Beruflich Dokumente

Kultur Dokumente

Technical Sheet CEB Case Study US

Hochgeladen von

luisgomezrojasOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Technical Sheet CEB Case Study US

Hochgeladen von

luisgomezrojasCopyright:

Verfügbare Formate

Case study: Petrochemical Plant (Texas)

Reduce your Plant Emissions & Save Significantly in Operating Costs

CEB 50

Keep the environment clean when combusting your waste gases No luminous flame No odor No heat radiation No smoke Low height Small footprint

Achievable emissions levels: NOx < 15 ppm < 0.018 lbs/MMBtu CO < 10 ppm < 0.008 lbs/MMBtu

CxHy < 10 ppm < 0.004 lbs/MMBtu Combustion efficiency: 99.99% over full operational range

CEB 50 is a product of

Bekaert CEB Technologies The Bekaert CEB vapor combustor is proven in various petrochemical plants throughout the world to significantly reduce your NOx and CO emissions, along with effectively treating all your hydrocarbon emissions. In addition, this unique technology will result in drastic operating cost reductions, compared to other flaring and thermal oxidizer technologies, as illustrated in the case study here further.

1395 S. Marietta Parkway Building 700, Suite 708 Marietta, GA 30067 USA T : + 1 770 514 2215 F : + 1 770 423 9181 infoceb@bekaert.com www.bekaert.com/flaring

$40,000 in operating savings per year NOx and CO emissions 1 ppmv

All mentioned trademarks are registered trademarks owned by NV Bekaert SA. 2008 Bekaert

2008/11

1/2

Emission regulations and compliance issues are no longer a problem with the Bekaert CEB vapor combustor. Indeed, Bekaert CEBs emit the lowest emissions achievable (NOx, CO, unburned CxHys), while maintaining greater than 99.99% destruction efficiency. This means that you will not only be able to operate under the local regulations, but you could potentially sell additional credits (where applicable). Equally important is that all this can be achieved at the lowest investment and operational costs. The Bekaert CEB combustors only need a calorific value of vapors or gases equal to 150 btu/ft3. In case your waste gas stream is lower than the 150 btu/ft3, then the system will automatically regulate the amount of fuel gas needed to be mixed with your vapors to assure complete destruction of your vapors at the lowest fuel gas consumption. For large units, staging possibilities allow the CEB unit to achieve a turndown ratio up to 1/40. Is space an issue? You only need a footprint of 4ft x 4ft to accomodate a medium unit (same as shown on the pictures). The CEB combustors are very compact and do not generate any heat radiation to the surroundings. This allows you to install the unit where space is limited or even in close proximity to other pieces of equipment. Bekaert CEB Technologies can deliver you the complete system including shut down valves, flame arrestors, gas trains for make up gas and pilot gas, etc ...

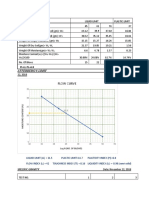

ACTUAL CASE STUDY RESULTS (PETROCHEMICAL PLANT - TEXAS) Bekaert CEB 350 units have been installed in various petrochemical sites and showed exceptional results. For example, the following have been reached after replacing a thermal oxider in one petrochemical location in Texas. Unit installed Installation data NOx Emissions CO Emissions Destruction Efficiency CEB 350 2003 (additional units since installed) Decreased by a factor of 7 to approximately 1 ppmv Decreased by more than 2 orders of magnitude to less than 1 ppmv Increased 1 order of magnitude from 99.3% to 99.95%* (*limit of the test equipment was 99.95%) Reduced Electrical Demand $35,000 annually Reduced Supplemental Fuel Costs $5,000 annually

Electrical Savings Fuel savings

All mentioned trademarks are registered trademarks owned by NV Bekaert SA. 2008 Bekaert

2008/11

2/2

Das könnte Ihnen auch gefallen

- Stanford-Binet Test Scoring Explained - Stanford-Binet IQ TestDokument3 SeitenStanford-Binet Test Scoring Explained - Stanford-Binet IQ TestLM R50% (2)

- BlahDokument8 SeitenBlahkwood84100% (1)

- Dynamic Stretching - Stability - Strength.570239Dokument2 SeitenDynamic Stretching - Stability - Strength.570239Sylvia GraceNoch keine Bewertungen

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesVon EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNoch keine Bewertungen

- CASE 721F TIER 4 WHEEL LOADER Operator's Manual PDFDokument17 SeitenCASE 721F TIER 4 WHEEL LOADER Operator's Manual PDFfjskedmmsme0% (4)

- Dual Laminate Piping HandbookDokument46 SeitenDual Laminate Piping HandbookA.Subin DasNoch keine Bewertungen

- 6 Field ExperienceDokument9 Seiten6 Field ExperiencescribdkhatnNoch keine Bewertungen

- NIOSHMVS2012 Tier 4 Technology ReviewDokument46 SeitenNIOSHMVS2012 Tier 4 Technology Reviewbuyadi100% (1)

- CFBC & PFBC Technology PSJalkote EA 0366Dokument18 SeitenCFBC & PFBC Technology PSJalkote EA 0366Jessica SimpsonNoch keine Bewertungen

- 8953-Specifications For Doosan Man 9l21 31Dokument7 Seiten8953-Specifications For Doosan Man 9l21 31Bae Juyeon100% (1)

- The Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995Von EverandThe Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995Bewertung: 5 von 5 Sternen5/5 (1)

- Carbon Capture Technologies for Gas-Turbine-Based Power PlantsVon EverandCarbon Capture Technologies for Gas-Turbine-Based Power PlantsNoch keine Bewertungen

- KBR - Ammonia Specific ExamplesDokument16 SeitenKBR - Ammonia Specific Examplesqwerty9123460% (5)

- Vibrating Grate BWDokument13 SeitenVibrating Grate BWcaiosicNoch keine Bewertungen

- Cansolve TechnologiesDokument10 SeitenCansolve TechnologiesBongibethu Msekeli HlabanoNoch keine Bewertungen

- Lesson Plan in Advanced Chemistry AlcohoDokument17 SeitenLesson Plan in Advanced Chemistry AlcohoGlaiza Mapute CaringalNoch keine Bewertungen

- RFCC KBR FeaturesDokument24 SeitenRFCC KBR FeaturesKannanGK100% (1)

- Ammonia TechnologyDokument7 SeitenAmmonia TechnologyAbhiyan Anala ArvindNoch keine Bewertungen

- 2010 Improving Steel Plant Work Environment r2Dokument14 Seiten2010 Improving Steel Plant Work Environment r2Khalil LasferNoch keine Bewertungen

- CFBC & PFBC TechnologyDokument18 SeitenCFBC & PFBC TechnologyomiitgNoch keine Bewertungen

- Technical Sheet CEB Heat Recovery EuropeDokument2 SeitenTechnical Sheet CEB Heat Recovery Europeandy131078Noch keine Bewertungen

- Technical Sheet CEB 500 EuropeDokument1 SeiteTechnical Sheet CEB 500 Europeandy131078Noch keine Bewertungen

- RPI TP 0200 v1 2007Dokument17 SeitenRPI TP 0200 v1 2007rmm99rmm99100% (1)

- Industrial Technologies Program: Ultra-Low Nox Burners With Flue Gas Recirculation and Partial ReformerDokument2 SeitenIndustrial Technologies Program: Ultra-Low Nox Burners With Flue Gas Recirculation and Partial ReformerOA AooNoch keine Bewertungen

- NOx ComplianceDokument2 SeitenNOx ComplianceUdhayakumar VenkataramanNoch keine Bewertungen

- Boiler Efficiency Combustion EfficiencyDokument8 SeitenBoiler Efficiency Combustion EfficiencyBelalNorNoch keine Bewertungen

- Double Downshot BoilersDokument9 SeitenDouble Downshot BoilersNaveen ShettyNoch keine Bewertungen

- Industrial Combustion System Riello PDFDokument8 SeitenIndustrial Combustion System Riello PDFAnonymous QY7Iu8fBNoch keine Bewertungen

- Foster Wheeler CfbbrochureDokument20 SeitenFoster Wheeler CfbbrochureEdgardo BoieroNoch keine Bewertungen

- Maxon M PAKT Bro 2007 08Dokument4 SeitenMaxon M PAKT Bro 2007 08John HowardNoch keine Bewertungen

- Combustion Optimization Part II ResultsDokument13 SeitenCombustion Optimization Part II ResultsAdil EL FARDAOUINoch keine Bewertungen

- Welcome: R.K. Balu Dgm/FesDokument38 SeitenWelcome: R.K. Balu Dgm/Fesrashm006ranjanNoch keine Bewertungen

- Ultra Low Nox Conventional and Regenerative Burner Retrofits: September 2015Dokument11 SeitenUltra Low Nox Conventional and Regenerative Burner Retrofits: September 2015Gabriel AlbornozNoch keine Bewertungen

- TECHNICAL373A Pages 14 16Dokument3 SeitenTECHNICAL373A Pages 14 16austintanNoch keine Bewertungen

- Presentazione Tec LanxessDokument27 SeitenPresentazione Tec Lanxesspec21102002Noch keine Bewertungen

- 2012 Burner Range: Leaders in Combustion TechnologyDokument5 Seiten2012 Burner Range: Leaders in Combustion TechnologyBbaPbaNoch keine Bewertungen

- Alphakat CY Presentation-1Dokument20 SeitenAlphakat CY Presentation-1Niko Koja0% (1)

- Sofa BurnerDokument32 SeitenSofa BurnerReuben VargheseNoch keine Bewertungen

- Folder Glasstec EDokument8 SeitenFolder Glasstec EHardikNoch keine Bewertungen

- GHG Reduction Through FiltrationDokument33 SeitenGHG Reduction Through FiltrationSohaib Faraz KhanNoch keine Bewertungen

- Styrene From Ethane and BenzeneDokument6 SeitenStyrene From Ethane and BenzeneAmy Puah100% (2)

- Em BaffleDokument2 SeitenEm Bafflecvolkan1Noch keine Bewertungen

- Btex Buster BrochureDokument2 SeitenBtex Buster BrochureSamaneh Hajipour0% (1)

- STOC03 (Emissions)Dokument20 SeitenSTOC03 (Emissions)tungluongNoch keine Bewertungen

- Gas Turbine Nox Emissions Approaching Zero - Is It Worth The Price?Dokument12 SeitenGas Turbine Nox Emissions Approaching Zero - Is It Worth The Price?hermans57Noch keine Bewertungen

- An Analytical 160-En ADokument6 SeitenAn Analytical 160-En ASyed Kazam RazaNoch keine Bewertungen

- Exelus Case StudyDokument2 SeitenExelus Case StudyLuAlvarado0% (1)

- What You Require To Know About NOx Reduction.20130104.123704Dokument2 SeitenWhat You Require To Know About NOx Reduction.20130104.123704anon_931869105Noch keine Bewertungen

- Alternative Fuels For Automotive Applications: Indian Institute of Petroleum DehradunDokument41 SeitenAlternative Fuels For Automotive Applications: Indian Institute of Petroleum DehradunAshish KumarNoch keine Bewertungen

- Integrated CHP Using Ultra-Low-Nox Supplemental FiringDokument11 SeitenIntegrated CHP Using Ultra-Low-Nox Supplemental FiringOmar SelamiNoch keine Bewertungen

- 5290 Alstom Oxy-Combustion Paper Clear Water Jun09Dokument11 Seiten5290 Alstom Oxy-Combustion Paper Clear Water Jun09sdiamanNoch keine Bewertungen

- Low Emission PackingDokument2 SeitenLow Emission PackingAhmedNoch keine Bewertungen

- Brochure Biomass & WTE BoilersDokument2 SeitenBrochure Biomass & WTE BoilersjmayorNoch keine Bewertungen

- Upgrades and Enhancements For Competitive Coal-Fired Boiler SystemsDokument8 SeitenUpgrades and Enhancements For Competitive Coal-Fired Boiler SystemsShankar Jha100% (1)

- Rentar Fuel Catalyst BrochureDokument4 SeitenRentar Fuel Catalyst BrochureMuhammad Asim ShabbirNoch keine Bewertungen

- TopsoeDokument5 SeitenTopsoelaiping_lumNoch keine Bewertungen

- Boiler Combustion & EmissionDokument15 SeitenBoiler Combustion & EmissionMustafa HusainNoch keine Bewertungen

- Presentation George BerbariDokument15 SeitenPresentation George BerbarirjchpNoch keine Bewertungen

- Catalytic ConverterDokument5 SeitenCatalytic Convertervminc1602Noch keine Bewertungen

- Waste Heat Boilers in Hazardous Waste Incineration ServiceDokument11 SeitenWaste Heat Boilers in Hazardous Waste Incineration ServiceSuzanne UllrichNoch keine Bewertungen

- Case Study Holcim Cement PlantDokument2 SeitenCase Study Holcim Cement PlantAiman DadoushNoch keine Bewertungen

- Com Bust orDokument9 SeitenCom Bust orDanishAmanNoch keine Bewertungen

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementVon EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNoch keine Bewertungen

- 77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016Von Everand77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016S. K. SundaramNoch keine Bewertungen

- Reducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemVon EverandReducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemNoch keine Bewertungen

- 1 Stra Bill FinalDokument41 Seiten1 Stra Bill FinalRajesh JhaNoch keine Bewertungen

- Electronic Over Current Relay (EOCR)Dokument2 SeitenElectronic Over Current Relay (EOCR)BambangsNoch keine Bewertungen

- Chemical Analysis and Mechancial Test Certificate: Yield Strength Tensile Strength ElongationDokument1 SeiteChemical Analysis and Mechancial Test Certificate: Yield Strength Tensile Strength ElongationDigna Bettin CuelloNoch keine Bewertungen

- Educational Facility Planning: Bsarch V-2 Arch. Rey GabitanDokument20 SeitenEducational Facility Planning: Bsarch V-2 Arch. Rey Gabitanidealistic03Noch keine Bewertungen

- Osh e MeerDokument3 SeitenOsh e MeerfatduckNoch keine Bewertungen

- Environmental Research and Public Health: International Journal ofDokument12 SeitenEnvironmental Research and Public Health: International Journal ofKarenNoch keine Bewertungen

- RIASEC Personality TestDokument2 SeitenRIASEC Personality TestSarah Jane NomoNoch keine Bewertungen

- Unmasking Pleural Mesothelioma: A Silent ThreatDokument11 SeitenUnmasking Pleural Mesothelioma: A Silent ThreatCathenna DesuzaNoch keine Bewertungen

- W4. Grade 10 Health - Q1 - M4 - v2Dokument22 SeitenW4. Grade 10 Health - Q1 - M4 - v2Jesmael PantalunanNoch keine Bewertungen

- Meditran SX Sae 15w 40 API CH 4Dokument1 SeiteMeditran SX Sae 15w 40 API CH 4Aam HudsonNoch keine Bewertungen

- Lab CompilationDokument11 SeitenLab CompilationJanita SiddiquiNoch keine Bewertungen

- 351 UN 1824 Sodium Hydroxide SolutionDokument8 Seiten351 UN 1824 Sodium Hydroxide SolutionCharls DeimoyNoch keine Bewertungen

- Learning Guide No 5Dokument19 SeitenLearning Guide No 5Menal JemalNoch keine Bewertungen

- Ams - 4640-C63000 Aluminium Nickel MNDokument3 SeitenAms - 4640-C63000 Aluminium Nickel MNOrnella MancinelliNoch keine Bewertungen

- Persyaratan COMA KP 241 TAHUN 2019 (SI 65-01 Rev 3)Dokument3 SeitenPersyaratan COMA KP 241 TAHUN 2019 (SI 65-01 Rev 3)Hafiz ZachariNoch keine Bewertungen

- Occlusal Appliance TherapyDokument14 SeitenOcclusal Appliance TherapyNam BuiNoch keine Bewertungen

- Carbo Hi DratDokument11 SeitenCarbo Hi DratILHAM BAGUS DARMA .NNoch keine Bewertungen

- CAT Test Series - 2014Dokument2 SeitenCAT Test Series - 2014dimevsnNoch keine Bewertungen

- PYMS Is A Reliable Malnutrition Screening ToolsDokument8 SeitenPYMS Is A Reliable Malnutrition Screening ToolsRika LedyNoch keine Bewertungen

- DDEV SPICES PVT LTD (Product List)Dokument1 SeiteDDEV SPICES PVT LTD (Product List)jaymin zalaNoch keine Bewertungen

- Policy Schedule Personal Accident Insurance Policy: (Plan 5)Dokument2 SeitenPolicy Schedule Personal Accident Insurance Policy: (Plan 5)Rana BiswasNoch keine Bewertungen

- 2015 4-H Show & Sale CatalogDokument53 Seiten2015 4-H Show & Sale CatalogFauquier NowNoch keine Bewertungen

- GeoSS Event Seminar 12 July 2012 - SlidesDokument15 SeitenGeoSS Event Seminar 12 July 2012 - SlidesNurmanda RamadhaniNoch keine Bewertungen