Beruflich Dokumente

Kultur Dokumente

Air Compressor

Hochgeladen von

Gogot Pantja ParijogoOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Air Compressor

Hochgeladen von

Gogot Pantja ParijogoCopyright:

Verfügbare Formate

ANNEX

Compressed Air

Air Compressors

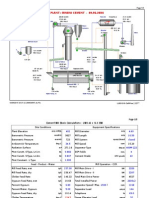

We can supply air compressors for all types of environmental applications. From 3/4 HP oil-less designs for ground water sampling up to 15 HP models for remediation projects. Selecting the optimum air compressor system will ensure efficient operation and reduce the need for maintenance and repairs. A correctly sized, good quality air compressor will provide years of trouble free operation. Two factors need to be considered when selecting the optimum size and type of compressor, air volume and pressure. The air volume required, usually expressed as CFM (cubic feet per minute). This is the actual volume of air delivered by the compressor as measured when discharged to the atmosphere at a set pressure. Once the CFM requirements have been determined, the compressor can be selected. It is important to allow for a 50% duty cycle for the compressor to prevent the system from cycling continuously. (See Tech Tip Below) A compressor will turn approximately 7 cubic feet of ambient air into 1 cubic foot of compressed air. The net result is seven times as much moisture and contamination inside the compressor receiver and air lines. The compression process will also increase the ambient temperature of the air inside the receiver. Air compressors can generate over 20 gallons of water in an 8-hour operating period. If not removed, the moisture and contaminants can cause premature failure of the air lines and pumping equipment. Compressors should therefore include the following accessories: an aftercooler, a receiver autodrain and, depending on the climatic conditions where the compressor will be used, an air dryer.

An after cooler will reduce the temperature of the compressed air. This will result in the water vapor condensing into droplets which will collect in the bottom of the receiver. An auto drain fitted to the receiver will open automatically, allowing the water to drain.

Tech Tip: Formula for determining total air flow (cfm) requirements: Total cfm required x 1.5 = Total cfm Example: If you are using two MVP IV Pumps each producing 3 gpm (1 cfm required per gallon pumped), your actual air requirements will be 6 cfm. Multiply this number by 1.5 (50% duty cycle) and your total cfm requirement will be 9 cfm.

Flow (cfm)

Flow Rate (lb/hr)

Velocity (ft/sec)

Air Flow & Pressure Loss

Tube Size

1/4 Tubing (.250 ID) Pressure Drop (psi/100 ft) 0.60 2.39 9.57 38.27 153.08 612.32 2449.27 9797.07 1/2 Tubing (.500 ID) Velocity (ft/sec) 6.11 12.23 24.45 48.91 97.81 195.63 391.25 782.51 Pressure Drop (psi/100 ft) 0.019 0.075 0.299 1.196 4.784 19.135 76.540 306.158 3/4 Tubing (.750 ID) Velocity (ft/sec) 2.72 5.43 10.87 21.74 43.47 86.95 173.89 347.78 Pressure Drop (psi/100 ft) 0.012 0.050 0.199 0.797 3.189 12.757 51.026 204.106 1 Tubing (1.00 ID) Velocity (ft/sec) 1.53 3.06 6.11 12.23 24.45 48.91 97.81 195.63 Pressure Drop (psi/100 ft) 0.01 0.04 0.15 0.60 2.39 9.57 38.27 153.08

0.5 1 2 4 8 16 32 64

15.01 30.02 60.04 120.07 240.15 480.30 960.59 1921.19

24.45 48.91 97.81 195.63 391.25 782.51 1565.01 3130.03

Dry Air @ 80F and 100psi Density = PV/RT P = Pressure, psi V = Volume, ft3 R = Gas Constant (for Air) = 53.33 T = Temperature, degR

Wh = Flow Rate, lb/hr = (60) x (Density, lb/ft3) x (Flow Rate, cfm) Velocity, ft/sec =( (183.4) x (Wh, lb/hr) ) / ( (3600) x (d, in)2 x (Density, lb.ft3) ) Pressure Drop, lb/in2 = [ ( (L, ft) x (Velocity, ft/sec)2 ) / ( (25000) x (d, in) ) ] / (16 oz/lb) = psi Density, lb/ft3 = 0.50 Cells highlighted in dark blue are for non-recommended flows.

32

www.durhamgeo.com solutions@durhamgeo.com Tel: 1-800-837-0864

770-465-7557

Das könnte Ihnen auch gefallen

- Southern Marine Engineering Desk Reference: Second Edition Volume IVon EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INoch keine Bewertungen

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersVon EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersBewertung: 4.5 von 5 Sternen4.5/5 (2)

- HVAC Formulas by AEMEPDokument9 SeitenHVAC Formulas by AEMEPZen LohNoch keine Bewertungen

- PUMPS and CALCULATIONSDokument7 SeitenPUMPS and CALCULATIONSkenoly123Noch keine Bewertungen

- Compressed Air ReceiversDokument6 SeitenCompressed Air Receiverstruong sanh NguyenNoch keine Bewertungen

- Air Compressors, Screw Type, Altitude Corrections - 01 PDFDokument28 SeitenAir Compressors, Screw Type, Altitude Corrections - 01 PDFluisbitron1527Noch keine Bewertungen

- CA Distribution System - Part2Dokument6 SeitenCA Distribution System - Part2Mohammad Abubakar SiddiqNoch keine Bewertungen

- Chiller Refrigeration TonsDokument6 SeitenChiller Refrigeration Tonsrogel_ganaNoch keine Bewertungen

- Cost Savings - Steam Air MotorsDokument25 SeitenCost Savings - Steam Air MotorsNouhaila BattahNoch keine Bewertungen

- Aeration System and Oxygen RequirementDokument7 SeitenAeration System and Oxygen Requirementdzari6738Noch keine Bewertungen

- Rules of Thumb-Chemical EngineeringDokument31 SeitenRules of Thumb-Chemical Engineeringintania66Noch keine Bewertungen

- Air Receiver Sizing PDFDokument3 SeitenAir Receiver Sizing PDFTifano KhristiyantoNoch keine Bewertungen

- Charts and TablesDokument4 SeitenCharts and TablesAbdul KharisNoch keine Bewertungen

- Desozone Odor ControlDokument5 SeitenDesozone Odor Controlsolo7651Noch keine Bewertungen

- Performance Test On Double Stage Reciprocating Air CompressorDokument8 SeitenPerformance Test On Double Stage Reciprocating Air Compressormohammed rashidNoch keine Bewertungen

- HVAC DistributionSystemsSizingDokument56 SeitenHVAC DistributionSystemsSizingAhmed OmarNoch keine Bewertungen

- Calculating Receivers in Compressed Air SystemsDokument4 SeitenCalculating Receivers in Compressed Air Systemsdharwin100% (1)

- Ce Series Filters & Moisture Separator: Compressed Air & Power SolutionsDokument4 SeitenCe Series Filters & Moisture Separator: Compressed Air & Power SolutionsTim MitchellNoch keine Bewertungen

- Experienced Based Rules of Chemical EngineeringDokument33 SeitenExperienced Based Rules of Chemical Engineeringintania66Noch keine Bewertungen

- Piping Systems Srac 1994Dokument6 SeitenPiping Systems Srac 1994maheshNoch keine Bewertungen

- Hydro Design & ConstructionDokument81 SeitenHydro Design & ConstructionSamNoch keine Bewertungen

- (Uav) - Hovercraft Thrust Calculation in A Duct Fan Assembly For HovercraftDokument14 Seiten(Uav) - Hovercraft Thrust Calculation in A Duct Fan Assembly For Hovercraftlyly209Noch keine Bewertungen

- HKS GT2540Dokument3 SeitenHKS GT2540Ashley MoggNoch keine Bewertungen

- HA Winter Vent Oct 2022Dokument51 SeitenHA Winter Vent Oct 2022Jack RbNoch keine Bewertungen

- API Sizing Calculations WebSiteDokument13 SeitenAPI Sizing Calculations WebSiteISTRANHANoch keine Bewertungen

- Cooling Tower ManualDokument80 SeitenCooling Tower ManualBikas Saha100% (3)

- Air Compressors - Rules of ThumbDokument2 SeitenAir Compressors - Rules of ThumbtylerstearnsNoch keine Bewertungen

- Sprinkler Irrigation Application Rates and DepthsDokument2 SeitenSprinkler Irrigation Application Rates and DepthsKhurram SherazNoch keine Bewertungen

- Design Formulae: Reference CardDokument4 SeitenDesign Formulae: Reference Cardcharge3Noch keine Bewertungen

- Cement MillDokument28 SeitenCement Millsaji kumar100% (2)

- Air RecieverDokument9 SeitenAir RecieverMichael Belmonte UrdanetaNoch keine Bewertungen

- Calculation of Thrust in A Ducted Fan Assembly For HovercarftDokument14 SeitenCalculation of Thrust in A Ducted Fan Assembly For HovercarftAndrew Whipple100% (2)

- Horizontal 2 Phase Separator SizingDokument10 SeitenHorizontal 2 Phase Separator SizingJermaine Heath100% (1)

- Pressed Air System NDokument35 SeitenPressed Air System NvmramakrishnanNoch keine Bewertungen

- Cooling of CPU Fan PDFDokument10 SeitenCooling of CPU Fan PDFLeonard LiangNoch keine Bewertungen

- Best Pratice Energy Efficiency in Compressed Air SystemDokument107 SeitenBest Pratice Energy Efficiency in Compressed Air SystemNoor LishinNoch keine Bewertungen

- A4372 HVAC DistributionSystemsSizingDokument57 SeitenA4372 HVAC DistributionSystemsSizingIdham ShukriNoch keine Bewertungen

- Conversion Chart Manuals and Instructions in PDF Format Glossary Recommended Books Web LinksDokument12 SeitenConversion Chart Manuals and Instructions in PDF Format Glossary Recommended Books Web LinksAziz Khan KakarNoch keine Bewertungen

- Steam Distribution System Design GuideDokument70 SeitenSteam Distribution System Design GuideMohamed RiyaazNoch keine Bewertungen

- Osc Leaflet en 2935082546Dokument2 SeitenOsc Leaflet en 2935082546ramonNoch keine Bewertungen

- Fd60hz Secador Atlas Copco - ManualDokument8 SeitenFd60hz Secador Atlas Copco - ManualEdvaldo França100% (1)

- MWM TCG 2020Dokument4 SeitenMWM TCG 2020MohammadFaisalAmjadNoch keine Bewertungen

- CEB601 Lab Report 5Dokument8 SeitenCEB601 Lab Report 5divikesh kumarNoch keine Bewertungen

- Petroleum Engineering Lab 1 (Pge313) Experiment 3 Determination of PermeabilityDokument20 SeitenPetroleum Engineering Lab 1 (Pge313) Experiment 3 Determination of PermeabilityAli AbubakarNoch keine Bewertungen

- Filtro XPLORDokument28 SeitenFiltro XPLORHéctor RomeroNoch keine Bewertungen

- Designing Auxiliary VentilationDokument12 SeitenDesigning Auxiliary VentilationMardee Wantssomecandy RabosaNoch keine Bewertungen

- Calculation of Air Pipe SizeDokument6 SeitenCalculation of Air Pipe SizePhyu Mar Thein Kyaw100% (1)

- Compressed Air PlantDokument88 SeitenCompressed Air PlantJerico LlovidoNoch keine Bewertungen

- Solution File Name: F:/solutia1Dokument3 SeitenSolution File Name: F:/solutia1Florian Marian MarțanNoch keine Bewertungen

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- Transactions of the American Society of Civil Engineers, vol. LXXII, June, 1911 Water Purification Plant, Washington, D. C. Results of Operation.Von EverandTransactions of the American Society of Civil Engineers, vol. LXXII, June, 1911 Water Purification Plant, Washington, D. C. Results of Operation.Noch keine Bewertungen

- Introduction To Light Aircraft DesignVon EverandIntroduction To Light Aircraft DesignBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Oral and Practical Review: Reflections on the Part 147 CourseVon EverandOral and Practical Review: Reflections on the Part 147 CourseNoch keine Bewertungen

- Dictionary of Textile Finishing: Deutsch/Englisch, English/GermanVon EverandDictionary of Textile Finishing: Deutsch/Englisch, English/GermanBewertung: 1.5 von 5 Sternen1.5/5 (3)

- Gas-Liquid And Liquid-Liquid SeparatorsVon EverandGas-Liquid And Liquid-Liquid SeparatorsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersVon EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNoch keine Bewertungen

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsVon EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsBewertung: 5 von 5 Sternen5/5 (1)