Beruflich Dokumente

Kultur Dokumente

Shimano Disc

Hochgeladen von

cipx2Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Shimano Disc

Hochgeladen von

cipx2Copyright:

Verfügbare Formate

SI-8EA0D-002-00

General Safety Information

WARNING

Please use extra caution to keep your fingers away from the rotating disc brake rotor during installing or servicing the wheel. The rotor is sharp enough to inflict severe injury to your fingers if caught within the openings of moving rotor. Adjust the inner cable so that the protruding length is less than 20 mm (3/4 inch). If the protruding length is any longer, the end of the inner cable may become stuck in the rotor, which could cause the wheel to lock and the bicycle could fall forward causing serious injuries. The calipers and rotor will become hot when the brakes are operated, so do not touch them while riding or immediately after dismounting from the bicycle, otherwise you may get burned. Check that the brake Less than 20mm components have cooled down sufficiently before attempting to adjust the brakes. Always make sure that the front and rear brakes are working correctly before you ride the bicycle. Before riding the bicycle, check that the pad thicknesses are 0.5 mm or more. If noise occurs when the brakes are operated, it may indicate that the brake pads have worn down to their usage limit. After checking that the brake system has cooled down sufficiently, check the brake pad thicknesses. Pad wear indicators Replace the brake pads if the pad wear indicators are visible. Be careful not to allow any oil or grease to get onto the rotor and brake pads, otherwise the brakes may not work correctly. If any oil or grease do get on the pads, you should replace the pads. If any oil or grease gets on the rotor, you should clean the rotor. If this is not done, the brakes may not work correctly. Check the brake cable for rust and fraying, and replace the cable immediately if any such problems are found. If this is not done, the brakes may not work correctly. The required braking distance will be longer during wet weather. Reduce your speed and apply the brakes early and gently. If the road surface is wet, the tires will skid more easily. If the tires skid, you may fall off the bicycle. To avoid this, reduce your speed and apply the brakes early and gently. If the quick release lever is on the same side as the rotor, there is the danger that it may interfere with the rotor, so check that it does not interfere. It is important to completely understand the operation of your bicycle's brake system. Improper use of your bicycle's brake system may result in a loss of control or an accident, which could lead to severe injury. Because each bicycle may handle differently, be sure to learn the proper braking technique (including brake lever pressure and bicycle control characteristics) and operation of your bicycle. This can be done by consulting your professional bicycle dealer and the bicycle's owners manual, and by practicing your riding and braking technique. The M416 disc brakes are designed for optimum performance when used in combination with the BR-M416 (calipers), ST-M410/M405/M360/BL-M421 (brake lever), SM-RT53/51 (rotor) and Shimano pad unit (B01S). The brake lever used should be a two-finger lever for V-brakes, such as the ST-M410/M405/M360/ BL-M421. If using in combination with 4-finger levers such as the ST-T300/T400, the braking force will be higher. Accordingly, under some conditions such as certain riding positions or overall weight, the bicycle may fall over and injury may result if proper care is not taken. Obtain and read the service instructions carefully prior to installing the parts. Loose, worn or damaged parts may cause the bicycle to fall over and serious injury may occur as a result. We strongly recommend only using genuine Shimano replacement parts. Read these Technical Service Instructions carefully, and keep them in a safe place for later reference.

Installation

Wheel spoke lacing

Check that the spokes have been laced as shown in the illustration. A radial assembly cannot be used. Lace the spokes as shown in Figure 1 below for the left side of the front wheel (the side where the rotor is installed), and the left and right sides of the rear wheel, and as shown in Figure 2 below for the right side of the front wheel.

Rotating direction of wheel Front left Rear left Rear right Front right

2. While wearing protective gloves, apply pressure to the adapter in the

counterclockwise direction while tightening the caliper clamp bolt.

Caliper clamp bolt

Adjusting when the pads are worn

Use the cable adjusting bolts at the brake lever and the caliper body and also the pad adjusting screws to adjust the clearance for pads which are worn. The pads can still be used as long as the thickness of the pad lining is 0.5 mm or more. Adjust so that clearances A and B are both 0.2 -- 0.4 mm.

Pad adjusting screw Cable adjusting bolt

< B side > Tighten the pad adjusting screw to adjust. < A side > Turn the cable adjusting bolt at the brake lever or the caliper body to adjust.

Pad adjusting screw

Adapter

Tightening torque: 6 - 8 Nm {53 - 69 in. lbs.}

Fig. 1

Fig. 2

Tightening plate Rotor

Installation of the rotor <SM-RT51>

Install the rotor and the rotor tightening plate to the hub, and then install and tighten the bolts as shown in Fig. 1.

Fig. 1

Securing the cable 1. Pass the inner cable through the

cable adjusting bolt, and then tighten the cable fixing bolt.

Cable adjusting bolt

When making the adjustment when the pad is worn, use both the cable adjusting bolt and the pad adjusting screw. If only the cable adjusting bolt is used, it will not be possible to use the pad down to the standard replacement thickness of 0.5 mm. Moreover, the pad and rotor may interfere with each other even when the brakes are not being operated.

Tightening torque: 6 - 8 Nm {53 - 69 in. lbs.}

Hub Inner cable

Replacing the brake pads

If the brake pads are worn down to a thickness of 0.5 mm, replace the brake pads.

1. Remove the bicycle wheel from the frame, and then remove the brake pads as

Rotor fixing bolts (#T25 torx) Cable fixing bolt

shown in the illustration.

While wearing gloves, apply a force to the rotor to turn it in a clockwise direction as shown in Fig. 2. While doing this, tighten the rotor fixing bolts in the order shown in the illustration.

Tightening torque: 2 - 4 Nm {18 - 35 in. lbs.}

Split pin

Use a flat-tipped screwdriver or similar tool to bend the edges of the tightening plate over the heads of the bolts as shown in Fig. 3.

Fig. 2 Fig. 3

Tightening plate

2. While depressing the brake lever, set the calipers to the required position and

then tighten the caliper fixing bolts.

Tightening torque: 6 - 8 Nm {53 - 69 in. lbs.}

Brake pad

Cable adjusting bolt

2. Loosen the pad adjusting screw 3. Loosen the pad adjustment screw by

two clicks.

Pads

and turn the cable adjusting bolts at the brake lever and caliper body clockwise to loosen them.

Pad adjusting screw

<SM-RT53>

Pad adjusting screw Rotor installation ring TL-LR15 Rotor

3. Install the new brake pads. After this,

bend open the split pin. Tighten the pad adjusting screw so that the clearance between the brake pad and the rotor is 0.2--0.4 mm.

Depress about 10 times

Split pin

CAUTION

Disc brakes have a burn-in period, and the braking force will gradually increase as the burn-in period progresses. Make sure that you are aware of any such increases in braking force when using the brakes during the burn-in period. The same thing will happen when the brake pads or rotor are replaced.

Tightening torque: 40 Nm {350 in. lbs.}

4. Depress the brake lever about

10 times until it touches the grip, and check that there are no problems with any components, and also that the rotors and the pads do not interfere with each other when the wheel is rotated.

Installation of the brake lever

Use a 5 mm Allen key to install. Use a handlebar grip with a maximum outer diameter of 32 mm.

Tightening torque: 6 - 8 Nm {53 - 69 in. lbs.}

4. After checking that the brake pad and

the rotor are not touching each other, check that there are no problems when the brake lever is depressed.

Note

The SM-RT53 rotor should be used together with resin pads. If it is used with metal pads, the pads will wear out very rapidly. If the brake caliper mounting boss and the dropout are not parallel, the rotor and caliper may touch. Parts are not guaranteed against natural wear or deterioration resulting from normal use. For maximum performance we highly recommend Shimano lubricants and maintenance products.

5. Turn the cable adjusting bolt to take up any slack in the cable.

Cable adjusting bolt

Technical Service Instructions

SI-8EA0D-002

Installing the calipers 1. Install the bicycle wheel. Loosen the

caliper fixing bolts, and then install the calipers to the frame so that the calipers work at the left and right.

Caliper clamp bolt

Disc Brake System

(For Cross-Country)

In order to realize the best performance, we recommend that the following combination be used.

Caliper Brake Lever Rotor Brake pad unit (Resin pads) Brake cable BR-M416 ST-M410 / ST-M405 / ST-M360 / BL-M421 SM-RT53 / SM-RT51 B01S 00

Secure the three bolts with a cap as shown in the illustration in order to prevent the bolts from coming loose. For post type

< Front > < Rear >

Caps

This service instruction explains how to use and maintain the Shimano bicycle parts which have been used on your new bicycle. For any questions regarding your bicycle or other matters which are not related to Shimano parts, please contact the place of purchase or the bicycle manufacturer.

One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003 Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222 3-77 Oimatsu-cho, Sakai-ku, Sakai-shi, Osaka 590-8577, Japan

Caps Caliper fixing bolts Please note: specifications are subject to change for improvement without notice. (English) Oct. 2008 by Shimano Inc. XBC SZK Printed in Malaysia.

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- KEMET Part Number: C322C223M1U5TADokument1 SeiteKEMET Part Number: C322C223M1U5TAcipx2Noch keine Bewertungen

- Controller Electronic Every Control Evk411 - 100... 1300c 230vac Evk411m7vhbs 378134 KalvaDokument2 SeitenController Electronic Every Control Evk411 - 100... 1300c 230vac Evk411m7vhbs 378134 Kalvacipx2Noch keine Bewertungen

- Compatibilità Gamma Prodotti M BUS Ver1.2Dokument1 SeiteCompatibilità Gamma Prodotti M BUS Ver1.2cipx2Noch keine Bewertungen

- User's Manual: 8F-3A/8F-3AW/8F-5A/8F-5AWDokument14 SeitenUser's Manual: 8F-3A/8F-3AW/8F-5A/8F-5AWcipx2Noch keine Bewertungen

- Water Meters Js JM dn15 40 PDFDokument8 SeitenWater Meters Js JM dn15 40 PDFcipx2Noch keine Bewertungen

- 9IS44317.07 IS ICPlus 915 EN-IT-ES-DE-FR 1021Dokument33 Seiten9IS44317.07 IS ICPlus 915 EN-IT-ES-DE-FR 1021cipx2Noch keine Bewertungen

- Directive 2004 22 Ec Mi005Dokument80 SeitenDirective 2004 22 Ec Mi005Hughes RobertNoch keine Bewertungen

- En 00013 2016 Smart PDFDokument4 SeitenEn 00013 2016 Smart PDFcipx2Noch keine Bewertungen

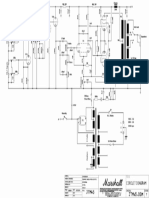

- Marshall jtm45 ReadableDokument1 SeiteMarshall jtm45 Readablecipx2Noch keine Bewertungen

- C5 Circuit Diagram CompleteDokument1 SeiteC5 Circuit Diagram Completewalrus_jcmNoch keine Bewertungen

- Vostro-3750 - Owner's Manual - En-Us PDFDokument147 SeitenVostro-3750 - Owner's Manual - En-Us PDFcipx2Noch keine Bewertungen

- VG2448 VG2748 Ug EngDokument74 SeitenVG2448 VG2748 Ug Engcipx2Noch keine Bewertungen

- D112 14263635 2018 03 PDFDokument1 SeiteD112 14263635 2018 03 PDFcipx2Noch keine Bewertungen

- Boneyard: MadbeanpedalsDokument9 SeitenBoneyard: MadbeanpedalsjleboNoch keine Bewertungen

- CLC Northeaster Dory Lug Addendum WebDokument26 SeitenCLC Northeaster Dory Lug Addendum Webcipx2100% (3)

- Carl Martin Plexitone Madbean Boneyard II TRANSFER PDFDokument4 SeitenCarl Martin Plexitone Madbean Boneyard II TRANSFER PDFcipx2Noch keine Bewertungen

- Division of Decimals PPT-Oct2013Dokument51 SeitenDivision of Decimals PPT-Oct2013cipx2Noch keine Bewertungen

- Brother Netw Usrs Guide CV - hl5350dnDokument203 SeitenBrother Netw Usrs Guide CV - hl5350dncipx2Noch keine Bewertungen

- A Headeache in The PelvisDokument236 SeitenA Headeache in The Pelviscipx2Noch keine Bewertungen

- Canskate Lesson Plan TemplatesDokument95 SeitenCanskate Lesson Plan Templatescipx2Noch keine Bewertungen

- Brother Mfc8370n User ManualDokument210 SeitenBrother Mfc8370n User Manualcipx2Noch keine Bewertungen

- A Collaborative Multimedia Annotation Tool For Enhancing KnowledgDokument19 SeitenA Collaborative Multimedia Annotation Tool For Enhancing Knowledgcipx2Noch keine Bewertungen

- Hammer Nutrition - The Endurance Athlete's Guide To SuccessDokument144 SeitenHammer Nutrition - The Endurance Athlete's Guide To Successpgcal3818Noch keine Bewertungen

- Kiwi RacerDokument4 SeitenKiwi Racercipx2Noch keine Bewertungen

- Shimano DiscDokument1 SeiteShimano Disccipx2Noch keine Bewertungen

- Vostro 3750 ManualDokument147 SeitenVostro 3750 Manualcipx2Noch keine Bewertungen

- Amp Can SchematicDokument2 SeitenAmp Can SchematicAlexandre S. CorrêaNoch keine Bewertungen

- Trike ManualDokument2 SeitenTrike Manualcipx2100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Analysis of Green Entrepreneurship Practices in IndiaDokument5 SeitenAnalysis of Green Entrepreneurship Practices in IndiaK SrivarunNoch keine Bewertungen

- Workplace Risk Assessment PDFDokument14 SeitenWorkplace Risk Assessment PDFSyarul NizamzNoch keine Bewertungen

- Handbook+for+Participants+ +GCC+TeenDokument59 SeitenHandbook+for+Participants+ +GCC+Teenchloe.2021164Noch keine Bewertungen

- Lifecycle of A Butterfly Unit Lesson PlanDokument11 SeitenLifecycle of A Butterfly Unit Lesson Planapi-645067057Noch keine Bewertungen

- Changing Historical Perspectives On The Nazi DictatorshipDokument9 SeitenChanging Historical Perspectives On The Nazi Dictatorshipuploadimage666Noch keine Bewertungen

- Sai Deepa Rock Drills: Unless Otherwise Specified ToleranceDokument1 SeiteSai Deepa Rock Drills: Unless Otherwise Specified ToleranceRavi BabaladiNoch keine Bewertungen

- 2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessDokument11 Seiten2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessOne PlusNoch keine Bewertungen

- Rules and Fallacies For Categorical SyllogismsDokument5 SeitenRules and Fallacies For Categorical SyllogismsFatima Ismael PortacioNoch keine Bewertungen

- A12 CanSat Technlology Forclimate Monitoring PDFDokument10 SeitenA12 CanSat Technlology Forclimate Monitoring PDFDany PABON VILLAMIZARNoch keine Bewertungen

- ITP - Plaster WorkDokument1 SeiteITP - Plaster Workmahmoud ghanemNoch keine Bewertungen

- Swanand 2009Dokument3 SeitenSwanand 2009maverick2929Noch keine Bewertungen

- 2021 Bookmatter BasicSciencesOfNuclearMedicineDokument12 Seiten2021 Bookmatter BasicSciencesOfNuclearMedicineBeatriz MartinhoNoch keine Bewertungen

- Help SIMARIS Project 3.1 enDokument61 SeitenHelp SIMARIS Project 3.1 enVictor VignolaNoch keine Bewertungen

- Excel Crash Course PDFDokument2 SeitenExcel Crash Course PDFmanoj_yadav735Noch keine Bewertungen

- FoundationDokument98 SeitenFoundationManognya KotaNoch keine Bewertungen

- 9300AE 10-30kseis LDN 2005 PDFDokument2 Seiten9300AE 10-30kseis LDN 2005 PDFDoina ClichiciNoch keine Bewertungen

- Form No. 1 Gangtok Municipal Corporation Deorali, SikkimDokument2 SeitenForm No. 1 Gangtok Municipal Corporation Deorali, SikkimMUSKAANNoch keine Bewertungen

- Mi Account ေက်ာ္နည္းDokument16 SeitenMi Account ေက်ာ္နည္းamk91950% (2)

- Riveted JointsDokument28 SeitenRiveted Jointsgnbabuiitg0% (1)

- Hayek - Planning, Science, and Freedom (1941)Dokument5 SeitenHayek - Planning, Science, and Freedom (1941)Robert Wenzel100% (1)

- BS7430 Earthing CalculationDokument14 SeitenBS7430 Earthing CalculationgyanNoch keine Bewertungen

- Social Science PedagogyDokument4 SeitenSocial Science PedagogyrajendraNoch keine Bewertungen

- Graduate Macro Theory II: The Real Business Cycle Model: Eric Sims University of Notre Dame Spring 2017Dokument25 SeitenGraduate Macro Theory II: The Real Business Cycle Model: Eric Sims University of Notre Dame Spring 2017Joab Dan Valdivia CoriaNoch keine Bewertungen

- Non-Emulsifying Agent W54Dokument12 SeitenNon-Emulsifying Agent W54Pranav DubeyNoch keine Bewertungen

- 2SA1016Dokument4 Seiten2SA1016catalina maryNoch keine Bewertungen

- Lalkitab Varshphal Chart PDFDokument6 SeitenLalkitab Varshphal Chart PDFcalvinklein_22ukNoch keine Bewertungen

- Bug Life Cycle in Software TestingDokument2 SeitenBug Life Cycle in Software TestingDhirajNoch keine Bewertungen

- Watershed Conservation of Benguet VisDokument2 SeitenWatershed Conservation of Benguet VisInnah Agito-RamosNoch keine Bewertungen

- Company Profile PT. Geo Sriwijaya NusantaraDokument10 SeitenCompany Profile PT. Geo Sriwijaya NusantaraHazred Umar FathanNoch keine Bewertungen

- SeparexgeneralbrochureDokument4 SeitenSeparexgeneralbrochurewwl1981Noch keine Bewertungen