Beruflich Dokumente

Kultur Dokumente

Marine Seawater Valves

Hochgeladen von

Phornlert WanaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Marine Seawater Valves

Hochgeladen von

Phornlert WanaCopyright:

Verfügbare Formate

Marine and Seawater Ball ValVeS

Shipbuilding Bilge Ballast Utility Seawater Sea-Chest Injection Water Pump Skids Water Flood

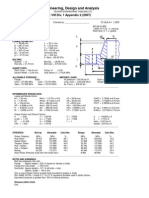

anatomy of a Seawater Ball

1/4 through 10 sizes full and reduced port, in various alloys

compatible with seawater environments. Spring-loaded washers create a live-loaded stem assembly for positive sealing. Internal design produces a bubble-tight seal. Standard bottom-entry stem provides protection against inadvertent stem removal. USCG Category A shut off is available. Valves are 100% factory-tested. Pneumatic, electric and hydraulic automation available. Solenoids and position indicators available.

ValVe

Bronze 2-way SP SerieS ValVe CoMPariSon

SERIES 1 Standard Body/End Material Standard Trim Material Standard Seat/Seal Material Swing Out Design Body Bolt Patterns Actuator Mounting Valve Weight (lbs.) 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 4 Face-to-Face Dimensions (inches)

836 Bronze (B62, C83600) 316 Stainless Steel RTFE (Glass Filled Teflon) No Non-Symmetric on 1/21 and 3 sizes Standard except 1-1/4

SERIES 5

922 Bronze (B61, C92200) 316 Stainless Steel TFM Yes Symmetric patterns on all sizes (4 bolts up to 3, 8 bolts on 4) Standard

FNPT, SilBraze, SW, Solder Joint

2 3 4 8 9.5 13 33 49 84

150# F.F. Flange

5.0 6.4 8.6 14.5 17 25 52 77 115

FNPT, SilBraze, SW, Solder Joint

2 2 5 N/A 11 17 37 50** 133**

150# F.F. Flange

4 6 0 N/A 17 26 53 64** 143**

taBle

of

ContentS

Anatomy and Design Features ..............2 Bronze 2-Way Valve Comparison ........2 SP Series 1 and 5 with Dimensions ......3 AN Series 1 with Dimensions ...............4 DP & MP Series 1 with Dimenisons .....5 Flow Patterns & Technical Data ...........6 Alloys and Materials .............................7 Ordering Information ...........................8

FNPT, SilBraze, SW, Solder Joint

150# F.F. Flange

FNPT, SilBraze, SW, Solder Joint

150# F.F. Flange

3.12 5.38 3.12 5.50 1/2 3.45 5.75 3.45 5.75 3/4 3.90 6.30 4.25 6.50 1 4.54 7.26 N/A N/A 1-1/4 5.36 6.98 5.50 8.00 1-1/2 5.75 8.43 6.00 9.75 2 8.36 10.86 8.00 11.50 2-1/2 8.62 12.04 9.00 12.75 3** 10.46 12.90 12.00 15.00 4** ** Series 1-3 valve had port I.D. of 2.75, Series 1-4 valve had port I.D. of 3.5. Series 5 valves are full port (3.00 and 4.00 respectively).

SP SerieS 1 (836 Bronze)

SP Series 1 seawater valves are 3-piece valves available in female NPT, socket-weld (for pipe), sil-braze (for pipe) and 150# flanged end fittings.

diMenSional data (inCheS)

A Valve Size

1/4 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 4

SP valves with Female NPT (Q-), Sil-Braze (S-), Socket Weld (U-), 150# Flanged (L-) End Fittings

B C to Face L Q- SU1.56 1.56 1.72 1.95 2.27 2.68 2.87 4.18 4.31 5.23

C Handle Length from C L

6.09 6.09 6.09 8.69 8.69 8.69 8.69 12.44 12.44 12.44

D C to L Top of Handle

3.03 3.03 3.15 3.53 4.90 5.08 5.45 5.50 6.82 7.32

E C to Bottom L Q- SU1.34 1.34 1.47 1.69 1.57 1.71 2.03 2.81 3.88 4.50

Port Dia.

Face to Face Q- SU3.12 3.12 3.45 3.90 4.54 5.36 5.75 8.36 8.62 10.46

Approx. Wgt. Q- SU2 2 3 4 8 10 13 33 49 84

L5.38 5.75 6.30 7.26 6.98 8.43 10.86 12.04 12.90

L2.69 2.88 3.15 3.63 3.49 4.21 5.42 6.02 6.45

L1.81 1.88 2.13 2.31 2.50 3.00 3.50 3.88 4.50

L5 6 9 15 17 25 52 77 115

0.62 0.62 0.81 1.00 1.25 1.50 2.00 2.50 2.75 3.50

SP & Sd SerieS 5 (StainleSS, 922 Bronze, CarBon Steel, haStelloy C, duPlex, otherS)

Female NPT (Q-), Socket Weld (U-), 150# Flange (L-), Butt Weld (B-, D-), Sil-Braze (S-)**, Solder Joint (T-)** **Bronze Only

Port Dia. A Face to Face Q- UB- DS- T3.12 3.12 3.12 3.45 4.25 5.50 6.00 8.00 9.00 12.00 5.50 5.50 5.50 5.50 5.99 7.50 8.00 11.50 13.50 16.00

B C to Face L LQ- UB- DS- T1.56 1.56 1.56 1.72 2.13 2.75 3.00 4.00 4.50 6.00 2.75 2.75 2.75 2.75 3.00 3.75 4.00 5.75 6.75 8.00

Size

Size Code

A B C D E G H J K L

L 2.75 2.88 3.25 4.00 4.88 5.75 6.38 7.50

1/4 3/8 1/2 3/4 1 1-1/2 2 2-1/2 3 4

0.50 0.50 0.50 0.75 1.00 1.50 2.00 2.50 3.00 4.00

5.50 5.75 6.50 8.00 9.75 11.50 12.75 15.00

E G C End Fitting Length L Handle C toBotto Length L tom Top of U- B-, D- Lfrom B-, DHandle Length Length Dia. C Q-, U,L S-, T4.15 4.15 4.15 4.15 5.09 8.68 8.68 12.44 12.44 24.40 2.63 2.63 2.63 2.78 3.03 4.10 4.41 6.45 6.78 7.34 0.92 0.92 0.92 1.00 1.33 1.78 2.15 2.79 3.14 4.91 .41 .41 .41 .53 .53 .53 .66 .69 .69 .81 1.50 1.50 1.50 1.50 1.50 2.01 1.90 3.04 3.65 3.85 3.50 3.88 4.25 5.00 6.00 7.00 7.50 9.00

Approx. Wgt. BDQU2 2 2 2 5 11 17 37 50 133

L-

4 4 4 6 10 17 26 53 64 143

noteS:

1. SP Series valves with 150# flanges are 3-piece valves that do not meet ANSI face to face dimensions. Use AN Series 2-piece flanged valves if ANSI face to face dimensions are required. 2. Consult PBM for actuator mounting dimensions. 3. For flanged valves, flange holes straddle the centerline except for the SP Series 1, 1-1/2 valves.

G E B A G Butt Weld B-, D150# Flange LG Socket Weld U3

an SerieS, 150# ClaSS (Bronze, aluMinuM Bronze, StainleSS, duPlex, and CarBon)

AN Series seawater valves are 2-piece valves with two flanged end fittings and meet ANSI B16.10 long pattern face to face dimensions. In addition, encapsulated seats facilitate performance in high-velocity applications and support the seats in elevated temperature applications.

diMenSional data (inCheS) C

Valve Size

1/2 3/4 1 1-1/2 2 3 4 6 8 10

D

C to Face L End

1.76 1.94 2.20 2.78 2.99 3.62 3.84 7.35 8.54 12.34

E

Handle Length from C L

6.09 6.09 6.09 8.06 8.06 12.06 14.06 CF5 CF5 CF5

F

C to top L of Handle

3.07 3.14 3.80 5.25 5.56 7.08 7.93

G

C to L Bottom of Flange

1.62 1.88 2.06 2.38 2.88 3.75 4.50 6.98 8.37 10.15

H

Flange Diameter

3.50 3.88 4.25 5.00 6.00 7.50 9.00 11.00 13.50 16.00

Port

.62 .81 1.00 1.50 2.00 3.00 4.00 6.00 8.00 10.00

Overall Length1

4.25 4.62 5.00 6.50 7.00 8.00 9.00 15.50 18.00 21.00

Approx. Weight (lbs.)

6 9 10 20 24 92 118 330 550 680

noteS:

1. Standard product is 316 Stainless Steel. Carbon Steel, Bronze and other materials are available upon request. Consult PBM. 2. Dimensions meet ASME Standard B16.10 long pattern. 3. Stainless Steel valves and Carbon Steel valves have raised face flanges, but are also available with flat faced flanges. Bronze valves have flat face flanges only. 4. Drawings are for illustration purposes only. Consult PBM prior to any fabrication or installation work. 5. A gear operator is recommended for valves 6 and larger. Consult PBM. 6. Dimensions are for ANSI 150# Class valves. Consult PBM for 300# Class.

dP SerieS 1 diMenSional data (836 Bronze)

diMenSional data (inCheS)

B Valve Size Ball Port C Face-to-Face QSU1/2 3/4 1 1-1/2 2 3 4 0.62 0.81 1.00 1.50 1.94 2.75 3.50 3.12 3.44 3.90 5.36 5.71 8.62 N/A LD C to End L QSU1.56 1.77 1.95 2.68 2.86 4.31 N/A LG C to Bottom or L Side QSU2.50 2.50 2.44 3.25 3.25 5.12 N/A L-

Diverter Port Valves with Female NPT (Q-), Sil-Braze (S-), Socket weld (U-) and 150# Flanged (L-) End Fittings

E Handle Length L from C

F C to L Top of Handle 150# Flange Diam. Approximate Weight QSU2 2 4 10 15 49 79 L-

N/A N/A 6.28 7.00 8.40 11.87 12.91

N/A N/A 3.14 3.50 4.20 5.93 6.45

N/A N/A 3.16 3.50 4.20 6.00 6.44

5.06 5.06 6.06 8.06 8.06 12.06 12.06

3.03 3.03 3.53 5.05 5.42 6.71 7.21

3.50 2.38 4.25 5.00 6.00 7.50 9.00

N/A N/A 10 23 30 79 120

MP SerieS 1 diMenSional data (836 Bronze)

B Size Ball Port QSU4.00 4.00 4.72 6.56 7.76 11.06 N/A C Face-to-Face LN/A N/A N/A 10.56 11.94 14.56 17.00 QSU2.00 2.00 2.36 3.28 3.88 5.53 N/A D, G C to Face L LN/A N/A N/A 5.28 5.97 7.28 8.50

Multi-Port Valves with Female NPT (Q-), Sil-Braze (S-), Socket weld (U-) and 150# Flanged (L-) End Fittings

E Handle Length L from C 6.09 6.09 8.06 12.44 12.44 12.44 14.06 F C to L Top of Handle 3.83 3.83 4.99 5.61 6.05 7.01 8.75 Approximate Weight QSU8 8 12 28 40 65 N/A L-

1/2 3/4 1 1-1/2 2 3 4 noteS:

1. 2. 3. 4. 5. 6.

0.62 0.81 1.00 1.50 1.94 2.75 3.50

N/A N/A N/A 46 64 105 220

Male NPT, Solder Joint, Camlock and Grooved end fittings are also available. Other flanged end fittings are available upon request. 1/2 through 1 valves have 3 bolts, 3/4 valves have 4 bolts, 1-1/4 through 2 valves have 4 bolts, 3 through 4 valves have 8 bolts. Flange holes straddle the centerline except for Series 1, 1-1/2 size. Drawings are for illustration purposes only. Consult PBM prior to any fabrication or installation work. Using a welded connection on the common port of a DP or MP valve may complicate maintenance. Provisions must be made to allow removal of end fittings and body from the line.

B G D C

Q-

S-

UG A 5

flow PatternS

and

teChniCal data

By specifying a T-Port, Double T-Port, Angle Port (L) or Double Angle Port (LL) Ball, different flow configurations are possible. For example, a DP valve with an Angle Port Ball might be used to control flow to one or two simultaneous operations. The side entry Angle Port Ball and the bottom entry Double Angle Port Ball are ideal for connecting two relief valves to a system. The Double Angle Port Ball diverts flow from one outlet to another outlet 180 away, with only 90 stem rotation. This allows use of 90 double acting or spring return actuation, instead of 180. For Flow Patterns, refer to PBM Industrial Catalog, pages 12-13.

an SerieS 1 ValVe Chart

Valve Size (inches)

1/2 3/4 1 1-1/2 2 3 4 6 8 10

SP & Sd SerieS 5 Chart

100F Working Pressure

Carbon 955 Bronze Steel Class 150 Class 150 (psig) (psig) 200 200 200 200 200 200 200 200 200 200 285 285 285 285 285 285 285 285 285 285

Cv (gpm)

Full Port 31 52 80 190 400 1,100 2,400 5,600 10,000 16,500 Reduced Port N/A N/A N/A N/A N/A 370 700 760 5,600 10,000

Stem Torque (in lbs.)

Full Port 40 50 72 168 192 420 780 2,400 7,200 12,000 Reduced Port N/A N/A N/A N/A N/A 192 420 780 2,400 7,200

Valve Size (inches)

1/4 3/8 1/2 3/4 1 1-1/2 2 2-1/2 3 4

Cv (gpm)

5 10 12 42 73 170 360 650 935 1,900

Stem Torque (in-lbs.)

32 32 32 40 58 154 182 288 430 787

100F Working Pressure

955 Bronze Non-Flanged (psig) 600 600 600 600 600 600 600 600 600 600 Carbon Steel Non-Flanged (psig) 900 900 900 900 900 900 740 740 740 740

SP, dP SerieS 1 Chart

Valve Size (inches) Cv (gpm)

Full Port, SP only 18 35 53 120 200 330 400 650 DP Series L-Port 12 21 33 79 149 N/A 290 460 DP Series T-Port Straight 14 25 39 93 180 N/A 345 540 Branch 8.7 16 24 58 110 N/A 210 340 48 60 72 168 192 300 420 540

MP SerieS 1 Chart

Stem Torque (in lbs.) 100F Working Pressure 836 Bronze Class 150

300 300 300 300 300 300 300 300 1/2 3/4 1 1-1/2 2 3 4 16 16 45 100 180 228 405 10 10 25 56 100 127 225 8 8 22 46 78 90 175 96 96 240 480 540 720 1,020

Cv (gpm) Valve Size Straight (inches) Thru Cv Side Cv LL Port Cv Stem Torque (in-lbs.)

100F Working Pressure

836 Bronze NonFlanged (psig)

300 300 300 300 300 300 300

1/2 3/4 1 1-1/2 2 2-1/2 3 4

Notes: 1. 2. 3.

AN Series Working Pressure and Seat Ratings are for 150# valves. For 300# valves, consult PBM. Actuator Sizing Torque is twice the Breakaway Torque. If valve has not been factory actuated by PBM, additional margin may be needed due to service conditions.

teSting

Testing procedures and acceptance criteria are in accordance with MSS SP-72 for bronze valves and ASTM B16.34 and MSS-61 for other materials.

CertifiCation

PBM valves, when specified, meet USCG Category A shutoff. Certifications of compliance and material certifications are available when requested at the time of order entry. PBM Marine and Seawater Ball Valves are also ABS (American Bureau of Shipbuilding) type approved for SP Series 1 and 5, AN Series 1. 6

Body, Ball,

for other MaterialS, ConSult PBM Bronze, alloy no. 922, B61

and

end fittingS

CarBon Steel

This versatile material efficiently handles mildly-corrosive media. Cast material is made to A216, WCB and wrought material is made to A105.

This material is referred to as Valve, Steam, or Naval Bronze. Alloy 922 (88-6-1.5-4.5) is 88% copper, 6% tin, 1.5% lead, and 4.5% zinc. Alloy 922 falls in the Tin Bronzes group. Typical end uses include valves, fittings, and pressure containing parts for use at elevated temperatures.

duPlex 2205

Monel 400

Monel 400 is used as a shaft (stem) and optional ball material. Monel 400 is 63-70% nickel, 25.5-32.5% copper, 2.5% iron, and 2% manganese. Stem and balls are machined from B164 (barstock) alloy N04400. Larger diameter balls are cast from A494 alloy M35-1.

Duplex 2205 is an austenitic/martensitic stainless steel with about 225 chromium, 65 nickel, 3% molybenum, and 0.16 nitrogen. The nitrogen serves to significantly improve the corrosion resistance of the alloy and to make the alloy very resistant to chloride stress corrosion cracking. Hence its ideal suitability for marine service. Cast parts are made from CD3MN and wrought parts are made from S31803.

Bronze, alloy no. 836, B62

aluMinuM Bronze, alloy no. 955, B148

Alloy 955 (89-1-10) is 81% copper, 4% iron, 11% aluminum and 4% nickel. Alloy 955 is the ideal choice for valve bodies, fittings, and balls used in a seawater environment due to its corrosion resistance in salt water, relatively high tensile and yield strengths, and lower density (lighter weight).

This material is the ideal choice for all general-purpose (mildly corrosive) applications. It is versatile and well suited for steam, air, fresh water, seawater, oil, and gas lines. 836 bronze is specified to MSS SP-72. Alloy 836 (85-5-5-5) is 85% copper, 5% tin, 5% lead, and 5% zinc. This alloy falls in the Red and Semi-Red Brasses group.

aluMinuM Bronze, alloy no. 953

316 StainleSS Steel

This metal is exceptionally corrosion-resistant to acidic and basic environments. Cast material is made to A351, CF8M and wrought material is made to A479 and S31600.

Alloy 953 (89-1-10) is 89% copper, 1% iron, and 10% aluminum. Typical end uses include pickling baskets, nuts, gears, steel mill slippers, and marine equipment. Alloy 953 is the ideal choice for valve bodies, fittings, and balls used in a seawater environment due to its corrosion resistance in salt water, relatively high tensile and yield strengths, and lower density (lighter weight).

Body, Ball

ALLOY

922 Bronze 953 Al. Bronze 90/10 Copper Nickel 955 Nickel-Al. Bronze 316 SS Carbon Steel Hastelloy C Duplex 2205 836 Bronze

and

end fitting alloy

TENSILE (ksi)

34.0 65.0 60.0 90.0 75.0 70-95 115.0 90.0 30.0

90/10 CoPPer niCkel

YIELD (ksi)

16.0 25.0 57.0 40.0 30.0 36.0 52.0 60.0 14.0

DENSITY (lb.cu.in)

0.312 0.272 0.323 0.272 0.289 0.280 0.321 0.285 0.318

90/10 Copper Nickel, Copper Alloy C70600, is an ideal material for valve end connections in copper piping systems. 90/10 copper nickel is also an ideal material for salt water piping and ferrules.

Body Bolt alloy CoMPariSon

BOLT/STUD MATERIAL

304 Stainless Steel Copper Silicon Bronze Monel

ALLOY NUMBER

B8 Cu651 Cu655 N.400 N.405

TENSILE (ksi)

75* 70-100 50-80 80-130 70-125

YIELD (ksi)

30* 55 20 40 30

Body BoltS

304 StainleSS Steel

Alloy 304, A193 grade B8, class 1 bolts/studs and A194, grade 8 nuts. PBM does not recommend the use of stainless steel in a salt-water environment. Stainless is subject to pitting and stress corrosion cracking when in contact with seawater. Alloy 304 is 18-20% chromium, 8-10% nickel, and a balance of iron and trace elements.

Soft MaterialS

tfM - TFM is Chemically Modified PTFE. It is standard on

Series 5.

rtfe - RTFE is Polytetrafluoroethylene reinforced with glass S-tef - Stainless Steel Reinforced Polytetrafluoroethylene. uhMwPe - UHMWPE is Ultra High Molecular Weight

Polyethylene.

fibers, commonly referred to as glass filled Teflon. It is standard on Series 1.

Monel

Monel bolts (F468) are alloy N.400 or N.405 nickel copper, and nuts (F467) are alloy N04400 or N04405 nickel copper. Composition is 63-70% nickel, 25.5-32.5% copper, 2.5% iron, and 2% manganese.

EPR - EPR is Ethylene Propylene Rubber, used for O-rings Viton

CoPPer SiliCon Bronze

Copper Silicon Bronze is supplied to alloy numbers Cu651 and Cu655. Alloy number Cu655 is 94.8% copper, 0.8% iron, 1.5% manganese, 0.6% nickel, 2.8-3.8% silicon, 1.5% zinc, and 0.05% lead. Alloy number Cu651 is 96% copper, 0.8% iron, 0.7% manganese, 0.8-2% silicon, 1.5% zinc, and 0.05% lead. Bolts and studs are made to specification F468 for non-ferrous bolts. Nuts are made to specification F467.

when used to seal the body and the end fitting in water and salt-water applications. Viton is recommended for O-rings when hydrocarbons or other organics are present in the fluid.Viton material is also available when EPR is not suitable for the application (example: hydrocarbons present in fluid).

United States Canada United Kingdom Mexico South America Europe Australia Taiwan

Visit PBM online at www.pbmvalve.com to find the PBM domestic or international representative near you.

SP, dP, MP & an SerieS ordering inforMation Standard

ProduCt ProduCt

SP Two-Way SD Two-Way steam (Series 5 only) DP Three-Way MP Three-Way

Material aterial

B 836 Bronze C Hastelloy C-276 E Carbon Steel C D E F G H J K L M

Size ize

1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 4 6

SerieS erieS

1* (836 Bronze only) 5 6** API 607 Rev. 4 Fire Safe L M Q R S

nd end fittingS ittingS

eat eal Seat & Seal/ filler/o-ring iller ring

low dP flow Pattern attern

Ball/SteM all teM

F internal and external ground monel ball 932 bronze ball monel stem, followers monel ball, stem, and followers G 17-4 PH stem I J K L

oPerator Perator

- - lever handle 02 no handle, with actuator prep 04 with locking handle 05 with stainless oval handwheel 08 with gear operator 13 NEMA 4 Electric Actuator (120 vac) 14 NEMA 7 Electric Actuator (120 vac) 18 4 ext. locking level handle 20 D/A Actuator 80 psi 27 D/A Actuator 60 psi 34 S/R Actuator 80 psi 41 S/R Actuator 60 psi Other options are available. For more detailed automation info and dimensional data, please visit www.pbmvalve.com.

150# Flange 300# Flange Female NPT Sil Braze Sil Braze (1) Groove

G TFM/None/Viton V RTFE/None/EPR Z TFM/None/EPR A RTFE/None/Viton B RTFE/VTFE/Viton H S-TEF/None/Viton I J L 0 3 S-TEF/VTFE/Viton TFM/VTFE/Viton UHMWPE/VTFE/Viton S-TEF/None/EPR UHMWPE/None/EPR

01* 02* 03 04 05* 06 07* 08* 09* 10 11* 12* 13* 14 15 16 18 18 19*

H 316 Stainless M Monel N 922 Bronze S 953 Alum Brz R 955 Alum Brz B 836 Bronze 9 954 Alum Brz 22 Duplex 2205

T U

Solder Joint Socket Weld

K UHMWPE/None/Viton

M aluminum ball N 922 bronze ball O hastelloy C-276 ball P C-276 ball, stem, and followers

* Add a 3 after End Fitting Code for nonAdjust-O-Seal.

AN ANSI Two-Way

B 836 Bronze C Hastelloy C-276 E Carbon Steel H 316 Stainless M Monel R 955 Nickle Alum Bronze S T 953 Alum Brz Gr 5 Titanium

C D E G H K L M N P

1/2 3/4 1

Cavity-fillers and other seal materials are available, consult PBM.

Q 922 ball & monel stem R monel stem, followers and bolting monel ball, stem, followers and bolting 922 ball, monel stem & followers, sil-bronze bolting

3** 1-1/2 API 607 2 Rev. 4 Fire Safe 3 4 6 8 10

T * MP valves only

U 922 ball, monel stem & followers

Y Hastelloy C-22

Notes: 1.

2. 3. 4. ** 5.

SP valves with 150# flanges are 3-piece valves that do not meet ANSI face to face dimensions. Use AN Series flanged valves if ANSI face to face dimensions are required. Standard ball material is 316/316L stainless steel. Standard stem material is 316/316L stainless steel. Standard O-ring material is EPR* or Viton. PBM, Inc. 1070 Sandy Hill Road, Irwin, Standard hardware material is 18/8 stainless steel*. Phone: 800.967.4PBM 724.863.0550 Fire Rated for Stainless, Carbon, and Hastelloy C-276 only. MP and DP are Series 1 only.

PA 15642 Fax: 724.864.9255 E-mail: info@pbmvalve.com Web: www.pbmvalve.com

LT-2C 6/09

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Quezon City Department of The Building OfficialDokument2 SeitenQuezon City Department of The Building OfficialBrightNotes86% (7)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Norsok M001 MaterialsDokument31 SeitenNorsok M001 MaterialsbreeeeezzzzzeNoch keine Bewertungen

- Esstd0202scjp Pip Pnfj8000Dokument71 SeitenEsstd0202scjp Pip Pnfj8000Engr Tahir UL HaqNoch keine Bewertungen

- Welding Log BookDokument5 SeitenWelding Log BookPhornlert WanaNoch keine Bewertungen

- PSL CatalogueDokument10 SeitenPSL CataloguePhornlert WanaNoch keine Bewertungen

- 2 Kinds of Pulsation StudiesDokument1 Seite2 Kinds of Pulsation StudiesmondelNoch keine Bewertungen

- Beta New API Standard 618Dokument11 SeitenBeta New API Standard 618Dae Ick Kim100% (1)

- Interpretations To Asme b31 3Dokument17 SeitenInterpretations To Asme b31 3Phornlert WanaNoch keine Bewertungen

- Swagelok Ball ValveDokument4 SeitenSwagelok Ball ValvePhornlert WanaNoch keine Bewertungen

- Starline Firesafe Ball ValveDokument6 SeitenStarline Firesafe Ball ValvePhornlert WanaNoch keine Bewertungen

- Flange Leakage CheckDokument1 SeiteFlange Leakage CheckPhornlert WanaNoch keine Bewertungen

- ShoeDokument1 SeiteShoePhornlert Wana100% (1)

- Fisher Globe ValveDokument16 SeitenFisher Globe ValvePhornlert WanaNoch keine Bewertungen

- APPENDIX D - CORROSION RATE and REMAINING LIFE CALCULATIONDokument6 SeitenAPPENDIX D - CORROSION RATE and REMAINING LIFE CALCULATIONPhornlert Wana100% (2)

- Living Quarter LayoutDokument69 SeitenLiving Quarter LayoutPhornlert WanaNoch keine Bewertungen

- Engineering DesignDokument55 SeitenEngineering DesignPhornlert WanaNoch keine Bewertungen

- Maps - Useful Phrases (Updated) (2021)Dokument2 SeitenMaps - Useful Phrases (Updated) (2021)Vy Đặng ThảoNoch keine Bewertungen

- Procedures For Hot Insulation - 2Dokument8 SeitenProcedures For Hot Insulation - 2Quy RomNoch keine Bewertungen

- Hot Oil Expansion TankDokument2 SeitenHot Oil Expansion TankAnonymous 70lCzDJv100% (1)

- Properties of SolidsDokument91 SeitenProperties of Solidsshreyamammachen22Noch keine Bewertungen

- Wire Rope-Steel TechnicalDokument37 SeitenWire Rope-Steel TechnicalAndreea LucaNoch keine Bewertungen

- Portfolio 2.4 DuctingDokument69 SeitenPortfolio 2.4 Ductingjitendrashukla10836Noch keine Bewertungen

- Course Outline UpdatedDokument1 SeiteCourse Outline UpdatedAddisu AyeleNoch keine Bewertungen

- Elementary Seismology: CT - LakshmananDokument54 SeitenElementary Seismology: CT - LakshmananMALAVIKANoch keine Bewertungen

- Boiler Dan ReboilerDokument15 SeitenBoiler Dan ReboilerLia SeptianaNoch keine Bewertungen

- Sikagrout 280 Hs Pds enDokument3 SeitenSikagrout 280 Hs Pds enDimas SaputraNoch keine Bewertungen

- REPERTORIO Menara Mesiniaga PDFDokument80 SeitenREPERTORIO Menara Mesiniaga PDFAnggy GNoch keine Bewertungen

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDokument1 Seite4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNoch keine Bewertungen

- PVM Su 4750 GDokument30 SeitenPVM Su 4750 GJEEVITHANoch keine Bewertungen

- Guidance Note For ToleranceDokument5 SeitenGuidance Note For ToleranceBui Chi TamNoch keine Bewertungen

- Mortar Analysis Part 3 - L SchnabelDokument4 SeitenMortar Analysis Part 3 - L SchnabelSugarPOP666Noch keine Bewertungen

- Control and Prevention HazardDokument32 SeitenControl and Prevention HazardEdward SmithNoch keine Bewertungen

- Peppers A2LCF GlandDokument2 SeitenPeppers A2LCF GlandBob JohnsonNoch keine Bewertungen

- Road CoastingDokument145 SeitenRoad CoastingBhavsar NilayNoch keine Bewertungen

- L4-Cable Rating-UpdateDokument29 SeitenL4-Cable Rating-UpdateboyNoch keine Bewertungen

- Installation User Instruction (KMC Corporation)Dokument33 SeitenInstallation User Instruction (KMC Corporation)Dan StroescuNoch keine Bewertungen

- Pipe Sizing Steam and Supply Condensate Return LinesDokument3 SeitenPipe Sizing Steam and Supply Condensate Return LinesMatthew Vest100% (1)

- Self Consolidating ConcreteDokument2 SeitenSelf Consolidating ConcreteaaNoch keine Bewertungen

- Product Data Sheet Check Valve: General Arrangement DrawingDokument2 SeitenProduct Data Sheet Check Valve: General Arrangement DrawingArunNoch keine Bewertungen

- New Nekkonda Ac SheetDokument86 SeitenNew Nekkonda Ac SheetManohar VangaNoch keine Bewertungen

- P355NL2 50mmDokument5 SeitenP355NL2 50mmslowmosquitoNoch keine Bewertungen

- 7 Medival ArchitectureDokument50 Seiten7 Medival ArchitectureRachana Muppala100% (3)

- 1562-2 Design and Installation of Sheet Roof and Wall CladdingDokument25 Seiten1562-2 Design and Installation of Sheet Roof and Wall CladdingVasko DrogriskiNoch keine Bewertungen

- First Semester Course AllocationDokument3 SeitenFirst Semester Course AllocationSonia GandhiNoch keine Bewertungen