Beruflich Dokumente

Kultur Dokumente

Extruded Products

Hochgeladen von

Sagl PreetOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Extruded Products

Hochgeladen von

Sagl PreetCopyright:

Verfügbare Formate

Extruded Products.

Technology without limits.

Without limits. Our view of extrusion.

Extrusion stands for food and feed products according to the latest understanding of nutritional science. What makes it really unique is its boundless versatility. Let your imagination run wild we turn dreams into reality!

Beat Mller, Manager Pasta & Extruded Products segment

Crispy, golden yellow and crunchy or airy, ery-spiced and bright colored. You know what is tasty! Snacks, cereals and other foodstuffs originate in the minds of our customers. We, at Buhler make products out of visions and offer a one-stop solution for all the required services. The plants and processes developed by us mirror the ideas of resourceful companies and the different lifestyles and customs of our cultural milieus. More than just goods Extrusion has a very decisive advantage: Its only limits are the one you set. Shape, colour, aroma here it is the market and its imagination that sets the pace. We convert trends and bring your ideas to life. In a world that demands more than simple goods, your cereals and snacks, cut a good gure, have style or are fun. In foodstuffs, other properties besides the form such as taste and consistency are in the spotlight. That is why extrusion has a future in the consumer markets. Buhlers expertise lies in the following areas: Cereals Snacks Pet food Aquafeed Food Ingredients Automation Customer Service

Individual until everything is right Our systems are tailored because our technologists and developers occupy themselves constantly with innovations for new products. Our customers and the consumers of cereals and snacks push us daily for this. Our motivations are solutions. We research, we strive, and we experiment until we can produce what you can sell well and with pleasure. Served from A to Z The depth of production of the Buhler Company ensures a concentrated amount of know-how. That is why competence for us is far beyond what is normally meant by this term. From the raw material in the silos up to the sales-ready packing our specialists make good use of synergies. We work with an overall view throughout the world. We provide an all-round service from the rst idea, through product development up to the layout of your factory. Our consultations greatly ease your corporate decisions. We rst test your new products in our own laboratory. There we plan your investment in detail to conrm their feasibility. That is why we set the standard in things quality. Which products are you dreaming of? Put our research abilities to the test.

BHLER PASTA & EXTRUDED PRODUCTS TECHNOLOGY WITHOUT LIMITS

Cereals and Snacks. Crispy Zeitgeist part of the scene.

Cereals and snacks are lifestyle products that attract attention in the marketplace. With our processes you are in pole position.

Doris Sieber, Marketing & Communication

Cereals Around the world they are the highlight of a proper breakfast table: cereals. They start the day right. Cereals are the rst consciously created reform foodstuff to conquer the market. Extrusion, batch cooking and aking are our processes for producing cereals. For this purpose we supply individual machines as well as product lines and processes.

Snacks Snacks accompany social or simply nice moments. For this reason we give them our full attention, already before production. Continuous cooking and shaping, or simply just kneading and shaping are the most important steps for direct or indirect expanding snacks. Everything is possible here: direct expanded snacks, as well as semi-nished snack pellets with two- or three-dimensional shapes and co-extruded shells with llings. Cooking and shaping can also be carried out in two steps in separate machines, Our single shaft press with vertical cut produces snack pellets with the highest precision.

Extruding, aking, drying These processes together are the three core steps. A pre-conditioner mixes grain ours with various additives and moistens them with direct steam. In order to save energy in the extruder, the mixture is heated to almost 100 C preconditioned. Renewed mixing, kneading and cooking are carried out by the Buhler extruder. Nozzle and cutter produce stars, owers, rings and innumerable other shapes, for instance lentil-type pellets for cornakes. The akes acquire their typical golden yellow color, ne taste and crispiness during roasting. Then they can be sprayed with sugar, aromas and vitamins.

Processes for trends Our plants provide everything that your marketing promises. Vitality, harmony, adventure and enjoyment there is almost no feeling that Buhler does not awaken with a process. With Buhler as a partner you are prepared for the consumer trends of tomorrow. Besides processes for the most varied of shapes, colours, consistency and tastes, we also offer revolutionary equipment for producing healthy nourishment. Products must keep to their promises. For this reason cereals and snacks from our systems are top sellers in shops throughout the world.

BHLER PASTA & EXTRUDED PRODUCTS TECHNOLOGY WITHOUT LIMITS

Diversity in colour, shape and taste. Cereals that inspire.

Flakes Our processes for your akes. Whether cornakes or multi-grain, rice or wheat, traditionally cooked or extruded, we are certain to have the right thing for you.

Co-extruded products Fill your cereals with water or fat-based masses. Whether sweet or salty, always a pleasure.

Directly expanded products Are you rather traditional or innovative adventurous? You can get your product from us. Popular, current shapes or products developed to your wishes. You decide on colour, shape and taste we on the process.

Inviting Snacks.

Directly expanded snacks Equipment and processes for your directly expanded snacks From our to sprayed and seasoned nished products With our products you are on the right path.

Indirectly expanded Snacks If you produce semi-nished snacks, pellets out of native or pre-cooked raw materials for further processing in a deep fryer or roaster.

Shape diversity Create new products. You decide on the shape we will develop the process. Whether shape-cut or cut at the nozzle we are happy to support you.

Extrusion. Twin-shaft extruder.

The modular twin-screw extrusion system covers the whole working range from laboratory scale to the highest production performance. The extruder can be adjusted to the desired application process.

Batch cooking. Rotary pressure cooker.

The rotag pressure cooker cooks batches (discontinuously) of whole grains and large grain fractions. The whole drum is of stainless steel. The pressure vessel has a volume of 1700 l and cooks batches of 800 kg. The cooking cycle is monitored by a separate control set.

BHLER PASTA & EXTRUDED PRODUCTS TECHNOLOGY WITHOUT LIMITS

Food Ingredients. Innovative processes for modern demands.

Consumers are discriminating, Consumers want healthy nutrition, Consumers want fair prices. Rightly so! Buhler systems meet the current, constantly changing requirements flexibly, efficiently and economically.

Christopher Rubin, Manager Product Marketing

The extruder is excellently suited for the production of our derivatives; bread crumbs as modied ours and starches and all types of other food ingredients. Our process makes possible very specic properties of the products. The extruder has also proven itself in producing textured proteins. Bread crumbs With suitable grinding, bread crumbs, llers and stufng are created when using the correct composition of the raw materials and the optimal settings during extrusion. Texture, porosity, colouring and granulation as desired. Modied ours and starches Pre-gelatinized our and pre-gelatinized starches are characterized by a changed water absorption and solubility. You decide how viscous this our-water suspension is to be. The ours and starches attain their desired properties by the introduction of suitable mechanical or thermal energy. Derivates Starches and our derivatives with special properties for the paper and textile industries. The extruder starts the necessary chemical reactions. Contrary to traditional batch cooking, these occur in the extruder much faster and with much less moisture. Instant foodstuffs Industrially produced foodstuffs for as convenience foods are growing. In emerging markets, on the other hand, they assist in covering basic nutritional requirements. The extruder also produces instant foodstuffs. You determine the suitable nutritional physiologically sensible recipe.

Mill by-products Extruders make waste and by-products valuable. Millers rene bran or rice polishings in that they process them in a targeted thermal or mechanical manner. The process stabilizes the product enzymatically for oil extraction. Bran is enhanced by the extruder in a tasty and nutritional physiological manner. Textrudates (textured Extrudate) Protein-rich raw materials primarily Soya form the basis of meat-type products. Buhler has also developed the special process which produces textured proteins as meat substitutes by means of extrusion. These correspond to a trend in modern nutrition. The extruder ensures brous meat-like textures. We differentiate between expanded textrudates and wet textrudates. Expanded textrudates are suitable for llers, for example, in meat balls or Pizza coverings. Larger pieces can be found in some prepared meals as a meat substitute. Wet textrudates, because of their properties have a large market potential. Because they ow out of the nozzle at low temperatures, they do not expand. Usually granulated and then deep-frozen, they possess an improved brous structure. Textrudates is a protected trademark of the Buhler Company. We will be happy to show you further innovations.

BHLER PASTA & EXTRUDED PRODUCTS TECHNOLOGY WITHOUT LIMITS

Diversity in Colour, Shape and Utilization. Basis for healthy nutrition.

Rice Rene broken rice. With our products you can extrude new rice grains from it if desired also enriched with vitamins.

Flours and starches High requirements of water absorption and Solubility of ours and starches? No problem. By means of extrusion you will achieve your desired product properties!

Soya Follow trends early: Extruded textured Soya proteins as meat Substitute products. A treat with a future.

Mill by-products Add value by means of extrusion. Rene your by-products such as bran or rice polishings.

Bread crumbs Grainstometry texture and colour your bread crumbs adapted to your requirements.

Derivates Produce our and starch derivatives with functional properties by means of extrusion.

BHLER PASTA & EXTRUDED PRODUCTS TECHNOLOGY WITHOUT LIMITS

Drying and cooling. Fluidized Bed Dryer/Cooler.

The uidized bed dryer/cooler is best suited for the continuous thermal treatment of extrudates from a size of 0.25 mm The uid bed uidizes as a cross-current immersion of individual particles, dries and cools them gently and efciently over the whole length of the bed.

Drying Roasting and Cooling. Fluid bed dryer and roaster.

By means of the uid bed, pellets and owing products are dried and roasted. A modular chamber system enables an exact dwell time and the corresponding throughput.

BHLER PASTA & EXTRUDED PRODUCTS TECHNOLOGY WITHOUT LIMITS

10

Animal Food. For animal success stories.

Extrusion fulfils innumerable wishes of animals and their owners. This calls upon the whole of our know-how.

Dieter Hofacker, Manager Engineering

Domestic animals are mankinds most loyal companions. That is why they deserve to be spoilt. Their food is attractive and so healthy that they can lead a long, healthy life. Also, keeping sh for optimal breeding requires particular feed properties. Domestic animal nutrition Modern domestic animal nutrition requires gentle preparation. Only with balanced feeding will there be no deciency symptoms in the loved ones. Extrusion guarantees high value feed. It is the ideal technology for exact dosing and to make the feed tasty with attractive colours and shapes. Acquaculture feed Whether utility shes or decorative shes both have very different requirements for their feed so that they can take it up and absorb it optimally. Decisive factors are density, rate of sinking, high water absorption and stability.

The process After ne-milling, sh feed is sieved in order to pull out coarser particles, which can block up the shaping nozzles. Both sh and domestic animal feeds seem to be made for the extruder. It modies starches, denatures proteins and adds shape and texture before the products expand. Subsequently, the hot melt is portioned by a cutting arrangement. This can be exchanged during the process. Thanks to multi-step drying (hot air movement, uid bed, belt or counterow dryer) even wet and sticky extrudates quickly acquire the desired moisture content gently and deformation-free. Spray fats, colouring, taste and attractants or even powder components onto the dried feed completely to the requirements of your consumers.

12

BHLER PASTA & EXTRUDED PRODUCTS TECHNOLOGY WITHOUT LIMITS

A la carte. Petfood for the dear one at home.

Kibbles For dogs and cats as well as for rodents. Kibbles with a moisture content of less than 8%.

Multi-coloured Produce multi-coloured products continuously on an extruder thanks to a patented Buhler process.

Filled Filled products on a dry or semi-moist base. The lled strings are sealed by a downstream cutting system.

Aquafeed

Floating Pellets with moderate protein and fat content for warmwater species such as Tilapia, Catsh, Eel, etc.

Sinking Pellets with high protein and fat contents with good water absorption and stability. Slow sinking in saltwater, special for Salmonides and sea water shes such as Yellow Tail, Sea Bream, Sea Bass, etc.

Fast sinking Fast sinking pellets which retain their elastic structure after hours in the water.

BHLER PASTA & EXTRUDED PRODUCTS TECHNOLOGY WITHOUT LIMITS

13

Pre-Conditioning and Extruding. ECOtwin twin shaft extruder.

The ECOtwinTM is distinguished by the highest degree of operating safety and user friendliness. Best reproducible qualities are the characteristics of its modules (SME, Density Control). The system reacts to swings in the raw material quality and changes the properties of the extrudate in the shortest time without reconguration. Cleaning is very simple as all critical zones are easily accessible.

Mixing and Dwelling. Two-Step Pre-Conditioner.

The pre-conditioner divides the process into two steps. First it mixes the raw material with steam, water or other uids, then the raw material is fed into the retention section. In six sizes, the Buhler pre-conditioners cover many applications of throughput and dwell times. Thus, the economical all-rounder is suitable for all possible applications.

BHLER PASTA & EXTRUDED PRODUCTS TECHNOLOGY WITHOUT LIMITS

14

Flaking. Noble quality does not fade.

Technological, technical and economic characteristics make the Buhler aking mill untouchable and also make the product successful.

Teddy Sutter, Sales Manager

The Buhler aking mill has proven itself well in the manufacture of delicious breakfast and grain akes. But not only that the mill is also selected for special products which are increasingly being asked for by consumers. The Buhler aking mill has long been established with the leading breakfast and grain akes manufacturers as the standard. Its popularity is especially due to its exibility and performance capability. The aking mill makes possible the best adaptation to customer-specic requirements. The small footprint, variable arrangement of the drive, the product feed and the outlet allow it to be placed as required. A signicant increase in

performance compared to the previous model leads to a high degree of economy. The aking mill delivers an excellent quality with a product-dependent output of 1300 6000 kg/h.

16

BHLER PASTA & EXTRUDED PRODUCTS TECHNOLOGY WITHOUT LIMITS

Buhler Process Automation. Economically fast.

Buhler offers the optimal solution especially for the production of extruded products. The extrusion controls are characterized by a high degree of exibility, user friendliness and open system structure. Here too, the basic system can be extended by individual modules. The utilization of tailored control technology by Buhler relieves the operating foreman, produces less waste with the same product quality. Time is saved by quick product changes leading to higher plant availability. In short the controls are also convincing due to their economic properties. Thanks to the Touch-PC, the intelligent process controls correspond to the trend and greatly support the work of the personnel. Automatic acquisition of the operating data and simultaneous display of stored values ensure exact traceability and regulable production parameters. Up to eight trend curves can be shown at the same time in the process controls. Complete language change, independent of the language of the PC operating system in use, lifts the Buhler controls clearly above the competition.

Service and Training. Lifelong contact person.

Even before the purchase of a Buhler plant our service begins with the planning of the installation, nancing and production development. Buhler provides support with competent specialists. Extrusion technology In our extrusion pilot plant we are constantly developing new products, procedures and equipment on a scientic basis. Our specialists continually optimize the processes. We concentrate fully on you so that you can completely work on your success. Your plans are a welcome challenge for us. Your products are tested by us, so that your operation does not suffer production losses. Engineering An engineering team is responsible for planning and coordination It ensures smooth development of your job. Erection and start-up Our own erection and start-up specialists ensure proper erection and building site management and a seamless operation up to start-up. Training for your operating personnel If desired, Buhler offers the training of your personnel at site or at the pilot plant at our headquarters. Customer service Our engineers are at your disposal at your premises or in Uzwil. They ensure problem-free utilization of our machines over the whole period of their utility. Have you any questions or proposals? We look forward to hearing from you!

BHLER PASTA & EXTRUDED PRODUCTS TECHNOLOGY WITHOUT LIMITS

17

Bhler AG CH-9240 Uzwil, Switzerland T + 41 71 955 11 11 F + 41 71 955 33 88 E-Mail: extrusion@buhlergroup.com www.buhlergroup.com

PE 55024 en 0407 2000 DF

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Owatch VR Games Quotation - 2017!4!24Dokument3 SeitenOwatch VR Games Quotation - 2017!4!24ali4957270Noch keine Bewertungen

- Power Tool Switches: Catalog 1308650 Issued 1-01Dokument18 SeitenPower Tool Switches: Catalog 1308650 Issued 1-01Gamal AhmadNoch keine Bewertungen

- CT v2.0 UnderstandingDokument36 SeitenCT v2.0 UnderstandingAbel Chaiña GonzalesNoch keine Bewertungen

- CV - Pramod For Store & Logistics..Dokument2 SeitenCV - Pramod For Store & Logistics..Anuj sainiNoch keine Bewertungen

- Carbon Regeneration KilnsDokument3 SeitenCarbon Regeneration KilnsLuis LabradorNoch keine Bewertungen

- Toyota 80 SeriesDokument5 SeitenToyota 80 Seriesaagi_dNoch keine Bewertungen

- Electrical Model of Thermal Power PlantDokument81 SeitenElectrical Model of Thermal Power PlantMahesh KumbharNoch keine Bewertungen

- Grade 11 Electricity W.sheetDokument6 SeitenGrade 11 Electricity W.sheetUsman AmeenNoch keine Bewertungen

- Ganesh Balasubramanian (Eds.) - Advances in Nanomaterials - Fundamentals, Properties and Applications-Springer International Publishing (2018)Dokument181 SeitenGanesh Balasubramanian (Eds.) - Advances in Nanomaterials - Fundamentals, Properties and Applications-Springer International Publishing (2018)Jesus Moreno Castillo100% (1)

- Technical Delivery Condition of S500MCDokument4 SeitenTechnical Delivery Condition of S500MCdcevipin100% (1)

- Calculating The Maximum Attenuation For Optical Fiber LinksDokument5 SeitenCalculating The Maximum Attenuation For Optical Fiber LinksMiguel LiceagaNoch keine Bewertungen

- Shrinkage Strip Method Statment and Ther PDFDokument4 SeitenShrinkage Strip Method Statment and Ther PDFhakim2020Noch keine Bewertungen

- Table StructureDokument180 SeitenTable StructureVictor PathakNoch keine Bewertungen

- Matrix APDDokument1 SeiteMatrix APDQHSE BTGNoch keine Bewertungen

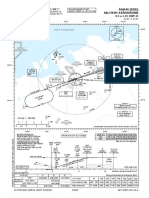

- I/G/O I/G/O A/M/I: Instrument Approach Chart - IcaoDokument1 SeiteI/G/O I/G/O A/M/I: Instrument Approach Chart - IcaoMIkołaj MorzeNoch keine Bewertungen

- Module Pool Select OptionDokument53 SeitenModule Pool Select Optionajit sahuNoch keine Bewertungen

- Physical Mechanical and Flexural Properties of 3 Orthodontic Wires An in Vitro Study. DANIELA DLICANDokument8 SeitenPhysical Mechanical and Flexural Properties of 3 Orthodontic Wires An in Vitro Study. DANIELA DLICANAlvaro ChacónNoch keine Bewertungen

- Tone ReportDokument58 SeitenTone ReportchuchisNoch keine Bewertungen

- Case Study: Line 1 Metro de Quito (Ecuador) : Project Specifications Project FiguresDokument4 SeitenCase Study: Line 1 Metro de Quito (Ecuador) : Project Specifications Project Figuresrodrigogomez87Noch keine Bewertungen

- Design and Development of Vibratory Cockles Grading MachineDokument23 SeitenDesign and Development of Vibratory Cockles Grading MachinehalizaNoch keine Bewertungen

- PD 8010 2 Presentation April 2005 NewDokument40 SeitenPD 8010 2 Presentation April 2005 NewSuphi YükselNoch keine Bewertungen

- HandRail Specsgf For CfvdrfsDokument3 SeitenHandRail Specsgf For CfvdrfsTarek TarekNoch keine Bewertungen

- Automotive DevicesDokument152 SeitenAutomotive DevicesLeticia PaesNoch keine Bewertungen

- An Assignment On Double Chute Feed SystemDokument11 SeitenAn Assignment On Double Chute Feed SystemShawan Roy100% (1)

- Sukrosa PDFDokument5 SeitenSukrosa PDFSilvi TatianNoch keine Bewertungen

- PPTDokument22 SeitenPPTMuhamMad TaufikNoch keine Bewertungen

- Tabl Navegacion Aqua SignalDokument4 SeitenTabl Navegacion Aqua SignalNelson Aguirre BravoNoch keine Bewertungen

- Hiab Knuckle Boom Articulating Cranes Spec 54f3f3Dokument5 SeitenHiab Knuckle Boom Articulating Cranes Spec 54f3f3Quỳnh Như Nguyễn ThịNoch keine Bewertungen

- Maps and Damos ID For EDC16 VAG ECUDokument7 SeitenMaps and Damos ID For EDC16 VAG ECUGuler RahimNoch keine Bewertungen

- ITC Guide For Thesis PreparationDokument26 SeitenITC Guide For Thesis PreparationPanha MenhNoch keine Bewertungen