Beruflich Dokumente

Kultur Dokumente

Ocean Thermal Energy Conversion

Hochgeladen von

Raviteja RokzOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ocean Thermal Energy Conversion

Hochgeladen von

Raviteja RokzCopyright:

Verfügbare Formate

OCEAN THERMAL ENERGY CONVERSION

(NON-CONVENTIONAL SOURCE OF ENERGY) OCEAN THERMAL ENERGY CONVERSION INTRODUCTION: Oceans which occupy large areas of earth surface are origin of variety of energy sources such as ocean currents, waves, tides, hydrates, and temperature and salinity gradients at varying depth. OTEC is based on tapping energy potential created by temperature difference between sun-warmed surface water and deep polar fed bottom currents to generate electricity. Assuming that about 1.5 percent of the total incident solar energy could be converted into electricity by using OTEC plants, the power output would be 500 million megawatts. This is equal to 6000 million barrels of oil per day in terms of energy equivalent. According to MNES estimates, India has a potential of exploiting 80,000 MW of OTEC based power.

WORKING PRINCIPLE

This plant works on the principle of a closed Rankine cycle. The operating cycle is essentially the same as the one used in Steam Power Plants fired by coal, oil or uranium. But the working fluid used here is either warm sea water or Ammonia or preferably a halocarbon refrigerant. The OTEC plant utilizes the temperature difference between the solar warmed ocean surface waters and the cold deep waters to produce electricity. Warm seawater is used in evaporators to evaporate the working fluid. This evaporated fluid expands in a low pressure turbine, which is coupled with a turbo alternator to produce electricity. Then the vapour from the turbine is condensed by the cold seawater taken from the deep sea. Power equation: The electrical power developed is given by, Efficiency of the alternator. = Density of the fluid. C = Specific Heat. Q = Volume of warm water. T = Temperature of the warm seawater. T = Temperature difference between warm & cold seawater. P = (CQ/T)(T)^2 =

Types of OTEC plants:

1. 2. 3.

Closed cycle OTEC plant. Open cycle OTEC plant. Hybrid cycle OTEC plant.

Closed cycle: In Closed cycle OTEC plants, ammonia or preferably a halocarbon refrigerant is used as the working fluid at about 27.5deg C. Warm seawater vaporizes a working fluid, flowing through a heat exchanger (evaporator). The vapor expands at moderate pressures and turns a turbine coupled to a generator that produces electricity. The condensed fluid from the condenser is again pumped back to the evaporator and recycled. The line diagram of closed cycle OTEC plant is

Open cycle: In open cycle OTEC plants the working fluid used is warm seawater. The warm seawater is "flash"-evaporated in a vacuum chamber to produce steam at an absolute pressure of about 2.4 kilopascals (kPa). As the pressure is low the turbine should be about 12 times larger in diameter than a closed cycle plant of the same rating. The steam coming out of the turbine condenses into ordinary water without salinity in the condenser. The line diagram of open cycle OTEC is

Hybrid cycle: A hybrid cycle combines the features of both the closed-cycle and open-cycle systems. In a hybrid OTEC system, warm seawater enters a vacuum chamber where it is flash-evaporated into steam, which is similar to the open-cycle evaporation process. The steam vaporizes the working fluid of a closed-cycle loop on the other side of an ammonia vaporizer. The vaporized fluid then drives a turbine that produces electricity.

The steam condenses within the heat exchanger and provides desalinated water. The line diagram of Hybrid cycle OTEC is

VARIOUS PARTS TURBINES: Steam flows through large, low-pressure turbines, entering at a pressure of about 2.4 kPa. These turbines must be able to handle the large steam flows necessary to produce a significant amount of electric power. The most reliable and cost-effective turbine for a 100-megawatt (electric) (MW) (net) plant would be a low-speed (200 rpm) unit measuring 43.6 meters in diameter, which requires more development. Multistage turbines used in nuclear or coalfired power plants are already available. The low-pressure stages of these turbines typically operate at conditions close to those needed in an open-cycle OTEC plant. The rotor that makes up the last stage (which is typically about 5 meters in diameter) together with a modified stator can produce about 2.5 MW of electricity (gross). Larger plants will require either several turbines operating in parallel or major advances in turbine technology that will lead to larger rotors. HEAT EXCHANGERS: Heat exchangers are a big part of the major performance and cost issues relating to closed-cycle systems. Open-cycle flash-evaporators include those with open-channel flow, falling films, and falling jets. These conventional evaporators typically perform to within 70% to 80% of the maximum thermodynamic performance at acceptable hydraulic losses. Research at the Solar Energy Research Institute (SERI), now the National Renewable Energy Laboratory (NREL), led to the development of a vertical-spout evaporator that can perform to within 90% of the thermodynamic limit. In this evaporator, water is drawn upward through a vertical pipe (a spout) and violently sprayed outward by escaping steam. To enhance performance, the spray may fall on screens that further break up the droplets and increase the evaporation rate.

Titanium was the original material chosen for closed-cycle heat exchangers because it resists corrosion. However, it is an expensive option for plants that use large heat exchangers. Corrosion-resistant copper-nickel alloys, which can be used to protect platforms and cold-water pipes, are not compatible with ammonia, the most common working fluid. A suitable alternative to these materials may be aluminum. Layers of slime and marine organisms can grow quickly on surfaces exposed to warm seawater. In heat exchangers, this buildupknown as biofoulingreduces the heat-transfer efficiency. The biofouling can be prevented by mixing chlorine in the pipes intermittently, for a total of about 1 hour a day, at a concentration of 70 ppb.

CONDENSERS:

After steam passes through the turbines, it can be condensed in direct-contact condensers or surface condensers. The surface condensers considered for use in OTEC systems are similar to those used in conventional power plants; however, these surface condensers must operate under lower pressures and with higher amounts of noncondensable gases in the steam. Surface con-densers keep the cooling seawater separate from the spent steam during condensation. By using indirect contact, the condensers produce desalinated water that is relatively free of seawater impurities. Steam in the open-cycle system contains non condensable gases that can interfere with power production. These gases oxygen, nitrogen, and carbon dioxide are released from the seawater when it is exposed to low pressures under vacuum. Air also enters the open-cycle vacuum vessel through leaks, although good construction techniques can reduce the rate of air leakage to very low levels. Unless these gases are removed from the vacuum chamber, they can interfere with condensation, particularly with surface condensers, by blanketing the condensing surfaces; they can even build up enough pressure to stop evaporation. An exhaust compressor can remove these non condensable gases.

Plant Location Commercial ocean thermal energy conversion (OTEC) plants must be located in an environment that

is stable enough for efficient system operation. The temperature of the warm surface seawater must differ about 20C (36F) from that of the cold deep water that is no more than about 1000 meters (3280 feet) below the surface. The natural ocean thermal gradient necessary for OTEC operation is generally found between latitudes 20 deg N and 20 deg S. Of these possible sites, a tropical islands with growing power requirements and

dependence on expensive imported oil are the most likely areas for OTEC development. The following map shows the regions, which are having different temperature differences between

surface and depth of 1000m.

ADVANTAGES Renewable energy resource Consistent 24-hour-a-day potential (wind and solar energy can only be captured when the wind is blowing

or the sun is shining)

Fresh Water-- Produces desalinated water for industrial, agricultural, and residential uses. System

analysis indicates that a 2-megawatt (electric) (net) plant could produce about 4300 cubic meters of desalinated water each day Food--Aquaculture products can be cultivated in discharge water - AND temperate agriculture products can be grown in the tropics by cooling the roots with the discharged cold seawater. Air Conditioning--The cold deep seawater can provide large amounts of very efficient air conditioning or industrial cooling - even after it has passed through the OTEC plant. OTEC can also be used to produce methanol, ammonia, hydrogen, aluminum, chlorine, and other chemicals Mineral Extraction-- OTEC could provide to mine ocean water for its 57 elements dissolved in solution. The only problem is the cost of the extraction process. The Japanese recently began investigating the concept of combining the extraction of uranium dissolved in seawater with wave-energy technology. OTEC is non-polluting. It is probably the most environmentally friendly energy available on the planet today

.MATHEMATIC CALCULATION

A igorous treatment of OTEC reveals that a 20 K temperature difference will provide as much energy as a hydroelectric plant with 34 m head for the same volume of water flow. The low temperature difference means that water volumes must be very large to extract useful amounts of heat and enormous heat exchangers must be employed compared to those used at a plant running with a larger temperature difference such as in conventional thermal power generation.[27] [edit]Variation

of ocean temperature with depth

The total insolation received by the oceans (covering 70% of the earth's surface, with clearness index of 0.5 and average energy retention of 15%) is5.457 x e10 Megajoules/year (MJ/yr) x .7 x .5 x .15 = 2.87 x e10 MJ/yr We can use Lambert's law to quantify the solar energy absorption by water,

where, y is the depth of water, I is intensity and is the absorption coefficient. Solving the above differential equation,

The absorption coefficient may range from 0.05 m1 for very clear fresh water to 0.5 m1 for very salty water. Since the intensity falls exponentially with depth y, heat absorption is concentrated at the top layers. Typically in the tropics, surface temperature values are in excess of 25 C (77 F), while at 1 kilometer (0.62 mi), the temperature is about 510 C (4150 F). The warmer (and hence lighter) waters at the surface means there are no thermal convection currents. Due to the small temperature gradients, heat transfer by conduction is too low to equalize the temperatures. The ocean is thus both a practically infinite heat source and a practically infinite heat sink. This temperature difference varies with latitude and season, with the maximum in tropical, subtropical and equatorial waters. Hence the tropics are generally the best OTEC locations. [edit]Open/Claude

cycle

In this scheme, warm surface water at around 27 C (81 F) enters an evaporator at pressure slightly below the saturation pressures causing it to vaporize.

Where Hf is enthalpy of liquid water at the inlet temperature, T1.

This temporarily superheated water undergoes volume boiling as opposed to pool boiling in conventional boilers where the heating surface is in contact. Thus the water partially flashes to steam with two-phase equilibrium prevailing. Suppose that the pressure inside the evaporator is maintained at the saturation pressure, T2.

Here, x2 is the fraction of water by mass that vaporizes. The warm water mass flow rate per unit turbine mass flow rate is 1/x2. The low pressure in the evaporator is maintained by a vacuum pump that also removes the dissolved non-condensable gases from the evaporator. The evaporator now contains a mixture of water and steam of very low vapor quality (steam content). The steam is separated from the water as saturated vapor. The remaining water is saturated and is discharged to the ocean in the open cycle. The steam is a low pressure/high specific volume working fluid. It expands in a special low pressure turbine.

Here, Hg corresponds to T2. For an ideal isentropic (reversible adiabatic) turbine,

The above equation corresponds to the temperature at the exhaust of the turbine, T5. x5,s is the mass fraction of vapor at state 5. The enthalpy at T5 is,

This enthalpy is lower. The adiabatic reversible turbine work = H3-H5,s . Actual turbine work WT = (H3-H5,s) x polytropic efficiency

The condenser temperature and pressure are lower. Since the turbine exhaust is to be discharged back into the ocean, a direct contact condenser is used to mix the exhaust with cold water, which results in a near-saturated water. That water is now discharged back to the ocean. H6=Hf, at T5. T7 is the temperature of the exhaust mixed with cold sea water, as the vapour content now is negligible,

The temperature differences between stages include that between warm surface water and working steam, that between exhaust steam and cooling water, and that between cooling water reaching the condenser and deep water. These represent external irreversibilities that reduce the overall temperature difference. The cold water flow rate per unit turbine mass flow rate,

Turbine mass flow rate,

Warm water mass flow rate,

Cold water mass flow rate

[edit]Closed/Anderson

cycle

Developed starting in the 1960s by J. Hilbert Anderson of Sea Solar Power, Inc. In this cycle, QH is the heat transferred in the evaporator from the warm sea water to the working fluid. The working fluid exits the evaporator as a gas near its dew point. The high-pressure, high-temperature gas then is expanded in the turbine to yield turbine work, WT. The working fluid is slightly superheated at the turbine exit and the turbine typically has an efficiency of 90% based on reversible, adiabatic expansion. From the turbine exit, the working fluid enters the condenser where it rejects heat, -QC, to the cold sea water. The condensate is then compressed to the highest pressure in the cycle, requiring condensate pump work, WC. Thus, the Anderson closed cycle is a Rankine-type cycle similar to the conventional power plant steam cycle except that in the Anderson cycle the working fluid is never superheated more than a few degrees Fahrenheit. Owing to viscous effects, working fluid pressure drops in both the evaporator and the condenser. This pressure drop, which depends on the types of heat exchangers used, must be considered in final design calculations but is ignored here to simplify the analysis. Thus, the parasitic condensate pump work, WC, computed here will be lower than if the heat exchanger pressure drop was included. The major additional parasitic energy requirements in the OTEC plant are the cold water pump work, WCT, and the warm water pump work, WHT. Denoting all other parasitic energy requirements by WA, the net work from the OTEC plant, WNP is

The thermodynamic cycle undergone by the working fluid can be analyzed without detailed consideration of the parasitic energy requirements. From the first law of thermodynamics, the energy balance for the working fluid as the system is

where WN = WT + WC is the net work for the thermodynamic cycle. For the idealized case in which there is no working fluid pressure drop in the heat exchangers,

and

so that the net thermodynamic cycle work becomes

Subcooled liquid enters the evaporator. Due to the heat exchange with warm sea water, evaporation takes place and usually superheated vapor leaves the evaporator. This vapor drives

Das könnte Ihnen auch gefallen

- Atom WorksheetsDokument4 SeitenAtom Worksheetsapi-271960049Noch keine Bewertungen

- HAZOP Training290620Dokument93 SeitenHAZOP Training290620NasrulNoch keine Bewertungen

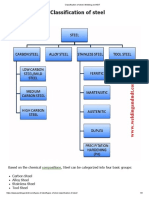

- Classification of Steel - Welding and NDTDokument3 SeitenClassification of Steel - Welding and NDTAshif Iqubal100% (1)

- Advanced PharmacognosyDokument13 SeitenAdvanced PharmacognosyLisa DamayantiNoch keine Bewertungen

- The Technically Impossible HolocaustDokument20 SeitenThe Technically Impossible HolocaustHuckelberry100% (2)

- DNV-RP-F106 (2003) - Factory Applied External Pipeline Coatings For Corrosion ControlDokument32 SeitenDNV-RP-F106 (2003) - Factory Applied External Pipeline Coatings For Corrosion ControlJohnnyNoch keine Bewertungen

- Sludge Dewatering PDFDokument36 SeitenSludge Dewatering PDFPaul Maposa100% (2)

- Renewable Energy Sources For Caribbean Territories and SIDS: OTECDokument40 SeitenRenewable Energy Sources For Caribbean Territories and SIDS: OTECMouaamou AbdeljabbarNoch keine Bewertungen

- For Power PlantDokument224 SeitenFor Power PlantIrene Mununi100% (2)

- Ocean Thermal Energy Conversion (OTEC)Dokument28 SeitenOcean Thermal Energy Conversion (OTEC)Sehati FisikaNoch keine Bewertungen

- Ocean Thermal Energy ConversionDokument43 SeitenOcean Thermal Energy ConversionMaitry DaveNoch keine Bewertungen

- CorrosionDokument14 SeitenCorrosionChalakAhmedNoch keine Bewertungen

- Ocean Thermal Energy Conversion Tide Current and Tide RangeDokument56 SeitenOcean Thermal Energy Conversion Tide Current and Tide RangeSiddharth PatelNoch keine Bewertungen

- Ocean Thermal Energy ConversionDokument13 SeitenOcean Thermal Energy ConversionRandroxRNoch keine Bewertungen

- AKL10 Laser Technology LiveDokument49 SeitenAKL10 Laser Technology LiveXin ChenNoch keine Bewertungen

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningVon EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningBewertung: 5 von 5 Sternen5/5 (2)

- Chem 152 Lab 4Dokument4 SeitenChem 152 Lab 4mifferdk23% (13)

- Thermo OTECDokument15 SeitenThermo OTECzikri annuurNoch keine Bewertungen

- Ocean Thermal Energy Conversion: By-Snehanshu Das 7 Sem, B.TechDokument20 SeitenOcean Thermal Energy Conversion: By-Snehanshu Das 7 Sem, B.TechJeanNoch keine Bewertungen

- Harness Solar Energy with OTECDokument6 SeitenHarness Solar Energy with OTECscharichNoch keine Bewertungen

- OTECDokument14 SeitenOTECTALLURI LAKSHMI PRASANNANoch keine Bewertungen

- OceanThermalEnergyConversion Converts Ocean Temperature Gradient into ElectricityDokument18 SeitenOceanThermalEnergyConversion Converts Ocean Temperature Gradient into ElectricityHappy PatelNoch keine Bewertungen

- Vivek Chand OTECDokument20 SeitenVivek Chand OTECvivek chand100% (1)

- Ocean Thermal Energy Conversion (OTECDokument14 SeitenOcean Thermal Energy Conversion (OTECRahul Kumar YadavNoch keine Bewertungen

- Close&Hybrid OTECDokument26 SeitenClose&Hybrid OTECJohn Jay AbinalNoch keine Bewertungen

- Otec Power Plant: NcercDokument22 SeitenOtec Power Plant: NcercVimi WilsonNoch keine Bewertungen

- OCEAN THERMAL ENERGY CONVERSION: A RENEWABLE ENERGY SOURCEDokument20 SeitenOCEAN THERMAL ENERGY CONVERSION: A RENEWABLE ENERGY SOURCEAthisayaraj RajNoch keine Bewertungen

- A Technical Paper Presentation On: Ocean Thermal Energy ConversionDokument20 SeitenA Technical Paper Presentation On: Ocean Thermal Energy ConversionsaurabhNoch keine Bewertungen

- Ocean Energy Conversion Methods: Arshad Babu. U M7B Roll No: 7457 TKMCE KollamDokument32 SeitenOcean Energy Conversion Methods: Arshad Babu. U M7B Roll No: 7457 TKMCE KollamgaviNoch keine Bewertungen

- BY Maha Barathi Engineering College Ramanathan.R/Ap/EeeDokument224 SeitenBY Maha Barathi Engineering College Ramanathan.R/Ap/EeeRaj RohitNoch keine Bewertungen

- Documenttopdf Trial Version, To Remove This Mark, Please Register This SoftwareDokument10 SeitenDocumenttopdf Trial Version, To Remove This Mark, Please Register This Softwareranga247Noch keine Bewertungen

- OotecDokument12 SeitenOotecLouie Jay Gitgitin SalvañaNoch keine Bewertungen

- Energy From The Oceans: (OTEC, Tides, Waves, and Small Hydroelectric)Dokument55 SeitenEnergy From The Oceans: (OTEC, Tides, Waves, and Small Hydroelectric)Patel NikhilNoch keine Bewertungen

- Ocean Power: Ed Lemery, Brooke Scatchard, Nate TrachimowiczDokument19 SeitenOcean Power: Ed Lemery, Brooke Scatchard, Nate TrachimowiczGanesh Kumar100% (1)

- OTEC - Ocean Thermal Energy Conversion: by Maria Bechtel and Erik NetzDokument12 SeitenOTEC - Ocean Thermal Energy Conversion: by Maria Bechtel and Erik NetzrodrigoflaNoch keine Bewertungen

- Chapter - 5 OTECDokument12 SeitenChapter - 5 OTECsahitNoch keine Bewertungen

- Ocean Thermal Energy Conversion (Otec)Dokument4 SeitenOcean Thermal Energy Conversion (Otec)Sarvani ShettigarNoch keine Bewertungen

- Documenttopdf Trial Version, To Remove This Mark, Please Register This SoftwareDokument11 SeitenDocumenttopdf Trial Version, To Remove This Mark, Please Register This Softwareranga247Noch keine Bewertungen

- All Power Plants in DetailDokument224 SeitenAll Power Plants in Detailk rajendraNoch keine Bewertungen

- Module No 5a.ocean EnergyDokument15 SeitenModule No 5a.ocean EnergyVaibhav Vithoba NaikNoch keine Bewertungen

- OCEAN THERMAL ENERGY CONVERSION SEMINAR REPORTDokument9 SeitenOCEAN THERMAL ENERGY CONVERSION SEMINAR REPORTShreya RathoreNoch keine Bewertungen

- Ocean Thermal Wave Energy ConversionsDokument12 SeitenOcean Thermal Wave Energy ConversionsJoseph Gil SalcedoNoch keine Bewertungen

- Case Study Report On: Pyre 202 - Wind Energy, Tidal Energy and OtecDokument15 SeitenCase Study Report On: Pyre 202 - Wind Energy, Tidal Energy and OtecsundarNoch keine Bewertungen

- OTECDokument18 SeitenOTECkss_sachinvarma12100% (2)

- AGOJO - Ocean Thermal Energy ConversionDokument14 SeitenAGOJO - Ocean Thermal Energy ConversionCarren MarquezNoch keine Bewertungen

- Ocean Thermal Energy Conversion (OTEC)Dokument8 SeitenOcean Thermal Energy Conversion (OTEC)Vanne Jo PajoNoch keine Bewertungen

- JMI ESc OTECDokument16 SeitenJMI ESc OTECAJKNoch keine Bewertungen

- Ocean Thermal EnergyDokument19 SeitenOcean Thermal EnergyabdulzubairNoch keine Bewertungen

- Ocean Thermal Energy ConversionDokument17 SeitenOcean Thermal Energy ConversionVamsi Pelluru100% (1)

- Orissa School of Mining Enginering Seminar On Geo Thermal EnergyDokument22 SeitenOrissa School of Mining Enginering Seminar On Geo Thermal EnergySailendra KumarNoch keine Bewertungen

- Ocean Thermal Energy Conversion: ETB 10 Desember 2013Dokument35 SeitenOcean Thermal Energy Conversion: ETB 10 Desember 2013Mohammad Hanri HardianNoch keine Bewertungen

- Presentation On Ocean Thermal Energy ConvertionDokument23 SeitenPresentation On Ocean Thermal Energy ConvertionAtal SahaNoch keine Bewertungen

- Renewable Energy Sources For Caribbean Territories and SIDS: OTECDokument42 SeitenRenewable Energy Sources For Caribbean Territories and SIDS: OTECVinay MaisuriyaNoch keine Bewertungen

- OTECDokument30 SeitenOTECNeelikaNoch keine Bewertungen

- Ocean Thermal Energy: Submitted To DR - Harmeet KaurDokument19 SeitenOcean Thermal Energy: Submitted To DR - Harmeet KaurAmitpal Singh CheemaNoch keine Bewertungen

- Nes Module IIIDokument12 SeitenNes Module IIIVenuNoch keine Bewertungen

- HereDokument3 SeitenHereBilly Joe BreakfastNoch keine Bewertungen

- Ocean Thermal Energy Conversion - PPTX Neelu OtecDokument17 SeitenOcean Thermal Energy Conversion - PPTX Neelu OtecrahulNoch keine Bewertungen

- Unit IV OTECDokument51 SeitenUnit IV OTECAisha JainNoch keine Bewertungen

- Ocean Thermal Energy Conversion: Harnessing Temperature DifferencesDokument12 SeitenOcean Thermal Energy Conversion: Harnessing Temperature DifferencesVidushi VinodNoch keine Bewertungen

- Ocean Thermal EnergyDokument23 SeitenOcean Thermal EnergyNAGMANI59Noch keine Bewertungen

- Presentation 3-2Dokument4 SeitenPresentation 3-2Vighnesh BhatNoch keine Bewertungen

- Seminar Report On Ocean Thermal Energy ConversionDokument21 SeitenSeminar Report On Ocean Thermal Energy ConversionHARENDRA BHINCHARNoch keine Bewertungen

- ORO551 Unit 5 Geothermal EnergyDokument58 SeitenORO551 Unit 5 Geothermal EnergyRakshambika RNNoch keine Bewertungen

- Ocean Thermal Energy Conversion: International Journal of Energy and Power EngineeringDokument4 SeitenOcean Thermal Energy Conversion: International Journal of Energy and Power EngineeringKemas Ganesha MahendraNoch keine Bewertungen

- Presented By: Anirban Karmakar (E.E) Roll No. 20Dokument20 SeitenPresented By: Anirban Karmakar (E.E) Roll No. 20Mayank GuptaNoch keine Bewertungen

- PCRES April2020 OTEC NotesDokument35 SeitenPCRES April2020 OTEC NotesVISHAL MUKUNDANNoch keine Bewertungen

- Mech Ocean Thermal EnergyDokument15 SeitenMech Ocean Thermal EnergyDarlig Harsha'sNoch keine Bewertungen

- Ocean Thermal Power Plant ReportDokument10 SeitenOcean Thermal Power Plant ReportMahmud L. MusaNoch keine Bewertungen

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesVon EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNoch keine Bewertungen

- Re 25715 - 2022-05Dokument8 SeitenRe 25715 - 2022-05HeiderHuertaNoch keine Bewertungen

- Laprak Distilasi UapDokument11 SeitenLaprak Distilasi UapRetnani Arum PertiwiNoch keine Bewertungen

- Monoproof Pu 1000: Single Component, Aliphatic, Water Based Exterior Pu Modified, Flexible Water Proofing MembraneDokument5 SeitenMonoproof Pu 1000: Single Component, Aliphatic, Water Based Exterior Pu Modified, Flexible Water Proofing MembraneMonarch DigitalNoch keine Bewertungen

- Imp Questions For Unit-1Dokument12 SeitenImp Questions For Unit-1aravelli abhinavNoch keine Bewertungen

- Marshall Tufflex: GRP Cable Management SystemsDokument18 SeitenMarshall Tufflex: GRP Cable Management SystemsGabriel BroascaNoch keine Bewertungen

- Year 8 Science End of Term 1 Test: AnswerDokument11 SeitenYear 8 Science End of Term 1 Test: Answerchan myaeNoch keine Bewertungen

- 4.7 Lab - Percentage of Water in PopcornDokument3 Seiten4.7 Lab - Percentage of Water in PopcornVansh PatelNoch keine Bewertungen

- Activity Coefficients of The Tetramethyl Compounds of Group 14 Elements in N-Alkane Solutions From g.1.c. MeasurementsDokument7 SeitenActivity Coefficients of The Tetramethyl Compounds of Group 14 Elements in N-Alkane Solutions From g.1.c. Measurementsm_adnane_dz3184Noch keine Bewertungen

- Recycling OF Aluminum Salt Cake: ANL/CP - 73449 DE92 003408Dokument20 SeitenRecycling OF Aluminum Salt Cake: ANL/CP - 73449 DE92 003408Vijaykumar SharmaNoch keine Bewertungen

- Charles Law ExplainedDokument3 SeitenCharles Law ExplainedKaren May UrlandaNoch keine Bewertungen

- Matriculation Chemistry (Reaction Kinetics) Part 1Dokument13 SeitenMatriculation Chemistry (Reaction Kinetics) Part 1ridwan100% (2)

- FINALDokument16 SeitenFINALdushyanth rajNoch keine Bewertungen

- TebuconazoleDokument195 SeitenTebuconazoleKen EspinoNoch keine Bewertungen

- S1 2016 330961 BibliographyDokument6 SeitenS1 2016 330961 BibliographyVelda KartikaswastiNoch keine Bewertungen

- Efficient Synthesis of 3-Hydroxy-1,4-Benzodiazepines Oxazepam and Lorazepam by New Acetoxylation Reaction of 3-Position of 1,4-Benzodiazepine Ring - Organic Process Research & DevelopmentDokument12 SeitenEfficient Synthesis of 3-Hydroxy-1,4-Benzodiazepines Oxazepam and Lorazepam by New Acetoxylation Reaction of 3-Position of 1,4-Benzodiazepine Ring - Organic Process Research & DevelopmentSimon GeschwindNoch keine Bewertungen

- Ch11EN Fluid Unit Flow PathDokument1 SeiteCh11EN Fluid Unit Flow PathHermeson SantiagoNoch keine Bewertungen

- Tandem Dyes For Flow Cytometry, Quality Concerns, Beckman CoDokument2 SeitenTandem Dyes For Flow Cytometry, Quality Concerns, Beckman CocandiddreamsNoch keine Bewertungen

- A Seminar Report OnDokument1 SeiteA Seminar Report Onu10ch019Noch keine Bewertungen

- PFOA Factsheet (Revised)Dokument8 SeitenPFOA Factsheet (Revised)AngshumanNoch keine Bewertungen

- Arkema POF Brochure 2019Dokument6 SeitenArkema POF Brochure 2019julioNoch keine Bewertungen