Beruflich Dokumente

Kultur Dokumente

In This Lecture:: Analogue PWM Encoding

Hochgeladen von

Malu MohanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

In This Lecture:: Analogue PWM Encoding

Hochgeladen von

Malu MohanCopyright:

Verfügbare Formate

Lecture 9 PWM Inverters 1

In this lecture:

9.1. 9.2. Introduction PWM encoding Analogue Digital Example PWM direct converter A MOSFET totem pole Choosing the switching frequency

9.1 Introduction

An inverter takes a D.C. voltage as input and produces time-varying output voltage, e.g. a sinusoid. Inverters are commonly used to power variable-speed A.C. machines etc. Pulse width modulation (PWM) is a simple, powerful technique used in many inverters. PWM is employed in a wide variety of applications, ranging from measurement and communications to power control and conversion. PWM-based power supplies can produce a power voltage of any desired wave shape. A signal voltage with the desired wave shape is applied to a PWM generator (e.g. slow sine wave, ramp etc.) The PWM generator outputs a PWM voltage (e.g. 0-5V) (effectively a square-wave voltage) whose duty ratio is proportional to the signal voltage. The PWM voltage is used to open and close a power semiconductor switch (a power MOSFET, for example), forming a PWM-based power supply.

EE301 GB09 Page 1 EE301 GB09 Page 2

9.3. 9.4.

9.2 PWM encoding

Analogue PWM encoding

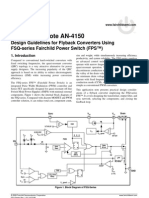

A signal voltage can be PWM-encoded quite easily in the analogue domain using a comparator (Figure 9. 1) by comparing it with a sawtooth voltage as shown.

Figure 9. 2 The amplitude of vPWM is fixed, but its duty ratio is proportional to vin

Hard low-pass filtering of this signal can recover its average value, which happens to be a good approximation to vin.

Figure 9. 1vin is PWM -encoded by comparing it with a sawtooth voltage

The output vPWM has uniform amplitude, VCC, but its duty ratio D depends on the instantaneous value of vin (Figure 9. 2).

EE301 GB09 Page 3

EE301 GB09 Page 4

Digital PWM encoding

Digital microprocessors can produce PWM-encoded signals very flexibly the shape of the desired power voltage is virtually unlimited.

VPWM + 0-5V -

Example

How could a microprocessor encode a PWM signal whose average value is 3.05V? The switching frequency is 10 kHz, and the clock frequency is 500kHz.

Solution

Assume the amplitude of the PWM signal is 5V. Then the duty ratio must be

D= Vav 3.05 = = 0.61 Vmax 5

Figure 9.3 A digital microprocessor can produce a programmable 0-5V PWM signal

A microprocessor (e.g. a P.C. with a serial port) can produce voltages that are either 0 or +VCC (normally 5V), in a highly programmable way. To PWM-encode a particular signal, a microprocessor repeatedly sets its output port high for ton, then low for toff. The microprocessors accuracy is limited, however, by its clock frequency, in a way shortly explained.

So the microprocessor produces a square wave at some frequency, which is high for 61% of its period and low for 39%. At a switching frequency of 1 kHz, the switching period is T=100s. The microprocessor, however, can set its output port only once at every tick of its on-board clock; consequently, the duration of each PWM pulse is some integer number of clock tics, n.

EE301 GB09 Page 5

EE301 GB09 Page 6

N=

Tswitch 100 10 6 = = 50 2 10 6 Tclock

and the number of tics to set high, to achieve duty ratio D, is

n = ND

Examples To achieve D = 1 (VAV=5V), set n = 501 = 50. To get D=0.2 (VAV=1V), set n = 500.2 = 10. To get D=0.602 (VAV=3.01V) set n = 50 0.61 = 30.5 (???) But the microprocessor can only set an integer number of clock tics high either 30 tics or 31. Therefore, the error in the PWM signal (and therefore in vAV) corresponds to a maximum of 1/2 a tic. In this case,

n = V 1 1 D = V AV = MAX 2 2N 2N

Figure 9.4 Digital PWM: the pulse duration is an integer number of clock tics

How many clock tics produce a PWM signal whose D=0.61 (VAV=3.05 V)? The clock frequency is 500 kHz, so the duration of a clock tick is 2 s. The number of clock tics, therefore, that make up one single PWM period is

EE301 GB09 Page 7

So here, 1/2 a tic corresponds to 5/(250) = 0.05V, or 1% error.

EE301 GB09 Page 8

So the answer: the microprocessor cant PWM-encode 3.05V! The closest it can do is 3V (n=30) or 3.1V (n=31). So the higher the clock speed, the better the accuracy of the PWM signal.

9.3. PWM direct converter

PWM direct conversion is a way of producing a time-varying power supply voltage from D.C using PWM. Figure 9.5 shows a popular switching circuit called a totem pole, which can drive heavy loads.

+5V +VDD

Notes

R

Consider a rapidly-switching PWM signal, modulated with a slowly changing input signal. The running average of the PWM signal tends to take on the value of the slowly changing input, provided that

Q2 Filter vout R Q3 C RL vout (filtered) iout (Heavy)

vPWM

Q1

the PWM switching frequency is much greater than the signal frequency!

Also in the modulated signal there will be a lot of high frequency noise, with especially strong components at the switching frequency and its harmonics. Aggressive filtering is usually needed to remove those components and recover the original signal.

EE301 GB09 Page 9

Figure 9.5 MOSFET Totem pole, with output low-pass filter

EE301 GB09 Page 10

The totem pole of Figure 9.5 inverts: a high input produces a low output, and vice versa: 1. vPWM high: Q1 on,Q3 on, Q2 off, so vout low. 2. vPWM low: Q1 off, Q3 off, Q2 on, so vout high. This could easily be fixed by inverting vPWM beforehand. So applying a PWM signal like that of Figure 9. 2, for example, produces a sinusoidal power voltage than can drive a heavy load. An RC stage is needed to low-pass filter the resulting PWM power signal, extracting the low-frequency component of the signal (e.g. the sine-wave).

Choosing the switching frequency super-pulses

In general, a PWM-encoded voltage has a harmonic at the signal frequency, and many higher harmonics at multiples of the switching frequency. As its easier to low-pass filter harmonics that are far apart, the switching frequency should be much higher than the signal frequency at least ten times higher. Recall: the nominal mean output voltage is

Vout(nominal) = Vin

t ON = Vin D Tswitch

where D is the duty ratio of the PWM signal. Recall that edge jitter and discretization error in the timing, t, is virtually unavoidable, and produces an extra error in the output voltage. For one period:

Vout ( actual ) = Vin t ON t = Vin D' Tswitch m t

EE301 GB09 Page 12

EE301 GB09 Page 11

The corresponding uncertainty in the output voltage is given by

voltage error = Vout ( nominal ) Vout ( actual ) Vout ( nominal ) D' D = Vin D Vin D ' Vin D

= 1

One way to minimize the error this incurs is to take clump together k pulses into a super-pulse. This super-pulse has a much longer switching period kTswitch: instead of Tswitch. This reduces the corresponding uncertainty in the output voltage by k.

Figure 9 6 Taking k pulses together into a single super-pulse reduces the error due to t, but also reduces the maximum achievable frequency

EE301 GB09 Page 13

EE301 GB09 Page 14

Of course, increasing the sampling time or measuring time by a factor of k shrinks the maximum representable frequency 1/Tswitch by a factor k. So theres the trade-off: a longer switching time means (and lower switching frequency)

more accurate rendering of the PWM signal (good)

but

lower maximum signal frequency (bad)

In the next lecture:

Choosing the switching frequency worked example PWM and the buck converter

END OF LECTURE

EE301 GB09 Page 15

Das könnte Ihnen auch gefallen

- Spice Ii: Prepared by Dr. Wagih GirgisDokument30 SeitenSpice Ii: Prepared by Dr. Wagih GirgisMostafa MohamedNoch keine Bewertungen

- Unit 3Dokument66 SeitenUnit 3Venky VellankiNoch keine Bewertungen

- Speed Control of DC Motor Using PDokument22 SeitenSpeed Control of DC Motor Using PAnanth Sai YadavNoch keine Bewertungen

- PWM Inverters: An Introduction to Pulse Width Modulation TechniquesDokument4 SeitenPWM Inverters: An Introduction to Pulse Width Modulation TechniquesHassan FarssiNoch keine Bewertungen

- Chapter 4: Analog and PWM Output ControlDokument20 SeitenChapter 4: Analog and PWM Output ControlNecNoch keine Bewertungen

- Power Electronics Experiments ECE-P-672Dokument9 SeitenPower Electronics Experiments ECE-P-672Sai SomayajulaNoch keine Bewertungen

- Buck Converter Simulation Using ArduinoDokument4 SeitenBuck Converter Simulation Using Arduinoxces 2312Noch keine Bewertungen

- Power Electronics Slides and Notes DC ConvertersDokument40 SeitenPower Electronics Slides and Notes DC ConvertersAnoop MathewNoch keine Bewertungen

- POL Power Supply Design ComparisonDokument30 SeitenPOL Power Supply Design ComparisonGlenn KerselaersNoch keine Bewertungen

- You. You Are Not Allowed To Share Your Solutions With Others in The ClassDokument16 SeitenYou. You Are Not Allowed To Share Your Solutions With Others in The ClassJitendra SinghNoch keine Bewertungen

- Implementation of A High Voltage Power SupplyDokument4 SeitenImplementation of A High Voltage Power SupplyJiakeat LiauNoch keine Bewertungen

- PWM To DC Voltage Conversion: Kyle Burgess 4/3/2015Dokument8 SeitenPWM To DC Voltage Conversion: Kyle Burgess 4/3/2015NaranLoganNoch keine Bewertungen

- IC Questions With Ans AnilsirDokument22 SeitenIC Questions With Ans AnilsirAniil J Kumaar50% (2)

- Auto Zero Op AmpDokument3 SeitenAuto Zero Op AmpAndrei SevcencoNoch keine Bewertungen

- Experiment 3Dokument6 SeitenExperiment 3piyushvarsh0Noch keine Bewertungen

- An H50Dokument4 SeitenAn H50Hugo RojasNoch keine Bewertungen

- Q02201300137Dokument8 SeitenQ02201300137Vikas PatelNoch keine Bewertungen

- Lab ManualDokument56 SeitenLab ManualNarendra ReddyNoch keine Bewertungen

- Tutorial Sheet 5Dokument2 SeitenTutorial Sheet 5Shashank SinghNoch keine Bewertungen

- 7+Diode+Circuits RectifiersDokument31 Seiten7+Diode+Circuits RectifiersRyan Anthony AndalNoch keine Bewertungen

- Operational Amplifier LAbDokument17 SeitenOperational Amplifier LAbAhmad DboukNoch keine Bewertungen

- CMOS Comparator Design: TSMC 0.25 Um TechnologyDokument15 SeitenCMOS Comparator Design: TSMC 0.25 Um TechnologySharath_Patil_7623Noch keine Bewertungen

- Lab Design and Analysis of Active CS and Cascode AmplifierDokument3 SeitenLab Design and Analysis of Active CS and Cascode AmplifierAzure HereNoch keine Bewertungen

- Assignment 1 Digital IC DesignDokument2 SeitenAssignment 1 Digital IC DesignsidhjajNoch keine Bewertungen

- Uc 3872 DWDokument8 SeitenUc 3872 DWCarlos CuebasNoch keine Bewertungen

- Introduction To Practical Exercises Using MODICOM 2 ... - LJ Create PDFDokument8 SeitenIntroduction To Practical Exercises Using MODICOM 2 ... - LJ Create PDFAnonymous FKMfvCbNoch keine Bewertungen

- Mbed CH 4 v1Dokument15 SeitenMbed CH 4 v1Brian YehNoch keine Bewertungen

- PWM Signal GeneratorsDokument3 SeitenPWM Signal GeneratorsjalalhNoch keine Bewertungen

- Ivc102 DatasheetDokument15 SeitenIvc102 DatasheetChristian CândidoNoch keine Bewertungen

- High Bandwidth Low Noise Amplifier with improved stabilityDokument11 SeitenHigh Bandwidth Low Noise Amplifier with improved stabilitysushil4056Noch keine Bewertungen

- Psim SVMDokument9 SeitenPsim SVMNarendra ReddyNoch keine Bewertungen

- Lab 10Dokument8 SeitenLab 10A. AlghamdiNoch keine Bewertungen

- Application Note AN-4150: Design Guidelines For Flyback Converters Using FSQ-series Fairchild Power Switch (FPS™)Dokument16 SeitenApplication Note AN-4150: Design Guidelines For Flyback Converters Using FSQ-series Fairchild Power Switch (FPS™)Nagendra ChaitanyaNoch keine Bewertungen

- Design A 200 Watt, 150 V PWM Bipolar InverterDokument11 SeitenDesign A 200 Watt, 150 V PWM Bipolar InverterSubzero Bill100% (1)

- Pspice Simulation of Power Electronics Circuits: Part 3 of Extra Material For Use WithDokument26 SeitenPspice Simulation of Power Electronics Circuits: Part 3 of Extra Material For Use WithawemetalNoch keine Bewertungen

- Dual-Phase, Quick-PWM Controllers For IMVP-IV CPU Core Power SuppliesDokument45 SeitenDual-Phase, Quick-PWM Controllers For IMVP-IV CPU Core Power Supplieslucian1961Noch keine Bewertungen

- Digital PSS Control for Flyback ConvertersDokument6 SeitenDigital PSS Control for Flyback ConvertersSuselleNoch keine Bewertungen

- Revisit: Resistance and Capacitance MOSFET Model For Digital CircuitsDokument33 SeitenRevisit: Resistance and Capacitance MOSFET Model For Digital Circuitsdilshan singhNoch keine Bewertungen

- Max1987 1988Dokument45 SeitenMax1987 1988s_vallespinNoch keine Bewertungen

- CMOS Inverter Modelling On CADENCEDokument5 SeitenCMOS Inverter Modelling On CADENCESanket KoleyNoch keine Bewertungen

- PWM Signal Generators: Testing Status: Mixed. Some Untested, Some SPICE SimulatedDokument15 SeitenPWM Signal Generators: Testing Status: Mixed. Some Untested, Some SPICE SimulatedSivareddy MudiyalaNoch keine Bewertungen

- Design AM Transceiver and Measure RegulationDokument66 SeitenDesign AM Transceiver and Measure RegulationjebadanielNoch keine Bewertungen

- 10.boot Strap SweepDokument3 Seiten10.boot Strap SweepBharadwaj MedapuramNoch keine Bewertungen

- EC319 (CS) Unit 1 Part 2Dokument72 SeitenEC319 (CS) Unit 1 Part 2Rahul LoharNoch keine Bewertungen

- Lab 9Dokument13 SeitenLab 9A. AlghamdiNoch keine Bewertungen

- Space Vector PWM - 2Dokument6 SeitenSpace Vector PWM - 2guanitouNoch keine Bewertungen

- SPWMDokument5 SeitenSPWMKiran Kumar NallamekalaNoch keine Bewertungen

- 2 in One LabDokument5 Seiten2 in One LabEnock KachokolaNoch keine Bewertungen

- Experiment No 10 Apparatus: To Study and Design DifferntiatorDokument5 SeitenExperiment No 10 Apparatus: To Study and Design DifferntiatorMohsin TariqNoch keine Bewertungen

- Direct Digital Synthesis Controlled Pure Sine Wave InverterDokument17 SeitenDirect Digital Synthesis Controlled Pure Sine Wave InverterNabil MohammadNoch keine Bewertungen

- PWM DemodulatorsDokument8 SeitenPWM DemodulatorsPutri PratiwiNoch keine Bewertungen

- Function Generator Op-Amp Summing Circuits Pulse Width Modulation LM311 ComparatorDokument7 SeitenFunction Generator Op-Amp Summing Circuits Pulse Width Modulation LM311 ComparatorMuhammad JunaidNoch keine Bewertungen

- Pulse Width Mod/Demod LabDokument2 SeitenPulse Width Mod/Demod LabBillion money FxNoch keine Bewertungen

- Boost DesignDokument4 SeitenBoost DesignmuthukumartharaniNoch keine Bewertungen

- Amplifier A PrelabDokument7 SeitenAmplifier A Prelabatomking73Noch keine Bewertungen

- Solution InverterDokument12 SeitenSolution InverterPragati Rana50% (2)

- University of Engineering & Technology LahoreDokument43 SeitenUniversity of Engineering & Technology LahoreKantesh KumarNoch keine Bewertungen

- IADC DesignDokument10 SeitenIADC Designchintu333Noch keine Bewertungen

- Chapter 8Dokument34 SeitenChapter 8Abhinav GuptaNoch keine Bewertungen

- FWF MMTC e LetterDokument3 SeitenFWF MMTC e LetterMalu MohanNoch keine Bewertungen

- CH8-E3-E4 EWS-Landline & Mobile VASDokument37 SeitenCH8-E3-E4 EWS-Landline & Mobile VASMalu MohanNoch keine Bewertungen

- 1 IntroductionDokument29 Seiten1 IntroductionMalu MohanNoch keine Bewertungen

- Fundamentals of Power Systems PDFDokument13 SeitenFundamentals of Power Systems PDFSurender ReddyNoch keine Bewertungen

- Nguyen Than Fiberoptic2Dokument18 SeitenNguyen Than Fiberoptic2Malu MohanNoch keine Bewertungen

- PQ 99Dokument13 SeitenPQ 99Malu MohanNoch keine Bewertungen

- CH 4Dokument22 SeitenCH 4Malu MohanNoch keine Bewertungen

- Ch1 E3 E4 Ews NGSDH ConceptsDokument25 SeitenCh1 E3 E4 Ews NGSDH ConceptsMalu MohanNoch keine Bewertungen

- Ch1 E3 E4 Ews NGSDH ConceptsDokument25 SeitenCh1 E3 E4 Ews NGSDH ConceptsMalu MohanNoch keine Bewertungen

- Synchronous Digital Hierarchy (SDH)Dokument53 SeitenSynchronous Digital Hierarchy (SDH)kunj bihari rajpootNoch keine Bewertungen

- EC2042 Embedded and Real Time Systems Lecture NotesDokument79 SeitenEC2042 Embedded and Real Time Systems Lecture NotesPraveen ChellapandianNoch keine Bewertungen

- Electrical Power System Fundamentals for Non-Electrical EngineersDokument42 SeitenElectrical Power System Fundamentals for Non-Electrical EngineersMoeed IqbalNoch keine Bewertungen

- Harmonic Wavelet AnalysisDokument23 SeitenHarmonic Wavelet AnalysisMalu MohanNoch keine Bewertungen

- Bi Directional InverterDokument7 SeitenBi Directional InverterMalu MohanNoch keine Bewertungen

- Frequency-Domain Control Systems Analysis and DesignDokument69 SeitenFrequency-Domain Control Systems Analysis and DesignMalu MohanNoch keine Bewertungen

- Classification of Power Quality Disturbances Using Dual Wavelet Transforms and SVMDokument6 SeitenClassification of Power Quality Disturbances Using Dual Wavelet Transforms and SVMMalu MohanNoch keine Bewertungen

- Finite State Machines: by Mike ChenDokument25 SeitenFinite State Machines: by Mike ChenKulwant NagiNoch keine Bewertungen

- Optimization and Implementation of The Wavelet Based Algorithms For Embedded Biomedical Signal ProcessingDokument21 SeitenOptimization and Implementation of The Wavelet Based Algorithms For Embedded Biomedical Signal ProcessingMalu MohanNoch keine Bewertungen

- Lect12 - Software QualityDokument15 SeitenLect12 - Software QualityMalu MohanNoch keine Bewertungen

- Finite State Machine (FSM) : ExampleDokument22 SeitenFinite State Machine (FSM) : ExampleDanish WilsonNoch keine Bewertungen

- Spread Spectrum: Wireless Networks Spring 2005Dokument30 SeitenSpread Spectrum: Wireless Networks Spring 2005Malu MohanNoch keine Bewertungen

- Power Quality LunchandLearnDokument41 SeitenPower Quality LunchandLearnMalu MohanNoch keine Bewertungen

- E Book Scheduling in Real Time SystemsDokument284 SeitenE Book Scheduling in Real Time SystemsMalu MohanNoch keine Bewertungen

- Heartbeat and Temperatire Monitoring SystemDokument20 SeitenHeartbeat and Temperatire Monitoring SystemMalu MohanNoch keine Bewertungen

- Tutorialv0 3Dokument92 SeitenTutorialv0 3Malu MohanNoch keine Bewertungen

- Mips DatapathDokument23 SeitenMips DatapathKaran KampaniNoch keine Bewertungen

- Heartbeat and Temperatire Monitoring SystemDokument20 SeitenHeartbeat and Temperatire Monitoring SystemMalu MohanNoch keine Bewertungen

- 03 Linked ListsDokument22 Seiten03 Linked ListsAnonymous V7P5fNQINoch keine Bewertungen

- Notice That The L293D Supports Two DC MotorsDokument10 SeitenNotice That The L293D Supports Two DC MotorsMalu MohanNoch keine Bewertungen

- Install Ns2 On Windows7Dokument1 SeiteInstall Ns2 On Windows7Malu MohanNoch keine Bewertungen

- Z-SH1N EATON MOELLER Fuse Disconnectors, 1pole+n, 10 X 38Dokument1 SeiteZ-SH1N EATON MOELLER Fuse Disconnectors, 1pole+n, 10 X 38co_stel817842Noch keine Bewertungen

- 3M™ Scotchcast™ Flexible Power Cable Splicing Kits 82-F and 82-BF SeriesDokument3 Seiten3M™ Scotchcast™ Flexible Power Cable Splicing Kits 82-F and 82-BF SeriesTiyok HariNoch keine Bewertungen

- Sony KV-29FS120 (Chassis BA-6) PDFDokument81 SeitenSony KV-29FS120 (Chassis BA-6) PDFJuan Diego Calsin TapiaNoch keine Bewertungen

- Christie RF80 K Specification SheetDokument6 SeitenChristie RF80 K Specification SheetJuan MartinezNoch keine Bewertungen

- Dynamic Vs Electret Vs Carbon HandsetDokument1 SeiteDynamic Vs Electret Vs Carbon HandsetPedro AlexandreNoch keine Bewertungen

- 3 - Electrical System PDFDokument39 Seiten3 - Electrical System PDFnamduong3680% (1)

- Thomas Young, (Born June 13, 1773, Milverton, Somerset, England-Died May 10Dokument11 SeitenThomas Young, (Born June 13, 1773, Milverton, Somerset, England-Died May 10OS WSNoch keine Bewertungen

- Fuse and Types of Fuses - Electrical Technology-OkDokument7 SeitenFuse and Types of Fuses - Electrical Technology-Okdrastir_777100% (1)

- Questions & Answers On Commutation Process & Excitation MethodsDokument23 SeitenQuestions & Answers On Commutation Process & Excitation Methodskibrom atsbhaNoch keine Bewertungen

- Class 7 - Chapter 14 - Electric Current and Its EffectsDokument4 SeitenClass 7 - Chapter 14 - Electric Current and Its EffectshamzaNoch keine Bewertungen

- Manual Usuario EspañolDokument144 SeitenManual Usuario EspañolNarda TiconaNoch keine Bewertungen

- Dr. Ahmed Said's Introduction to Electronics Chapter on Atoms, SemiconductorsDokument28 SeitenDr. Ahmed Said's Introduction to Electronics Chapter on Atoms, Semiconductorsmustafa osmanNoch keine Bewertungen

- Design of 220kV Transmission Line Tower Using STAAD.ProDokument27 SeitenDesign of 220kV Transmission Line Tower Using STAAD.ProIlham HusseinNoch keine Bewertungen

- ConductorsDokument19 SeitenConductorsNavdeep KaurNoch keine Bewertungen

- 10 Dollar Phone Patch PDFDokument2 Seiten10 Dollar Phone Patch PDFblesk2hotNoch keine Bewertungen

- сервис мануал LG 43UJ634V шасси UD74P PDFDokument101 Seitenсервис мануал LG 43UJ634V шасси UD74P PDFsebas ruiz100% (1)

- Maitinimo Saltiniai Sitop - kt10 1Dokument164 SeitenMaitinimo Saltiniai Sitop - kt10 1Jucimar BrilhanteNoch keine Bewertungen

- Elebtikartech - 2 MVA OfferDokument7 SeitenElebtikartech - 2 MVA Offerاحمد العبيديNoch keine Bewertungen

- Aqh 2213Dokument6 SeitenAqh 2213johnbad36Noch keine Bewertungen

- 10ka Class 2 Arresters Certified Test Report cp0408Dokument11 Seiten10ka Class 2 Arresters Certified Test Report cp0408Siddhartha MishraNoch keine Bewertungen

- Series and Parallel CircuitsDokument19 SeitenSeries and Parallel CircuitsBrandon WhymanNoch keine Bewertungen

- XL LX: TO THE To Eb IN A: XDokument13 SeitenXL LX: TO THE To Eb IN A: XCrystal Joy DizonNoch keine Bewertungen

- Bit3193g PDFDokument10 SeitenBit3193g PDFh.keulder1480Noch keine Bewertungen

- Signal Condititioning DevicesDokument17 SeitenSignal Condititioning DevicesAnish LotraNoch keine Bewertungen

- Wiring Phone JackDokument2 SeitenWiring Phone JackBrett WoodsNoch keine Bewertungen

- Circuit Elements and ParametersDokument30 SeitenCircuit Elements and ParametersCarl PNoch keine Bewertungen

- Automatic Water Level Indicator With AlarmDokument31 SeitenAutomatic Water Level Indicator With Alarmchuck254Noch keine Bewertungen

- HV MemoDokument17 SeitenHV MemohadrienNoch keine Bewertungen

- IMI TRM 420ma LowresDokument20 SeitenIMI TRM 420ma LowresALEXSANDRONoch keine Bewertungen

- Lecture 11 - Opaerational Amplifiers-3Dokument48 SeitenLecture 11 - Opaerational Amplifiers-3Kamran AbdullahNoch keine Bewertungen