Beruflich Dokumente

Kultur Dokumente

The Influence of Knudsen Number On The Hydrodynamic Development Length Within Parallel Plate Micro-Channels

Hochgeladen von

Chong Jen HawOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

The Influence of Knudsen Number On The Hydrodynamic Development Length Within Parallel Plate Micro-Channels

Hochgeladen von

Chong Jen HawCopyright:

Verfügbare Formate

Advances in Fluid Mechanics IV Eds. M. Rahman, R. Verhoeven and C.A. Brebbia WIT Press, Southampton, UK, 2002. pp.

207-216. ISBN: 1-85312-910-0

The influence of Knudsen number on the hydrodynamic development length within parallel plate micro-channels

R.W. Barber & D.R. Emerson

Centre for Microfluidics, CLRC Daresbury Laboratory, U.K.

Abstract

One of the major difficulties in predicting the flow of gases through micron-sized channels can be attributed to the breakdown of the continuum flow assumption in the Navier-Stokes equations. If the dimensions of a channel are comparable to the mean free path of the gas molecules, the fluid can no longer be regarded as being in thermodynamic equilibrium and a variety of non-continuum or rarefaction effects will occur. Velocity profiles, mass flow rates and boundary wall shear stresses are all influenced by the non-continuum regime. In addition, the length of the hydrodynamic development region at the entrance to a channel may also be affected. The present study examines the role of the Reynolds and Knudsen numbers on the hydrodynamic development length at the entrance to parallel plate microchannels. Numerical simulations are carried out over a range of Knudsen numbers covering the continuum and slip-flow regimes ( 0 Kn 0.1 ). The results demonstrate that at the upper limit of the slip-flow regime ( Kn 0.1 ), the entrance development region is almost 25% longer than that predicted using continuum flow theory.

1 Introduction

The development of precision fabrication techniques for constructing MicroElectro-MechanicalSystems (MEMS) has emerged as one of the most exciting and revolutionary new areas of technology. For example, the use of microfluidic systems to manipulate small volumes of fluid will generate significant benefits in the chemical engineering and bio-chemical industries by enabling faster mixing

208

Advances in Fluid Mechanics IV

and reaction times, increased chemical yields and faster throughput rates for chemical assays. In addition, the small length scales of microfluidic systems offer the prospect of developing miniaturised pressure sensors and chemical detectors with extremely high frequency responses. Advanced microfluidic components currently under development include miniaturised heat-exchangers to cool integrated circuits, micro-reactors to generate small quantities of dangerous or expensive chemicals, lab-on-a-chip bio-chemical sensors which perform complex biological assays on sub-nanolitre samples and hand-held gas chromatography systems for the detection of trace concentrations of air-borne pollutants. A common link between these examples is the requirement to move fluid through the device in a controlled manner. However, one of the emerging research issues is the realisation that the fluid mechanics at such small scales is not the same as that experienced in the macroscopic world. Early investigations of non-continuum gas flows in channels were conducted by researchers in the rarefied gas community who were primarily interested in low-density applications such as high-altitude aircraft or vacuum technology. However, advances in micromachining technology have enabled flow channels to be constructed with sub-micron depths leading to a new area of research where rarefied gas behaviour is relevant. For example, recent experiments conducted by Pfahler et al. [1], Harley et al. [2] and Arkilic et al. [3,4,5] on the transport of gases in silicon micro-machined channels confirm that conventional (continuum) analyses are unable to predict flow rates in micron-sized devices with any degree of accuracy.

2 Non-continuum analysis

For an ideal gas modelled as rigid spheres, the mean free path of the molecules, L, can be related to the temperature, T, and pressure, p, via kT L= (1) 2 p p s c2 where,

k = Boltzmann's constant = 1.380662 1023 J K -1 , T = temperature (K), p = pressure (Nm-2 ) and s c = collision diameter of the molecules (m).

The continuum assumption in the Navier-Stokes equations is valid provided the mean free path of the molecules is smaller than the characteristic dimension of the flow domain. If this condition is violated, the fluid will no longer be under local thermodynamic equilibrium and the linear relationship between the shear stress and rate of shear strain (Newtons law of viscosity) cannot be applied. Velocity profiles, boundary wall shear stresses, mass flow rates and pressure differences will then be influenced by non-continuum effects. In addition, the

Advances in Fluid Mechanics IV

209

conventional no-slip boundary condition imposed at the solid-gas interface will begin to break down even before the linear stress-strain relationship becomes invalid (Gad-el-Hak [6]). The ratio between the mean free path, L, and the characteristic dimension of the flow geometry, L, is commonly referred to as the Knudsen number, Kn: L Kn = . (2) L The value of the Knudsen number determines the degree of rarefaction of the gas and the validity of the continuum flow assumption. For Kn 0.001 , the continuum hypothesis is appropriate and the flow can be analysed using the Navier-Stokes equations with conventional no-slip boundary conditions. However, for 0.001 Kn 0.1 (commonly referred to as the slip-flow regime) rarefaction effects start to influence the flow and the Navier-Stokes equations can only be employed provided tangential slip-velocity boundary conditions are implemented along the walls of the flow domain [6,7]. Beyond Kn = 0.1 , the continuum assumption of the Navier-Stokes equations begins to break down and alternative simulation techniques such as particle based DSMC (Direct Simulation Monte Carlo) approaches must be adopted. Finally, for Kn 10 , the continuum approach breaks down completely and the regime can then be described as being a free molecular flow. The analysis of developing flows at the entrance to rectangular ducts has received considerable attention over the years. Whilst most researchers have concentrated their efforts on the no-slip (continuum) flow regime, several studies have considered the hydrodynamic entrance problem under rarefied conditions where the momentum transport starts to be affected by the discrete molecular composition of the gas. For example, Ebert & Sparrow [8] formulated an analytical slip-flow solution for a rectangular channel whilst Quarmby [9] and Gampert [10] used finite-difference simulations to investigate developing slipflow in circular pipes and parallel plates. In the present investigation, the role of the Reynolds and Knudsen numbers on the hydrodynamic development length at the entrance to a parallel plate micro-channel is investigated. The parallel-plate micro-channel is an important geometry as it forms the limiting flow condition for large aspect-ratio rectangular ducts commonly encountered in silicon micro-machined components. Knowledge of the expected hydrodynamic development length is particularly important when designing the layout of microfluidic inlet structures or when choosing a suitable location for the upstream boundary of a numerical model.

3 Governing hydrodynamic equations

The governing hydrodynamic equations for a continuous (infinitely divisible) fluid can be written in tensor notation as follows:

210

Advances in Fluid Mechanics IV

continuity:

r ( r uk ) + =0 t xk

momentum:

(3)

p ik ( ui ) ( uk ui ) + = + (4) t xk xi xk where u is the velocity, p is the pressure, is the fluid density and ik is the second-order stress tensor. For a Newtonian, isotropic fluid, the stress tensor is given by u j u u ik = i + k + (5) x ik xk xi j where and are the first and second coefficients of viscosity and d ik is the unit second-order tensor (Kronecker delta). Implementing Stokes continuum hypothesis allows the first and second coefficients of viscosity to be related via 2 + =0 (6) 3 although the validity of the above equation has occasionally been questioned for fluids other than dilute monatomic gases (Gad-el-Hak [11]).

3.1 Slip-velocity boundary conditions To account for non-continuum effects in the slip-flow regime ( Kn 0.1), the Navier-Stokes equations are solved in conjunction with the tangential slipvelocity boundary condition first proposed by Basset [12]:

t = ut

(7)

where ut is the tangential slip-velocity at the wall, t is the shear stress at the wall and is the slip coefficient. Schaaf & Chambre [13] have shown that the slip coefficient can be related to the mean free path of the molecules as follows: m (8) b= 2s L s where s is the tangential momentum accommodation coefficient (TMAC) and L is the mean free path. The tangential momentum accommodation coefficient is introduced to account for the reduction in the momentum of gas molecules colliding with the wall as described by Schaaf & Chambre [13]. For an idealised surface (perfectly smooth at the molecular level), the angles of incidence and reflection are identical and therefore the molecules conserve their tangential momentum. This is referred to as specular reflection and results in perfect slip at the boundary ( 0). Conversely, in the case of an extremely rough surface, the molecules are reflected at totally random angles and lose, on average, their

Advances in Fluid Mechanics IV

211

entire tangential momentum: a situation commonly referred to as diffusive reflection ( = 1). The crystalline surfaces found in silicon micro-machined components often exhibit sub-unity tangential momentum accommodation, with s typically ranging from 0.8 to 1.0 (Arkilic et al. [5]). Equations (7) and (8) can be combined and rearranged to give 2 L ut = t . (9) At this stage it is convenient to recast the mean free path in the above equation in terms of a non-dimensionalised Knudsen number, Kn. The choice of the characteristic length scale depends upon the flow geometry under consideration. In the case of non-circular ducts, a convenient length scale can be found by invoking the concept of the hydraulic diameter of the cross-section, Dh: 4 area 4A = Dh = . (10) wetted perimeter P For the specific case of flow between parallel plates separated by a distance, H, it can readily be shown that the hydraulic diameter equals twice the plate separation. The Knudsen number, Kn, can therefore be defined as the ratio of the mean free path of the gas molecules to the hydraulic diameter of the duct: L L = Kn = . (11) Dh 2 H Substituting equation (11) into (9) allows the tangential slip-velocity at the solid perimeter wall to be written as 2 Kn 2 H ut = t . (12) The governing hydrodynamic equations were solved using THOR-2D a two-dimensional finite-volume Navier-Stokes solver developed by the Computational Engineering Group at CLRC Daresbury Laboratory. Since most microfluidic devices operate at extremely low Mach numbers, compressibility effects were ignored in the present study. In addition, isothermal conditions were assumed throughout the flow domain. 3.2 Inflow/outflow boundary conditions At the entrance to the duct, a uniform non-dimensionalised velocity distribution was prescribed parallel to the longitudinal axis of the channel:

u = 1 and v = 0

at

x=0 , 0 yH

(13)

whilst at the outlet, the axial gradients of the flow variables were set to zero: u v = 0 and =0 at x=l , 0 y H (14) x x where l is the total length of duct.

212

Advances in Fluid Mechanics IV

3.3 Hydrodynamic development length When a viscous fluid enters a duct, the uniform velocity distribution at the entrance is gradually redistributed towards the centreline due to the retarding influence of the shear stresses along the side walls. Ultimately the fluid will reach a location where the velocity profile no longer changes in the axialdirection, and under such conditions the flow is said to be fully-developed. Theoretically, the required distance to reach the fully-developed solution is infinitely large. However, for practical engineering calculations, the hydrodynamic development length, L, is arbitrarily defined as the axial distance required for the centre line velocity to reach 99% of the fully-developed value. The fully-developed slip-velocity profile in a parallel plate micro-channel can readily be obtained from the axial direction Navier-Stokes equation. It can be shown that the theoretical velocity profile across a micro-channel of height, H, is given by

y y2 2s Kn 1 + 12 2 s Kn u ( y) = 6 u 2 + 2 s s H H

(15)

where u is the mean velocity in the duct. In addition, the maximum velocity along the centreline of the duct (y=H/2) can be derived as

2s 3 Kn 1 + 12 2 s Kn . umax = u 1 + 8 s 2 s

(16)

As an aside, in the limit of Kn 0 (i.e. under continuum flow conditions), equation (16) reverts to the familiar no-slip (NS) solution given by Poiseuille theory: 3 umax ( NS) = u . (17) 2 Using equation (16) in conjunction with a 99% velocity cut-off point allows the hydrodynamic development length to be defined as the location where the longitudinal velocity at the centre of the duct reaches a value of

2s Kn 1 + 12 2 s Kn . u = 1.485 u 1 + 8 s s

(18)

4 Results and discussion

The simulations assessed the entrance development length over a range of Reynolds and Knudsen numbers in the laminar slip-flow regime. In the present study, the Reynolds number was varied from Re = 1 to Re = 400 whilst the Knudsen number was varied from Kn = 0 (continuum flow) to Kn = 0.1 (a frequently adopted upper bound for the slip-flow regime). The upper limit of Re = 400 was chosen since previous experimental work by Wu & Little [14] has

Advances in Fluid Mechanics IV

213

suggested that the transition to turbulence in micro-geometries may occur at Reynolds numbers as low as 400. In the absence of additional information, the tangential momentum accommodation coefficient, , was assumed to have a value of unity. The Reynolds and Knudsen numbers were defined using the hydraulic diameter of the cross-section as the characteristic length scale, i.e. u 2H L Re = Kn = and . (19) 2H Preliminary validation of the hydrodynamic code was accomplished by comparing the analytical velocity profile across the duct (equation 15) against predictions from the downstream boundary of the numerical model. The tests involved a number of different grid resolutions, including meshes composed of 51q21, 101q41 and 201q81 nodes. In addition, numerical experimentation was used to decide upon a suitable length of duct, l. The computational domains were curtailed a finite distance downstream of the entrance, with the location chosen so as not to affect the computed entrance length. For Reynolds numbers up to 400, it was found that duct lengths of l = 20 Dh were sufficient to achieve a reliable estimate of hydrodynamic development length. In addition, an exponential stretching of the meshes in the axial-direction was implemented to achieve a finer grid resolution in the critical boundary-layer formation zone at the entrance. Hydrodynamic development lengths were computed for three separate Knudsen numbers ( Kn = 0 , 0.05 and 0.10 ) and a range of Reynolds numbers between 1 and 400. Figure 1 illustrates the non-dimensionalised entrance development length as a function of Reynolds number for the 201q81 mesh. Superimposed on the results are the continuum ( Kn = 0) development length equations presented by Atkinson et al. [15] and Chen [16]. Atkinson et al. found that the non-dimensionalised development length for a parallel-plate duct could be related to the Reynolds number via the following linear relationship: L = 0.3125 + 0.011 Re (20) Dh whereas Chen [16] proposed a more elaborate function of the form: L 0.315 = + 0.011 Re . (21) Dh 0.0175 Re + 1 Figure 1 indicates that the present continuum results ( Kn = 0) are in good agreement with the hydrodynamic entrance lengths predicted by Chen. It can also be seen that Atkinson et al.s solution tends to over-predict the development length at all but the lowest Reynolds numbers. More importantly, the present results show that the Knudsen number has a significant effect on the length of the development region. Inspection of Figure 1 reveals that at a Reynolds number of 400, the entrance length for a Knudsen number of 0.1 is approximately 25% longer than the corresponding no-slip solution. Even at relatively low Reynolds numbers, the increase in the length of the development region may still be important. It can therefore be concluded that the formulae proposed by Atkinson

214

Advances in Fluid Mechanics IV

et al. [15] and Chen [16] for the parallel-plate geometry are no longer valid in the slip-flow regime and consequently a new development length equation accounting for both the Reynolds number and Knudsen number must be evaluated.

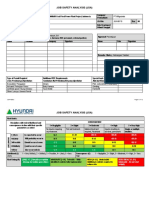

6 Kn=0.0 Kn=0.05 Kn=0.10 Atkinson et al. (Kn=0.0) Chen (Kn=0.0)

L/Dh

0 0 100 200 300 400

Re

Figure 1: Non-dimensionalised development length for rarefied slip-flow in a parallel plate micro-channel. A non-linear least-squares curve-fitting procedure employing the LevenbergMarquardt method was used to determine the relationship between L / Dh , Re and Kn. The effect of the Knudsen number was taken into account by multiplying the coefficient in the second term of Chen's development length equation (21) by a correction factor of the form:

1 + A Kn (22) 1 + B Kn where A and B are constants and Kn is defined as 2 Kn = Kn . (23) The Knudsen number correction shown in equation (22) was chosen because the analytical expression for the fully-developed centreline velocity has a similar Knudsen number modification factor. Applying the Levenberg-Marquardt leastsquares technique yields the following expression for the hydrodynamic development length: 1 + 14.78 Kn L 0.332 = + 0.011 Re . Dh 0.0271 Re + 1 1 + 9.78 Kn

(24)

Advances in Fluid Mechanics IV

215

6 Kn=0.0 Kn=0.05 Kn=0.10 Least-squares fit Kn=0.0 Least-squares fit Kn=0.05 Least-squares fit Kn=0.10

L/Dh

0 0 100 200 300 400

Re

Figure 2: Least-squares fit of non-dimensionalised development length for rarefied slip-flow in a parallel plate micro-channel. Figure 2 illustrates the results of the Levenberg-Marquardt least squares fit. It can be seen that the proposed equation provides a good representation of the numerical development length data. Moreover, the linearity of the Reynolds number dependency in the second term of equation (24) implies that the expression will provide a reliable estimate of hydrodynamic development length up to the transition to turbulence. The proposed entrance length equation should therefore be appropriate for the entire laminar slip-flow regime.

5 Conclusions

An investigation of low Reynolds number rarefied gas behaviour at the entrance of a parallel-plate micro-channel has been conducted using a specially adapted two-dimensional Navier-Stokes solver. The hydrodynamic model is applicable to the slip-flow regime which is valid for Knudsen numbers between 0 < Kn 0.1 . Within this range, rarefaction effects are important but the flow can still be modelled using the Navier-Stokes equations provided tangential slip-velocity boundary conditions are implemented along the walls of the flow domain. The numerical model has indicated that the Knudsen number has a significant effect on the hydrodynamic development length at the entrance to parallel plates. At the upper limit of the slip-flow regime ( Kn 0.1) , entrance lengths have been shown to be approximately 25% longer than those experienced in the continuum (no-slip) regime.

216

Advances in Fluid Mechanics IV

References

[1] Pfahler, J., Harley, J., Bau, H. & Zemel, J.N., Gas and liquid flow in small channels. DSC-Vol. 32, Micromechanical Sensors, Actuators and Systems, ASME, pp. 49-60, 1991. [2] Harley, J.C., Huang, Y., Bau, H.H. & Zemel, J.N., Gas flow in microchannels. J. Fluid Mech., 284, pp. 257-274, 1995. [3] Arkilic, E.B., Breuer, K.S. & Schmidt, M.A., Gaseous flow in microchannels. FED-Vol. 197, Application of Microfabrication to Fluid Mechanics, ASME, pp. 57-66, 1994. [4] Arkilic, E.B., Schmidt, M.A. & Breuer, K.S., Gaseous slip flow in long micro-channels. J. Micro-Electro-Mechanical Systems, 6(2), pp. 167-178, 1997. [5] Arkilic, E.B., Schmidt, M.A. & Breuer, K.S., TMAC measurement in silicon micromachined channels. Rarefied Gas Dynamics, 20, Beijing University Press, 1997. [6] Gad-el-Hak, M., The fluid mechanics of microdevices The Freeman Scholar Lecture. Trans. ASME, J. Fluids Engineering, 121, pp. 5-33, 1999. [7] Beskok, A. & Karniadakis, G.E., Simulation of heat and momentum transfer in complex microgeometries. J. Thermophysics and Heat Transfer, 8(4), pp. 647-655, 1994. [8] Ebert, W.A. & Sparrow, E.M., Slip flow in rectangular and annular ducts. Trans. ASME, J. Basic Engineering, 87, pp. 1018-1024, 1965. [9] Quarmby, A., A finite-difference analysis of developing slip flow. Applied Scientific Research, 19, pp. 18-33, 1968. [10] Gampert, B., Inlet flow with slip. Rarefied Gas Dynamics, 10, pp. 225-235, 1976. [11] Gad-el-Hak, M., Questions in fluid mechanics: Stokes hypothesis for a Newtonian, isotropic fluid. Trans. ASME, J. Fluids Engineering, 117, pp. 35, 1995. [12] Basset, A.B., A Treatise on Hydrodynamics, Cambridge University Press, 1888. [13] Schaaf, S.A. & Chambre, P.L., Flow of Rarefied Gases, Princeton University Press, 1961. [14] Wu, P. & Little, W.A., Measurement of friction factors for the flow of gases in very fine channels used for micro-miniature Joule-Thomson refrigerators. Cryogenics, pp. 273-277, 1983. [15] Atkinson, B., Brocklebank, M.P., Card, C.C.H. & Smith, J.M., Low Reynolds number developing flows. A.I.Ch.E. Journal, 15(4), pp. 548-553, 1969. [16] Chen, R.Y., Flow in the entrance region at low Reynolds numbers. Trans. ASME, J. Fluids Engineering, 95, pp. 153-158, 1973.

Das könnte Ihnen auch gefallen

- The Limits of Navier-Stokes Theory and Kinetic Extensions For Describing Small-Scale Gaseous HydrodynamicsDokument19 SeitenThe Limits of Navier-Stokes Theory and Kinetic Extensions For Describing Small-Scale Gaseous HydrodynamicsPrabal NegiNoch keine Bewertungen

- CFD Ball ValveDokument8 SeitenCFD Ball ValveKelvin Octavianus DjohanNoch keine Bewertungen

- CH 1Dokument24 SeitenCH 1Bireswar PaulNoch keine Bewertungen

- Mass Ow and Tangential Momentum Accomodation in Silicon Micromachined ChannelsDokument16 SeitenMass Ow and Tangential Momentum Accomodation in Silicon Micromachined ChannelsMauricio Fabian Duque DazaNoch keine Bewertungen

- International Journal of Numerical Methods For Heat & Fluid FlowDokument22 SeitenInternational Journal of Numerical Methods For Heat & Fluid FlowharshalsparksNoch keine Bewertungen

- Numerical Study of Cavitation Inception Due To Vortex/Vortex Interaction in A Ducted PropulsorDokument33 SeitenNumerical Study of Cavitation Inception Due To Vortex/Vortex Interaction in A Ducted PropulsorncharalaNoch keine Bewertungen

- Effect of Channel Dimensions On Micro PEM Fuel Cell Performance Using 3D ModelingDokument6 SeitenEffect of Channel Dimensions On Micro PEM Fuel Cell Performance Using 3D ModelingSergi C. CortadaNoch keine Bewertungen

- Results in Engineering: Ricardo VinuesaDokument11 SeitenResults in Engineering: Ricardo VinuesaSomesh MishraNoch keine Bewertungen

- Marine Structures: Muk Chen Ong, Torbjørn Utnes, Lars Erik Holmedal, Dag Myrhaug, Bjørnar PettersenDokument12 SeitenMarine Structures: Muk Chen Ong, Torbjørn Utnes, Lars Erik Holmedal, Dag Myrhaug, Bjørnar Pettersensam0025Noch keine Bewertungen

- Flow Over A CylinderDokument14 SeitenFlow Over A CylinderHariVathsalaNoch keine Bewertungen

- Numerical Modeling For Simulation Transient Flow in Distribution System With Crank-Nicolson MethodDokument9 SeitenNumerical Modeling For Simulation Transient Flow in Distribution System With Crank-Nicolson MethodInternational Journal of Structronics & MechatronicsNoch keine Bewertungen

- 1 Transport Laws: 1.1 Boundary Slip of LiquidsDokument14 Seiten1 Transport Laws: 1.1 Boundary Slip of Liquidshemendrag_1Noch keine Bewertungen

- Hanjalic-Launder JFM Vol52 1972Dokument30 SeitenHanjalic-Launder JFM Vol52 1972LucaNoch keine Bewertungen

- Numerical Study of Gas-Solid Flow in A Cyclone Separator: B. Wang, D. L. Xu, G. X. Xiao, K. W. Chu and A. B. YUDokument6 SeitenNumerical Study of Gas-Solid Flow in A Cyclone Separator: B. Wang, D. L. Xu, G. X. Xiao, K. W. Chu and A. B. YUAzharuddin Ehtesham FarooquiNoch keine Bewertungen

- Lid Driven Cavity CFD Simulation Report by S N TopannavarDokument127 SeitenLid Driven Cavity CFD Simulation Report by S N TopannavarAkshay PatilNoch keine Bewertungen

- Pressure Transient Model of Water-Hydraulic Pipelines With CavitationDokument14 SeitenPressure Transient Model of Water-Hydraulic Pipelines With Cavitationjayant pathakNoch keine Bewertungen

- A Project Report On Turbulent FlowsDokument14 SeitenA Project Report On Turbulent FlowsNishant KumarNoch keine Bewertungen

- Assessment of A New Fluent Model For Particle Dispersion in Turbulent FlowsDokument18 SeitenAssessment of A New Fluent Model For Particle Dispersion in Turbulent FlowsgarridolopezNoch keine Bewertungen

- Knu ViscoDokument8 SeitenKnu ViscoJOAQUIM P JOSSYNoch keine Bewertungen

- Experimental Investigation of Microscale Effects IDokument11 SeitenExperimental Investigation of Microscale Effects IMauricio Fabian Duque DazaNoch keine Bewertungen

- 169Dokument24 Seiten169zynpyasaNoch keine Bewertungen

- Slip Flow McVeighDokument8 SeitenSlip Flow McVeighTubaguts1234Noch keine Bewertungen

- 1999 DaunheurDokument9 Seiten1999 DaunheurAzhar Ali ZafarNoch keine Bewertungen

- Prediction of Two-Phase Pipe Flows Using Simple Closure Relations in A 2D Two-Fluid ModelDokument13 SeitenPrediction of Two-Phase Pipe Flows Using Simple Closure Relations in A 2D Two-Fluid Modelvivek9199Noch keine Bewertungen

- Cold flow analysis of trapped vortex combustorDokument12 SeitenCold flow analysis of trapped vortex combustorAnonymous 6SivdzjNoch keine Bewertungen

- Convection Heat Transfer in Micro-ChannelsDokument50 SeitenConvection Heat Transfer in Micro-ChannelsBehzad Mohajer100% (1)

- Quasi-3D Modelling of Two-Phase Slug Flow in PipesDokument12 SeitenQuasi-3D Modelling of Two-Phase Slug Flow in PipeskumarNoch keine Bewertungen

- Hydrodynamic slug modelingDokument11 SeitenHydrodynamic slug modelingfanziskusNoch keine Bewertungen

- Draft ASMEDokument21 SeitenDraft ASMEManoj TripathiNoch keine Bewertungen

- Wang 2011Dokument23 SeitenWang 2011MortezaNoch keine Bewertungen

- Numerical and Experimental Study of Classical Hydraulic JumpDokument16 SeitenNumerical and Experimental Study of Classical Hydraulic JumpM A AbdulrazaqNoch keine Bewertungen

- A New Concept For The Correlation of Relative Permeability Data and Capillary Pressure For Microfissured RocksDokument12 SeitenA New Concept For The Correlation of Relative Permeability Data and Capillary Pressure For Microfissured RocksRosa K Chang HNoch keine Bewertungen

- Direct Numerical Simulation of Turbulent in A Square Duct: Asmund Husert Sedat BiringenDokument31 SeitenDirect Numerical Simulation of Turbulent in A Square Duct: Asmund Husert Sedat BiringenMaiman LatoNoch keine Bewertungen

- Kravchenko 2016 J. Phys.: Conf. Ser. 774 012026Dokument8 SeitenKravchenko 2016 J. Phys.: Conf. Ser. 774 012026Muhammad NasrulNoch keine Bewertungen

- Characteristics of Inclined Thin Films, WavinesDokument12 SeitenCharacteristics of Inclined Thin Films, WavinesDzeli123Noch keine Bewertungen

- Vol2 No3 6Dokument6 SeitenVol2 No3 6lokeshmopuriNoch keine Bewertungen

- A Computational Approach For The Unsteady Flow of Maxw - 2018 - Alexandria Engin PDFDokument8 SeitenA Computational Approach For The Unsteady Flow of Maxw - 2018 - Alexandria Engin PDFJay KasodariyaNoch keine Bewertungen

- Application of CFD To Find The Dispersion of Contaminants inDokument13 SeitenApplication of CFD To Find The Dispersion of Contaminants inEjaz KNoch keine Bewertungen

- Simulation of Gas Flow in Microchannels With A SuddenDokument11 SeitenSimulation of Gas Flow in Microchannels With A SuddenAyoub HaranjaNoch keine Bewertungen

- Turbulence Modeling of The Von Karman Flow: Viscous and Inertial StirringsDokument39 SeitenTurbulence Modeling of The Von Karman Flow: Viscous and Inertial StirringsDeep PatelNoch keine Bewertungen

- Compressible Effects Modelling in Turbulent Cavitating p.8 p.18Dokument85 SeitenCompressible Effects Modelling in Turbulent Cavitating p.8 p.18劉平本Noch keine Bewertungen

- Articulo Jaime Gonzalez PDFDokument6 SeitenArticulo Jaime Gonzalez PDFFélix Gallo CruzNoch keine Bewertungen

- Modeling Concentration Polarization in Reverse Osmosis Processes PDFDokument18 SeitenModeling Concentration Polarization in Reverse Osmosis Processes PDFIbrahim Al-MutazNoch keine Bewertungen

- A New Role For Reduction in Pressure Drop in Cyclones Using Computational Fluid Dynamics TechniquesDokument9 SeitenA New Role For Reduction in Pressure Drop in Cyclones Using Computational Fluid Dynamics Techniquesmahreza189Noch keine Bewertungen

- Modeling Knudsen Layer Effects in Micro-Scale Backward-Facing Step FlowDokument15 SeitenModeling Knudsen Layer Effects in Micro-Scale Backward-Facing Step FlowjohnNoch keine Bewertungen

- ICONE16 Kesmiri PrePublic21!12!2007Dokument10 SeitenICONE16 Kesmiri PrePublic21!12!2007Vijay KumarNoch keine Bewertungen

- CFD Simulation of The Solid-Liquid Slurry FLow in A Pipeline (Ej) (NABIL, T El-SAWAF, I. El-NAHHAS, K.) (17th Int. Water Techn. Conf. IWTC17 2013) (14s)Dokument14 SeitenCFD Simulation of The Solid-Liquid Slurry FLow in A Pipeline (Ej) (NABIL, T El-SAWAF, I. El-NAHHAS, K.) (17th Int. Water Techn. Conf. IWTC17 2013) (14s)R_M_M_Noch keine Bewertungen

- Measurement and Modeling of Unsaturated Hydraulic Conductivity: Issues, Techniques and ApplicationsDokument16 SeitenMeasurement and Modeling of Unsaturated Hydraulic Conductivity: Issues, Techniques and Applicationszeeshansheikh7Noch keine Bewertungen

- Near-surface motions and air-water gas transfer ratesDokument37 SeitenNear-surface motions and air-water gas transfer ratesLeandro DijonNoch keine Bewertungen

- Batchelor Vs Stewartson Flow Structures in A Rotor Statotr CavityDokument58 SeitenBatchelor Vs Stewartson Flow Structures in A Rotor Statotr CavitykoolwaveoceanicNoch keine Bewertungen

- Comparison of LES and RANS Calculations of The Flow Around Bluff BodiesDokument21 SeitenComparison of LES and RANS Calculations of The Flow Around Bluff BodiesMahrukh ZAIDINoch keine Bewertungen

- Passive Scalar Mixing in A Turbulent Jet: Massimo FalchiDokument6 SeitenPassive Scalar Mixing in A Turbulent Jet: Massimo FalchiMassimo FalchiNoch keine Bewertungen

- Computational Investigation, On Thermohydraulic Characterization of Liquid Hydrogen and Liquid Nitrogen in MicrochannelsDokument14 SeitenComputational Investigation, On Thermohydraulic Characterization of Liquid Hydrogen and Liquid Nitrogen in MicrochannelsTJPRC PublicationsNoch keine Bewertungen

- Catamaran Wetdeck Slamming Loads Using CFDDokument6 SeitenCatamaran Wetdeck Slamming Loads Using CFDAhmadA.SwidanNoch keine Bewertungen

- Aiaa 18973 703Dokument10 SeitenAiaa 18973 703Pablo ApasionadoNoch keine Bewertungen

- Attenuation of Cavity Flow Oscillation Through Leading Edge Flow ControlDokument25 SeitenAttenuation of Cavity Flow Oscillation Through Leading Edge Flow ControlRehan NaseerNoch keine Bewertungen

- Ciclones Modelamiento FlujoDokument97 SeitenCiclones Modelamiento Flujodaraos3Noch keine Bewertungen

- International Conference on Nuclear Energy in Slovenia 2006Dokument8 SeitenInternational Conference on Nuclear Energy in Slovenia 2006Chien NguyenNoch keine Bewertungen

- Computational Fluid Mechanics: Selected PapersVon EverandComputational Fluid Mechanics: Selected PapersNoch keine Bewertungen

- Applied Mathematical Modelling: C.D. Argyropoulos, N.C. MarkatosDokument40 SeitenApplied Mathematical Modelling: C.D. Argyropoulos, N.C. MarkatoskaranbeeshmNoch keine Bewertungen

- Khatib Et Al. 2012 A Review of Solar Energy Modeling TechniquesDokument6 SeitenKhatib Et Al. 2012 A Review of Solar Energy Modeling TechniquesChong Jen HawNoch keine Bewertungen

- Tian Et Al. 2016 Numerical Model of A Parallel Flow Minichannel Evaporator With New Flow Boiling Heat Transfer CorrelationDokument13 SeitenTian Et Al. 2016 Numerical Model of A Parallel Flow Minichannel Evaporator With New Flow Boiling Heat Transfer CorrelationChong Jen HawNoch keine Bewertungen

- Radulescu and Robinson 2008 Numerical Study of Marangoni - Thermocapillary Convection Influence During Boiling Heat Transfer in MinichannelsDokument8 SeitenRadulescu and Robinson 2008 Numerical Study of Marangoni - Thermocapillary Convection Influence During Boiling Heat Transfer in MinichannelsChong Jen HawNoch keine Bewertungen

- Krishnamurthy and Peles 2010 Flow Boiling Heat Transfer On Micro Pin Fins Entrenched in A MicrochannelDokument10 SeitenKrishnamurthy and Peles 2010 Flow Boiling Heat Transfer On Micro Pin Fins Entrenched in A MicrochannelChong Jen HawNoch keine Bewertungen

- Alavi 2010 Pool Boiling Heat Transfer To Pure LiquidsDokument7 SeitenAlavi 2010 Pool Boiling Heat Transfer To Pure LiquidsChong Jen HawNoch keine Bewertungen

- Alagesan 2012 Flow Boiling Heat Transfer in Mini and Micro Channels - A State of The Art ReviewDokument13 SeitenAlagesan 2012 Flow Boiling Heat Transfer in Mini and Micro Channels - A State of The Art ReviewChong Jen HawNoch keine Bewertungen

- Abarajith and Dhir 2002 A Numerical Study of The Effect of Contact Angle On The Dynamics of A Single Bubble During Pool BoilingDokument9 SeitenAbarajith and Dhir 2002 A Numerical Study of The Effect of Contact Angle On The Dynamics of A Single Bubble During Pool BoilingChong Jen HawNoch keine Bewertungen

- Magnini Et Al. 2013 Numerical Investigation of Hydrodynamics and Heat Transfer of Elongated Bubbles During Flow Boiling in A MicrochannelDokument21 SeitenMagnini Et Al. 2013 Numerical Investigation of Hydrodynamics and Heat Transfer of Elongated Bubbles During Flow Boiling in A MicrochannelChong Jen HawNoch keine Bewertungen

- Shkarah Et Al. 2014 Analysis of Boiling in Rectangular Micro Channel Heat SinkDokument4 SeitenShkarah Et Al. 2014 Analysis of Boiling in Rectangular Micro Channel Heat SinkChong Jen HawNoch keine Bewertungen

- Szczukiewicz Et Al. 2014 Proposed Models, Ongoing Experiments, and Latest Numerical Simulation of Microchannel TP FB - (CP)Dokument18 SeitenSzczukiewicz Et Al. 2014 Proposed Models, Ongoing Experiments, and Latest Numerical Simulation of Microchannel TP FB - (CP)Chong Jen HawNoch keine Bewertungen

- Alexeev Et Al. 2006 A Numerical Model For The Thermocapillary Flow and Heat Transfer in A Thin Liquid Film On A Microstructured WallDokument18 SeitenAlexeev Et Al. 2006 A Numerical Model For The Thermocapillary Flow and Heat Transfer in A Thin Liquid Film On A Microstructured WallChong Jen HawNoch keine Bewertungen

- Fiorelli Et Al. 2012 Semi-Empirical Model of MOST and Passive Devices Focused On Narrowband RF BlocksDokument16 SeitenFiorelli Et Al. 2012 Semi-Empirical Model of MOST and Passive Devices Focused On Narrowband RF BlocksChong Jen HawNoch keine Bewertungen

- Merek and Straub 2001 The Origin of Thermocapillary Convection in Subcooled Nucleate Pool BoilingDokument14 SeitenMerek and Straub 2001 The Origin of Thermocapillary Convection in Subcooled Nucleate Pool BoilingChong Jen HawNoch keine Bewertungen

- Kuo and Peles 2009 Flow Boiling of Coolant (HFE-7000) Inside Structured and Plain Wall MicrochannelsDokument9 SeitenKuo and Peles 2009 Flow Boiling of Coolant (HFE-7000) Inside Structured and Plain Wall MicrochannelsChong Jen HawNoch keine Bewertungen

- Houshmand and Peles 2014 Impact of Flow Dynamics On Heat Transfer of Bubbly Flow in A Microchannel-Zpz PDFDokument8 SeitenHoushmand and Peles 2014 Impact of Flow Dynamics On Heat Transfer of Bubbly Flow in A Microchannel-Zpz PDFChong Jen HawNoch keine Bewertungen

- Krishnamurthy and Peles 2010 Flow Boiling Heat Transfer On Micro Pin Fins Entrenched in A MicrochannelDokument10 SeitenKrishnamurthy and Peles 2010 Flow Boiling Heat Transfer On Micro Pin Fins Entrenched in A MicrochannelChong Jen HawNoch keine Bewertungen

- Surface tension forces induce convection cells in thin liquid filmsDokument12 SeitenSurface tension forces induce convection cells in thin liquid filmsChong Jen Haw100% (1)

- Chang and Pan 2007 Two-Phase Flow Instability For Boiling in A Microchannel Heat SinkDokument11 SeitenChang and Pan 2007 Two-Phase Flow Instability For Boiling in A Microchannel Heat SinkChong Jen HawNoch keine Bewertungen

- Younes and Hassan 2012 An Analytical Model of Flow Boiling Heat Transfer For Slug Flow in A Single Circular Horizontal Micro-Channel PDFDokument8 SeitenYounes and Hassan 2012 An Analytical Model of Flow Boiling Heat Transfer For Slug Flow in A Single Circular Horizontal Micro-Channel PDFChong Jen HawNoch keine Bewertungen

- Rosa Et Al. 2009 Single-Phase Heat Transfer in Microchannels - The Importance of Scaling EffectsDokument22 SeitenRosa Et Al. 2009 Single-Phase Heat Transfer in Microchannels - The Importance of Scaling EffectsChong Jen HawNoch keine Bewertungen

- A Guided Tour Through Buoyancy Driven Flows and Mixing: Achim Wirth November 12, 2014Dokument66 SeitenA Guided Tour Through Buoyancy Driven Flows and Mixing: Achim Wirth November 12, 2014Carl WoodsNoch keine Bewertungen

- Houshmand and Peles 2014 Impact of Flow Dynamics On Heat Transfer of Bubbly Flow in A Microchannel-Zpz PDFDokument8 SeitenHoushmand and Peles 2014 Impact of Flow Dynamics On Heat Transfer of Bubbly Flow in A Microchannel-Zpz PDFChong Jen HawNoch keine Bewertungen

- Thakkar Et Al. 2014 Thermal and Hydraulic Characteristics of Single Phase Flow in Mini-Channel For Electronic Cooling - ReviewDokument8 SeitenThakkar Et Al. 2014 Thermal and Hydraulic Characteristics of Single Phase Flow in Mini-Channel For Electronic Cooling - ReviewChong Jen HawNoch keine Bewertungen

- Younes and Hassan 2012 An Analytical Model of Flow Boiling Heat Transfer For Slug Flow in A Single Circular Horizontal Micro-Channel PDFDokument8 SeitenYounes and Hassan 2012 An Analytical Model of Flow Boiling Heat Transfer For Slug Flow in A Single Circular Horizontal Micro-Channel PDFChong Jen HawNoch keine Bewertungen

- Forster & Zuber 1954 Growth of A Vapor Bubble in A Superheated LiquidDokument5 SeitenForster & Zuber 1954 Growth of A Vapor Bubble in A Superheated LiquidChong Jen HawNoch keine Bewertungen

- Younes and Hassan 2012 An Analytical Model of Flow Boiling Heat Transfer For Slug Flow in A Single Circular Horizontal Micro-Channel PDFDokument8 SeitenYounes and Hassan 2012 An Analytical Model of Flow Boiling Heat Transfer For Slug Flow in A Single Circular Horizontal Micro-Channel PDFChong Jen HawNoch keine Bewertungen

- Fluid flow and heat transfer characteristics of low temperature two-phase micro-channel heat sinksDokument15 SeitenFluid flow and heat transfer characteristics of low temperature two-phase micro-channel heat sinksChong Jen HawNoch keine Bewertungen

- Houshmand and Peles 2014 Impact of Flow Dynamics On Heat Transfer of Bubbly Flow in A Microchannel-Zpz PDFDokument8 SeitenHoushmand and Peles 2014 Impact of Flow Dynamics On Heat Transfer of Bubbly Flow in A Microchannel-Zpz PDFChong Jen HawNoch keine Bewertungen

- Lee & Mudawar 2008 Fluid Flow and Heat Transfer Characteristics of Low Temperature Two Phase Microchannel Heat Sink - P1Dokument12 SeitenLee & Mudawar 2008 Fluid Flow and Heat Transfer Characteristics of Low Temperature Two Phase Microchannel Heat Sink - P1Chong Jen HawNoch keine Bewertungen

- Acceptance Test PlanDokument12 SeitenAcceptance Test Planapi-3806986Noch keine Bewertungen

- Hydrology Lecture01Dokument24 SeitenHydrology Lecture01Mohd. YunusNoch keine Bewertungen

- The Shell and Shell Scripting: Echo $SHELL - To See The Working Shell in SSHDokument12 SeitenThe Shell and Shell Scripting: Echo $SHELL - To See The Working Shell in SSHThai PhuongNoch keine Bewertungen

- Fuel Pressure Regulator - Remove and InstallDokument3 SeitenFuel Pressure Regulator - Remove and InstallGerardo VelazquezNoch keine Bewertungen

- Reaffirmed Indian Standards for Water Resources DepartmentDokument2 SeitenReaffirmed Indian Standards for Water Resources Departmentjamjam75Noch keine Bewertungen

- Blueendo MorcellatorDokument7 SeitenBlueendo MorcellatorLia GuslianiNoch keine Bewertungen

- Planning of Electrical NetworksDokument32 SeitenPlanning of Electrical NetworksSerge RINAUDONoch keine Bewertungen

- Instruction Manual Fisher 657 Diaphragm Actuator Sizes 30 30i Through 70 70i 87 en 122366Dokument32 SeitenInstruction Manual Fisher 657 Diaphragm Actuator Sizes 30 30i Through 70 70i 87 en 122366APE MKTNoch keine Bewertungen

- Detailed Analysis of Plane Table SurveyingDokument11 SeitenDetailed Analysis of Plane Table SurveyingNirbhay SinghNoch keine Bewertungen

- Otis Relay Coils SpecificationsDokument1 SeiteOtis Relay Coils SpecificationsDamian Alberto EspositoNoch keine Bewertungen

- IWA SG Global TrendsDokument113 SeitenIWA SG Global Trendsandik_yNoch keine Bewertungen

- Va80 PDFDokument4 SeitenVa80 PDFomar leonNoch keine Bewertungen

- Stampingjournal20130102 DLDokument36 SeitenStampingjournal20130102 DLWaqar MansoorNoch keine Bewertungen

- PHD Thesis BentzDokument320 SeitenPHD Thesis Bentzcrusanu50% (2)

- (CIDECT DG1) - Design Guide For Circular Hollow Section (CHS) Joints Under Predominantly Static LoadingDokument142 Seiten(CIDECT DG1) - Design Guide For Circular Hollow Section (CHS) Joints Under Predominantly Static Loading_at_to_50% (2)

- Hazardous Area ClassificationDokument15 SeitenHazardous Area ClassificationpmnasimNoch keine Bewertungen

- Attribute Achievement FormDokument14 SeitenAttribute Achievement FormPablo Guzmán López0% (2)

- Stability Data BookletDokument18 SeitenStability Data BookletPaul Ashton25% (4)

- ABB MNS System GuideDokument34 SeitenABB MNS System GuideLeslie HallNoch keine Bewertungen

- Hospital Management SystemDokument63 SeitenHospital Management Systemsanjay yadavNoch keine Bewertungen

- CalibrationDokument7 SeitenCalibrationstolen mechieducNoch keine Bewertungen

- UAE Visa Occupation ListDokument89 SeitenUAE Visa Occupation ListSiddharth JaloriNoch keine Bewertungen

- N248J ManualDokument13 SeitenN248J ManualChit KhunNoch keine Bewertungen

- Terminal Blocks: KasugaDokument6 SeitenTerminal Blocks: KasugaKs MuraliNoch keine Bewertungen

- Tiny House MovementDokument51 SeitenTiny House MovementAngelique Lucille PumanesNoch keine Bewertungen

- Mechanics of A Diesel Fuel Injection SystemDokument8 SeitenMechanics of A Diesel Fuel Injection Systemekitriandi0% (1)

- Jsa-Wif-9 Pulling CableDokument12 SeitenJsa-Wif-9 Pulling CableY a n i. A h m e dNoch keine Bewertungen

- 1756 Controllogix I/O ModulesDokument7 Seiten1756 Controllogix I/O ModulesminurajraNoch keine Bewertungen

- Terumo BCT Trima Accel Blood Collection System - Service ManualDokument340 SeitenTerumo BCT Trima Accel Blood Collection System - Service Manualmorton1472Noch keine Bewertungen

- SEP2 MeterViewDokument23 SeitenSEP2 MeterViewmarcofffmota3196Noch keine Bewertungen