Beruflich Dokumente

Kultur Dokumente

Hydro Electricity Alternative

Hochgeladen von

dhakagladiatorsOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hydro Electricity Alternative

Hochgeladen von

dhakagladiatorsCopyright:

Verfügbare Formate

Alternative Concentrate on improving and increasing hydroelectric power generation in all countries of operation.

Pros

Hydroelectricity is undoubtedly the most widely-used form of renewable energy as compared to other energy forms such as solar energy, tidal energy, wind energy, etc. It is also the most feasible of all renewable energy options and therefore, the most popular. In terms of reliability and consistency, hydroelectricity is way ahead of its other renewable energy counterparts. No wonder then, that hydroelectric power is a preferred choice of power, not just for small scale industries, but also for heavy duty industries and manufacturing plants. Hydroelectric power is completely independent of fossil fuels or other perishable resources. It does not involve any combustion or burning of fuel, coal, etc. and therefore, does not release any toxic chemicals in the atmosphere and nor does it create any harmful byproducts. Unlike many other forms of energy, power generation is almost instantaneous in case of hydroelectricity. In a hydroelectric power plant, starting the turbine or stopping it is a process that hardly takes a few minutes (sometimes even seconds). The operational cost is quite low and it is also a clean way of producing energy. Also, the water can be reused for agriculture, irrigation, civic water supply, etc., therefore losses are minimal.

Cons

One of the major cons of hydroelectricity is the need for a large enough reservoir. Constructing a large reservoir is a major challenge, both in terms of time and money. Also, it often involves relocation of families who happen to be residing in the area that has been approved for the construction of the reservoir. Regardless of how strong and unbreakable a reservoir may seem, there is always the theoretical risk of the reservoir giving way in the event of unexpected heavy and prolonged torrential rain. Although such incidents are rare, if they indeed do happen, they can cause mass damage to livelihood. In some cases, constructing a reservoir or damming a river at a certain location may lead to adverse ecological effects on its immediate surroundings. Since the amount of power generated depends largely on the altitude difference between the reservoir and the turbine, finding a suitable place for both the reservoir and the turbine often becomes a problem. Droughts can have a severely adverse impact on hydroelectric power generation. Silt is a problem that adversely affects quite a few reservoirs, and consequently, the respective hydroelectric power plants as well.

Hydroelectricity, in the simplest of terms, is the electricity that is generated using flowing water, or that water which is stored in a reservoir. In both cases however, the basic fundamental principle of power generation remains the same. A large volume of water is stored in a reservoir at a high altitude. A power generation plant, consisting of multiple turbines is constructed downstream, at a much lower altitude. The reservoir and the power generation plant are connected by large pipelines known as penstocks. When water is released from the reservoir, it flows down the penstock at a high speed towards the turbine. Naturally, the speed at which the water flows down the penstock will be directly proportional to the difference between the altitudes of the reservoir and the turbine. As the water flows down, its potential energy gets converted into kinetic energy, which therein works the turbine blades and produces electricity. This is how hydroelectric power is generated. Now, the question is, how can Enersis build on its efficiency. Power plant efficiencies are typically defined as the amount of heat content in (Btu) per the amount of electric energy out (kWh), commonly called a heat rate (Btu/kWh). In the EIA and IEA outlooks both show power plant efficiencies improvements over time. These expected improvements mainly come from the substitution of old plants with new plants that have better efficiencies. The existing unit efficiency is flat. This indicates some efficiency improvement since many of the existing units will likely install environmental controls. Installation of environmental control systems will add internal energy requirements reducing the efficiency of the plant. There are a few changes one can make to make an existing unit more efficient. However these changes typically will only result in a few percentage point improvements to efficiency. The efficiency of a new power plant is largely a function of economic choice. The technology is well understood in order to produce a highly efficient plant. In order to produce higher efficiencies, higher pressure and temperatures are required. This increases the cost of the plant as special alloy materials will be needed. Technology improvements could assist by lowering the cost of these special materials through discovery and better manufacturing process. Coal efficiency merit much focus since coal represents over 50% of current generation in the US. Many countries in the world from Germany to Japan have demonstrated coal plants with heat rates of less than 9,000 Btu/kWh. The US has also demonstrated such technology since the 1950s. However the Chilean coal fleet current operating heat rate is nowhere near those levels, 10,400 Btu/kWh. The Chilean fuel diversity, relative abundance of various fuels, competitive landscape, the age of industry, and focus on reliability has lead to less efficiency in our coal fleet relative to other countries. In the developing countries there is an opportunity to introduce much higher efficient units in the beginning. Power plants can have lifetimes greater than 40 years, so it becomes important to introduce the efficient units early in the development of the infrastructure. According to the EIA, China is expected to have slightly better coal power plant fleet efficiency as in the US by 2030. Power plant efficiency can add value by reducing the amount of fuel used and thereby the amount of CO2 emitted. With the increased efficiency in the EIA forecast the fleet reduced CO2 emissions by 261 million tons in the year 2030 versus holding current heat rates. The following factors affect the efficiency of a given power plant. Design choices. Designs for natural gas and coal-fired power plants represent a trade off between capital cost, efficiency, operational requirements, and availability. For example, a steam turbine system that operates at a higher temperature and pressure can achieve a higher efficiency. The higher temperatures and pressures, however, require more exotic materials of construction for both the boiler and turbine, thus the capital cost goes up. The technology has been proven and demonstrated since the 1950s. The problems were severe superheater material wastage, unacceptable creep, and thermal fatigue cracking experienced when metal temperatures exceeded

approximately 1,025F.1 The issue was corrosion and strength at these extreme conditions. Heat integration represents another trade off. Rather than transferring cooling water to a process stream that needs to be cooled down and steam to another process stream that needs to be heated up, the work can be partially accomplished by bringing the two streams into thermal contact via a heat exchanger. There is a significant efficiency benefit, but process-process heat exchangers can cause operational problems, especially during transient phases and in the event of fouling or fluid leakage across the exchanger. Thus heat integration represents a trade-off between efficiency and availability. Unit role, peaking, base loading, etc, affect design and operational practices of using units for a role other than which they were designed. Old base load design units are often used for cycling duty. The supercritical to ultra-supercritical units are not capable of cycling without reducing longevity and ultimately the efficiency for which was the ultimate purpose of additional investment. Operational Practices. Efficiency can be improved by pressing over fire air to the minimum, fully utilizing heat integration systems, staying after steam leaks and exchanger fouling, and a large number of other practices. Operating at full load capacity continuously will enhance efficiency. However the reality is that load is ever changing and the requirements of market based systems focus on reliability and leads to the inability to always run at full load. Fuel. Among coals the higher ranking coals enable higher efficiency because they contain less ash and less water. However additional coal production is largely focused on the Powder River Basin which is sub-bituminous. Pollutant control. The level of pollutant emission control (including thermal) effects efficiency. NOx reduction units and SOx scrubbers represent parasitic loads that decrease net generation and thus reduce efficiency. Ambient conditions. Colder water and ambient air achieves higher efficiency. Additionally, higher altitudes have lower ambient pressure which affects compression and expansion. For example, gas turbines produce lower power at elevations above sea level. The power output loss is a function of the loss in ambient pressure. All else equal, lower altitude enables higher efficiency. The actual operating efficiency of a power plant is the summation of a lot of factors. The Clean Water Act amendments of 1977 placed certain limitations on water intake and discharge at certain facilities which included steam power plants. Water is used in large amounts as the method to cool the effluent steam from the steam turbine. Cooling water is used from an external source such as a river or lake to condense this exiting steam. In 2000 approximately 195,000 million gallons per day (MGD) were used to produce electricity in thermal plants alone (i.e. excluding hydroelectric facilities).13 There are currently three major methods of cooling steam turbine effluent (in order of most to least water consumed): (1) once-through cooling systems which intake water, pump it through the condenser and directly back into the environment. (2) wet cooling tower in which the cooling water is constantly re-circulated from the condenser to a cooling tower where it cools by evaporation and convection; makeup water is added to account for water loss due to evaporation (3) indirect dry cooling tower in which cooling water is constantly re-circulated from the condenser to a cooling tower where it cools by forced air convection via metal fins The National Energy Technology Laboratory (NETL) at the Department of Energy studied the effects of cooling water systems on power generation.14 The temperature of the cooling water as it enters the condenser can have significant impacts on turbine performance by changing the vacuum at

discharge from the steam turbine. In general terms, cooler water will create a larger vacuum allowing more energy to be generated. Conversely, warmer water creates lower vacuum and impedes generation. This effect is known as the energy penalty. The NETL modeled a retrofit of a once-through cooling system to both wet and dry cooling tower systems for a 400 MW unit. The annual average energy penalty for conversion to a wet cooling tower ranged from 0.8-1.5%, while the penalty was 4.2-8.8% with a dry cooling tower. Additional simulations were run for peak ambient temperatures, which also coincide with peak power demand. For the peak case the energy penalties range from 2.4-4.0% and 8.9-16.0% respectively. This is a significant amount of capacity loss during peak demand, when generating capacity is most critical. It is important to note the potential impacts of water cooling systems on new builds, particularly west of the Mississippi. Due to the arid climate, this western region is expected to have strict limitations on cooling water systems, with dry cooling towers likely being the system required. As shown above these systems can demonstrate significant efficiency losses. It is important to note that the proposed efficiencies provided in the subsequent sections may not be achievable due to the cooling water system requirements. Existing hydroelectric power plants worldwide do not achieve the highest efficiency possible based on their design. The loss of efficiency can be categorized as controllable or noncontrollable. Controllable losses are generally due to poor operation and maintenance practices. Non-controllable losses are due to environmental conditions (i.e. cooling water temperature, etc), dispatching requirements (i.e. customer demand) and normal deterioration. Deterioration naturally occurs, and if left unchecked it can become substantial. Therefore, some amount of deterioration, normal deterioration, will always be present and noncontrollable. There is a gradual increase in the unrecoverable portion as the unit ages which would require a replacement rather than a refurbishment to eliminate. Poor maintenance practices regarding the timing of the intervals and the amount of refurbishment may result in excessive deterioration and is controllable. When we hear the term Asolar energy, we usually think of heat from the sun=s rays which can be put to work. But there are other forms of solar energy. Just as hydropower is a form of solar energy, so too is windpower. In effect, the sun causes the wind to blow by heating air masses that rise, cool, and sink to earth again. Solar energy in some form is always at work -- in rays of sunlight, in air currents, and in the water cycle. Solar energy, in its various forms, has the potential of adding significant amounts of power for our use. The solar energy that reaches our planet in a single week is greater than that contained in all of the earth=s remaining coal, oil, and gas resources. However, the best sites for collecting solar energy in various forms are often far removed from people, their homes, and work places. Building thousands of miles of new transmission lines would make development of the power too costly. Because of the seasonal, daily, and even hourly changes in the weather, energy flow from the wind and sun is neither constant nor reliable. Peak production times do not always coincide with high power demand times. To depend on the variable wind and sun as main power sources would not be acceptable to most American lifestyles. Imagine having to wait for the wind to blow to cook a meal or for the sun to come out from behind a cloud to watch television! As intermittent energy sources, solar power and wind power must be tied to major hydroelectric power systems to be both economical and feasible. Hydropower can serve as an instant backup and to meet peak demands. Linking windpower and hydropower can add to the Nations supply of electrical energy. Large wind machines can be tied to existing hydroelectric powerplants. Wind power can be used, when the wind is blowing, to reduce demands on hydropower. That would allow dams to save their water for later release to generate power in peak periods. Hydropower is important from an operational standpoint as it needs no "ramp-up"

time, as many combustion technologies do. Hydropower can increase or decrease the amount of power it is supplying to the system almost instantly to meet shifting demand. With this important load-following capability, peaking capacity and voltage stability attributes, hydropower plays a significant part in ensuring reliable electricity service and in meeting customer needs in a market driven industry. In addition, hydroelectric pumped storage facilities are the only significant way currently available to store electricity. Hydropower=s ability to provide peaking power, load following, and frequency control helps protect against system failures that could lead to the damage of equipment and even brown or blackouts. Hydropower, besides being emissions-free and renewable has the above operating benefits that provide enhanced value to the electric system in the form of efficiency, security, and most important, reliability. The electric benefits provided by hydroelectric resources are of vital importance to the success of our National experiment to deregulate the electric industry. Water is one of our most valuable resources, and hydropower makes use of this renewable treasure. As a National leader in managing hydropower, Reclamation is helping the Nation meet its present and future energy needs in a manner that protects the environment by improving hydropower projects and operating them more effectively.

Das könnte Ihnen auch gefallen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Antimatter Explosions PDFDokument10 SeitenAntimatter Explosions PDFMahendra TantuwayNoch keine Bewertungen

- Grade12 Physics PracticeDokument44 SeitenGrade12 Physics Practicejaifar100% (1)

- ABB Industrie AG: Schedule For Commissioning of UNITROL 6800Dokument2 SeitenABB Industrie AG: Schedule For Commissioning of UNITROL 6800Adriana MartinezNoch keine Bewertungen

- Super CapacitorDokument54 SeitenSuper Capacitorharisri269Noch keine Bewertungen

- MQ SP e 6001Dokument41 SeitenMQ SP e 6001jaseel kNoch keine Bewertungen

- 3PT3 60Dokument2 Seiten3PT3 60PATIÑO QUILLER PABLO ALEJANDRONoch keine Bewertungen

- Material and Energy Balances For Methanol From Biomass Using Biomass GasifierDokument136 SeitenMaterial and Energy Balances For Methanol From Biomass Using Biomass Gasifierapi-3799861Noch keine Bewertungen

- Chapter 7 - Geothermal PowerDokument2 SeitenChapter 7 - Geothermal PowerHectorCabz100% (1)

- Success - Story - HCR6000 - Shandong - China - Alu - March 2017Dokument2 SeitenSuccess - Story - HCR6000 - Shandong - China - Alu - March 2017Sanjay RajawatNoch keine Bewertungen

- TUGASAN KUMPULAN (DC Generator)Dokument43 SeitenTUGASAN KUMPULAN (DC Generator)Zainuddin BusuNoch keine Bewertungen

- SE DS Fronius Primo EN PDFDokument4 SeitenSE DS Fronius Primo EN PDFBarun BiswasNoch keine Bewertungen

- Power Quality Issues and Recommendations: Copper Development Association IncDokument2 SeitenPower Quality Issues and Recommendations: Copper Development Association IncJulio SamaméNoch keine Bewertungen

- Demand Assessment of Natural Gas in Selected Sectors in FaridabadDokument78 SeitenDemand Assessment of Natural Gas in Selected Sectors in FaridabadGaurav Gupta100% (1)

- Unnati Oil and Gas 2018Dokument103 SeitenUnnati Oil and Gas 2018Harshit Dhawan100% (1)

- Solar Quiz: How Much Do You Know About Solar Power?: The Questions: True or False?Dokument2 SeitenSolar Quiz: How Much Do You Know About Solar Power?: The Questions: True or False?Armando Giraldo PradoNoch keine Bewertungen

- Hype and Reality in The Middle East - Lux MagazineDokument3 SeitenHype and Reality in The Middle East - Lux MagazineovaishashmiNoch keine Bewertungen

- Postal Address: Curriculum VitaeDokument3 SeitenPostal Address: Curriculum VitaesambhuNoch keine Bewertungen

- Department of Systems Engineering University of LagosDokument33 SeitenDepartment of Systems Engineering University of LagosOlaolu AjoseNoch keine Bewertungen

- Eco Friendly Housing SynopsisDokument12 SeitenEco Friendly Housing SynopsisNazish100% (1)

- Project Proposal @ (BEE) PDFDokument5 SeitenProject Proposal @ (BEE) PDFAnil KatteNoch keine Bewertungen

- Geothermal PPT For Presentation)Dokument27 SeitenGeothermal PPT For Presentation)anil patel0% (1)

- Genset Handbook Portable Generators 2015LR 6mbDokument28 SeitenGenset Handbook Portable Generators 2015LR 6mbepicenterrulezNoch keine Bewertungen

- 20160527.thailand's Energy - ChaiDokument87 Seiten20160527.thailand's Energy - ChaiMD Shamim Hasan SajibNoch keine Bewertungen

- ABB Leaflet Comem BR-En 2018-06-07Dokument2 SeitenABB Leaflet Comem BR-En 2018-06-07Dave ChaudhuryNoch keine Bewertungen

- DCS - OC4000 Maintenance Manual (Unit-3)Dokument33 SeitenDCS - OC4000 Maintenance Manual (Unit-3)rahulNoch keine Bewertungen

- TSNPDCL Previous Paper 2015: Useful LinksDokument35 SeitenTSNPDCL Previous Paper 2015: Useful Linksnaresh nickyNoch keine Bewertungen

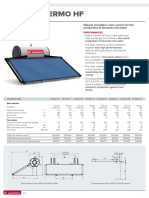

- Kairos Thermo HF: Natural Circulation Solar System For The Production of Domestic Hot WaterDokument4 SeitenKairos Thermo HF: Natural Circulation Solar System For The Production of Domestic Hot WaterFILID MADNoch keine Bewertungen

- Operation and Maintenance Instructions Manual: DDFP Series Engines FOR Fire Pump ApplicationsDokument92 SeitenOperation and Maintenance Instructions Manual: DDFP Series Engines FOR Fire Pump ApplicationsSonthi MooljindaNoch keine Bewertungen

- Importance of O&M For Solar Power PantDokument6 SeitenImportance of O&M For Solar Power PantSanthosh ThangarajNoch keine Bewertungen

- Steag O&M Business in Gas & Coal Based Power PlantsDokument5 SeitenSteag O&M Business in Gas & Coal Based Power Plants8103 Anshu PatilNoch keine Bewertungen