Beruflich Dokumente

Kultur Dokumente

AMP Net Connect AMPTRAC Whitepage

Hochgeladen von

haivnptOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AMP Net Connect AMPTRAC Whitepage

Hochgeladen von

haivnptCopyright:

Verfügbare Formate

AMP NETCONNECT AMPTRAC CABLING MANAGEMENT SYSTEM

Real-Time, Real Smart Cabling Management

TABLE OF CONTENTS

TABLE OF CONTENTS .......................................................................................................... 2 INTRODUCTION ..................................................................................................................... 3 HOW THE SYSTEM WORKS.................................................................................................. 4 THE AMPTRAC SYSTEM ....................................................................................................... 5 ANALYZER ............................................................................................................................. 6 PATCH CORDS....................................................................................................................... 7 INPUT/OUTPUT (I/O) CABLES (24 PORT) ............................................................................ 8 INPUT/OUTPUT (I/O) CABLES (LESS THAN 24 PORTS) .................................................... 8 REFERENCE CABLE.............................................................................................................. 9 SENSOR PEN ....................................................................................................................... 10 SENSOR STRIPS.................................................................................................................. 10 AMP NETCONNECT UTP PATCH PANELS ........................................................................ 11 AMP NETCONNECT SHIELDED TWISTED-PAIR PATCH PANELS................................... 12 AMP NETCONNECT MRJ21 PATCH PANELS.................................................................... 13 AMP NETCONNECT OPTICAL FIBER PATCH PANELS .................................................... 13 IM SOFTWARE ..................................................................................................................... 14 DESIGN CONFIGURATION .................................................................................................. 16 CONCLUSION....................................................................................................................... 18

INTRODUCTION

Network communications are a vital part of the day-to-day operations within an organization. The cabling infrastructure is an even more critical portion today, as organizations continue to invest in the latest advancements in computers, high-speed networks, and cabling systems. As the complexity and speed of the networking infrastructure increase, so does the importance of reducing down time. To minimize down time, and to streamline the moves, adds and changes (MAC) process, an effective cabling management system that documents the cable plant is a critical addition to the physical layer infrastructure.

To respond to these needs, Tyco Electronics AMP NETCONNECT along with software partner iTRACS have created an intelligent structured cabling management solution called The AMP NETCONNECT AMPTRAC Cabling Management System. In basic terms, the

system monitors patch cord connections between ports by monitoring the continuity between sensor pads. Network equipment and AMPTRAC-enabled AMP NETCONNECT patch Analyzers, which are active hardware

panels have sensor pads above each port.

components connected to the sensor pads via input/output (I/O) cables, detect when the AMPTRAC conductor in an AMPTRAC patch cord completes a circuit between two sensor pads. The Analyzer communicates that information and the iTRACS Infrastructure Manager Software takes action based on that information.

This integrated, intelligent, structured cabling solution automates the management of the physical layer, which minimizes network downtime, reduces staff workload, reduces MAC implementation, and improves MAC accuracy. The system will also provide security benefits as well as complete up-to-date documentation for troubleshooting and disaster recovery preparedness.

HOW THE SYSTEM WORKS

When an AMPTRAC patch cord is inserted into a monitored port, a spring-loaded pin (located in the boot of the patch cord plug) touches the sensor strip (see photo on right). That spring-loaded pin is connected to the spring-loaded pin in the boot of the other plug by a conductive wire. When the other plug of this patch cord is inserted into another monitored port, a closed electrical circuit is established between the two sensor strip pads. Similarly, when either plug of the patch cord is disconnected, that electrical circuit is broken (see figures below). The AMPTRAC Analyzer detects this closing or opening of each electrical circuit as well as the exact port identifiers (sensor pads) and communicates this information to the iTRACS IM

I/O Cable Port #1 Analyzer Sensor Pad Sensor Pad Port #2 I/O Cable Port #1 Analyzer Sensor Pad Sensor Pad Port #2 I/O Cable Port #1 Analyzer Sensor Pad Sensor Pad Port #2 Patch Cord Patch Cord

Open Circuit (no connected patch cord)

Closed Circuit (connected patch cord)

Open Circuit (disconnected patch cord)

software over a TCP/IP network connection. It is important to note that these AMPTRAC circuits are constructed outside of the normal data path, so there is no impact on data flow, system integrity, or network performance.

THE AMPTRAC SYSTEM

A typical AMPTRAC system includes analyzers, AMPTRAC-enabled patch panels, sensor strips (placed on LAN switches), Input/Output (I/O) cables from the sensor pads to the analyzer, and AMPTRAC patch cords in each monitored location. The Analyzers and the

Switch with Sensor Strip

LED Status Switch Switch LED Status

Ethernet

AMPTRAC Patch Panel Analyzer

TCP/IP Network

AMPTRAC Analyzer LAN 2 LAN 3 Status Power

AMPTRAC I/O Cable

LED Status Switch

AMPTRAC Analyzer

LED Status Switch

LAN 2 LAN 3 Status Power

AMPTRAC Server

iTRACS Secure Protocol

AMPTRAC Server (where the iTRACS IM software resides) are connected to a TCP/IP network. These components are described further in the following paragraphs.

ANALYZER

Front

When a patch cord is inserted or removed from a port, the Analyzer discovers the connection or disconnection and communicates the identification of the ports to the iTRACS software over a TCP/IP connection. The sensory circuit immediately notifies the iTRACS database software to update and document the connectivity change. This provides network administrators with vital time saving, up-toRear

the minute information about the status of their network from the hardware layer up, anytime, anywhere. Any change in connectivity can be checked and authorization verified, and if appropriate, action taken if the connect/disconnect is unauthorized. Since the whole system is scalable, LAN administrators responsible for small networks or even large multi-site networks can realize these benefits.

Analyzer Features: For use in office buildings, data centers, and remote/branch offices Sold with a license to the iTRACS IM software Two analyzers available: 336-ports or 168-ports Secured, keyed, reliable DB25 connection for I/O cables Shallow depth of only 6.25 inches (16 cm)

Suitable for stand-alone (shelf) or for 19 rack or cabinet mounting Large 4-line LCD display provides interactive communications with the database Connection ports for PDAs, electronic tablets, or computers Three 10/100BASE-T Ethernet ports for connections to LAN and server No added concerns over heat management in rack or cabinet

PATCH CORDS

AMPTRAC twisted-pair patch cords are standardscompliant, although they dont look like a common patch cord. The patch cords have that spring-loaded pin built into the plug boots of the cord, which is connected to the AMPTRAC conductor, a 9

th

wire in a four-pair cable

assembly. The spring-loaded pin on each end of the cord is designed to contact the sensor pad simply by mating the connector no additional step is necessary. circuit is created when the patch cord is connected! The

Similarly, AMPTRAC optical fiber patch cords feature standards-compliant MT-RJ, LC, and SC connectors. AMPTRAC conductor is incorporated into the The cable

assembly, and the spring-loaded pins are built onto the fiber plugs. With optical fiber patch cords, the circuit is also

created when the patch cord is connected.

INPUT/OUTPUT (I/O) CABLES (24 PORT)

The Input/Output cables provide the connection from the sensor strip pads to the Analyzer. There are several I/O cable versions available. Analyzer DB25-to-IDC punch down use with AMPTRAC-enabled Patch Panels (UTP, MT-RJ or Duplex LC) Analyzer DB25-to-110 Connector quick connection to AMPTRAC-enabled Patch Panels(UTP, MT-RJ or Duplex LC) Analyzer DB25-to-2.0mm connector use with PCB style sensor strips and AMPTRACenabled shielded patch panels Analyzer DB25-to-HD22 connector use with AMPTRAC-enabled MRJ21 Patch Panels

INPUT/OUTPUT (I/O) CABLES (LESS THAN 24 PORTS)

For optical fiber snap-in-adapters, MPO cassettes, and other sensor strips less than 24 ports, the I/O cable end on the Analyzer side is a 2.0mm connector. 8 This 2.0mm

connector plugs into a DB25-to-2.0mm adapter. connections of multiple 2.0mm I/O connectors. several constructions.

The adapter allows for side-by-side These I/O cables are also available in

2.0mm-to-RJ11 - use with AMPTRAC MPO cassettes with MT-RJ or duplex LC 2.0mm-to-MTE - use with AMPTRAC Duplex SC adapter plates and AMPTRAC MPO cassettes with SC duplex 2.0mm-to-2.0mm connector use with sensor strips less than 24 ports

REFERENCE CABLE

The analyzers transmit a unique signal for each I/O port. When this signal is received on another I/O port (when the circuit is closed), the analyzer establishes that a connection has been made. These signals are based on a reference voltage.

Reference Cable

When the two affected I/O ports belong to the same analyzer, these ports can be identified internally. However, if the connected I/O ports are from different analyzers in the same zone (TR), the reference voltages must be communicated between a reference port on each analyzer. So, all analyzers that form a patch zone must be interconnected via a reference cable, which is provided with each Analyzer. Longer reference cables, if needed, can be easily made from 22 AWG cable terminated to 2 mm banana-type plugs.

SENSOR PEN

The Sensor Pen is used to map ports, identify cord connections, and troubleshoot sensor strip pads and analyzer cable connections. The pen plugs into the Analyzers RJ11 modular jack (located on the left side of the front panel). Touching the pen to any ports sensor pad while holding down the button on the pen will display the port ID. For sensor pads with a connected patch cord, both ends of the patch cord will be identified in the Analyzer LCD display.

SENSOR STRIPS

Sensor strips are available for most standard network equipment and structured cabling components such as patch panels, routers, switches, and hubs. AMPTRAC-enabled patch panels and cassettes have the sensor strip built into the panel. If necessary, sensor strips can be manufactured if a compatible strip is not available.

10

AMP NETCONNECT UTP PATCH PANELS

The AMPTRAC-enabled twisted-pair patch panel has sensor pads incorporated within the panel for enhanced protection, appearance, and reliability. I/O connections are made via a 110 IDC punch down or with the 110 plug and play cable assembly. Panels are available in standard versions and in angled versions using Cat 5e and 6 SL series modular jacks.

Panel with 110 Plug and Play I/O Cable

Panel (6 Pack) with 110 IDC I/O Cable

11

AMP NETCONNECT SHIELDED TWISTED-PAIR PATCH PANELS

AMPTRAC-enabled shielded 110Connect patch panels are Category 6, 10-gigabit ready and AMPTRAC ready patch panels. These patch panels incorporate fully integrated sensor pads for enhanced protection, appearance, and reliability.

AMPTRAC-enabled

AMPTRAC Ready

AMPTRAC Ready patch panel versions are also available. These patch panels are easily upgraded to AMPTRAC-enabled with a field-installed upgrade kit.

Upgrade Kit

AMPTRAC-enabled

SL

series

shielded

patch panels accept SL series shielded jacks and utilize a 2.0mm I/O connection in the rear of the panel or an HD22 connection in the front of the panel.

SL Series

12

AMP NETCONNECT MRJ21 PATCH PANELS

Front

The AMPTRAC system is also compatible with the high-density and high performance AMP The

NETCONNECT MRJ21 Cabling System.

AMPTRAC MRJ21 panels provide high-density MRJ21 ports in the rear and RJ45 ports in the front. These panels utilize the HD22 style I/O

Rear

connector in the rear of the panel.

AMP NETCONNECT OPTICAL FIBER PATCH PANELS

1U and 4U AMPTRAC fiber enclosures accept MT-RJ jacks or SL series LC adapters. They also accept AMPTRAC MPO cassettes (those without snap-in pins). The SL series six packs utilize the 110 IDC or the plug and play I/O cable; the MPO cassettes utilize the 2.0mm-toRJ11 I/O cable.

1U AMPTRAC Enclosure

MT-RJ Six Pack

4U AMPTRAC Enclosure

13

Standard AMP NETCONNECT fiber panels are used with AMPTRAC Duplex SC connectivity. The 1U, 2U, 3U and 4U rack-mount designs accept from three (1U) to twelve (4U) AMPTRAC Duplex SC snap-in adapter plates or AMPTRAC Duplex SC/MPO cassettes. These adapter plates and cassettes utilize the 2.0mm-to-MTE I/O cable.

AMPTRAC SC Snap-in Adapter Plate 2U Rack-mount Enclosure AMPTRAC MPO Cassette

IM SOFTWARE

iTRACS IM software is designed to work with the AMPTRAC Connectivity Management Hardware. Together they create an automated, accurate, real-time physical layer management system. This combined system proactively responds to changes in connectivity and intelligently records your cabling system and its devices with

accurate documentation.

Eliminating a

time-consuming manual work order processes with an automated process simplifies the procedure and provides timely and accurate notification of completed work. The software 14

can also generate utilization reports to assist efforts to maximize your existing network investment by identifying under-utilized assets.

Software Features: Real-Time monitoring automates the process of discovering, documenting, and managing the physical network connections and its devices Automatically updates the database with any detected change Self-discover patching discovers all AMPTRAC-enabled port connectivity Creates a log entry for every detected connectivity change Reports authorized or unauthorized changes in real time Automated work order process provides an automated work order system to be shared by the Help Desk, network managers, and technicians - each user works from a simple user interface that is unique to their task Terminal service allows access via terminal service, allowing full functionality and viewing by remote users Security features distinguishes unauthorized changes from authorized ones then issues alerts via email containing a pre-defined message Detailed reports provide a library of detailed reports of cable, port, and asset utilization for network administrators and asset managers

iTRACS IM software is ideally suited to customers with complex data/telecom networks and critical applications such as financial institutions, insurance providers, data centers, highsecurity government facilities, military defense facilities, airports, medical centers, universities, and corporate headquarters. These customers and clients share the difficult management of complicated networks, requiring accurate record-keeping, high security, and frequent MACs.

15

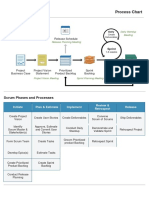

DESIGN CONFIGURATION

The AMP NETCONNECT AMPTRAC Cabling Management System can accommodate any network infrastructure, including those with single and multiple floors and multi-building campus network designs.

The AMPTRAC bills of materials, which include the Analyzers, I/O cables, Sensor Strips, patch cords, and patch panels are based on the number and type of monitored ports at each location. For each telecommunications room (TR), for example, add the number of

monitored patch panel and LAN electronic ports to get a monitored port count.

Horizontal Cable to Outlet

Daisy Chain LAN Cable

Analyzer to Sensor Strip Connections on the Patch Panel and Network Equipment via AMPTRAC I/O Cables Patch Panel

Master Analyzer

AMPTRAC Analyzer

AMPTRAC Patch Cord

LAN 2

Slave

LED Switc

LAN 3 Status Power

Reference Cable

Analyzer to Network Connection uses Standard Patch Cord

Network Switch

Sensor Strips on Patch Panel and Network Equipment

Next, determine the number of 336 and 168 port Analyzers that are required.

Rooms with

large port counts may require multiple analyzers. This is accomplished by establishing a

16

Master Analyzer then connecting multiple Slave Analyzers to the Master Analyzer. The Analyzers are physically the same, but are simply configured as either the Master or as a Slave Analyzer. Both ends of a physical connection to be monitored, typically the patch panel and the LAN electronics, must be routed to the same Patch Zone (Master and Slaves). For this reason, it is advisable to have only one Master analyzer per telecommunications room. Remember to consider future expansion of monitored ports when determining the Analyzer size or number of analyzers.

Then, determine the correct I/O cables and remaining components depending on the type of panel or equipment port to be monitored.

Remember, there are no LAN backbone connections between the Analyzers in different locations. The Master and Slave Analyzers have a unique IP address and communicate through a TCP/IP network to each other. Only Master Analyzers communicate to the

iTRACS Server. Up to 195 individual analyzers can be connected together, providing a maximum of 65520 monitored ports in a single patching zone.

The complete cable drop path to a work area outlet passes through two monitored ports, the network equipment (switch) and the patch panel. Therefore, the number of cable drops is half the number of ports monitored.

Additional information on design guidelines can be found in the AMPTRAC Hardware Manual.

17

CONCLUSION

The AMP NETCONNECT AMPTRAC Cabling Management System is an intelligent, realtime structured cabling management solution that reduces the costs of running the network infrastructure by minimizing network downtime, reducing staff workload, and streamlining the moves, adds, and changes process by automating the management of the physical layer. The solution provides a new level of security to the physical layer by providing real-time centralized monitoring of critical network connections. These features make the AMPTRAC solution a strategic enhancement tool for the network infrastructure system. Look no further than Tyco Electronics for your cabling and cabling management solutions.

18

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Lab Manual CS AmplifierDokument10 SeitenLab Manual CS Amplifieramey bhirangeNoch keine Bewertungen

- Resistor DatasheetDokument10 SeitenResistor DatasheetEndradno KurniaNoch keine Bewertungen

- Kuokuang Petrochemicals Executive SummaryDokument40 SeitenKuokuang Petrochemicals Executive SummaryKhoh Kai ShengNoch keine Bewertungen

- Unit 16Dokument35 SeitenUnit 16api-334267616Noch keine Bewertungen

- Brilliance - 64 - (ct101) - Site - Guidefor TrailerDokument19 SeitenBrilliance - 64 - (ct101) - Site - Guidefor Trailerbody2030Noch keine Bewertungen

- Procesos SCRUMDokument2 SeitenProcesos SCRUMRoseNoch keine Bewertungen

- Comparison of IEC IP and UL/NEMA TYPE Ratings: ControlsDokument1 SeiteComparison of IEC IP and UL/NEMA TYPE Ratings: ControlsEdwin LinNoch keine Bewertungen

- Curriculam Vitae: ObjectiveDokument4 SeitenCurriculam Vitae: ObjectiveSachin DeoNoch keine Bewertungen

- Croatia: Approved Port Facilities in CroatiaDokument1 SeiteCroatia: Approved Port Facilities in CroatiaАлександрNoch keine Bewertungen

- 010 Zircoat MDokument3 Seiten010 Zircoat MvsdeepakchandraNoch keine Bewertungen

- Fema 154 FormsDokument3 SeitenFema 154 FormslesgiuNoch keine Bewertungen

- Rockwell DynarixDokument39 SeitenRockwell DynarixridipisaNoch keine Bewertungen

- MR ValvesDokument56 SeitenMR ValvesIdris SiddiquiNoch keine Bewertungen

- Steering Wheel Slip - Check: Pruebas y AjustesDokument2 SeitenSteering Wheel Slip - Check: Pruebas y AjustesLENIN JHAIR VALDERRAMA SEGURANoch keine Bewertungen

- Ghorbani - AlfalfaDokument7 SeitenGhorbani - AlfalfaarizalNoch keine Bewertungen

- A Practical Guide To Understanding Bearing Damage Related To PWM Drives - CNFDokument7 SeitenA Practical Guide To Understanding Bearing Damage Related To PWM Drives - CNFjoe4709Noch keine Bewertungen

- MSM Carbon FibreDokument35 SeitenMSM Carbon FibrelokeshkrkushwahaNoch keine Bewertungen

- Reason Key CommandsDokument6 SeitenReason Key CommandsVijay KumarNoch keine Bewertungen

- (GUNSMITHING) The .22 PistolDokument18 Seiten(GUNSMITHING) The .22 PistolMago Invisivel88% (25)

- Hydraulic Home ElevatorDokument38 SeitenHydraulic Home ElevatorPatrisha SantosNoch keine Bewertungen

- AAAC Guideline For Apartment and Townhouse Acoustic Rating 2010Dokument10 SeitenAAAC Guideline For Apartment and Townhouse Acoustic Rating 2010Benjamín AlainNoch keine Bewertungen

- Adjustable Juice Groove Jig: Step 1: Jig Base and Bit DistanceDokument5 SeitenAdjustable Juice Groove Jig: Step 1: Jig Base and Bit DistanceRod HyattNoch keine Bewertungen

- Gear Trains ProblemsDokument9 SeitenGear Trains Problemsa c s Kumar100% (1)

- 13 Ijee2962nsDokument15 Seiten13 Ijee2962nspurvakul10Noch keine Bewertungen

- NEMA Premium CatalogDokument38 SeitenNEMA Premium CatalogPedro SanchezNoch keine Bewertungen

- MRT PrjectDokument59 SeitenMRT PrjectFahrul 2394Noch keine Bewertungen

- Rossler Chaotic Circuit and It's Application For Communication SecureDokument10 SeitenRossler Chaotic Circuit and It's Application For Communication SecureMada Sanjaya WsNoch keine Bewertungen

- f77 f55 User ManualDokument36 Seitenf77 f55 User ManualGabi GabrielNoch keine Bewertungen

- Is 1786Dokument5 SeitenIs 1786Jeevan ShendreNoch keine Bewertungen

- DHLDokument3 SeitenDHLfmartinNoch keine Bewertungen