenColumn Splices Not Requiring Full Continuity of StiffnessBobaru MariusNoch keine Bewertungen

- Tekla Structural Designer 2016: Reference Guides (BS)Dokument98 SeitenTekla Structural Designer 2016: Reference Guides (BS)akankwasaNoch keine Bewertungen

- CIV 4235 ExamDokument9 SeitenCIV 4235 Exammalumius100% (2)

- Bending Strength: Overall Buckung Check L R - R at - o - 5 X 7 o o o - . o T Y - 5 T F - o / ' UDokument8 SeitenBending Strength: Overall Buckung Check L R - R at - o - 5 X 7 o o o - . o T Y - 5 T F - o / ' UReef20Noch keine Bewertungen

- International Lateral LoadsDokument38 SeitenInternational Lateral LoadsRamilArtates100% (1)

- How2 Flat SlabsDokument8 SeitenHow2 Flat SlabsTim DanNoch keine Bewertungen

- Composite ColumnDokument73 SeitenComposite ColumnraymondNoch keine Bewertungen

- BS 5950-2000 Example 001Dokument5 SeitenBS 5950-2000 Example 001Anitha Hassan KabeerNoch keine Bewertungen

- AD 261 - Elastic Modulus of AnglesDokument1 SeiteAD 261 - Elastic Modulus of Anglessymon ellimacNoch keine Bewertungen

- Example Elastic Analysis of A Single Bay Portal FrameDokument29 SeitenExample Elastic Analysis of A Single Bay Portal FrameYam BalaoingNoch keine Bewertungen

- SX011a en GB Example Unrestrained Beam With End MomentsDokument9 SeitenSX011a en GB Example Unrestrained Beam With End MomentsBenediktas DervinisNoch keine Bewertungen

- Elastic Critical Moment For Lateral Torsional BucklingDokument13 SeitenElastic Critical Moment For Lateral Torsional BucklingSabina Atencio100% (1)

- Flow Chart - Frame AnalysisDokument4 SeitenFlow Chart - Frame Analysisjmcc2Noch keine Bewertungen

- Analysis and Design of Precast Concrete Structures To Eurocode 2Dokument81 SeitenAnalysis and Design of Precast Concrete Structures To Eurocode 2Abdullah RamziNoch keine Bewertungen

- Eurocode AdviceDokument1 SeiteEurocode Advicemassive85Noch keine Bewertungen

- Welds of A Fin Plate ConnectionDokument2 SeitenWelds of A Fin Plate Connectioncretz2Noch keine Bewertungen

- 4.3 Design of Base Plate W STIFFENER (Feb 21 2015)Dokument54 Seiten4.3 Design of Base Plate W STIFFENER (Feb 21 2015)MuhammadIqbalMughalNoch keine Bewertungen

- 2.design of Shallow Foundation Using EC 7 - DR NavarathnarajaDokument20 Seiten2.design of Shallow Foundation Using EC 7 - DR NavarathnarajaefackopaNoch keine Bewertungen

- Pad Foundation With Two Columns ExampleDokument10 SeitenPad Foundation With Two Columns ExampleakankwasaNoch keine Bewertungen

- Bolted Slip Resistant Connection EC3Dokument2 SeitenBolted Slip Resistant Connection EC3cretz2Noch keine Bewertungen

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionVon EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNoch keine Bewertungen

- Simply Supported Secondary Composite BeamDokument11 SeitenSimply Supported Secondary Composite BeamgeorgeispasoiuNoch keine Bewertungen

- Example - Simply Supported Beam With Lateral Restraint at Load Application PointDokument11 SeitenExample - Simply Supported Beam With Lateral Restraint at Load Application PointVarga ZoranNoch keine Bewertungen

- Beam UnrestrainedDokument9 SeitenBeam Unrestrainedgorgika papandNoch keine Bewertungen

- Fin Plate Beam To Column Flange ConnectionDokument16 SeitenFin Plate Beam To Column Flange ConnectionVlad MosNoch keine Bewertungen

- Hexoskin - Information For Researchers - 01 February 2023Dokument48 SeitenHexoskin - Information For Researchers - 01 February 2023emrecan cincanNoch keine Bewertungen

- D - MMDA vs. Concerned Residents of Manila BayDokument13 SeitenD - MMDA vs. Concerned Residents of Manila BayMia VinuyaNoch keine Bewertungen

- Basic of An Electrical Control PanelDokument16 SeitenBasic of An Electrical Control PanelJim Erol Bancoro100% (2)

- Capital Expenditure DecisionDokument10 SeitenCapital Expenditure DecisionRakesh GuptaNoch keine Bewertungen

- Familiarization With Apparatus and Equipment Used in Testing of MaterialsDokument5 SeitenFamiliarization With Apparatus and Equipment Used in Testing of MaterialsEmanoAce33% (6)

- The Internal Environment: Resources, Capabilities, Competencies, and Competitive AdvantageDokument5 SeitenThe Internal Environment: Resources, Capabilities, Competencies, and Competitive AdvantageHenny ZahranyNoch keine Bewertungen

- Audit Certificate: (On Chartered Accountant Firm's Letter Head)Dokument3 SeitenAudit Certificate: (On Chartered Accountant Firm's Letter Head)manjeet mishraNoch keine Bewertungen

- Unit 2Dokument97 SeitenUnit 2MOHAN RuttalaNoch keine Bewertungen

- TLE - IA - Carpentry Grades 7-10 CG 04.06.2014Dokument14 SeitenTLE - IA - Carpentry Grades 7-10 CG 04.06.2014RickyJeciel100% (2)

- Phase 1: API Lifecycle (2 Days)Dokument3 SeitenPhase 1: API Lifecycle (2 Days)DevendraNoch keine Bewertungen

- Interoperability Standards For Voip Atm Components: Volume 4: RecordingDokument75 SeitenInteroperability Standards For Voip Atm Components: Volume 4: RecordingjuananpspNoch keine Bewertungen

- SND Kod Dt2Dokument12 SeitenSND Kod Dt2arturshenikNoch keine Bewertungen

- Electricity 10thDokument45 SeitenElectricity 10thSuryank sharmaNoch keine Bewertungen

- Weekly Learning PlanDokument2 SeitenWeekly Learning PlanJunrick DalaguitNoch keine Bewertungen

- Dike Calculation Sheet eDokument2 SeitenDike Calculation Sheet eSaravanan Ganesan100% (1)

- Selvan CVDokument4 SeitenSelvan CVsuman_civilNoch keine Bewertungen

- Rofi Operation and Maintenance ManualDokument3 SeitenRofi Operation and Maintenance ManualSteve NewmanNoch keine Bewertungen

- Fedex Service Guide: Everything You Need To Know Is OnlineDokument152 SeitenFedex Service Guide: Everything You Need To Know Is OnlineAlex RuizNoch keine Bewertungen

- Portrait of An INTJDokument2 SeitenPortrait of An INTJDelia VlasceanuNoch keine Bewertungen

- Ingles Avanzado 1 Trabajo FinalDokument4 SeitenIngles Avanzado 1 Trabajo FinalFrancis GarciaNoch keine Bewertungen

- CSEC Jan 2011 Paper 1Dokument8 SeitenCSEC Jan 2011 Paper 1R.D. KhanNoch keine Bewertungen

- Form16 2018 2019Dokument10 SeitenForm16 2018 2019LogeshwaranNoch keine Bewertungen

- Course Specifications: Fire Investigation and Failure Analysis (E901313)Dokument2 SeitenCourse Specifications: Fire Investigation and Failure Analysis (E901313)danateoNoch keine Bewertungen

- Unit Process 009Dokument15 SeitenUnit Process 009Talha ImtiazNoch keine Bewertungen

- Binary File MCQ Question Bank For Class 12 - CBSE PythonDokument51 SeitenBinary File MCQ Question Bank For Class 12 - CBSE Python09whitedevil90Noch keine Bewertungen

- 1 PBDokument14 Seiten1 PBSaepul HayatNoch keine Bewertungen

- Presentation Report On Customer Relationship Management On SubwayDokument16 SeitenPresentation Report On Customer Relationship Management On SubwayVikrant KumarNoch keine Bewertungen

- Ytrig Tuchchh TVDokument10 SeitenYtrig Tuchchh TVYogesh ChhaprooNoch keine Bewertungen

- Executive Summary - Pseudomonas AeruginosaDokument6 SeitenExecutive Summary - Pseudomonas Aeruginosaapi-537754056Noch keine Bewertungen

- Allan ToddDokument28 SeitenAllan ToddBilly SorianoNoch keine Bewertungen