Beruflich Dokumente

Kultur Dokumente

Fire Water Network Document

Hochgeladen von

Joydip MisraOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fire Water Network Document

Hochgeladen von

Joydip MisraCopyright:

Verfügbare Formate

Important points of Fire water Network Drg

Criteria for above / underground network 1. The fire water network piping should normally be laid above ground at a height of 300 to 400 mm above finished ground level. However, the fire water network piping shall be laid below ground level at the following places. i) Road crossings ii) Places where the above ground piping is likely to cause obstruction to operation and vehicle movement, and get damaged mechanically.

Protection for underground pipelines The main shall have at least one meter earth cushion in open ground and 1.5 mtrs earth cushion under the roads. In case of crane movement areas, pipes may be protected with concrete/steel encasement. ii) The mains shall be provided with protection against soil corrosion by suitable coating/wrapping. iii) In case of poor soil conditions it is recommended that concrete/ masonary supports be provided under the pipe. Protection for above ground pipelines 1. The fire water mains shall be laid on independent sleepers by the side of road. These shall not be laid along with process piping on common sleepers. 2. The mains shall be supported at regular intervals not exceeding 6 mtrs. Layout i) Fire water mains shall not pass through buildings or dyked areas. ii) Hydrants / monitors shall not be located inside the dyke area. Fire hydrants The maximum distance between two hydrants, however, shall not exceed 30 mtrs around hydrocarbon storage and hazardous areas and 45 mtrs in other areas. Each hydrant shall have two outlets inclined towards the ground. The outlets shall be of female instantaneous type having a standard size of 63.5 mm conforming to Indian Standards. Hydrants 1. At least one hydrant post shall be provided for every 30 mtrs of external wall measurement or perimeter of unit battery limit in case of high hazard areas. Hydrants protecting utilities and miscellaneous buildings in high hazard areas may be spaced at 45 mtrs intervals. 2. The hydrants shall be located at a minimum distance of 15 mtrs from the periphery of storage tank or hazardous equipment under protection. For process plants location of hydrants shall be decided based on coverage of all areas. In the case of buildings, this distance shall not be less than 5 mtrs and more than 15 mtrs from the face of building. Provision of hydrants within buildings shall be in accordance with Standard IS Standard 3844. Hydrants/Monitors shall be located along road side berms for easy accessibility. 3. Double headed hydrants with two separate landing valves on 4" stand post shall be used. All hydrant outlets shall be situated at a workable height of about 1.2 mtrs above ground level. 4. Hydrants / Monitors shall be preferably located with branch connections and not directly over main header for easy accessibility. Monitors 1. The monitors should not be installed less than 15 mtrs from hazardous equipment. 2. The location of water monitors shall not exceed 45 mtrs. from the hazard to be protected. Hydrants and monitors shall not be installed inside the dyked areas. MATERIAL SPECIFICATIONS 1. Pipes: Carbon Steel as per IS: 3589/ IS:1239 or its equivalent.

2. The use of Cl pipes is not recommended for fire water service within installations. Use of Cast Steel valves is preferable in offsite areas also. However, it may be decided on economic considerations for each case. Isolation valves having open/close indication shall be Gate valves, however, for 12" & above sizes, Butterfly valves should be used. 3. Hydrant: Stand post: Carbon Steel Outlet valves/ .. Gunmetal / Aluminium / landing valves Stainless Steel / AIZn 4. Monitors : Carbon Steel/ Gun Metal 5. Fire Hose IS 636: Reinforced rubber lined of Type A or Synthetic hose of Type B 6. In case of underground mains the isolation valves shall be located in RCC/brick masonry chamber. 7. The above ground fire water mains and the fire hydrant stand post shall be painted with corrosion resistant "Fire Red" paint

Das könnte Ihnen auch gefallen

- Building Risk AssessmentDokument6 SeitenBuilding Risk AssessmentSubhradip BhattacharjeeNoch keine Bewertungen

- Spray - Chapter 2 - Deluge SystemsDokument48 SeitenSpray - Chapter 2 - Deluge SystemsMilanNoch keine Bewertungen

- 01 - Fire Concept & Fire ScenarioDokument30 Seiten01 - Fire Concept & Fire ScenarioAnnisaNoch keine Bewertungen

- Fire Zone Analysis A Brief GuideDokument2 SeitenFire Zone Analysis A Brief GuideRicardo Bec100% (1)

- ANNEXURE For HVW SPRAY SYSTEM - StandardDokument1 SeiteANNEXURE For HVW SPRAY SYSTEM - StandardVaibhav SawantNoch keine Bewertungen

- Fire Protection Philosophy (D 15)Dokument16 SeitenFire Protection Philosophy (D 15)Elias EliasNoch keine Bewertungen

- Fire Water Demand BasisDokument2 SeitenFire Water Demand BasisEmamokeNoch keine Bewertungen

- ENTS 400 NewDokument62 SeitenENTS 400 Newmohammadimranshah0% (1)

- 2016-S-RPT-000-0001 Rev 1 Fire and Explosion Report 06-12-2012Dokument21 Seiten2016-S-RPT-000-0001 Rev 1 Fire and Explosion Report 06-12-2012Basil OguakaNoch keine Bewertungen

- QCDFSS-7.2 - Car Park VentilationDokument3 SeitenQCDFSS-7.2 - Car Park VentilationReinhart85Noch keine Bewertungen

- Pages From Research Report Dispersion Modelling and Calculation in Support of EI MCoSP Part 15 Mar 2008Dokument11 SeitenPages From Research Report Dispersion Modelling and Calculation in Support of EI MCoSP Part 15 Mar 2008Blake White0% (2)

- D6.5 HAZOP Report PDFDokument83 SeitenD6.5 HAZOP Report PDFTaarani AmbigavathyNoch keine Bewertungen

- 002 Fire&Life Safet ReportDokument42 Seiten002 Fire&Life Safet ReportRagul0042Noch keine Bewertungen

- Fire Protection (Water Based Systems) Basics & DesignDokument18 SeitenFire Protection (Water Based Systems) Basics & DesignHaiderAliJuttNoch keine Bewertungen

- Spray - Chapter 4 - Advanced TopicsDokument73 SeitenSpray - Chapter 4 - Advanced TopicsEslam ShiblNoch keine Bewertungen

- PhastDokument2 SeitenPhastXiruo WangNoch keine Bewertungen

- Comments Resolution SheetDokument16 SeitenComments Resolution SheetPurushothaman SeenuNoch keine Bewertungen

- NPF-FGCRT-060001Rev0 Fire Protection Design CriteriaDokument20 SeitenNPF-FGCRT-060001Rev0 Fire Protection Design CriteriainnovativekarthiNoch keine Bewertungen

- NMMC DCR SummaryDokument33 SeitenNMMC DCR SummaryRoyal JadhavNoch keine Bewertungen

- Spray - Chapter 2 - Deluge SystemsDokument48 SeitenSpray - Chapter 2 - Deluge SystemsNitesh KirnakeNoch keine Bewertungen

- Foam Concentrates Application Rate and Their FlowDokument6 SeitenFoam Concentrates Application Rate and Their FlowInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- MHDP-08-R-01 YDH BRA Full Report Issue 6.0 PDFDokument159 SeitenMHDP-08-R-01 YDH BRA Full Report Issue 6.0 PDFbillNoch keine Bewertungen

- Cqs Epr Ts Gen PHL 001 Rev 3.0Dokument25 SeitenCqs Epr Ts Gen PHL 001 Rev 3.0Atty AttyNoch keine Bewertungen

- Appendix 13P.2-Firewater EquipmentDokument22 SeitenAppendix 13P.2-Firewater EquipmentdidoniphicNoch keine Bewertungen

- Gap Analysis of Kandla Site With Respect To Fire Protection and Control Document Number 0101Dokument13 SeitenGap Analysis of Kandla Site With Respect To Fire Protection and Control Document Number 0101kirandevi1981Noch keine Bewertungen

- The Art of Tank GaugingDokument26 SeitenThe Art of Tank Gaugingnixsol75Noch keine Bewertungen

- Gas Fire Installation and MaintDokument29 SeitenGas Fire Installation and Maintwally_watkins4061Noch keine Bewertungen

- Project Work Estimation: Mumbai Office: C-62/204, Sector-9, Shantinagar, Miraroad (East), Thane-401107, Maharashtra, IndiaDokument6 SeitenProject Work Estimation: Mumbai Office: C-62/204, Sector-9, Shantinagar, Miraroad (East), Thane-401107, Maharashtra, IndiaAmul AmnajeNoch keine Bewertungen

- Gas Installation PDFDokument31 SeitenGas Installation PDFNelson VargasNoch keine Bewertungen

- Building Siting StudyDokument12 SeitenBuilding Siting Studyminah22Noch keine Bewertungen

- Fire Services System Training MaterialDokument46 SeitenFire Services System Training Materialmark pangNoch keine Bewertungen

- Fire Flow by ISODokument38 SeitenFire Flow by ISOFarraz Sarmento Salim100% (1)

- QRA Scope of WorkDokument3 SeitenQRA Scope of Workvarunkumar415100% (1)

- Fire Protection System For Large Chem Storage - Mohammed Al MujainiDokument22 SeitenFire Protection System For Large Chem Storage - Mohammed Al MujainiVeera ManiNoch keine Bewertungen

- Oil and Chemical Plant Layout and Spacing PDFDokument13 SeitenOil and Chemical Plant Layout and Spacing PDFtiffanyyy00Noch keine Bewertungen

- Section 5 - LPG266 - 154562Dokument11 SeitenSection 5 - LPG266 - 154562handoyo_eko20017573Noch keine Bewertungen

- NFPA Codes and Their Relevance To Chemical Processes: Jonathan Eisenberg, P.E. Jeremy LebowitzDokument29 SeitenNFPA Codes and Their Relevance To Chemical Processes: Jonathan Eisenberg, P.E. Jeremy LebowitzEko PoerwantoNoch keine Bewertungen

- Hazardous Area ClassificationDokument7 SeitenHazardous Area Classificationhassenova.kNoch keine Bewertungen

- FW Jetfoil Fan BrochureDokument9 SeitenFW Jetfoil Fan BrochuremajortayNoch keine Bewertungen

- Fire Safety Guidelines For Open Plant Structures in Oil Chemical and Process IndustriesDokument50 SeitenFire Safety Guidelines For Open Plant Structures in Oil Chemical and Process IndustriesMosaddekNoch keine Bewertungen

- Firewater OnshoreDokument10 SeitenFirewater OnshoresegunoyesNoch keine Bewertungen

- Fire & Gas Design BasisDokument2 SeitenFire & Gas Design BasisAdil MominNoch keine Bewertungen

- Pipenet Vision Training Manual Spray: Chapter 4 Page 1 of 62 REVISION 2.1, SEP 2010Dokument62 SeitenPipenet Vision Training Manual Spray: Chapter 4 Page 1 of 62 REVISION 2.1, SEP 2010ToyinNoch keine Bewertungen

- Piping Design 5 PDFDokument9 SeitenPiping Design 5 PDFSandra MArrugo100% (1)

- Flaresim PDFDokument448 SeitenFlaresim PDFAnonymous exuebXBKXX71% (7)

- MhdpIssue 6.1Dokument137 SeitenMhdpIssue 6.1billNoch keine Bewertungen

- Spray - Chapter 3 - Ringmain SystemsDokument66 SeitenSpray - Chapter 3 - Ringmain SystemsEslam Shibl100% (1)

- Dispersion ModellingDokument4 SeitenDispersion ModellingSigma HSENoch keine Bewertungen

- Siemens - Provent Return For Tank Farm and TerminalDokument24 SeitenSiemens - Provent Return For Tank Farm and TerminalapisituNoch keine Bewertungen

- Fire System - Maaz AhmedDokument11 SeitenFire System - Maaz AhmedMiniYumNoch keine Bewertungen

- Al Rashid Mall Mu 15504 0317 GBDokument2 SeitenAl Rashid Mall Mu 15504 0317 GBmahmadwasiNoch keine Bewertungen

- CSSP RubayaDokument148 SeitenCSSP RubayaChaudhary Wasim MurtazaNoch keine Bewertungen

- IEA-GLE Workshop: LNG Safety IssuesDokument5 SeitenIEA-GLE Workshop: LNG Safety IssuesrarelimNoch keine Bewertungen

- 3 Codified Requirements For MORE THAN 2 LPG CYLINDERDokument5 Seiten3 Codified Requirements For MORE THAN 2 LPG CYLINDERMrigank AggarwalNoch keine Bewertungen

- Plot Plan & LayoutDokument32 SeitenPlot Plan & LayoutShahfaraz AhmadNoch keine Bewertungen

- Inspection of The SystemsDokument12 SeitenInspection of The SystemsTulen CabuldinNoch keine Bewertungen

- Fire Hydrant in ST Alation ManualDokument13 SeitenFire Hydrant in ST Alation ManualMohammad ElhedabyNoch keine Bewertungen

- LPG StorageDokument2 SeitenLPG StoragejsumillanoNoch keine Bewertungen

- Fire Protection in MalaysiaDokument37 SeitenFire Protection in MalaysiaCastiel Arumugam50% (2)

- Liquefied Petroleum Gas (LPG)Dokument11 SeitenLiquefied Petroleum Gas (LPG)Aditi GuptaNoch keine Bewertungen

- Api 32Dokument2 SeitenApi 32Joydip Misra100% (1)

- Pump KW CalculationDokument3 SeitenPump KW CalculationJoydip Misra100% (1)

- Hyper DisaterDokument22 SeitenHyper DisaterJoydip MisraNoch keine Bewertungen

- API 676 Datasheet 5Dokument2 SeitenAPI 676 Datasheet 5Joydip MisraNoch keine Bewertungen

- Jar TestingDokument4 SeitenJar TestingSugumar Panneer SelvamNoch keine Bewertungen

- K Value of FittingsDokument4 SeitenK Value of FittingsJoydip Misra100% (6)

- Delhi Metro Route MapDokument1 SeiteDelhi Metro Route Mapnakulyadav7Noch keine Bewertungen

- 10th Aug. 2011 Structural Calculation (For Sub.) - 03Dokument29 Seiten10th Aug. 2011 Structural Calculation (For Sub.) - 03Nguyễn Tiến Việt100% (1)

- Electrical Design Project (Three Bedroom House)Dokument13 SeitenElectrical Design Project (Three Bedroom House)Sufi Shah Hamid Jalali100% (2)

- ST 36Dokument4 SeitenST 36ray72roNoch keine Bewertungen

- Resumen C37 010 Aplicacion de Breaker Disenados IC Simetrica PDFDokument9 SeitenResumen C37 010 Aplicacion de Breaker Disenados IC Simetrica PDFglendathais100% (1)

- Complete Processing Lines For Extruded Pet FoodDokument13 SeitenComplete Processing Lines For Extruded Pet FoodденисNoch keine Bewertungen

- Siemens Internship ReportDokument84 SeitenSiemens Internship Reportujjawalbhojawala100% (1)

- Of The Month Is Live. 100+ Subjects. Participate Now!: Sanfoundry Certification ContestDokument4 SeitenOf The Month Is Live. 100+ Subjects. Participate Now!: Sanfoundry Certification ContestBaydaa QaidyNoch keine Bewertungen

- ODA X9 2SL DatasheetDokument8 SeitenODA X9 2SL DatasheetYudy UtamaNoch keine Bewertungen

- Project Title Discipline Project Stage Client Attendance CirculationDokument4 SeitenProject Title Discipline Project Stage Client Attendance CirculationgregNoch keine Bewertungen

- Unit 2 - Presentations (Image, Impact and Making An Impression) 2Dokument25 SeitenUnit 2 - Presentations (Image, Impact and Making An Impression) 2LK Chiarra Panaligan100% (1)

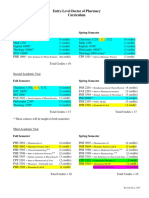

- Pharmd CurriculumDokument18 SeitenPharmd Curriculum5377773Noch keine Bewertungen

- Exp6.Single Phase Bridge Inverter Using PWMDokument6 SeitenExp6.Single Phase Bridge Inverter Using PWMAbdullah MohammedNoch keine Bewertungen

- Salem RPGDokument16 SeitenSalem RPGabstockingNoch keine Bewertungen

- Final TestDokument10 SeitenFinal TestbennyNoch keine Bewertungen

- The Unofficial Aterlife GuideDokument33 SeitenThe Unofficial Aterlife GuideIsrael Teixeira de AndradeNoch keine Bewertungen

- #Dr. Lora Ecg PDFDokument53 Seiten#Dr. Lora Ecg PDFمحمد زينNoch keine Bewertungen

- Properties of Matter ReviewDokument8 SeitenProperties of Matter Reviewapi-290100812Noch keine Bewertungen

- (G. Lakshmi Narasaiah) Finite Element Analysis PDFDokument349 Seiten(G. Lakshmi Narasaiah) Finite Element Analysis PDFmoljaime1326Noch keine Bewertungen

- How To Eat WellDokument68 SeitenHow To Eat WelleledidiNoch keine Bewertungen

- Abdominal Examination OSCE GuideDokument30 SeitenAbdominal Examination OSCE Guideزياد سعيدNoch keine Bewertungen

- Kwasaki ZX10R 16Dokument101 SeitenKwasaki ZX10R 16OliverNoch keine Bewertungen

- DCS YokogawaDokument17 SeitenDCS Yokogawasswahyudi100% (1)

- Maha Shivratri: (Shiv Avtaran, Incarnation of God)Dokument4 SeitenMaha Shivratri: (Shiv Avtaran, Incarnation of God)Varsha RoyNoch keine Bewertungen

- Siprotec 7ut82 ProfileDokument2 SeitenSiprotec 7ut82 ProfileOliver Atahuichi TorrezNoch keine Bewertungen

- Lecture5 PDE 2016Dokument22 SeitenLecture5 PDE 2016isele1977Noch keine Bewertungen

- Adaptive Cruise ControlDokument5 SeitenAdaptive Cruise ControlIJIRSTNoch keine Bewertungen

- YogaDokument116 SeitenYogawefWE100% (2)

- Five Star Hotel and ResortDokument9 SeitenFive Star Hotel and ResortAISHNoch keine Bewertungen

- Kodak Easyshare Z712 Is Zoom Digital Camera: User'S GuideDokument75 SeitenKodak Easyshare Z712 Is Zoom Digital Camera: User'S GuideIronko PepeNoch keine Bewertungen

- Time Value of Money LectureDokument54 SeitenTime Value of Money LectureRanin, Manilac Melissa SNoch keine Bewertungen

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionVon EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Building Construction Technology: A Useful Guide - Part 1Von EverandBuilding Construction Technology: A Useful Guide - Part 1Bewertung: 4 von 5 Sternen4/5 (3)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideVon Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideBewertung: 3.5 von 5 Sternen3.5/5 (7)

- A Place of My Own: The Architecture of DaydreamsVon EverandA Place of My Own: The Architecture of DaydreamsBewertung: 4 von 5 Sternen4/5 (242)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseVon EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseBewertung: 5 von 5 Sternen5/5 (3)

- Field Guide for Construction Management: Management by Walking AroundVon EverandField Guide for Construction Management: Management by Walking AroundBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesVon EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNoch keine Bewertungen

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEVon EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEBewertung: 4 von 5 Sternen4/5 (1)

- Practical Power Distribution for IndustryVon EverandPractical Power Distribution for IndustryBewertung: 2.5 von 5 Sternen2.5/5 (2)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftVon EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftBewertung: 5 von 5 Sternen5/5 (5)

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialVon EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNoch keine Bewertungen

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishVon EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishBewertung: 4 von 5 Sternen4/5 (3)

- Shipping Container Homes: How to build a shipping container home, including plans, cool ideas, and more!Von EverandShipping Container Homes: How to build a shipping container home, including plans, cool ideas, and more!Noch keine Bewertungen

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyVon EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyBewertung: 4 von 5 Sternen4/5 (1)

- Civil Engineer's Handbook of Professional PracticeVon EverandCivil Engineer's Handbook of Professional PracticeBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingVon EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingBewertung: 5 von 5 Sternen5/5 (2)