Beruflich Dokumente

Kultur Dokumente

Shell Diala D Oil

Hochgeladen von

Basim Al-AttarOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Shell Diala D Oil

Hochgeladen von

Basim Al-AttarCopyright:

Verfügbare Formate

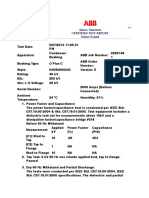

Technical Data Sheet

Shell Diala Oil D

Very high performance electrical oil

Shell Diala D is a non-inhibited insulating oil manufactured from specially refined naphthenic feedstock. It offers very high oxidation stability, very good dielectric properties and excellent low temperature properties without the use of pour point depressants. Shell Diala D meets both the established and new copper corrosion tests. Applications

restricted regions in bulk) as Shell Diala D dried, specially handled to retain a high breakdown voltage as delivered. This enables the product to be used in many applications without further treatment.

Transformers Electrical insulating oil for transformers, grid and industrial transformers up to maximum load. Electrical equipment Components like rectifiers, circuit breakers, switchgears.

Specification and Approvals

Shell Diala D meets the following specifications: IEC 60296 (2003) Table 2 Transformer Oil (U), uninhibited Baader oxidation test of (obsolete) DIN 57370-1 (1978)

Advice on applications not covered in this leaflet may be obtained from your Shell Representative.

Performance Features and Advantages

Excellent oxidation stability Diala D offers inherent natural resistance to oil degradation and is suitable for long life applications. Very good dielectric properties Meets the requirements of all major specifications. Anti corrosion properties Shell Diala D is non-corrosive towards copper, with no need for passivation. Diala D meets all relevant tests on copper corrosion, namely the established DIN 51353 (Silver Strip Test) and ASTM D1275, and also the newer tests: IEC 62535 and ASTM D1275B. Very good low temperature properties The naphthenic nature of the feedstock of Diala D provides a superior low temperature performance without the use of additives. Very good heat transfer characteristics The very good fluidity of the oil ensures proper heat transfer inside the transformer, even from lowest starting temperatures.

Storage precautions

The critical electrical properties of Shell Diala D are easily compromised by trace contamination with foreign material. Typically encountered contaminants include moisture, particles, fibres and surfactants. Therefore, it is imperative that electrical insulating oils be kept clean and dry. It is strongly recommended that storage containers be dedicated for electrical service and include airtight seals. It is further recommended that electrical insulating oils be stored indoors in climate-controlled environments.

Health and Safety

Guidance on Health and Safety are available on the appropriate Material Safety Data Sheet which can be obtained from your Shell representative. Shell Diala D is free of polychlorinated biphenyls (PCB).

Protect the environment

Take used oil to an authorized collection point. Do not discharge into drains, soil or water.

Low water content of delivered oil

Diala D is available in drums and pails (and in

Shell Lubricants

Page 1 of 2

November 2008

Technical Data Sheet

Typical Characteristics

Property Appearance Density at 15 C Density at 20 C Kinematic viscosity at 40 C Kinematic viscosity at 20 C Kinematic viscosity at 30 C Flashpoint P.M. Pourpoint Neutralisation value Corrosive Sulphur Corrosive Sulphur Corrosive Sulphur Breakdown voltage Untreated After treatment Dielectric dissipation factor (DDF) at 90 C Oxidation Stability (164 h /120 C) Total acidity Sludge DDF at 90 C Oxidation Stability Baader (140h /110 C) Neutralisation value Sludge content Dielectric dissipation factor (DDF) at 90 C mg KOH/g %m DIN 51554 0,09 0,02 0,1 mg KOH/g %m IEC 60247 IEC 61125 C Max. 1,2 Max. 0,8 Max. 0,5 0,23 0,1 0,15 kV kg/m3 kg/m3 mm2/s mm2/s mm2/s C C mg KOH/g Units Method IEC 60296 ISO 3675 ISO 3675 ISO 3104 ISO 3104 ISO 3104 ISO 2719 ISO 3016 IEC 62021-1 DIN 51353 IEC 62535 ASTM D 1275 B IEC 60156 Min. 30 Min. 70 Max. 0,005 >30 >70 0,001 IEC 60296 Requirements Clear, free from sediment and suspended matters Max. 895 Max. 12 Max. 1.800 Min. 135 Max. -40 Max. 0,01 Not corrosive -

Diala D

Complies 884 881 8,1 17,3 730 138 -60 < 0,01 Not corrosive Not corrosive Not corrosive

These characteristics are typical of current production. Whilst future production will conform to Shell's specification, variations in these characteristics may occur.

Shell Lubricants

Page 2 of 2

November 2008

Das könnte Ihnen auch gefallen

- 1329809804Dokument1 Seite1329809804muh4iminNoch keine Bewertungen

- Shell Diala Oil D PDFDokument2 SeitenShell Diala Oil D PDFSecret64Noch keine Bewertungen

- Shell Diala BDokument2 SeitenShell Diala BArnold Steven75% (4)

- Telenor BDVDokument15 SeitenTelenor BDVShahid IqbalNoch keine Bewertungen

- Ehv Circuit BreakersDokument12 SeitenEhv Circuit BreakersBoreda RahulNoch keine Bewertungen

- L&T GIC Catalogue 25 Sep 09Dokument24 SeitenL&T GIC Catalogue 25 Sep 09Naresh KapuNoch keine Bewertungen

- Simoprime Catalog English Aug2010Dokument16 SeitenSimoprime Catalog English Aug2010muktivarNoch keine Bewertungen

- SERVERON TM3 ® ™ On-Line DGA MonitorDokument6 SeitenSERVERON TM3 ® ™ On-Line DGA Monitorlxd.hepNoch keine Bewertungen

- Synergy Elektrik (PVT.) LTD PDFDokument3 SeitenSynergy Elektrik (PVT.) LTD PDFMuhammad KashifNoch keine Bewertungen

- IEEE - STD C57.12.90-2010 CONVERSION 50-60HZDokument5 SeitenIEEE - STD C57.12.90-2010 CONVERSION 50-60HZTXEMANoch keine Bewertungen

- Transformer Failure AnalysisDokument12 SeitenTransformer Failure AnalysisABHINAV SAURAVNoch keine Bewertungen

- BushingDokument8 SeitenBushingrasheed313Noch keine Bewertungen

- Cast Resin TransformersDokument7 SeitenCast Resin TransformersNandkumar Chinai100% (1)

- Transformer Test: Prepared By: Nishant AcharyaDokument30 SeitenTransformer Test: Prepared By: Nishant AcharyaVishal PatelNoch keine Bewertungen

- Schneider Electric OKKEN IntroductionDokument26 SeitenSchneider Electric OKKEN IntroductionDuško TovilovićNoch keine Bewertungen

- Cap P13Dokument5 SeitenCap P13Siva NandhamNoch keine Bewertungen

- MIDEL 7131 Dielectric Insulating Fluid OverviewDokument2 SeitenMIDEL 7131 Dielectric Insulating Fluid Overviewvzimak2355Noch keine Bewertungen

- 4 - Prevost - Oil Analysis PDFDokument42 Seiten4 - Prevost - Oil Analysis PDFbcqbaoNoch keine Bewertungen

- Dead Tank Circuit-Breakers Brochure GEA31987Dokument12 SeitenDead Tank Circuit-Breakers Brochure GEA31987sani priadiNoch keine Bewertungen

- Transformer Oil TerminologyDokument7 SeitenTransformer Oil TerminologyUtkarsh AnandNoch keine Bewertungen

- Bushings COT 24kV To 550kVDokument24 SeitenBushings COT 24kV To 550kVtatianaNoch keine Bewertungen

- Flyer - MD1501 Series Auxiliary RelaysDokument5 SeitenFlyer - MD1501 Series Auxiliary Relaysmuhammad nazirNoch keine Bewertungen

- Catalog ABB 2018Dokument42 SeitenCatalog ABB 2018Razvan Pislaru0% (1)

- Pdms India. (Partial Discharge Monitoring Services India)Dokument17 SeitenPdms India. (Partial Discharge Monitoring Services India)VISHAL TELANGNoch keine Bewertungen

- Bushing ABBDokument2 SeitenBushing ABBedgardNoch keine Bewertungen

- K-Factor Rated Transformer For Deal With Harmonic Generating LoadsDokument4 SeitenK-Factor Rated Transformer For Deal With Harmonic Generating Loadsp41005679Noch keine Bewertungen

- DGA Oil SamplingDokument6 SeitenDGA Oil Samplinghino_kaguNoch keine Bewertungen

- Trench - COT PDFDokument24 SeitenTrench - COT PDFDes LawlessNoch keine Bewertungen

- Transformer BushingDokument11 SeitenTransformer BushingNunna BaskarNoch keine Bewertungen

- Slip Ring Motor Liquid Resistor Soft Starting System (HV-LRS) PDFDokument4 SeitenSlip Ring Motor Liquid Resistor Soft Starting System (HV-LRS) PDFLouie FernandezNoch keine Bewertungen

- Customer Seminar Off-Line Testing Using Doble - Manila - March 2018Dokument95 SeitenCustomer Seminar Off-Line Testing Using Doble - Manila - March 2018Jay KuizonNoch keine Bewertungen

- MG Transformers and Packaged Substations TX5299.V2Dokument20 SeitenMG Transformers and Packaged Substations TX5299.V2engnajeeb75Noch keine Bewertungen

- VCB EvolisDokument21 SeitenVCB Evolispb21Noch keine Bewertungen

- Brosura Myrkos PDFDokument4 SeitenBrosura Myrkos PDFBahtiar AfandiNoch keine Bewertungen

- Analysis of The Root Causes of Transformer Bushing FailuresDokument7 SeitenAnalysis of The Root Causes of Transformer Bushing FailuresSamwel MmariNoch keine Bewertungen

- Siemens DTC PresentationDokument8 SeitenSiemens DTC Presentationgiolgau01Noch keine Bewertungen

- Sivacon 8PT-Busbar Rear-Technical CatalogueDokument69 SeitenSivacon 8PT-Busbar Rear-Technical CatalogueLaurentiu CatalinNoch keine Bewertungen

- SchneiderDokument2 SeitenSchneiderAbdul GafoorNoch keine Bewertungen

- Transformer BrochureDokument6 SeitenTransformer Brochuresunil patelNoch keine Bewertungen

- ABB Distribution: SF - Circuit Breaker ManualDokument28 SeitenABB Distribution: SF - Circuit Breaker ManualwiyatnoNoch keine Bewertungen

- Omega Acb Catalogue April 17Dokument126 SeitenOmega Acb Catalogue April 17Elaiyaraja Palani100% (2)

- Oil Draining Device O Ring DIN42551Dokument1 SeiteOil Draining Device O Ring DIN42551Juan Carlos Añazco PazosNoch keine Bewertungen

- Instruction Manual-DTR-EN-ABB Revised 20131028 - Rev - 5 PDFDokument46 SeitenInstruction Manual-DTR-EN-ABB Revised 20131028 - Rev - 5 PDFSung Hye ChoiNoch keine Bewertungen

- Paper 9.5 - H DingDokument22 SeitenPaper 9.5 - H Dingmarg1972Noch keine Bewertungen

- Configuration: No. Function ScopeDokument53 SeitenConfiguration: No. Function ScoperahulNoch keine Bewertungen

- 24kV (20 22kV) Cable Termination, Outdoor, Polymeric CWS, 50 95sqmm 3M Cold Shrink 93EP621 2 PDFDokument8 Seiten24kV (20 22kV) Cable Termination, Outdoor, Polymeric CWS, 50 95sqmm 3M Cold Shrink 93EP621 2 PDFAnonymous IvZSKJCNoch keine Bewertungen

- (Susol MCCB) Catalog en 202107Dokument376 Seiten(Susol MCCB) Catalog en 202107paryonoNoch keine Bewertungen

- Transformer OilDokument2 SeitenTransformer OilAdetunji TaiwoNoch keine Bewertungen

- Maintenance of TransformerDokument80 SeitenMaintenance of Transformerajaynmenon100% (2)

- Abb Circuit Breaker-LiteratureDokument44 SeitenAbb Circuit Breaker-LiteraturecetpcapgencoNoch keine Bewertungen

- Oil Tan Delta and Resistivity Test - OTDDokument5 SeitenOil Tan Delta and Resistivity Test - OTDAnand MandalNoch keine Bewertungen

- Shell Diala Oil D Dried: Very High Performance Electrical OilDokument3 SeitenShell Diala Oil D Dried: Very High Performance Electrical OilmedrayaliNoch keine Bewertungen

- Gpcdoc Gtds Shell Diala s3 Zx-I (En) TdsDokument2 SeitenGpcdoc Gtds Shell Diala s3 Zx-I (En) TdsSecret64Noch keine Bewertungen

- PDS Nytro Bear ASTM EN PDFDokument2 SeitenPDS Nytro Bear ASTM EN PDFP_sanchezNoch keine Bewertungen

- Nynas OilDokument2 SeitenNynas OilusefiNoch keine Bewertungen

- Nytro 10XN: Designed For Heavy Duty Product DescriptionDokument2 SeitenNytro 10XN: Designed For Heavy Duty Product DescriptionusefiNoch keine Bewertungen

- Shell Diala S3 ZX-IGDokument2 SeitenShell Diala S3 ZX-IGAnonymous oAbjbl4HNoch keine Bewertungen

- Shell Diala S3 ZX-IG DriedDokument2 SeitenShell Diala S3 ZX-IG DriedAnonymous oAbjbl4HNoch keine Bewertungen

- Heat Transfer OilDokument2 SeitenHeat Transfer OilDony LieNoch keine Bewertungen

- Lightning Protection GuideDokument331 SeitenLightning Protection GuideGeFi100% (19)

- Arrester Selection Guide: Select An ANSI Arrester Select An IEC ArresterDokument3 SeitenArrester Selection Guide: Select An ANSI Arrester Select An IEC ArresterBasim Al-AttarNoch keine Bewertungen

- Dimensioning of CT For Protection ApplicationDokument16 SeitenDimensioning of CT For Protection ApplicationBijaya Kumar MohantyNoch keine Bewertungen

- CT Sizing CalculationDokument11 SeitenCT Sizing CalculationEmmanuel_Quitos67% (3)

- R6010e Mvax PDFDokument9 SeitenR6010e Mvax PDFBasim Al-AttarNoch keine Bewertungen

- ABB HV Shunt ReactorDokument30 SeitenABB HV Shunt Reactortkdrt2166100% (1)

- GRR 100Dokument16 SeitenGRR 100Basim Al-AttarNoch keine Bewertungen

- IEC StandardsDokument22 SeitenIEC StandardsBasim Al-AttarNoch keine Bewertungen

- Alstom L3-KBCH-BR-04-05-0910-GBDokument8 SeitenAlstom L3-KBCH-BR-04-05-0910-GBsteve_osullivanNoch keine Bewertungen

- IEC 71-2 (1996) Air ClearanceDokument2 SeitenIEC 71-2 (1996) Air ClearanceBasim Al-Attar100% (1)

- Wind Turbine Power Plant in NigeriaDokument12 SeitenWind Turbine Power Plant in NigeriaAhmed AbdelhamidNoch keine Bewertungen

- AccessPasswords PDFDokument2 SeitenAccessPasswords PDFabelasisi1450% (2)

- Lesson Plan - Plants and AnimalsDokument2 SeitenLesson Plan - Plants and Animalsapi-243062687Noch keine Bewertungen

- AWS Advanced Networking - Specialty Sample Exam QuestionsDokument4 SeitenAWS Advanced Networking - Specialty Sample Exam Questionsraghs4uNoch keine Bewertungen

- Compressor Oil SDokument2 SeitenCompressor Oil SQuy CocanhNoch keine Bewertungen

- SEW Explosion Proof Gear Unit Gearmotors - Ex - Instructions - 11281413Dokument116 SeitenSEW Explosion Proof Gear Unit Gearmotors - Ex - Instructions - 11281413asiapowerdriveNoch keine Bewertungen

- IS: 8009 (Part I) - 1976Dokument42 SeitenIS: 8009 (Part I) - 1976SonalMhaisalgikarNoch keine Bewertungen

- Frenzel Self Test Chapter 9Dokument6 SeitenFrenzel Self Test Chapter 9Aileen May Santillan HerreraNoch keine Bewertungen

- Tie BarsDokument18 SeitenTie BarsKutty Mansoor100% (1)

- CB 240 Assembly Instructions enDokument96 SeitenCB 240 Assembly Instructions enSanja RadovicNoch keine Bewertungen

- Rectangular Column CalculationsDokument1 SeiteRectangular Column Calculationsabu taherNoch keine Bewertungen

- 7519v2.2 (G52 75191XI) (P45 C51 - P43 C51) ASIA PDFDokument181 Seiten7519v2.2 (G52 75191XI) (P45 C51 - P43 C51) ASIA PDFCiprian MihaiNoch keine Bewertungen

- Heat Transfer in All Pipe Flow Regimes - Laminar, Transitional - Intermittent, and TurbulentDokument7 SeitenHeat Transfer in All Pipe Flow Regimes - Laminar, Transitional - Intermittent, and TurbulentLeoncio Santos TressNoch keine Bewertungen

- X10CrNi18-8 MaterialsDokument10 SeitenX10CrNi18-8 MaterialsRinda ManuNoch keine Bewertungen

- Strainer Datasheet English PDFDokument4 SeitenStrainer Datasheet English PDFChemicalProgrammerNoch keine Bewertungen

- Genesis Series ManualDokument16 SeitenGenesis Series ManualsashilaNoch keine Bewertungen

- Smart Card Research and Advanced Applications 13th International ConferenceDokument261 SeitenSmart Card Research and Advanced Applications 13th International ConferencesaurabhadeNoch keine Bewertungen

- 3D Simulation of The Vertical Axis Wind TurbinesDokument4 Seiten3D Simulation of The Vertical Axis Wind TurbinesMostafa RashedNoch keine Bewertungen

- Gs106-1 - Cement-Mortar Lined Steel Pipe and FittingsDokument39 SeitenGs106-1 - Cement-Mortar Lined Steel Pipe and FittingsMohamed AhmedNoch keine Bewertungen

- Bradmark Solutions CH 12Dokument2 SeitenBradmark Solutions CH 12Allan Ahmad SaripNoch keine Bewertungen

- Tacha's ReusmeDokument2 SeitenTacha's ReusmeJames HamptonNoch keine Bewertungen

- Carmix 25 FX EngDokument2 SeitenCarmix 25 FX Engjoyli22Noch keine Bewertungen

- Clarification of Vehicle Cone IndexDokument12 SeitenClarification of Vehicle Cone IndexrobiniscNoch keine Bewertungen

- Arch Des BibDokument4 SeitenArch Des BibHossam SeifNoch keine Bewertungen

- Documentary ScriptDokument4 SeitenDocumentary Scriptapi-294975941Noch keine Bewertungen

- Koss Owners Manual CM SeriesDokument11 SeitenKoss Owners Manual CM SeriesPierreDolonymous100% (1)

- 3-Week Lesson PlanDokument5 Seiten3-Week Lesson Planapi-421046122Noch keine Bewertungen

- OE - August 2016Dokument100 SeitenOE - August 2016anjangandak2932Noch keine Bewertungen

- 5440 15044 1 PBDokument10 Seiten5440 15044 1 PBDelfia Tanjung SariNoch keine Bewertungen

- LTE 112 Daily Report - Query - Result - 20190410084829315Dokument70 SeitenLTE 112 Daily Report - Query - Result - 20190410084829315quykiem02Noch keine Bewertungen