Beruflich Dokumente

Kultur Dokumente

Osaka's Kansai International Airport

Hochgeladen von

Izzuddin ShahidanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Osaka's Kansai International Airport

Hochgeladen von

Izzuddin ShahidanCopyright:

Verfügbare Formate

Kansai International Airport ( Kansai Kokusai Kk?

) (IATA: KIX, ICAO: RJBB) is an international airport located on an artificial island in the middle of Osaka Bay, 38 km (24 mi) southwest of saka Station,[1] located within three municipalities, including Izumisano (north),[3] Sennan (south),[4] and Tajiri (central),[5] in Osaka Prefecture, Japan. The airport is off the Honshu shore. The airport serves as an international hub for All Nippon Airways, Japan Airlines, and Nippon Cargo Airlines. Peach, the first international low-cost carrier in Japan, plans to make Kansai its main hub starting in 2012. It is colloquially known as Kank (?) in Japanese. Kansai opened in 1994 to relieve overcrowding at Osaka International Airport, which is closer to the city of Osaka and now handles only domestic flights. During the 2006 fiscal year, KIX had 116,475 aircraft movements, of which 73,860 were international (31 countries, 71 cities), and 42,615 were domestic (19 cities). The total number of passengers was 16,689,658 of which 11,229,444 were international, and 5,460,214 were domestic, sixth in Japan and second in Osaka area. However, in 2009, airport traffic has fallen by almost 20% in just two years to 13.4 million.[6] Freight volume was at 802,162 tonnes total, of which 757,414 t were international (18th in the world), and 44,748 t were domestic.[2] The 4,000 60 m (13,123 197 ft) second runway was opened on 2 August 2007. Kansai Airport has become an Asian hub, with 499 weekly flights to Asia, 66 weekly flights to Europe and the Middle East, and 35 weekly flights to North America. It was ranked 4th overall in the Airport of the Year 2006 awards named by Skytrax, after Singapore Changi Airport, Hong Kong International Airport and Munich Airport.

Contents

[hide]

1 Flights 2 History o 2.1 Construction o 2.2 Operation o 2.3 Expansion o 2.4 Relationship with Itami Airport 3 Terminal 4 Airlines and destinations o 4.1 Cargo 5 Ground transportation o 5.1 Rail o 5.2 Bus o 5.3 Parking o 5.4 Ferry service 6 Other facilities 7 See also 8 References

9 External links

[edit] Flights

Weekly international passenger flights: 614 Weekly international freighter flights: 200 Weekly domestic (passenger and freighter) flights: 495

(Summer 2008 schedule)[7]

[edit] History

3rd floor boarding lobby, part of the longest airport concourse in the world. In the 1960s, when the Kansai region was rapidly losing trade to Tokyo, planners proposed a new airport near Kobe and Osaka. Osaka International Airport, located in the densely-populated suburbs of Itami and Toyonaka, was surrounded by buildings; it could not be expanded, and many of its neighbors had filed complaints because of noise pollution problems. After the protests surrounding New Tokyo International Airport (now Narita International Airport), which was built with expropriated land in a rural part of Chiba Prefecture, planners decided to build the airport offshore. The new airport was part of a number of new developments to revitalize Osaka, which had lost economic and cultural ground to Tokyo for most of the century.[8] Initially, the airport was planned to be built near Kobe, but the city of Kobe refused the plan, so the airport was moved to a more southerly location on Osaka Bay. There, it could be open 24 hours per day, unlike its predecessor in the city.

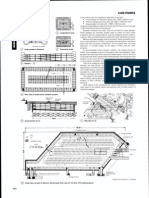

[edit] Construction

Satellite photo of Kansai Airport (lower-right island) in Osaka Bay. Kobe Airport is being built on the unfinished island near the middle of the photo. Central Osaka is in the upper-right corner, along with Osaka International.

Closeup of the artificial island A man-made island, 4 km (2.5 mi) long and 2.5 km (1.6 mi) wide, was proposed. Engineers needed to overcome the extremely high risks of earthquakes and typhoons (with storm surges of up to 3 m (10 ft)). Construction started in 1987. The sea wall was finished in 1989 (made of rock and 48,000 tetrahedral concrete blocks). Three mountains were excavated for 21,000,000 m3 (27,000,000 cu yd) of landfill. 10,000 workers and 10 million work hours over three years, using eighty ships, were needed to complete the 30-metre (98 ft) layer of earth over the sea floor and inside the sea wall. In 1990, a three kilometer bridge was completed to connect the island to the mainland at Rinku Town, at a cost of $1 billion. Completion of the artificial island increased the area of Osaka Prefecture just enough to move it past Kagawa Prefecture in size (leaving Kagawa as the smallest by area in Japan). The bidding and construction of the airport was a source of international trade friction during the late 1980s and early 1990s. Prime Minister Yasuhiro Nakasone responded to American concerns, particularly from Senator Frank Murkowski, that bids would be rigged in Japanese companies' favor by providing special offices for prospective international contractors,[9] which ultimately did little to ease the participation of foreign contractors in the bidding process.[10] Later, foreign airlines complained that two-thirds of the departure hall counter space had been allocated to Japanese carriers, disproportionately to the actual carriage of passengers through the airport.[11]

The island had been predicted to gradually sink as the weight of the material used for construction would cause it to compress. However, by this time, the island had sunk 8 m (26 ft), much more than predicted. The project then became the most expensive civil works project in modern history after twenty years of planning, three years of construction and several billion dollars of investment. Much of what was learned went into the successful artificial islands in silt deposits for New Kitakyushu Airport, Kobe Airport, and Chbu Centrair International Airport. The lessons of Kansai Airport were also applied in the construction of Hong Kong International Airport.[12] In 1991, the terminal construction commenced. To compensate for the sinking of the island, adjustable columns were designed to support the terminal building. These could be extended by inserting thick metal plates at their bases. Government officials proposed reducing the length of the terminal to cut costs, but architect Renzo Piano insisted on keeping the terminal at its full planned length.[13] The airport opened in 1994. On 17 January 1995, Japan was struck by the Kobe earthquake, whose epicenter was about 20 km (12 mi) away from KIX and killed 6,434 people on Japan's main island of Honsh. Due to its earthquake engineering, the airport emerged unscathed, mostly due to the use of sliding joints. Even the glass in the windows remained intact. Later, in 1998, the airport survived a typhoon with wind speeds of up to 200 km/h (120 mph). On 19 April 2001, the airport was one of ten structures given the "Civil Engineering Monument of the Millennium" award by the American Society of Civil Engineers.[14] The total cost of Kansai Airport so far is $20 billion. This includes land reclamation, two runways, terminal and facilities. Most additional costs were initially due to the island sinking, expected due to the soft soils of Osaka Bay. After construction the rate of sinking was considered so severe that the airport was widely criticized as a geotechnical engineering disaster. The sink rate has since fallen from 50 cm (20 in) during 1994 to 7 cm (2.8 in) in 2008.[15]

[edit] Operation

Aircraft in front of the terminal building

4th floor ticketing hall, illustrating the terminal's airfoil roof. Opened on 4 September 1994, the airport serves as a hub for several airlines such as All Nippon Airways, Japan Airlines, and Nippon Cargo Airlines. It is the international gateway for Japan's Kansai region, which contains the major cities of Kyoto, Kobe, and Osaka. Other Kansai domestic flights fly from the older but more conveniently located Osaka International Airport in Itami, or from the newer Kobe Airport. The airport had been deeply in debt, losing $560 million in interest every year. Airlines had been kept away by high landing fees (about $7,500 for a Boeing 747), the second most expensive in the world after Narita's. In the early years of the airport's operation, excessive terminal rent and utility bills for on-site concessions also drove up operating costs: some estimates before opening held that a cup of coffee would have to cost US$10.[16] Osaka business owners pressed the government to take a greater burden of the construction cost to keep the airport attractive to passengers and airlines.[17] Nowadays, after deep discounts, the number of flights are increasing. On 17 February 2005, Chubu Centrair International Airport opened in Nagoya, just east of Osaka. The opening of the airport was expected to increase competition between Japan's international airports. Despite this, passenger totals were up 11% in 2005 over 2004, and international passengers increased to 3.06 million in 2006, up 10% over 2005. Adding to the competition was the opening of Kobe Airport, less than 25 km (16 mi) away, in 2006 and the lengthening of the runway at Tokushima Airport in Shikoku in 2007. The main rationale behind the expansions is to compete with Incheon International Airport and Hong Kong International Airport as a gateway to Asia, as Tokyo area airports are severely congested. However, with the regional trend in open skies agreements being signed, it is possible that all airports can see increases in traffic. Kansai has been marketed as an alternative to Narita Airport for international travellers from the Greater Tokyo Area. By flying to Kansai from Haneda Airport and connecting to international flights there, travellers can save the additional time required to get to Narita: up to one and a half hours for many residents of Kanagawa Prefecture and southern Tokyo. Due to the time-limited nature of Haneda's new long-haul international slots this will remain a viable option for daytime travelers.

[edit] Expansion

Second phase of Kansai International Airport under construction The airport was at its limit during peak times, owing especially to freight flights, so a portion of Phase II expansionthe second runwaywas made a priority.[18] Thus, in 2003, believing that the sinking problem was almost over, the airport operators started to construct a 4,000 m (13,000 ft) second runway and terminal. The second runway opened on 2 August 2007, but without the originally planned terminal portion, now postponed to a later date. This lowered the project cost to JPY910 billion (approx. US$8 billion), saving 650 billion from the first estimate.[19] The additional runway development, which was opened in time for the IAAF world athletics championships in Osaka, has expanded the airport size to 10.5 km2 (4.1 sq mi). Further into the future, the airport is planning to construct a new terminal building, several aprons, a third runway (06C/24C) with a length of 3,500 m (11,483 ft), a new cargo terminal and expanding the airport size to 13 km2 (5.0 sq mi). However, the Japanese Government is postponing these plans for economic reasons. The new runway is only used for landings unless there are incidents prohibiting take off use of runway A. The airport now expects to handle 129,000 flights during the year 2007, an increase of 11% compared to 2006 figures of 116,475 flights. The new runway allowed the airport to start 24 hour operations in September 2007.[20][21]

[edit] Relationship with Itami Airport

Since July 2008, Osaka Prefecture governor Toru Hashimoto has been a vocal critic of Itami Airport, arguing that the Chuo Shinkansen maglev line will make much of its domestic role irrelevant, and that its domestic functions should be transferred to Kansai Airport in conjunction with upgraded high-speed access to Kansai from central Osaka.[22] In 2009, Hashimoto also publicly proposed moving the functions of Marine Corps Air Station Futenma to Kansai Airport as a possible solution for the political crisis surrounding the base.[23] In May 2011, the Diet of Japan passed legislation to form a new Kansai International Airport Corporation using the state's existing equity stake in Kansai Airport and its property holdings at Itami Airport. The move was aimed at offsetting Kansai Airport's debt burden.[24]

[edit] Terminal

The ground level of the terminal looking north from the center The KIX passenger terminal is a single four-storey building designed by Renzo Piano Building Workshop (Renzo Piano and Noriaki Okabe) and has a gross floor space of 296,043 square metres (3,186,580 sq ft). It was once the longest airport terminal in the world, at a total length of 1.7 km (1.1 mi) from end to end. It has a sophisticated people mover system called the Wing Shuttle, which moves passengers from one end of the pier to the other. The terminal's roof is shaped like an airfoil. This shape is used to promote air circulation through the building: giant air conditioning ducts blow air upwards at one side of the terminal, circulate the air across the curvature of the ceiling, and collect the air through intakes at the other side. Mobiles are suspended in the ticketing hall to take advantage of the flowing air. The ticketing hall overlooks the international departures concourse, and the two are separated by a glass partition. During Kansai's early days, visitors were known to throw objects over the partition to friends in the corridor below. The partition was eventually modified to halt this practice.

ASK THE EXPERT Do you have a question About your home seawall needs? Ask The Expert Here! Name Email Phone Question

* *

Check here for a FREE ESTIMATE.

Testimonials . . . You have the quickest turn around time in the Industry. Morehead City, NC Marine Contractor

Seawall Construction

Seawall construction is growing quickly as a popular way to improve residential and commercial properties that are bordered by water. We are finding that many property owners are seeing the advantages to having seawall construction done in order to protect the environment and their own property. As environmental awareness grows around the world, one of the primary concerns is the erosion of land. As sea levels rise, coastal erosion increases. People are more aware of this now on a social consciousness level as we become more educated about the interaction of land and water on our planet. However, coastal homeowners are particularly aware of the effects of erosion, because it has a very direct effect on the value of their real estate. This is where seawall construction can be a very sound investment.

There are a couple of primary reasons why a homeowner will hire a contractor for seawall construction:

The prevention of land erosion If a property includes land that is bordered by water (whether ocean, gulf or lake), its in everyones best interest to keep that border exactly where it is. However, water doesnt always move with our best interest in mind. There is a tendency for the water to push back against the land, and over time there is more water and less land. This is seen more prominently in property that borders the ocean, due to the constant tidal movement. However, land that lies next to any large body of water can experience this, particularly after some inclement weather causes a storm surge. Seawall construction puts a barrier in front of the land, so the movement of the water has virtually no effect. The prevention of flooding In addition to the gradual erosion of land, water can cause a much more urgent and damaging situation: flooding. After an extended period of rain, water levels can sometimes reach heights that are not commonly seen. Since these water levels are not experienced regularly, the tendency is to not be fully prepared when it happens. If the water gets higher than the land, there is obviously nothing left to stop it from coming into your home.

Of course, the further away your house is from the waterline, the less likely you are to have a problem. But if the water surges sufficiently, there is really nothing to stop it from entering your home and causing untold damage. Those homes that have seawall construction can hold out much longer before coming into contact with water, and are therefore much less likely to experience any damage. If the water does come in because of extraordinarily high sea levels, the damage can at least be minimized by providing the homeowner extra time to prepare.

Portland limestone was used for groyne construction, brought to site by road. Each rock for the head section of groyne weighs three to six tonnes, and for the section from the head back to the promenade one to three tonnes. At the beach, sand is first excavated from the area where the groyne will be located. The area is then backfilled with a bedding layer of stone to prevent subsidence of the groyne structure. Using this method of construction the groyne is extended seawards with bedding material and rock, building up to a level that will permit plant to run on it. As construction progresses to full groyne length manhole rings are used to create voids to take the piles for the walkway that allow public access to the groyne. Walkways are independent structures consisting of concrete beams spanning piles driven along the length of the groyne. Walkway sections and pile caps are made at the beach from reinforced precast concrete and lifted into

position.

Construction proceeds with the head of the groyne being built to its full height. Piles are then driven into position through the voids by a vibrating rig (and air hammer if required). Working shoreward pile heads and walkway sections are put into position at the same time as rock is built up to the finished level. The whole operation is then able to retreat off the groyne leaving a near completed structure; just the in situ joints and infill between the walkways and pile heads are completed later. Access ramps are situated between the back of the groynes and the promenade, made from concrete poured in-situ and tied back into the existing stepped sea wall. First the wall sections of the ramps are poured, then the ramp is filled with beach sand and the slab section is cast on top. Groyne construction methods have changed little since groynes were first built at Sandbanks in 1996 and again in 2001 (photos above are from those previous projects).

20.3.2012 Wharf Cari wharf type of wharf Ada closed, open type

Jetty or Pier Dan kadang kadang breakwater tu pun boleh dibuat Jetty jugak Steel tubular pile n concrete deck jetty Fenders Benda tepi Jetty yang macam tayar tu, tahan kapal hentam jetty bila ombak beralun Port Structures Dolphin Liquid bulk berth Breasting dolphins Mooring dolphins Loading dolphins Interconnecting walkways Approach trestles Bila melibat kan kerja marine, of kos jadik expensive Berthing Senarios 1. 2. 3. 4. Dolphin berthing Ship to ship berthing End berthing Passing lock entrance

A dolphin as a man made structures that extends above the water and is not connected to shore. Kedalaman dolphin punya piling boleh hingga 101m depth Buat dolphin ni jeh 40 juta

Structure Components 1. 2. 3. 4. 5. Piles Bulkheads Pile Caps Decks Fenders a. Ada timber, rubber b. Kena sesuai dengan saiz kapalLukis bentuk fenders around the world c. 6. Mooring Fitting ikat kapal jangan Lari a. Terdiri daripada Bollard b. Cleats c. Quick release hooks d.

Das könnte Ihnen auch gefallen

- Designing Airport Terminals to Optimize Passenger FlowDokument16 SeitenDesigning Airport Terminals to Optimize Passenger FlowSherelyn RoblesNoch keine Bewertungen

- Presentation1 of IRIDokument29 SeitenPresentation1 of IRIJohn Eric OliverNoch keine Bewertungen

- Noi Bai International Airport Terminal 2 ConstructionDokument2 SeitenNoi Bai International Airport Terminal 2 ConstructionManh TuNoch keine Bewertungen

- Dynatest-RSP III PDFDokument14 SeitenDynatest-RSP III PDFPurshottam SharmaNoch keine Bewertungen

- The HKIE Structural Examination - Written Examination 2018: Section 2: Design QuestionsDokument27 SeitenThe HKIE Structural Examination - Written Examination 2018: Section 2: Design Questionsdexterbox1Noch keine Bewertungen

- Construction Contract Administration Manual (CAH)Dokument232 SeitenConstruction Contract Administration Manual (CAH)waqas aliNoch keine Bewertungen

- Airport Engineering 3 TaxiwayDokument17 SeitenAirport Engineering 3 Taxiwayraghav VarmaNoch keine Bewertungen

- Design Fabrication of A Hover Craft - MpashaDokument10 SeitenDesign Fabrication of A Hover Craft - MpashapothirajkalyanNoch keine Bewertungen

- D 6140 - 00 - RdyxndaDokument3 SeitenD 6140 - 00 - RdyxndaCasey RybackNoch keine Bewertungen

- BPM Aris Part2Dokument34 SeitenBPM Aris Part2smallik3Noch keine Bewertungen

- FinalReport 05 08Dokument253 SeitenFinalReport 05 08Share the Knowledge100% (2)

- Transportation Planning and Engineering: Airport Master Plan, and Airport FinancingDokument28 SeitenTransportation Planning and Engineering: Airport Master Plan, and Airport FinancingFortiter FysproNoch keine Bewertungen

- Designing For Vehicles PDFDokument3 SeitenDesigning For Vehicles PDFNerinel CoronadoNoch keine Bewertungen

- Valmex FR 700Dokument11 SeitenValmex FR 700sealion72Noch keine Bewertungen

- A Chip Seal (Also Called A "Seal Coat") Is Essentially A Single Layer of Asphalt Binder That IsDokument24 SeitenA Chip Seal (Also Called A "Seal Coat") Is Essentially A Single Layer of Asphalt Binder That IsHalmat GharibNoch keine Bewertungen

- Lagos State Ministry of Waterfront Infrastructure DevelopmentDokument12 SeitenLagos State Ministry of Waterfront Infrastructure DevelopmentDenis AkingbasoNoch keine Bewertungen

- Runway OrientationDokument24 SeitenRunway OrientationAbdulkareem Adeyinka100% (2)

- Concrete0709 PDFDokument144 SeitenConcrete0709 PDFlu190765Noch keine Bewertungen

- Triax TX 160Dokument2 SeitenTriax TX 160Ion MateiNoch keine Bewertungen

- Chapter 8. Analysis of Slope Stability: AssignmentDokument9 SeitenChapter 8. Analysis of Slope Stability: AssignmentDuyAnhThảoNoch keine Bewertungen

- Curriculum PMLDokument67 SeitenCurriculum PMLisele1977Noch keine Bewertungen

- Slip resistance floor tilesDokument6 SeitenSlip resistance floor tilesspzemunNoch keine Bewertungen

- Pavement Classification NumberDokument14 SeitenPavement Classification NumberShane VinceNoch keine Bewertungen

- Masterplan Greenfield Airport at Mopa, North GoaDokument105 SeitenMasterplan Greenfield Airport at Mopa, North GoaSunil SagarNoch keine Bewertungen

- Airport EnggDokument14 SeitenAirport EnggSF QuadriNoch keine Bewertungen

- Aerofoil TerminologyDokument66 SeitenAerofoil TerminologyafdsfagadgNoch keine Bewertungen

- Al-Maktoum Airport ProjectDokument18 SeitenAl-Maktoum Airport ProjectFajr MirNoch keine Bewertungen

- Narita International Airport Report 2012-2013Dokument40 SeitenNarita International Airport Report 2012-2013hondacrv22100% (1)

- High Expansion and Fire Suppression System For Hangar: by PT. Pratama Megah Indonesia InternasionalDokument12 SeitenHigh Expansion and Fire Suppression System For Hangar: by PT. Pratama Megah Indonesia InternasionalBagus PrambudiNoch keine Bewertungen

- Airport DrainageDokument68 SeitenAirport DrainageAngelo Ros100% (1)

- Factors in Heliport SelectionDokument10 SeitenFactors in Heliport SelectionAdrian AnzanoNoch keine Bewertungen

- General Presentation 2Dokument33 SeitenGeneral Presentation 2María Paula DávilaNoch keine Bewertungen

- Chapter 18 - Pavement DesignDokument18 SeitenChapter 18 - Pavement DesignDiyoke HenryNoch keine Bewertungen

- Beach StabilizationDokument44 SeitenBeach StabilizationAbinya AlfatihNoch keine Bewertungen

- Faarfield IntroDokument11 SeitenFaarfield IntroTim LinNoch keine Bewertungen

- The Integration of Value and Risk Management Ininfrastructure ProjectsDokument14 SeitenThe Integration of Value and Risk Management Ininfrastructure ProjectsShonette ThomasNoch keine Bewertungen

- Airport DesignDokument6 SeitenAirport DesignDIBYENDU MONDALNoch keine Bewertungen

- Airports PDFDokument114 SeitenAirports PDFJaelani Abdul KNoch keine Bewertungen

- Techbro Wa LRDokument44 SeitenTechbro Wa LRy2kareinNoch keine Bewertungen

- NDECIDokument6 SeitenNDECIRishaalRamNoch keine Bewertungen

- Chapter 8 AIR POLLUTION PDFDokument20 SeitenChapter 8 AIR POLLUTION PDFMy SelfNoch keine Bewertungen

- E-4-2 Traffic Appraisal Manual, Chapter 13Dokument26 SeitenE-4-2 Traffic Appraisal Manual, Chapter 13sareenpriya100% (1)

- Emasmax Brochure EngDokument3 SeitenEmasmax Brochure EngflotterotterNoch keine Bewertungen

- Policy on Airport Infrastructure DevelopmentDokument11 SeitenPolicy on Airport Infrastructure DevelopmentRaja174100% (1)

- GE July 1976 Foundations and Earthworks For Cylindrical Steel Storage TanksDokument113 SeitenGE July 1976 Foundations and Earthworks For Cylindrical Steel Storage Tanksselvakumar100% (1)

- CANRM HeliportsDokument85 SeitenCANRM HeliportsJayant LakhlaniNoch keine Bewertungen

- CEASIOM XML File StructureDokument29 SeitenCEASIOM XML File Structuresharath_87Noch keine Bewertungen

- MNL 67-2009 PDFDokument128 SeitenMNL 67-2009 PDFlolo100% (2)

- Report Site VisitDokument4 SeitenReport Site VisitFaiz SalimNoch keine Bewertungen

- Signage Design Guide Rev K Oct2012Dokument29 SeitenSignage Design Guide Rev K Oct2012Septa CartoonNoch keine Bewertungen

- Importance of Grid Maps for FirefightersDokument20 SeitenImportance of Grid Maps for FirefightersMd Arifur RahmanNoch keine Bewertungen

- BS 6349 Part 4 2014Dokument54 SeitenBS 6349 Part 4 2014vojtaNoch keine Bewertungen

- Section 14520 - Baggage Handling SystemsDokument7 SeitenSection 14520 - Baggage Handling SystemsHaryo WidodoNoch keine Bewertungen

- Is SP 27 1987 - 0 PDFDokument130 SeitenIs SP 27 1987 - 0 PDFluckyyermalNoch keine Bewertungen

- Sanu SeminarDokument22 SeitenSanu SeminarDeekshith ANNoch keine Bewertungen

- The Hong Kong Airport Core ProgramDokument15 SeitenThe Hong Kong Airport Core Programlenil27Noch keine Bewertungen

- Technological Institute of The Philippines: 938 Aurora Boulevard, Cubao, Quezon CityDokument3 SeitenTechnological Institute of The Philippines: 938 Aurora Boulevard, Cubao, Quezon CityMichael AbeledaNoch keine Bewertungen

- Chek Lap KokDokument13 SeitenChek Lap KokRishabh MalikNoch keine Bewertungen

- Kansai International Airport Case Study FoundationDokument17 SeitenKansai International Airport Case Study FoundationPriscila QuintelaNoch keine Bewertungen

- ScriptDokument4 SeitenScriptIzzuddin ShahidanNoch keine Bewertungen

- ScriptDokument4 SeitenScriptIzzuddin ShahidanNoch keine Bewertungen

- RujukanDokument1 SeiteRujukanIzzuddin ShahidanNoch keine Bewertungen

- SHORINGDokument10 SeitenSHORINGIzzuddin ShahidanNoch keine Bewertungen

- Civil Unrest in Eswatini. Commission On Human Rights 2021Dokument15 SeitenCivil Unrest in Eswatini. Commission On Human Rights 2021Richard RooneyNoch keine Bewertungen

- Arvind Goyal Final ProjectDokument78 SeitenArvind Goyal Final ProjectSingh GurpreetNoch keine Bewertungen

- The Books of The Bible-ModuleDokument38 SeitenThe Books of The Bible-Modulejillene catapang67% (3)

- March 3, 2014Dokument10 SeitenMarch 3, 2014The Delphos HeraldNoch keine Bewertungen

- MSA BeijingSyllabus For Whitman DizDokument6 SeitenMSA BeijingSyllabus For Whitman DizcbuhksmkNoch keine Bewertungen

- Symptomatic-Asymptomatic - MedlinePlus Medical EncyclopediaDokument4 SeitenSymptomatic-Asymptomatic - MedlinePlus Medical EncyclopediaNISAR_786Noch keine Bewertungen

- ALM & Liquidity RiskDokument11 SeitenALM & Liquidity RiskPallav PradhanNoch keine Bewertungen

- PinoyInvestor Academy - Technical Analysis Part 3Dokument18 SeitenPinoyInvestor Academy - Technical Analysis Part 3Art JamesNoch keine Bewertungen

- MC71206A Practices of The Culture IndustryDokument24 SeitenMC71206A Practices of The Culture IndustrykxNoch keine Bewertungen

- UCSP Exam Covers Key ConceptsDokument2 SeitenUCSP Exam Covers Key Conceptspearlyn guelaNoch keine Bewertungen

- Cease and Desist DemandDokument2 SeitenCease and Desist DemandJeffrey Lu100% (1)

- Land Land Patent - Declaration (19291)Dokument2 SeitenLand Land Patent - Declaration (19291)Seasoned_Sol100% (2)

- Accounting Time Allowed - 2 Hours Total Marks - 100: You Are Required To Calculate TheDokument3 SeitenAccounting Time Allowed - 2 Hours Total Marks - 100: You Are Required To Calculate TheNew IdNoch keine Bewertungen

- Demographic and Clinical Pattern of Uveitis in Tertiary Eye Care Institute of Central IndiaDokument7 SeitenDemographic and Clinical Pattern of Uveitis in Tertiary Eye Care Institute of Central Indiajassi nishadNoch keine Bewertungen

- ROCKS Air-to-Surface Missile Overcomes GPS Jamming in 38 CharactersDokument2 SeitenROCKS Air-to-Surface Missile Overcomes GPS Jamming in 38 CharactersDaniel MadridNoch keine Bewertungen

- Different Western Classical Plays and Opera (Report)Dokument26 SeitenDifferent Western Classical Plays and Opera (Report)Chaorrymarie TeañoNoch keine Bewertungen

- Final Project Taxation Law IDokument28 SeitenFinal Project Taxation Law IKhushil ShahNoch keine Bewertungen

- United States Court of Appeals, Fourth CircuitDokument22 SeitenUnited States Court of Appeals, Fourth CircuitScribd Government DocsNoch keine Bewertungen

- RoughGuide之雅典Dokument201 SeitenRoughGuide之雅典api-3740293Noch keine Bewertungen

- Factors Affecting Exclusive BreastfeedingDokument7 SeitenFactors Affecting Exclusive BreastfeedingPuput Dwi PuspitasariNoch keine Bewertungen

- CH08 Location StrategyDokument45 SeitenCH08 Location StrategyfatinS100% (5)

- Approvalsand Notificationsfor Authorisersand RequisitionersDokument15 SeitenApprovalsand Notificationsfor Authorisersand RequisitionersSharif AshaNoch keine Bewertungen

- Gross Estate PDFDokument20 SeitenGross Estate PDFSweet EmmeNoch keine Bewertungen

- STP Analysis of ICICI BANK vs SBI for Savings AccountsDokument28 SeitenSTP Analysis of ICICI BANK vs SBI for Savings AccountsUmang Jain0% (1)

- Human Rights Violations in North KoreaDokument340 SeitenHuman Rights Violations in North KoreaKorea Pscore100% (3)

- Civil Air Patrol News - Mar 2007Dokument60 SeitenCivil Air Patrol News - Mar 2007CAP History LibraryNoch keine Bewertungen

- KATU Investigates: Shelter Operation Costs in OregonDokument1 SeiteKATU Investigates: Shelter Operation Costs in OregoncgiardinelliNoch keine Bewertungen

- Syntel Placement Paper 2 - Freshers ChoiceDokument3 SeitenSyntel Placement Paper 2 - Freshers ChoicefresherschoiceNoch keine Bewertungen

- English Final Suggestion - HSC - 2013Dokument8 SeitenEnglish Final Suggestion - HSC - 2013Jaman Palash (MSP)Noch keine Bewertungen

- 55850bos45243cp2 PDFDokument58 Seiten55850bos45243cp2 PDFHarshal JainNoch keine Bewertungen