Beruflich Dokumente

Kultur Dokumente

Elevator Safety Features

Hochgeladen von

KarthikAravindOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Elevator Safety Features

Hochgeladen von

KarthikAravindCopyright:

Verfügbare Formate

Elevator Safety Features

Elevator systems got a wide variety of features designed in such a way that we can reduce the chances of accidents so that the passengers can travel safely. There are two basic types of elevator systems Traction Hydraulic.

Hydraulic elevators are attached by a jack mounted below the elevator. Hydraulic oil is moved by a pump into the jack who makes the elevator to rise. While coming down oils is controlled by vales to return to the system's storage tank and safely lowering an elevator car. The rope system is the first line of defense in hydraulic system. Each and every elevator rope is made up of several lengths of strong steel material wound around one another like a twist. With this very powerful structure, one rope can hold the weight of the entire elevator car and the counterweight on its own. But usually elevators are made up of multiple ropes. It is highly without a solution for elevator rope to break, if incase it breaks the remaining will hold an elevator car and still the elevator car can move up and down freely. Even if all of the ropes going to break or the sheave systems going to release them, it is highly not possible that an elevator car would fall to the bottom of the shaft as hydraulic elevator cars got an integrated braking systems or safeties that catch the rail when an elevator car moves too fast.

Whenever the elevator car moves too quickly the governor will activate safeties. A mostly governor system is present in the region of a sheave and is positioned at the top of the elevator shaft. The governor rope is looped around the governor sheave and another weighted sheave is present at the bottom of the sheave shaft. The elevator rope moves up and down when the elevator car moves

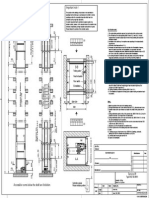

as the elevator rope is connected to elevator car. As the elevator car moves quickly and the governor will also moves quickly. The diagram below shows one representative governor design.

Source: http://science.howstuffworks.com/transport/engines-equipment/elevator5.htm

In this governor, the sheave is made up of with two hooked flyweights that spin around on anchor pins. The flyweights are attached in such a way that they can swing freely back and forth on the governor. But most of the time the flyweights are kept in position by a high-tension coil. When the elevator rope breaks in the elevator car governor builds up the rotary movement and the centrifugal force comes into play. Centrifugal force moves the flyweights outward and pushing the flyweight against the spring. If the elevator car falls fast enough the centrifugal force will be strong enough to push both the ends of the flyweights as they catch the outer edges of the governor. Spinning in this position the end of flyweights hold the stationary ratchets mounted to a stationary cylinder surrounding the sheave. This will hold the fast moving elevator car. The governor ropes are connected to the elevator car via a movable actuator arm attached to a lever linkage. When the governor ropes can move freely the arm stays in the same position relative to the elevator car. But when the governor sheave locks itself the governor ropes jerk the actuator arm up. This moves the lever linkage which operates the brakes.

In this design the linkage pulls up on a wedge-shaped safety which sits in a stationary wedge guide. As the wedge moves up it is pushed into the guide rails by the slanted surface of the guide. This will bring the elevator car to a stop. Elevators also have electromagnetic brakes which makes the elevator car to stop. The electromagnetic break is always kept in open position instead of closing them. With this type of design the elevator car stops automatically as the break shuts once power losses. Elevators also got automatic braking systems near the top and the bottom of the elevator shaft. The break is automatically applied if the elevator car moves too fast in any one direction. If everything fails and the elevator moves too fast ,in order to save the passengers a heavy-duty shock absorber system is mounted at the bottom of the shaft which looks like a typically a piston mounted in an oil-filled cylinder. A heavy-duty shock absorber system works like a cushion to soften the elevator cars landing and passenger can escape from heavy landing.

The door system on a modern elevator also includes several safety devices. Sensors detect passengers or objects in the door opening, preventing the continued closing of the doors. Older systems use mechanical "safety edges" which cause the doors to stop or retract when they make contact with a person or object. More modern systems use a large number of invisible light rays to detect people or objects in the doorway and reverse or stop the doors without having to make physical contact. Door operators contain devices which limit the amount of closing force. Newer systems are better able to keep the closing force consistent even under unusual conditions such as the "stack effect" which can cause heavy air movement in elevator shafts. Interlocks on the hoistway doors help assure that the elevator cannot leave a landing unless the doors are fully closed and secured. Should the doors be forced open, the interlock circuit will be broken, causing the elevator to immediately stop. Various switches in the elevator shaft detect the presence of the car at certain stages of its journey. They initiate slowdowns and stops at the proper points, and help prevent overtravel in the up or down direction. To discourage the very dangerous practice of passengers trying to open the door of a stalled elevator, door restraints can allow normal operation of the door when the car is near the floor level, but will restrict forcible movement of the door when the car is away from the floor. The emergency evacuation hatch on most elevators is designed to be opened only from the outside, by trained emergency personnel. This too is intended to help prevent any passenger from gaining access to the dangerous elevator shaftway. Buffers, located in the "pit" below the car, serve to cushion any unplanned travel below the lowest landing. In the elevator cab you'll find several items to help increase safety. An emergency alarm switch will sound an alarm when activated by a passenger. In most elevators, an emergency telephone or intercom can serve as a link to assistance if the car should stall. And, in the event of a power failure, emergency lighting maintains illumination for hours. In some systems, emergency power is available to permit movement of the elevator and evacuation of the passengers. In many elevator systems, a special fire emergency system has been installed. It may be manually activated, or may respond to smoke sensors in the building. Exact operation varies by local codes, but generally such systems return the elevator to the main floor, open the doors to allow passengers to exit, and make the elevators available to emergency personnel.

Das könnte Ihnen auch gefallen

- Elevator 101 - Elevator Terminology PDFDokument2 SeitenElevator 101 - Elevator Terminology PDFLabib Romzi60% (5)

- New Elevator MaintenanceDokument108 SeitenNew Elevator MaintenanceJodoNoch keine Bewertungen

- EN81 lift pit safety requirementsDokument2 SeitenEN81 lift pit safety requirementsSupri AdiNoch keine Bewertungen

- Two New European Standards For The Design and Manufacture of Lifts Were Introduced in August 2014Dokument5 SeitenTwo New European Standards For The Design and Manufacture of Lifts Were Introduced in August 2014moudshahineNoch keine Bewertungen

- A Guide To The New European Lift Standards: EN81-20 and EN81-50Dokument5 SeitenA Guide To The New European Lift Standards: EN81-20 and EN81-50moudshahineNoch keine Bewertungen

- VERTICAL TRANSPORTATION SOLUTIONS FOR BUILDINGSDokument71 SeitenVERTICAL TRANSPORTATION SOLUTIONS FOR BUILDINGSrini0026Noch keine Bewertungen

- ZJ - Esclators PDFDokument8 SeitenZJ - Esclators PDFShapolaNoch keine Bewertungen

- Lifts Elevators Escalators and Moving Walkways Travelators 2DE2Dokument169 SeitenLifts Elevators Escalators and Moving Walkways Travelators 2DE2jvicec826050% (2)

- Express Lifts Planning GuideDokument24 SeitenExpress Lifts Planning GuideFERNSNoch keine Bewertungen

- Larsson Quotation Sample Lsh320m-0.4-VvvfDokument7 SeitenLarsson Quotation Sample Lsh320m-0.4-VvvfvinayNoch keine Bewertungen

- Installation and Operating Instructions Overspeed Governor Type 7/8/9Dokument16 SeitenInstallation and Operating Instructions Overspeed Governor Type 7/8/9RuiNoch keine Bewertungen

- Deq2016 5661Dokument5 SeitenDeq2016 5661Juan CarlosNoch keine Bewertungen

- Codes For Lifts and EscalatorsDokument19 SeitenCodes For Lifts and EscalatorsMing Hong100% (1)

- Thyssenkrupp: Elevator Technology Synergy Element Package. Fact SheetDokument15 SeitenThyssenkrupp: Elevator Technology Synergy Element Package. Fact SheetTek tek hapNoch keine Bewertungen

- Elevator SystemDokument6 SeitenElevator SystemEdna Moreno100% (1)

- Stress Analysis of Guide Rails of Elevators: Hayder F. Neamah Wisam H. AliDokument13 SeitenStress Analysis of Guide Rails of Elevators: Hayder F. Neamah Wisam H. Alikikokiko KarimNoch keine Bewertungen

- Schindler 6500 Elevator Mod BrochureDokument11 SeitenSchindler 6500 Elevator Mod BrochurePrega sNoch keine Bewertungen

- QuoteDokument5 SeitenQuoteDeepanshu SinghNoch keine Bewertungen

- Machine Room NotesDokument2 SeitenMachine Room NotesSayed NagyNoch keine Bewertungen

- Elevators & Escalators: Compiled by Ar. B. K. PrabuDokument35 SeitenElevators & Escalators: Compiled by Ar. B. K. PrabushobanaNoch keine Bewertungen

- The Cabin Lift Cibes A6000 - Key FeaturesDokument4 SeitenThe Cabin Lift Cibes A6000 - Key FeaturesmecmakNoch keine Bewertungen

- Kinetek Elevator CatalogueDokument28 SeitenKinetek Elevator CatalogueNasco TradingNoch keine Bewertungen

- India ElevatorDokument14 SeitenIndia ElevatorNaren AnandNoch keine Bewertungen

- Guiding Rail Decoupling for ElevatorsDokument5 SeitenGuiding Rail Decoupling for ElevatorsbertzmNoch keine Bewertungen

- KONE Factsheet EN81 20 50 - tcm45 32332Dokument2 SeitenKONE Factsheet EN81 20 50 - tcm45 32332moudshahineNoch keine Bewertungen

- EN81-28 Risk of Trapping FlowChart v3Dokument1 SeiteEN81-28 Risk of Trapping FlowChart v3Ashraful ShohagNoch keine Bewertungen

- Transportation in Buildings: 1. Vertical 2. Inclined 3. HorizontalDokument104 SeitenTransportation in Buildings: 1. Vertical 2. Inclined 3. HorizontalManoj JainNoch keine Bewertungen

- LUXEN ElevatorDokument17 SeitenLUXEN ElevatorAzm FaisalNoch keine Bewertungen

- TKE Mod SolutionsDokument32 SeitenTKE Mod SolutionsLono BradyNoch keine Bewertungen

- PLC Based ElevatorDokument10 SeitenPLC Based ElevatorShisir KandelNoch keine Bewertungen

- Table of Contents for Elevator Design and Installation StandardsDokument60 SeitenTable of Contents for Elevator Design and Installation Standardspastorgee50% (2)

- Safety Rules For The Construction and Installation of Escalators and Passenger ConveyorsDokument64 SeitenSafety Rules For The Construction and Installation of Escalators and Passenger ConveyorsLina NimriNoch keine Bewertungen

- 14 21 00 MRL and MRA Electric Traction Passenger Elevators (Schindler Elevator Corporation)Dokument10 Seiten14 21 00 MRL and MRA Electric Traction Passenger Elevators (Schindler Elevator Corporation)Bahaa RaslanNoch keine Bewertungen

- Lift 1Dokument27 SeitenLift 1shelmi100% (1)

- Safety Considerations For The Design of Modern Elevator SystemsDokument72 SeitenSafety Considerations For The Design of Modern Elevator SystemsYunus MushagaNoch keine Bewertungen

- Car Size Calculation Sheet: Calculate DimensionsDokument2 SeitenCar Size Calculation Sheet: Calculate DimensionsJeannehayekNoch keine Bewertungen

- Mitsubishi Lifts BrochureDokument28 SeitenMitsubishi Lifts Brochurenaveenarora298040Noch keine Bewertungen

- Intro To ElevatorsDokument20 SeitenIntro To ElevatorsSadhikaNoch keine Bewertungen

- An Introduction To EN81 The New British and European Lift StandardDokument5 SeitenAn Introduction To EN81 The New British and European Lift StandardXiaofu LiuNoch keine Bewertungen

- Quote - Eluru G+4Dokument7 SeitenQuote - Eluru G+4prasadmvkNoch keine Bewertungen

- Elevator 2003Dokument150 SeitenElevator 2003Tita AnielaNoch keine Bewertungen

- ElevatorDokument21 SeitenElevatormmzzzNoch keine Bewertungen

- Assignment ELEVATORDokument7 SeitenAssignment ELEVATORRenzo LopezNoch keine Bewertungen

- Vertical TransportationDokument8 SeitenVertical TransportationNupur BhadraNoch keine Bewertungen

- Hydraulic Elevators: OTIS Solution for Low-Rise BuildingsDokument8 SeitenHydraulic Elevators: OTIS Solution for Low-Rise BuildingsRadu NegoitaNoch keine Bewertungen

- Elevator Control Wiring and Simple Configuration: Button ModeDokument7 SeitenElevator Control Wiring and Simple Configuration: Button ModeAgnelo FernandesNoch keine Bewertungen

- Use and Maintenance of Elevator Guide ShoesDokument5 SeitenUse and Maintenance of Elevator Guide ShoesGERARDO GABAY100% (1)

- MRL CatalogueDokument30 SeitenMRL CatalogueNadeem HassoonNoch keine Bewertungen

- SIEPC80000045C SigmaV User Manual Design Maintenance Rotational MotorDokument402 SeitenSIEPC80000045C SigmaV User Manual Design Maintenance Rotational MotorNguyễn Hữu Tuân100% (1)

- Factsheet Elevator Norms En81 20 En81 50Dokument2 SeitenFactsheet Elevator Norms En81 20 En81 50Michael LagundinoNoch keine Bewertungen

- Elevator Violation CodesDokument31 SeitenElevator Violation CodesAnonymous YzSzB0rpNKNoch keine Bewertungen

- The Components of ElevatorDokument12 SeitenThe Components of ElevatorJuri JurieNoch keine Bewertungen

- Installation Method Statement (Scaffoldless)Dokument10 SeitenInstallation Method Statement (Scaffoldless)faizbukhari100% (1)

- MaisonLIFT BASIC Hydraulic LiftDokument2 SeitenMaisonLIFT BASIC Hydraulic LiftKleemmann Hellas SANoch keine Bewertungen

- Elevator Ride QualityDokument10 SeitenElevator Ride QualitySadanand RaoNoch keine Bewertungen

- Elevator Exam 01Dokument6 SeitenElevator Exam 01Jeff BrownNoch keine Bewertungen

- LF 1Dokument1 SeiteLF 1opulitheNoch keine Bewertungen

- Elevator Inspector: Passbooks Study GuideVon EverandElevator Inspector: Passbooks Study GuideNoch keine Bewertungen

- Elevator Mechanic: Passbooks Study GuideVon EverandElevator Mechanic: Passbooks Study GuideNoch keine Bewertungen

- Elevator Systems of the Eiffel Tower, 1889Von EverandElevator Systems of the Eiffel Tower, 1889Bewertung: 3 von 5 Sternen3/5 (1)

- Cisco Prime Infrastructure 3.1 V1 30 Minutes Part 1 Scenario 1: DashboardDokument14 SeitenCisco Prime Infrastructure 3.1 V1 30 Minutes Part 1 Scenario 1: DashboardRatnesh KumarNoch keine Bewertungen

- GT-P5100 Repair GuideDokument93 SeitenGT-P5100 Repair GuideJan Soukup100% (1)

- PHP Scripts DownloadDokument2 SeitenPHP Scripts DownloadAbram AncisoNoch keine Bewertungen

- CSI-209: Newark Flex Tester: Benefits User Friendly Low Maintenance Versatile Accurate and Repeatable ResultsDokument2 SeitenCSI-209: Newark Flex Tester: Benefits User Friendly Low Maintenance Versatile Accurate and Repeatable ResultsAnthony VargasNoch keine Bewertungen

- About Network နက္၀ပ္ အေၾကာင္း PDFDokument6 SeitenAbout Network နက္၀ပ္ အေၾကာင္း PDFEithu ThutunNoch keine Bewertungen

- Piping Handbook Guide for Design and StandardsDokument136 SeitenPiping Handbook Guide for Design and StandardsAnonymous Vg5IAD0I100% (9)

- Mef6 1 1Dokument11 SeitenMef6 1 1shohobiNoch keine Bewertungen

- Installation, Operation AND Maintanance Manual: Always A Step Ahead in TechnologyDokument26 SeitenInstallation, Operation AND Maintanance Manual: Always A Step Ahead in TechnologyBharat TailorNoch keine Bewertungen

- Moja TV Live StreamsDokument3 SeitenMoja TV Live StreamsAmina MujčinovićNoch keine Bewertungen

- Beckhoff Embedded PCDokument78 SeitenBeckhoff Embedded PCblackslash82Noch keine Bewertungen

- Sharp Lc-32d44e S Ru-Bk Gy - EtDokument136 SeitenSharp Lc-32d44e S Ru-Bk Gy - Etlucas22010Noch keine Bewertungen

- Sandvik TH540 technical specificationDokument3 SeitenSandvik TH540 technical specificationSriram NambiNoch keine Bewertungen

- SC-Introductory Slides On Project ManagementDokument34 SeitenSC-Introductory Slides On Project ManagementGurucharan Bhat100% (1)

- 556U Immobolizer InterfaceDokument9 Seiten556U Immobolizer InterfaceLuis Perez100% (1)

- Deep Sea 500 Ats ManDokument18 SeitenDeep Sea 500 Ats ManLeo Burns50% (2)

- Hardox 360 enDokument2 SeitenHardox 360 enAndréVitorinoNoch keine Bewertungen

- Lem Ar 297 in - 108 4.2 Haf V0001 IvecoDokument28 SeitenLem Ar 297 in - 108 4.2 Haf V0001 IvecoFagner LucasNoch keine Bewertungen

- Uniform Technical Guidelines For Water Reticulation and PlumbingDokument211 SeitenUniform Technical Guidelines For Water Reticulation and PlumbingFahmi YusoffNoch keine Bewertungen

- Basics of Small Bore FittingsDokument9 SeitenBasics of Small Bore FittingsJosh LeBlancNoch keine Bewertungen

- 9-12 Flat File Schema Developers GuideDokument86 Seiten9-12 Flat File Schema Developers GuideVenkata Mohan Reddy PathiNoch keine Bewertungen

- Michael BuckleyDokument15 SeitenMichael BuckleyPEFC InternationalNoch keine Bewertungen

- Manual Ceberus EcoDokument60 SeitenManual Ceberus EcoAad Pupu SaputraNoch keine Bewertungen

- 8BK80 ModifiedDokument57 Seiten8BK80 Modifiedrohitvdave5250% (2)

- Minimum Automotive Quality Management System Requirements For Sub-Tier Suppliers - AUG 14 PDFDokument9 SeitenMinimum Automotive Quality Management System Requirements For Sub-Tier Suppliers - AUG 14 PDFFer Jesus Nieves UribeNoch keine Bewertungen

- Project Management and The Aspects of Quality Management - An Integrative ApproachDokument7 SeitenProject Management and The Aspects of Quality Management - An Integrative Approachabel asratNoch keine Bewertungen

- Report Electric Vehicles en Page 26Dokument86 SeitenReport Electric Vehicles en Page 26Mohsin Hassan SyedNoch keine Bewertungen

- Productbrochurev52 UKDokument6 SeitenProductbrochurev52 UKjavier8970Noch keine Bewertungen

- Tl-Wpa4220 Kit V1 Qig PDFDokument2 SeitenTl-Wpa4220 Kit V1 Qig PDFΔημήτρηςNoch keine Bewertungen

- Rights of Persons with Disabilities Act 2008 SummaryDokument6 SeitenRights of Persons with Disabilities Act 2008 SummaryAlia ShahiraNoch keine Bewertungen

- Oracle Application Server 10g Release 3 (10.1.3.1) - Enterprise Web ServicesDokument17 SeitenOracle Application Server 10g Release 3 (10.1.3.1) - Enterprise Web ServicesHoratio CainNoch keine Bewertungen