Beruflich Dokumente

Kultur Dokumente

Agitator Catalogue

Hochgeladen von

sushant_jhawerOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Agitator Catalogue

Hochgeladen von

sushant_jhawerCopyright:

Verfügbare Formate

Mixing Solutions KemixTM made name with low cost well engineered mixers and Delkor are manufacturing

KemixTM mixing equipment with the same philosophy. Many years of experience and the latest technology has been applied to design each Agitator / mixer undertaken.

DELKOR is the leader in providing fully integrated design and construction of various types of mechanical Agitators for solid liquid Mixing applications to all types of process industries. DELKOR has earned a worldwide reputation as a specialist in the fields of solid-liquid Mixing / Separation. DELKOR offers the most comprehensive range of mixers & mixing technology available. The KemixTM range of mixers are indigenously manufactured to meet the needs of the chemical, mineral, mining, dairy, food & pharmaceutical industries. Research & development in the test laboratory have given KemixTM a lead over our competition, and enabled us to introduce a range of impeller allowing for power saving and greater efficiency. OPTIMIZING PROCESS DESIGN : The process industry has most varied, difficult mixing problems and DELKOR offer application engineering to optimize the design and provide most suitable technology. Our designs are optimized by computerized programs and then rationalized to be compatible with known operating conditions. Our design focuses on the critical parameters of mixing and seeks to enhance the efficiency of the manufacturing process by improving the mixing operation, saving power and generally optimizing agitation systems.

DELKOR TECHNIK INDIA PVT LTD.,

108/D, 6th Main Road, III Phase, Peenya Industial Area, Peenya, Bangalore 560058 Tel No. 080 2839 2823 / 2824 Tel Fax No.080 2839 7540 E Mail : delkor@delkorindia.com,

Mixing Solutions If your process has any of unit operations like solid suspension, Blending, Dissolving, Dispersion, Homogenization, Emulsification, Heat transfer, Crystallization etc. if you are looking for process improvement CALL DELKOR!!!! MECHANICAL DESIGN Mechanical design are computerized and take into account all operating conditions. Ease of maintenance and reliability are prime objectives in each design undertaken. DELKOR do not compromise on materials engineering and workmanship. MANUFACTURING / ASSEMBLY In fact while manufacturing and agitator, there must be no uncertainty or overstepped tolerances, which could result in a drastically reduced service life and / or a variety of operating problems (vibration, noise etc). Our quality system monitors every stage of the production process to achieve high degree of accuracy necessary for smooth and trouble free agitator performance. The impellers are statically balanced and over 300rpm dynamically balancing will be conducted. Once assembled and checked, all agitators are no load tested at the workshop for predicting power consumption and checking temperatures at critical points, vibrations, noise level and shaft defection at mechanical seals or stuffing boxes. The Kemix three-bladed Hi-flo axial impeller has proved to be up to 60% more economical than conventional 45 pitched blade turbines. The unique impeller designing makes it suitable for solid suspension blending, heat transfer and gas dispersion in most vessel sizes, as well as the mixing of highly viscous materials. These impeller can be supplied with either bolted or welded construction. PRODUCTS We offer the complete range of mixers / agitators (top entry) for chemical, mineral, Fertilizer, Food, Environmental, Metallurgical, and Pharmaceutical etc. Our standard

DELKOR TECHNIK INDIA PVT LTD.,

108/D, 6th Main Road, III Phase, Peenya Industial Area, Peenya, Bangalore 560058 Tel No. 080 2839 2823 / 2824 Tel Fax No.080 2839 7540 E Mail : delkor@delkorindia.com,

Mixing Solutions models extend from 0.37 kW portable agitators to 250 kW heavy duty units ranging from 0.1m3 to 5000 m3. These agitators are characterized by seals up to 100 bars pressure and temperatures in the region of 300 0 C. All type of sealing devices can be considered including lip seals, stiffing boxes, single or double mechanical seals. All workable materials can be used, as the choice of material is limited only be the conditions involved in the process such as temperature, pressure, corrosion and abrasion. A wide range of high performance turbines is available to suit all applications. DELKOR can supply many special designed impellers such as helical ribbons, anchors, rotating cages, shear disc etc. ADDITIONALLY, we can also offer series of INLINE STATIC MIXERS, ATTRITION SCRUBBERS.

DELKOR STANDARD IMPELLERS

VERTICAL FLAT BLADE TURBINE Vertical Flat Blade Turbines are used for gas disperion or where high Shear is required. Flow is premominantly radial and power requirements are high relative to axial flow turbines. Suitable for applications like High Shear Blendin, Gas Dispersion. MARINE PROPELLERS Marine propellers are very versatile pumping tubines with high Flow/low shear characteristics. Suitable for the applications like Blending, Solid in Supensions, Dispersion etc. PITCH BLADE TURBINE Pitch Blade Turbines are used in general blending and on soids supspension duties. They give a useful combition of moderate shear and axial flow characterisitics.

DELKOR TECHNIK INDIA PVT LTD.,

108/D, 6th Main Road, III Phase, Peenya Industial Area, Peenya, Bangalore 560058 Tel No. 080 2839 2823 / 2824 Tel Fax No.080 2839 7540 E Mail : delkor@delkorindia.com,

Mixing Solutions CURVED BLADE TURBINE The CBT, is essence, the same as the FBT but without the high shear charactertisitics. Suitable for the applications like Blending, Solids in Suspension and Heat transfer.

HYDROFOIL Keeping in mind the needs of mining/metallurgical applications this is developed. Suitable for applications like Solid Suspension, Digestion, Leaching, Blending, Heat Trasfer.

AGITATOR TYPES

Portable and light duty agitators Medium duty agitators Heavy duty agitators Hydrofoil Turbines Draft Tube Circulators Attrition Scrubbers Conditioners Stallion portable mixers For further details please contact us.

DELKOR TECHNIK INDIA PVT LTD.,

108/D, 6th Main Road, III Phase, Peenya Industial Area, Peenya, Bangalore 560058 Tel No. 080 2839 2823 / 2824 Tel Fax No.080 2839 7540 E Mail : delkor@delkorindia.com,

Das könnte Ihnen auch gefallen

- Apron Feeder Data SheetDokument1 SeiteApron Feeder Data SheetPat AuffretNoch keine Bewertungen

- Makron Fibretec 1000-2000 EngDokument10 SeitenMakron Fibretec 1000-2000 EngMAKRONNoch keine Bewertungen

- Sismat Externally Fed Drum Screen (DAT) Brochure A4 - SpreadsDokument5 SeitenSismat Externally Fed Drum Screen (DAT) Brochure A4 - SpreadsasddNoch keine Bewertungen

- Hydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediaDokument5 SeitenHydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediazamburittiNoch keine Bewertungen

- Filter & Size ReductionDokument20 SeitenFilter & Size ReductionMuhammad Putra RamadhanNoch keine Bewertungen

- Hms Drum PlantDokument2 SeitenHms Drum Plantrichard gutierrez100% (1)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsVon EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNoch keine Bewertungen

- Vibrating Screen Data SheetDokument1 SeiteVibrating Screen Data SheetAkhmad Audi HarvanNoch keine Bewertungen

- Training Manual Green Anode Plant Vedanta - Jharsuguda: File: 138-02-043 - 08 - 0.doc, Codeword: VedantaDokument47 SeitenTraining Manual Green Anode Plant Vedanta - Jharsuguda: File: 138-02-043 - 08 - 0.doc, Codeword: VedantaSubhransu MohapatraNoch keine Bewertungen

- Screw ConveyorDokument6 SeitenScrew ConveyorJobsonReisNoch keine Bewertungen

- Bag Filter & GasometerDokument9 SeitenBag Filter & GasometerPoovanaan Sathiya SeelanNoch keine Bewertungen

- AgitatorDokument10 SeitenAgitatoragrocel_bhv5591Noch keine Bewertungen

- Mechanical Model of Scraper Rake Torque in Deep-cone Thickener - 《Journal of Central South University (Science and Technology) 》2012年04期Dokument1 SeiteMechanical Model of Scraper Rake Torque in Deep-cone Thickener - 《Journal of Central South University (Science and Technology) 》2012年04期saidNoch keine Bewertungen

- THICKENER Mechanism - Center Pier Type ManualDokument35 SeitenTHICKENER Mechanism - Center Pier Type ManualAnonymous PWrmAKNoch keine Bewertungen

- Kemix Interstage Screen BrochureDokument8 SeitenKemix Interstage Screen BrochureFernandim SoaresNoch keine Bewertungen

- SCREW CONVEYOR Design Speed CalculatorDokument1 SeiteSCREW CONVEYOR Design Speed Calculatorozzy22Noch keine Bewertungen

- Beam Deflection CalculationDokument2 SeitenBeam Deflection CalculationAriful IslamNoch keine Bewertungen

- Trommel Drum Scrubber Jiangxi IndustryDokument11 SeitenTrommel Drum Scrubber Jiangxi IndustryCarlos Daniel Cuba JaraNoch keine Bewertungen

- FLSmidthAFP Filter Press BrochureDokument4 SeitenFLSmidthAFP Filter Press BrochureLENINROMEROH4168Noch keine Bewertungen

- Plate and Frambhhe LAB REPORTDokument10 SeitenPlate and Frambhhe LAB REPORTrossangel35Noch keine Bewertungen

- Screw Conveyor RatingDokument6 SeitenScrew Conveyor RatingPereiraeNoch keine Bewertungen

- ScreeningDokument16 SeitenScreeninganthony ijigaNoch keine Bewertungen

- Linear Screen SizingDokument4 SeitenLinear Screen SizingHARIPRASADNoch keine Bewertungen

- TrommelDokument2 SeitenTrommelÁlvaro BarbosaNoch keine Bewertungen

- Catalogue R I Tang Đ NG Cơ Rulmeca PDFDokument8 SeitenCatalogue R I Tang Đ NG Cơ Rulmeca PDFRulmeca Việt Nam100% (1)

- Belt Filter Press TBEDokument2 SeitenBelt Filter Press TBEmayukhguha1988Noch keine Bewertungen

- Delkor Brochure Apic Jig 2015-01 LowresDokument6 SeitenDelkor Brochure Apic Jig 2015-01 LowresBurak CANDANNoch keine Bewertungen

- Dorner 3200 Vacuum ConveyorDokument8 SeitenDorner 3200 Vacuum ConveyorBobKatNoch keine Bewertungen

- CIP / CIL Interstage Screening: Your Specialist in Screening MediaDokument4 SeitenCIP / CIL Interstage Screening: Your Specialist in Screening MediaevalenciaNoch keine Bewertungen

- Rapid Sand FilterDokument30 SeitenRapid Sand Filtersachinambekar100% (1)

- Agitator DesignDokument8 SeitenAgitator Designsandesh_honraoNoch keine Bewertungen

- Belt FilterDokument18 SeitenBelt FilterNaik LarkaNoch keine Bewertungen

- Primary Clarifier MechanismDokument12 SeitenPrimary Clarifier MechanismKriztopher UrrutiaNoch keine Bewertungen

- Gravity ThickenerDokument4 SeitenGravity ThickenerEllie Jane MapaNoch keine Bewertungen

- Filter CakeDokument7 SeitenFilter CakeMarion AlyssaNoch keine Bewertungen

- PB Filter Press Sidebar Me1500 Me2500 en Web DataDokument4 SeitenPB Filter Press Sidebar Me1500 Me2500 en Web DataTiago J C MachadoNoch keine Bewertungen

- Materials Handling and HoistingDokument6 SeitenMaterials Handling and HoistingNARGISNoch keine Bewertungen

- BHG - Bucket Elevator Data SheetDokument2 SeitenBHG - Bucket Elevator Data Sheetrimarima2bar100% (1)

- Delkor Apic JigDokument6 SeitenDelkor Apic JigruzmirNoch keine Bewertungen

- Double Roll CrusherDokument3 SeitenDouble Roll CrusherjtpmlNoch keine Bewertungen

- PT - 241properties and Characteristics of ParticlesDokument49 SeitenPT - 241properties and Characteristics of ParticlesAli HasSsan100% (1)

- Sizing of Grinding Equipment 3Dokument9 SeitenSizing of Grinding Equipment 3JazmínARNoch keine Bewertungen

- Screw Conveyor (Kaple)Dokument68 SeitenScrew Conveyor (Kaple)DIPAK VINAYAK SHIRBHATE100% (10)

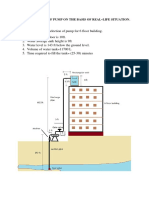

- Pump Final New ModelDokument9 SeitenPump Final New ModelAnukoolNoch keine Bewertungen

- Telescopic ChuteDokument2 SeitenTelescopic Chutebiswajit sabuiNoch keine Bewertungen

- Jaw Crusher SizingDokument7 SeitenJaw Crusher Sizingvaper123Noch keine Bewertungen

- Hammer MillsDokument3 SeitenHammer Millswebmaster9441Noch keine Bewertungen

- How To Size A ThickenerDokument7 SeitenHow To Size A ThickenerJesus Sing RoblesNoch keine Bewertungen

- Data Sheet For Rotary Calciner - TEPLDokument2 SeitenData Sheet For Rotary Calciner - TEPLpuneet gehlotNoch keine Bewertungen

- Screw Conveyor Excel CalculationDokument8 SeitenScrew Conveyor Excel Calculationhardik033Noch keine Bewertungen

- Roll Crusher BrochureDokument4 SeitenRoll Crusher BrochureWaris La Joi Wakatobi100% (1)

- Agitator DesignDokument9 SeitenAgitator DesignAnonymous 48jYxR1CNoch keine Bewertungen

- 2014.05.08 GNJBQ Agitator ManualDokument31 Seiten2014.05.08 GNJBQ Agitator ManualHamed Gerami100% (1)

- R0 ModelDokument1 SeiteR0 ModeltylerdurdaneNoch keine Bewertungen

- Enexco BrochureDokument35 SeitenEnexco BrochureErin CraigNoch keine Bewertungen

- Capability DeliveredDokument24 SeitenCapability DeliveredAlejandroAldaoGonzalez100% (1)

- MRO Product Range From Project Sales Corp, IndiaDokument43 SeitenMRO Product Range From Project Sales Corp, IndiaProject Sales CorpNoch keine Bewertungen

- Transformer BrochureDokument6 SeitenTransformer Brochuresunil patelNoch keine Bewertungen

- Damper Technology BrochureDokument8 SeitenDamper Technology Brochurejoy100% (1)

- Edoc - Pub - Piping Sensing Line Layout of Fire Pump and JockeyDokument1 SeiteEdoc - Pub - Piping Sensing Line Layout of Fire Pump and Jockeysushant_jhawerNoch keine Bewertungen

- Deliverables List Feed Vs Detail EngineeringDokument9 SeitenDeliverables List Feed Vs Detail Engineeringsushant_jhawer100% (5)

- Steam Control and Condensate Drainage For Heat Exchangers: GeneralDokument6 SeitenSteam Control and Condensate Drainage For Heat Exchangers: Generalsushant_jhawerNoch keine Bewertungen

- Concrete FDN Insp. Checklist Rev1 On 26-12-2012Dokument1 SeiteConcrete FDN Insp. Checklist Rev1 On 26-12-2012sushant_jhawerNoch keine Bewertungen

- Edoc - Pub - Foundation Design Philosophy For Rotating EquipmenDokument8 SeitenEdoc - Pub - Foundation Design Philosophy For Rotating Equipmensushant_jhawerNoch keine Bewertungen

- Checking Piping Drawings ProcedureDokument9 SeitenChecking Piping Drawings ProcedureAntoshal83% (6)

- Edoc - Pub - Fire Hydrant Pump CalculationDokument3 SeitenEdoc - Pub - Fire Hydrant Pump Calculationsushant_jhawerNoch keine Bewertungen

- Dennis Gertenbach, and Brian L. Cooper: Solid - Liquid Separations in Pilot-And Commercial - Scale OperationsDokument25 SeitenDennis Gertenbach, and Brian L. Cooper: Solid - Liquid Separations in Pilot-And Commercial - Scale Operationssushant_jhawerNoch keine Bewertungen

- Pilot PlantsDokument21 SeitenPilot PlantsFebby Ryanti MayasariNoch keine Bewertungen

- Chemical Reactors and Reactions Test MethodDokument63 SeitenChemical Reactors and Reactions Test Methodsushant_jhawer100% (1)

- Scaleup Issues From Bench To PilotDokument14 SeitenScaleup Issues From Bench To PilothoustonmathNoch keine Bewertungen

- Safet Design For ReactionDokument8 SeitenSafet Design For Reactionsushant_jhawerNoch keine Bewertungen

- Rotary Dryer CalculationDokument5 SeitenRotary Dryer Calculationsushant_jhawer100% (2)

- Fire Sprinkler DesignDokument68 SeitenFire Sprinkler DesignJuan Paulo Mayor89% (9)

- Design of Pressure Drop Flow MeterDokument6 SeitenDesign of Pressure Drop Flow Metersushant_jhawerNoch keine Bewertungen

- Static ElectricDokument28 SeitenStatic Electricunijhon100% (1)

- Evaporative Condenser Control in Industrial Refrigeration SystemsDokument21 SeitenEvaporative Condenser Control in Industrial Refrigeration SystemsMichael BasaNoch keine Bewertungen

- Basic Engineering Package - Ideal ApproachDokument2 SeitenBasic Engineering Package - Ideal Approachsushant_jhawerNoch keine Bewertungen

- Sequence of Civil WorkDokument33 SeitenSequence of Civil WorkDevendra Potdar100% (6)

- Cryo CondenserDokument2 SeitenCryo Condensersushant_jhawerNoch keine Bewertungen

- Green Field Building-ConstructionDokument7 SeitenGreen Field Building-Constructionsushant_jhawerNoch keine Bewertungen

- Chemical Composition For Stud BoltsDokument1 SeiteChemical Composition For Stud Boltssushant_jhawerNoch keine Bewertungen

- Green Field Building-ConstructionDokument7 SeitenGreen Field Building-Constructionsushant_jhawerNoch keine Bewertungen

- Green Field Building-ConstructionDokument7 SeitenGreen Field Building-Constructionsushant_jhawerNoch keine Bewertungen

- Finned Aircool CondensersDokument3 SeitenFinned Aircool Condenserssushant_jhawerNoch keine Bewertungen

- HE Fouling ReasonDokument8 SeitenHE Fouling Reasonsushant_jhawerNoch keine Bewertungen

- Flange FVC DataDokument36 SeitenFlange FVC DataachillesntroyNoch keine Bewertungen

- Sequence of Works For Building ConstructionDokument2 SeitenSequence of Works For Building ConstructionBoni Amin76% (34)

- Air Cool CondensersDokument8 SeitenAir Cool CondensersKarthick VelayuthamNoch keine Bewertungen

- Heat Exchanger Failure Analysis: Case HistoryDokument1 SeiteHeat Exchanger Failure Analysis: Case Historysushant_jhawerNoch keine Bewertungen

- Types of Chemical ReactionsDokument7 SeitenTypes of Chemical ReactionsAirene PalerNoch keine Bewertungen

- 531 (1999) T. R. Golub: Science Et AlDokument8 Seiten531 (1999) T. R. Golub: Science Et AlBair PuigNoch keine Bewertungen

- WW-WASG03 Electrical Wire Sizes-WEB 7-7-11 PDFDokument1 SeiteWW-WASG03 Electrical Wire Sizes-WEB 7-7-11 PDFSemion VirtudazoNoch keine Bewertungen

- Electrozincados en 10152 (2009)Dokument18 SeitenElectrozincados en 10152 (2009)joaopedrosousaNoch keine Bewertungen

- 7 - Casing DesignDokument36 Seiten7 - Casing Designام فاطمة البطاط100% (1)

- Eisco Industrial Catalogue - FinalDokument276 SeitenEisco Industrial Catalogue - FinalSOHAM AlhatNoch keine Bewertungen

- Carbon Dioxide Capture by Amines Increasing The Efficiency by Amine Structure Modification PDFDokument2 SeitenCarbon Dioxide Capture by Amines Increasing The Efficiency by Amine Structure Modification PDFJorgeSantosAquinoNoch keine Bewertungen

- LK Priceguide2003Dokument24 SeitenLK Priceguide2003Praveen PrabhakaranNoch keine Bewertungen

- Valves SpecificationDokument13 SeitenValves Specificationkselvan_1Noch keine Bewertungen

- Antinociceptive Activity of Buddleja Globosa (Matico)Dokument6 SeitenAntinociceptive Activity of Buddleja Globosa (Matico)alinumlNoch keine Bewertungen

- 12345Dokument1 Seite12345Praveen KumarNoch keine Bewertungen

- CentrifugationDokument43 SeitenCentrifugationSudeeksha RavikotiNoch keine Bewertungen

- Tensa Neoferma: Expansion JointsDokument4 SeitenTensa Neoferma: Expansion JointsAlexandra SanduNoch keine Bewertungen

- Iso 14687 3 2014Dokument11 SeitenIso 14687 3 2014Tatiana Sainara Maia FernandesNoch keine Bewertungen

- Ohm's Law and Circuits: 2. Conductance, Insulators and ResistanceDokument29 SeitenOhm's Law and Circuits: 2. Conductance, Insulators and ResistanceDita PramidaNoch keine Bewertungen

- Benzocaine Synthesis PDFDokument2 SeitenBenzocaine Synthesis PDFLive FlightsNoch keine Bewertungen

- 810.00 MR-N, NC, NSDokument110 Seiten810.00 MR-N, NC, NSnqh2009100% (1)

- 6.0 Biology Lab ManualDokument49 Seiten6.0 Biology Lab ManualJacob SmithNoch keine Bewertungen

- Fisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyDokument20 SeitenFisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyAlberto GuillenNoch keine Bewertungen

- S.No. Type Medicine NameDokument6 SeitenS.No. Type Medicine Namered petalsNoch keine Bewertungen

- Lampara de Fotocurado Bluephase MCDokument72 SeitenLampara de Fotocurado Bluephase MCErika PinillosNoch keine Bewertungen

- Green Glue Material Safety DataDokument4 SeitenGreen Glue Material Safety DatawilldoyeahNoch keine Bewertungen

- Surgical Sutures & BandagesDokument49 SeitenSurgical Sutures & BandagesAnni Sholihah100% (1)

- Structure Based Drug DesignDokument91 SeitenStructure Based Drug DesignMariamNoch keine Bewertungen

- Use of Hydrogen Gas As Suppymentry Fuel in 4 - Stroke Si EngineDokument6 SeitenUse of Hydrogen Gas As Suppymentry Fuel in 4 - Stroke Si Enginepetchiappan pNoch keine Bewertungen

- Chlorine and Water-A Table ResearchDokument5 SeitenChlorine and Water-A Table ResearchrajaratnaNoch keine Bewertungen

- Paradip Refinery Project Write UpDokument25 SeitenParadip Refinery Project Write UpHarsha Jayaram100% (3)

- Installation and Operating Instructions: Busch Produktions GMBH Schauinslandstr. 1 79689 Maulburg GermanyDokument28 SeitenInstallation and Operating Instructions: Busch Produktions GMBH Schauinslandstr. 1 79689 Maulburg GermanyRenārs BērtiņšNoch keine Bewertungen

- Chemical Bonding and Molecular Structure - Lecture NotesDokument51 SeitenChemical Bonding and Molecular Structure - Lecture NotesEdith EatonNoch keine Bewertungen