Beruflich Dokumente

Kultur Dokumente

Yuvraj Sir Word Document

Hochgeladen von

Mahesh SatheOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Yuvraj Sir Word Document

Hochgeladen von

Mahesh SatheCopyright:

Verfügbare Formate

4

TRANSFORMER

Introduction : The transformer is a static device (i.e. the one which does not contain any rotating or moving parts) which is used to transfer electrical energy from one ac circuit to another ac circuit, with increase or decrease in voltage/ current but without any changes in frequency.

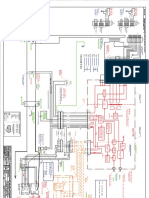

Types of Transformer : Transformers are designed for either single-phase or three-phase supply. Accordingly they are called as single-phase transformers or three-phase transformers. However the principle of operation for both the types is same. Principle of Operation : The construction of single-phase transformer is as shown in Fig.(a) below. It consists of two highly inductive coils (windings) wound on an iron or steel core. The winding (coil) connected to the ac supply is called as primary winding whereas the other one is called as the secondary winding. The ac supply is connected to the primary winding whereas the load is connected to the secondary winding.

The primary and secondary windings are isolated from each other as well as from the iron core. Thus there is absolutely no physical connection between the primary and secondary windings. Operating principle of a transformer 1. As soon as the primary winding is connected to the single-phase ac supply, an ac current starts flowing through it. 2. The ac primary current produces an alternating flux in the core. 3. Most of this changing flux gets linked with the secondary winding through the core. 4. The varying flux will induce voltage into the secondary winding according to the Faradays laws of electromagnetic induction. Thus due to primary current, there is an induced voltage in the secondary winding due to mutual induction. Hence the emf induced in the secondary is called as the mutually induced emf. Construction of a Transformer : The most important parts of a transformer are the windings (coil) and the core. Laminated Steel Core : The material used for the construction of the transformer core is silicon steel. It is used for its high permeability and low magnetic reluctance. Due to this the magnetic field produced in the core is very strong. The core is in the form of stacks of laminated thin steel sheets which are electrically isolated from each other. The laminations are typically 0.35 to 0.5 mm thick. The various ways of core construction are shown in below fig. The core is assembled in such a way, that the assembly provides a continuous path for the magnetic flux with a minimum air gap.

Windings of the Transformer : There are two types of windings : Concentric cylindrical type of winding Sandwiched type winding

Concentric cylindrical type of winding : The cylindrical coils (windings) are placed in the concentric way around the same limb with the low voltage winding placed inside and high voltage winding is placed outside it with proper insulation between the windings as shown in Fig. below.

Sandwiched type winding : The other type of windings is called as the sandwiched type winding which is shown in following fig. Here the high voltage and low voltage windings are divided into a number of small coils and then these small windings are interleaved as shown in fig.

Transformer Tank : The whole assembly of large size transformer is placed in a sheet metal tank. Inside the tank the assembly of the transformer is immersed in oil which acts as an insulator as well as a coolant. Function of transformer oil : The construction of the transformer should be such that the heat generated at the core and at the windings should be removed efficiently. Moreover, in order to avoid the insulation deterioration, the moisture should not be allowed to creep into the insulation. Both these objectives can be achieved by immersing the built up transformer in a closed tank filled with non-inflammable insulating oil called transformer oil.

In order to increase the cooling surface exposed to ambient, tubes or fins are provided on the outside of tank walls. Conservator : When the oil temperature increases, it expands and the air will be expelled out from the conservator. Whereas when the oil cools, it contracts and the outside air gets sucked inside the conservator. This process is called as the breathing of the transformer.

Breather : The apparatus through which breathing of the transformer takes place is called as Breather. The air goes in or out through the breather. To reduce the moisture content of this air, some drying agent (material that absorbs moisture) such as silica gel or calcium chloride is used in the breather. The dust particles present in the air are also removed by the breather. Buccholz Relay : As shown in above fig. there is a pipe connecting the tank and conservator. On this pipe a protective device called Buccholz Relay is mounted. When the transformer is about to be faulty and draws large currents, the oil becomes very hot and decomposes. During this process different types of gases are liberated. The Buccholz relay get operated by these gases and gives an alarm to the operator. If the fault continues to persist, then the relay will trip off the main circuit breaker to protect the transformer. Transformer Types : Transformers ------------------------------------------------------------ Core type Shell type Berry type

Core Type Transformer :

The core of this transformer is in the form of a rectangular frame made from laminations. It provides a single magnetic circuit as shown in fig. above. The primary and secondary windings are uniformly distributed on two limbs of the core.

Shell Type Transformer :

The primary and secondary windings are placed on the central limb of the core. The high voltage and low voltage windings are of sandwich type, which are in the form of interleaved pancakes. This type of core provides double magnetic circuit. This type of core provides a better mechanical support and protection for the windings.

Comparison of core type and shell type transformer Sr. No. 1. 2. 3. 4. 5. 6. Core type transformer The core has only one window. Windings encircle the core. Cylindrical windings are used. This transformer is easy to repair. Better cooling since more surface is exposed to the atmosphere. Less mechanical protection to the coils (windings). Shell type transformer The core has two windows. Core encircles the windings. Sandwich type windings are used. It is not so easy to repair. Cooling is not very affective. Better mechanical protection to the coils (windings).

Berry Type Transformers :

EMF Equation of a Transformer :

Expressions for the Induced Voltages : Let us now obtain the expressions for the induced voltages in the primary and secondary windings. Let N1 be the number of primary winding turns and N2 be the number of secondary winding turns. Let f be the frequency of the ac voltage applied to the primary winding and let m be the value of maximum flux. Let E1 be the rms induced voltage in the primary winding with N1 turns and E2 be the rms induced voltage in the secondary winding having N2 turns. Therefore RMS value of induced voltage in primary is, given by ... E1 = 4.44 f.N1. m volts .. (a) Similarly rms value of induced voltage in the secondary winding is, E2 = 4.44 f.N2. m volts (b) Equations (a) and (b) represent the EMF equations of a transformer.

Factors affecting the induced Emf : The factors affecting the induced emf are : 1. Flux m 2. Frequency of applied voltage.

3. Number of turns N.

Voltage and Current Ratios of a Transformer : For obtaining the voltage and current ratios of a transformer, consider the elementary transformer shown in fig.

Voltage Ratios for the Transformer Without Load :

Transformation Ratio (K) : The transformation ratio for voltage is defined as the ratio of secondary voltage to the primary voltage of a transformer. It is denoted by K. Transformation Ratio K = =

Turns Ratio of the Transformer : The turns ratio of a transformer is defined as the ratio of the number of primary turns to the number of secondary turns. Turns Ratio =

Types of Transformers Based on the Value of K : Step up transformer : The transformer having K > 1 or V2 > V1 is called as the step up transformer. Step down transformer : The transformer having K < 1 or V2 < V1 is called as the step down transformer.

Ratings of Transformer : Rating of a transformer is expressed in terms of voltage and current as follows : Rating of a transformer = Primary voltage x Primary current Or = Secondary voltage x Secondary current As the voltage and current may or may not be in phase, the units of transformer ratings are

Volt Ampere (VA) or kilo Volt- Ampere (kVA) or Mega Volt Ampere (MVA).

. Rating in VA or kVA or MVA = V1 x I1 = V2 x I2 Why is the transformer rated in VA or kVA ? The VA or kVA rating of the transformer simply indicates how much maximum apparent power or total power a transformer can supply. It includes the active power (true power) and the reactive power (useless power). At the time of manufacturing of a transformer, the nature of load is not known. Hence the maximum total (apparent) power supplying capacity is given as the rating. Hence the transformer is rated in VA or kVA and not in W or kW. The complete ratings of a transformer : The complete ratings of a transformer includes 3300 V/240, 5kVA, 50Hz Where 3300 V is the primary voltage V1 240 V is the secondary voltage V2 5 kVA is the kVA rating and 50 Hz is the supply frequency.

Losses in a Transformer : Losses in a transformer

_____________________________________________ Copper losses (P cu) Iron losses (P i) ______________________________ Hysteresis losses Eddy current losses

Copper Loss (P cu) : Copper loss = Power loss in the primary resistance + Power loss in the secondary resistance. Therefore P cu = I12 R 1 + I22 R2

Hysteresis Losses : The hysteresis loss taking place in a magnetic material. The area enclosed by the hysteresis loop of a material represents the hysteresis loss. Hence special magnetic materials should be used in order to reduce the hysteresis loss. Materials such as silicon steel has hysteresis loops with very small area. Eddy Current Losses : Due to the time varying flux, there is some induced emf in the transformer core. This induced emf causes some currents to flow through the core body. These currents are known as the eddy currents. Eddy current loss = (Eddy current)2 x r The eddy current losses are minimized by using the laminated core. The core is manufactured as a stack of laminations rather than a solid iron core.

The iron loss is denoted by P i. It is the sum of hysteresis and eddy current loss. Iron loss is a constant loss which does not depend on the level of load.

Advantages of a Two Winding Transformer : (1) It provides complete isolation between primary and seconary. (2) It has no moving parts. (3) Its construction is simple. (4) We can step up or step down the voltage. Disadvantages : (1) Large size. (2) Low efficiency. (3) Poor voltage regulation. (4) High power losses in the windings. (5) More copper is required to be used because it has two windings. (6) Variable output voltage can not be obtained. (7) Variable frequency operation is not possible. Application of Two winding Transformer : (1) As the distribution transformer. (2) As isolation transformer. (3) As a step down transformer in the dc power supplies. (4) Welding applications.

Autotransformer : The normal transformer has separate primary and secondaryb windings. Ut the autotransformer is a special transformer in which a part of winding is common for the primary and secondary windings. The construction of an autotransformer is as shown in fig. It consists of only one winding on a laminated magnetic core., with a rotary movable contact. Thus from the autotransformer three terminals are brought out for connection. The autotransformer can operate as a step down or a step up transformer.

Autotransformer as Step Down Transformer: The connection of autotransformer as a step down transformer is shown in fig. It shows that the two fixed terminals A and B are connected to the single-phase AC supply V1. Thus winding AB acts as the primary winding. A part of the complete winding i.e. CB acts as the secondary winding across which the load is connected.

Autotransformer as a Step Up Transformer : Below Fig. shows the connection of an autotransformer for operating it as the step up transformer. Note that the part CB of the complete winding acts as theprimaryb winding. The ac input voltage V1 is applied between terminals C and B. The full winding AB acts as a secondary winding and the load is connected between these terminals.

Advantages of Autotransformer : (1) As only one winding is used the copper required for the transformer is very less. (2) The size and hence the cost is reduced as compared to the conventional transformer. (3) Thye losses taking place in the winding are reduced hence the efficiency is higher than the conventional transformer. (4) Due to reduced resistance, the voltage regul;ation is better than the conventional transformer. Disadvantages of an Autotransformer : (1) There is no electrical isolation between the primary and secondary windings. This can prove to be dangerous for high voltage applications. (2) If the common part of the winding (winding CB) breaks (open circuited) then the transformer action is lost and full primary voltage appears across the secondary as shown in fig. (3) It posses a low impedance, hence if the secondary circuit is short circuited, then a large current will flow on the secondary side.

Applications of an Autotransformer : (1) It can be used as variac, i.e. variable ac supply to vary the ac voltage applied to the load smoothly from 0V to about 270V. (2) In order to start the ac machines such as induction motors or synchronous motors. (3) To vary the supply voltage (as per requirements) of a furnace. (4) As a dimmerstst : When the variac autotransformer is used to control the intensity of lamps in the cinema halls etc, it is called as the dimmerstat. Comparision of Two winding and Autotransformer : Sr. Parameter Two winding transformer No 1 Separate winding Primary and secondary 2 3 4 5 6 7 8 9 10 11 12 13 14 Movable contact Type Copper saving Possibility of getting a variable secondary voltage Electrical isolation Size Number of windings Cost Losses in the winding Efficiency Regulation Applications Symbol No movable contact It can operate as step up or step down None

Autotransformer A part of winding is common between primary and secondary There is a movable contact It can work as step up as well as step down. Copper saving takes place. Yes No electrical isolation between primary and secondary. Small 1 Low Low High Better Variac, starting of ac motors, dimmerstat

Yes, there is electrical isolation between primary and secondary Large 2 High High Low Poor Mains transformer, power supply, welding, isolation transformer

Isolation Transformers : Isolation transformers are specially designedtransformers for providing electrical isolation between the primary and secondary windings. The turns ratio of isolation transformers is 1:1 that means N1 = N2. Hence the voltage and current levels on the primary and secondary sides are identical. . V1 = V2 and I1 = I2

Functions of Isolation Transformers : (1) Disconnect the instrument acting as a load from the supply ground. (2) To reduce the amplitude of voltage spikes.

Reduction of Voltage Spikes : Another function of the isolation transformer is reduction of the amplitude of voltage spikes. Voltage spikes are short duration high amplitudes pulses get superimposed on the ac supply. These spikes are dangerous, so expensive and delicate equipments should be protected against such spikes. We can use the isolation transformer for this purpose. The isolation transformer reduces the amplitude of spike due to the following internal action.

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX____________________________XXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Ground Power Unit To Supply AircraftsDokument64 SeitenThe Ground Power Unit To Supply AircraftsWilliam Jaldin CorralesNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- P-Channel Enhancement Mode Power MOSFET: FeaturesDokument4 SeitenP-Channel Enhancement Mode Power MOSFET: FeaturesMarco MoralesNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- IES OBJ Electrical Engineering 2005 Paper IIDokument16 SeitenIES OBJ Electrical Engineering 2005 Paper IIjitenNoch keine Bewertungen

- VW Amarok 2011 Circuit Diagrams Eng PDFDokument1.041 SeitenVW Amarok 2011 Circuit Diagrams Eng PDFAmarok100% (8)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- AN042 - Low-Cost DC Motor Speed Control With CMOS ICs PDFDokument3 SeitenAN042 - Low-Cost DC Motor Speed Control With CMOS ICs PDFpierdonneNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Commissioning Check ListDokument15 SeitenCommissioning Check ListAnuradheNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Appendix 1 93M-0501-B13-NC000-DGM-00003 NCC Mainline Power Sectioning Diagram (FDR)Dokument15 SeitenAppendix 1 93M-0501-B13-NC000-DGM-00003 NCC Mainline Power Sectioning Diagram (FDR)AHMED ATIFNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- FR-D700 Series: Max Load Capacity CapacityDokument1 SeiteFR-D700 Series: Max Load Capacity CapacityangelNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- PFC Harmonic Filter SelectionDokument19 SeitenPFC Harmonic Filter SelectionSusheel DeshpandeNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- 001 Manual Digital 400.4 Evox2 InglesDokument16 Seiten001 Manual Digital 400.4 Evox2 InglesFabio Miranda Destak SomNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- EE232 Exp4Dokument5 SeitenEE232 Exp4Mei QiiNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Led Highbay Ecomax II-familysheetDokument3 SeitenLed Highbay Ecomax II-familysheetM. Fikri UtomoNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Apc Back Ups Bk650-AsDokument3 SeitenApc Back Ups Bk650-AsHarman SandhuNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- List of IEC Standards - WikipediaDokument26 SeitenList of IEC Standards - WikipediaEngr saqibNoch keine Bewertungen

- Hettich Mikro22 - Service Manual PDFDokument51 SeitenHettich Mikro22 - Service Manual PDFCarlos GonzálezNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Three Phase Synchronous MachinesDokument14 SeitenThree Phase Synchronous MachinesMohdFirdausNoch keine Bewertungen

- ACB35416-F1A9-4777-BC7B-0D12CD80CDA9Dokument4 SeitenACB35416-F1A9-4777-BC7B-0D12CD80CDA9Raúl Alfonso López GarcíaNoch keine Bewertungen

- Diagrama Power Mig 180 DualDokument1 SeiteDiagrama Power Mig 180 DualDannielOrellanaNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Motorcycle Universal Gear IndicatorDokument15 SeitenMotorcycle Universal Gear IndicatorDavidErantzeNoch keine Bewertungen

- Switches Relayscircuitprotection2015catalogue190218Dokument188 SeitenSwitches Relayscircuitprotection2015catalogue190218Đồng Ngọc TrungNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Chapa de Bloque KiddeDokument3 SeitenChapa de Bloque KiddeCesar MuñozNoch keine Bewertungen

- ECE467: Introduction To VLSI: Lecture-3Dokument32 SeitenECE467: Introduction To VLSI: Lecture-3snagaraj.cool7813Noch keine Bewertungen

- TroubleshootingDokument20 SeitenTroubleshootingbingNoch keine Bewertungen

- Bobisoft Winding Design Software PDFDokument17 SeitenBobisoft Winding Design Software PDFxxNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Unipower ML-MN-DS SeriesDokument2 SeitenUnipower ML-MN-DS SeriesLilik Eko Budi SantosoNoch keine Bewertungen

- Thyristors & Triacs - Ten Golden RulesDokument11 SeitenThyristors & Triacs - Ten Golden RulesVlad ThalheimerNoch keine Bewertungen

- Service Manual 6060 - 3302098ADokument39 SeitenService Manual 6060 - 3302098ATommy MellemstrandNoch keine Bewertungen

- ICPS IftiDokument19 SeitenICPS IftiMohebul AhsanNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Electrical Isolator PDFDokument23 SeitenElectrical Isolator PDFLimuel OlandriaNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)