Beruflich Dokumente

Kultur Dokumente

Ion Exchange 2007 2008

Hochgeladen von

Cassandra BoduchOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ion Exchange 2007 2008

Hochgeladen von

Cassandra BoduchCopyright:

Verfügbare Formate

EXPERIMENTAL ANALYTICAL CHEMISTRY II LAB WORK 2 3+ DETERMINATION OF THE Fe AND 3+ Al CONCENTRATIONS IN A FLOCULANT FROM A WATER TREATMENT PLANT AFTER

THEIR SEPARATION BY ION EXCHANGE

DEPARTMENT OF ANALYTICAL CHEMISTRY UNIVERSITY OF THE BASQUE COUNTRY 2007-2008 - Second Term

In order to reach the aims stated for this Course, the following partial objectives are pursued in this lab work: 1. To reinforce the use, understanding and valuation of the chemical methods of analysis 2. To get initiated in the experimentation for the elimination of interferences 3. To practice the ion exchange processes and to check their advantages and drawbacks 4. To reinforce the lab performance protocols in order to produce exact and precise quantitative values, comparing them with those obtained in Lab Work 1.

Theoretical Background

Ion exchange processes allow the separation of species with different ionic properties (same sign but different charge or different sign species). In this particular case, before being able to determine the total concentrations of iron and aluminum in a oculant used in a water treatment plant, by means of complexometric titrations with EDTA, it is necessary to carry out the separation of both meta ions because their interfere with each other in their reaction with EDTA. The Fe(III) and Al(III) separation can be achieved by ion exchange taking advantage of the Fe(III) to form an anionic chlorocomplex while Al(III) can not form such complexes and remains in solution as a cationic species. Thus, both metals can be separated in concentrated HCl media by ion exchange with the strongly basic Purolite A100 anionic resin. The Fe(III) tetrachlorocomplex is captured by the resin as long as it remains as such anion (for instance, in a 6 M HCl media). As Al(III) does not form anionic complexes under these conditions it is not retained in the resin which allows the following separation process: Al3+ + FeCl aq + R+ Cl R+ FeCl res + Cl + Al3+ aq res aq aq 4 4 In this way, Al(III) stays in the aqueous phase (take an aliquot for its titration), while Fe(III) is quantitatively retained in the resin. In order to determine the Fe(III) concentration it is necessary to elute it from the resin phase to an aqueous phase. This can be done according to: R+ FeCl res + NOaq (pH = 2) FeCl4aq + R+ NOres 4 3 3 1

Therefore, Fe(III) is quantitatively returned to an aqueous phase (take an aliquot for its titration) without Al(III) being present now.

Operating Procedure

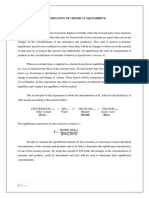

Column preparation The ion exchange resin may have been stored dry. Because of the phenomena known as swelling, the resin must be properly hydrated and conditioned before use. To do this, add the dry resin to the column with a spoon and then add distilled water to facilitate settling. Keep doing this until the length of swollen hydrated resin in the column is 15 cm. Use a slim glass stick to remove any bubbles that might have formed. Once the resin in the column is completely hydrated and has settled, it should be cleaned by pouring about 200 mL of deionized water. Column use For all the experiments in this lab work, the column ow should not be higher than 4 mL/min. The ow can be measured with a graduated test tube while cleaning the resin with water as mentioned before. When not in use, the column should be left with at least 2 cm of liquid above the column head (stand-by position, Figure 1a). Before starting any elution operation, the column should be brought to the start position: the level of the liquid is at the same level of the resin head (Figure 1b). In a normal elution operation there should be at least 2 cm of the eluting solution above the resin (operation position, Figure 1c). Fe(III) and Al(III) separation in concentrated HCl media using the PUROLITE A100 resin 1. Prepare a 6 M HCl solution and condition the resin in chloride form by pouring about 50 mL of this solution through it. To do this, go from the stand-by to the start and to the operation positions. 2. Go to the start position again, take a 20 mL sample and pour it through the resin. Use a glass stick to lead the sample through the column wall in order no to stir the resin. 3. When the last part of the 20 mL sample has already gone under the resin head (that is, in the start position again), begin the addition of the 6 M HCl solution until 100 mL have been collected in a 100 mL volumetric ask. Al(III) concentration will be determined from the collected solution. Fe(III) elution with HNO3 at pH = 2 1. Prepare 250 mL of HNO3 at pH = 2. 2. Go to the start position and pour this solution trough the resin containing Fe(III). 3. In the operation position, start collecting the eluate in a 100 mL volumetric ask. Keep pouring the HNO3 solution until the ask is full to the mark. Fe(III) concentration will be determined from this solution.

Quantitative Determination Methods

Both metals will be determined by complex formation titration using EDTA as ligand. As with any titration, it is not only necessary to have a quantitative reaction free from interferences but also to have an adequate indicator which allows the detection of the end point. In this case, Fe(III) can be directly titrated because an indicator is available. However, no good indicators can be found for Al(III) and thus a back titration will be employed.

2 cm

2 cm

15 cm

15 cm

15 cm

Flow = 0 a)

Flow = 0 b)

Flow = 4 mL/min c)

Figure 1: Column use: a) Stand-by mode, b) Start mode, c) Operation mode. Legend: 1 = Resin, 2 = Resin bed, 3 = Liquid above resin.

3.1

EDTA standardization with ZnO at pH = 10.5 using EBT as indicator

EDTA (approx. 0.01 M) standardization must be carried out rst with ZnO as primary standard in a 1 M NH4 + /NH3 buffer at pH = 10.5 using Eriochrome Black T1 as indicator. EDTA mol weight = 372.24 g/mol ZnO mol weight = 81.37 g/mol At least 3 titrations must be performed for EDTA standardization. For each titration, weight (in a dry Erlenmeyer ask at ambient temperature) the ZnO amount which involves the use of about 20 mL EDTA. Dissolve ZnO in the minimum amount of concentrated HCl drops (maybe 5 or 6 are enough). Add about 50 mL water and neutralize with 0.01 M NaOH until pH is in the interval 5-10. Add 25 mL of the buffer solution and make sure pH is in the 10-10.5 interval. If pH is more acidic than that, add a base (NaOH or NH3 ) directly to the Erlenmeyer. Finally, add the EBT indicator (a violet color -red on a blue background- should be observed). Titrate with the EDTA solution until the indicator changes color to blue (the red disappears from the blue background). After this EDTA standardization both metals can be titrated.

3.2

Al+3 titration with EDTA by means of a back titration with Zn+2 at pH = 5 using Xylenol Orange as indicator

First, the standardization of the Zn+2 solution (approx. 0.01 M) must be carried out Zn(NO3 )2 .6H2 O mol weight = 297.47 g/mol This standardization is performed taking an 10 or 20 mL aliquot of the Zn+2 solution and titrating it with the standardized EDTA solution using the previous procedure. To titrate Al(III), take a 10 mL aliquot from the volumetric ask where the Al(III) eluate was collected, neutralize2 it to a pH of about 5 and add 25 mL of the 0.01 EDTA solution. Check that, in any case, pH is in the 3 - 5.5 interval and adjust it with diluted HNO3 or NaOH if needed. Now, heat the Erlenmeyer in a sand bath for about 10 minutes to make sure all the Al(III) is complexed with EDTA. After cooling the Erlenmeyer, add 25 mL of a 1 M HAc/Ac solution and the Xylenol Orange indicator (a yellow color should be observed). Finally, proceed to titrate the excess EDTA with the Zn+2 solution until the rst orange/red shades are observed.

3.3

Direct Fe+3 titration with EDTA at pH = 2 using SCN as indicator

Take a 10 mL aliquot from the volumetric ask where the Fe(III) eluate was collected. Add about 100 mL of water and adjust to pH = 1.5 - 2 if needed. Add either some drops of a 0.1 M SCN solution or half a microspoonful of the solid KSCN or NH4 SCN indicator until the yellow Fe(III) turns to red (the more red the more SCN is added). Titrate with 0.01 M EDTA until all shades of red/orange have disappeared from the yellow (greenish) background of the solution containing the Fe-EDTA complex.

in Spanish. do this, a concentrated NaOH solution (or even solid NaOH) can be used. Perform the necessary calculations to know the volume of solution or weight of solid to be added.

2 To

1 NET,

Das könnte Ihnen auch gefallen

- Oiler Feed Water TestDokument7 SeitenOiler Feed Water TestRISHIKESH KUMARNoch keine Bewertungen

- Lab 3: AlkalinityDokument7 SeitenLab 3: Alkalinityabulyalee0% (1)

- E13 Volumetric Analysis Acid / Base Titrations: The TaskDokument7 SeitenE13 Volumetric Analysis Acid / Base Titrations: The TaskbokjooooNoch keine Bewertungen

- Experiment# 01: Experiment Title: Water Analysis ObjectivesDokument7 SeitenExperiment# 01: Experiment Title: Water Analysis ObjectivesAasia FarrukhNoch keine Bewertungen

- Ion Exchange LabDokument8 SeitenIon Exchange LabHassan HaiderNoch keine Bewertungen

- Le McCabe-Theile DiagramDokument10 SeitenLe McCabe-Theile DiagramBen KalNoch keine Bewertungen

- Standardization of Acid and Base SolutionsDokument4 SeitenStandardization of Acid and Base SolutionsMAISHA TASNEEMNoch keine Bewertungen

- Photometric Titration of Copper (Ii) With Edta Experiment Reading: Harris, Chapter 13 & 6Dokument3 SeitenPhotometric Titration of Copper (Ii) With Edta Experiment Reading: Harris, Chapter 13 & 6RyzzaYvonneSaclausoMedalleNoch keine Bewertungen

- Lab Report (Final Editied)Dokument8 SeitenLab Report (Final Editied)Alexia Channer100% (4)

- Lab Procedure Experiment 5 - PCDokument6 SeitenLab Procedure Experiment 5 - PCNur Farhana LukhmanNoch keine Bewertungen

- Water Tests PupilDokument14 SeitenWater Tests PupilJAMES CURRANNoch keine Bewertungen

- Cys51 InorgDokument6 SeitenCys51 Inorgpiyush kumarNoch keine Bewertungen

- Soil Survey Standard Test MethodDokument5 SeitenSoil Survey Standard Test MethodMPK08Noch keine Bewertungen

- K en FertilizanteDokument2 SeitenK en FertilizanteMarianita GonzalezNoch keine Bewertungen

- Level 3 Chemistry 3.1 ReportDokument16 SeitenLevel 3 Chemistry 3.1 Reportbenmcmorran05Noch keine Bewertungen

- Application of Ion Exchange ResinDokument3 SeitenApplication of Ion Exchange ResinEdna Lip AnerNoch keine Bewertungen

- Experiment 14: The Friedel-Crafts Acylation Of Ferrocene: + Alcl Δ + HxDokument4 SeitenExperiment 14: The Friedel-Crafts Acylation Of Ferrocene: + Alcl Δ + HxAnkita Khan roll no:- 07Noch keine Bewertungen

- Fe CL 3Dokument11 SeitenFe CL 3chemikanthNoch keine Bewertungen

- Lab Manual-Total AlkalinityDokument4 SeitenLab Manual-Total AlkalinitySuvanka DuttaNoch keine Bewertungen

- Preparations Observation ChemDokument17 SeitenPreparations Observation ChemShailendri AishuNoch keine Bewertungen

- AP Chemistry - Equilibrium and LeChatelier's Principle LabDokument5 SeitenAP Chemistry - Equilibrium and LeChatelier's Principle LabJonathan Chen50% (4)

- Alkalinity ExperimentDokument7 SeitenAlkalinity ExperimentUbeiden CifuentesNoch keine Bewertungen

- Iron Determination, SpectrophotometricDokument2 SeitenIron Determination, SpectrophotometricNiaz Ali KhanNoch keine Bewertungen

- Summary of Method: Standard Operating Procedure RW2: AlkalinityDokument3 SeitenSummary of Method: Standard Operating Procedure RW2: AlkalinityMoneek ParkerNoch keine Bewertungen

- Practical 22.1 Iron Wool Redox TitrationDokument6 SeitenPractical 22.1 Iron Wool Redox TitrationDanielle CarterNoch keine Bewertungen

- Bài Tập Phân Tích Công CụDokument38 SeitenBài Tập Phân Tích Công Cụ12a50% (1)

- Experiment 3 Redox Titration Percent Purity Analysis PDFDokument5 SeitenExperiment 3 Redox Titration Percent Purity Analysis PDFnanaNoch keine Bewertungen

- Experiment 3 Redox Titration Percent Purity AnalysisDokument5 SeitenExperiment 3 Redox Titration Percent Purity AnalysisnanaNoch keine Bewertungen

- Chemistry PracticalDokument38 SeitenChemistry PracticalMukhtar MalikNoch keine Bewertungen

- Iron LabDokument13 SeitenIron Labsenthilkumar100Noch keine Bewertungen

- Dav School (Affiliated To CBSE New Delhi) Sree Nandeeswarar Campus - Adambakkam Xii STD Chemistry Practical ManualDokument54 SeitenDav School (Affiliated To CBSE New Delhi) Sree Nandeeswarar Campus - Adambakkam Xii STD Chemistry Practical ManualSivaRamaKrishnan R.Noch keine Bewertungen

- Experimental Chemistry IDokument60 SeitenExperimental Chemistry IadminchemNoch keine Bewertungen

- Applied Chemistry I Lab ManualDokument51 SeitenApplied Chemistry I Lab ManualBipin PrajapatiNoch keine Bewertungen

- Experiment 3Dokument8 SeitenExperiment 3Faris Amzar SuhaimiNoch keine Bewertungen

- Chemistry ReportDokument5 SeitenChemistry ReportAngel Trisha Mae DelMundoNoch keine Bewertungen

- Lab 8 StudentDokument5 SeitenLab 8 Studentscribbyscrib0% (2)

- Experiment 3 Synthesis, Characterization and Ligand Exchange Equilibria of Potassium Tris (Oxalato) Ferrate (Iii)Dokument7 SeitenExperiment 3 Synthesis, Characterization and Ligand Exchange Equilibria of Potassium Tris (Oxalato) Ferrate (Iii)skrim240100% (1)

- Lab Manual 7 in TextDokument3 SeitenLab Manual 7 in Textardakargyn4Noch keine Bewertungen

- Laboratory Manual CHE102 Chemistry LabDokument41 SeitenLaboratory Manual CHE102 Chemistry LabSushil KumarNoch keine Bewertungen

- 1955 - Boyes - Methods For The AnalysisDokument8 Seiten1955 - Boyes - Methods For The Analysisjlcheefei9258Noch keine Bewertungen

- A - Lab - Chem EquilibDokument4 SeitenA - Lab - Chem EquilibshayneNoch keine Bewertungen

- Ion Exchange Resin.F2005Dokument3 SeitenIon Exchange Resin.F2005Almira Kaye CuadraNoch keine Bewertungen

- Calcium-Magnesium by EDTA TitrationDokument5 SeitenCalcium-Magnesium by EDTA TitrationnisscriNoch keine Bewertungen

- Aniline Separation From TolueneDokument41 SeitenAniline Separation From ToluenecaprolactamclNoch keine Bewertungen

- Expt 6 - 7 - 8 - 08Dokument12 SeitenExpt 6 - 7 - 8 - 08Rahimi ShahimiNoch keine Bewertungen

- Experiment 3: Preparing SolutionDokument4 SeitenExperiment 3: Preparing SolutionÇiğdem DÜLGERBAKİNoch keine Bewertungen

- Titration - Dry Lab - 2020Dokument6 SeitenTitration - Dry Lab - 2020MariaPaulaGonzalezRojasNoch keine Bewertungen

- Titration - Dry Lab - 2020Dokument6 SeitenTitration - Dry Lab - 2020MariaPaulaGonzalezRojasNoch keine Bewertungen

- Jomo Kenyatta University of Agriculture and TechnologyDokument16 SeitenJomo Kenyatta University of Agriculture and TechnologyJoe NjoreNoch keine Bewertungen

- Refer To Health & Safety and Technical Notes Section Below For Additional InformationDokument5 SeitenRefer To Health & Safety and Technical Notes Section Below For Additional InformationĶxňğ ŘeňňyNoch keine Bewertungen

- Argento Me TryDokument5 SeitenArgento Me TryGino GalanoNoch keine Bewertungen

- Physical Chemistry Laboratory I Experiment 3 Effect of Ionic Strength On The Solubility of CasoDokument6 SeitenPhysical Chemistry Laboratory I Experiment 3 Effect of Ionic Strength On The Solubility of CasorajNoch keine Bewertungen

- Lower 6 - Lab 4 Redox TitrationDokument3 SeitenLower 6 - Lab 4 Redox TitrationYvonne RagguettNoch keine Bewertungen

- Advanced Pharmaceutical analysisVon EverandAdvanced Pharmaceutical analysisBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresVon EverandThe Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresBewertung: 5 von 5 Sternen5/5 (1)

- The Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterVon EverandThe Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterNoch keine Bewertungen

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesVon EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesNoch keine Bewertungen

- A Further Investigation of the Symmetrical Chloride of Paranitroorthosulphobenzoic AcidVon EverandA Further Investigation of the Symmetrical Chloride of Paranitroorthosulphobenzoic AcidNoch keine Bewertungen

- Emergency Psychiatry: Care in Special SettingsDokument15 SeitenEmergency Psychiatry: Care in Special SettingsCassandra BoduchNoch keine Bewertungen

- Eating Disorders: Evaluation and Management: Key PointsDokument21 SeitenEating Disorders: Evaluation and Management: Key PointsCassandra BoduchNoch keine Bewertungen

- Biol 2334 - Molecular Biology Translation WorksheetDokument3 SeitenBiol 2334 - Molecular Biology Translation WorksheetCassandra BoduchNoch keine Bewertungen

- Series Convergence/Divergence Flow ChartDokument2 SeitenSeries Convergence/Divergence Flow ChartCassandra BoduchNoch keine Bewertungen

- Elasticity - . .: Is A Measure of How Much Buyers and Sellers Respond To Changes in Market ConditionsDokument52 SeitenElasticity - . .: Is A Measure of How Much Buyers and Sellers Respond To Changes in Market ConditionsCassandra BoduchNoch keine Bewertungen

- KarcherDokument21 SeitenKarcherSIVARAMANJAGANATHANNoch keine Bewertungen

- Sistema A-101 LVSDokument4 SeitenSistema A-101 LVSAdministrador AngloNoch keine Bewertungen

- Interior Plains Unit PlanDokument6 SeitenInterior Plains Unit Planapi-256482747Noch keine Bewertungen

- Prescriptions For Closing The Seven Service Quality GapsDokument1 SeitePrescriptions For Closing The Seven Service Quality GapsReema NegiNoch keine Bewertungen

- PQA824 ManualDokument100 SeitenPQA824 ManualElkin AguasNoch keine Bewertungen

- 688 (I) Hunter-Killer - User ManualDokument115 Seiten688 (I) Hunter-Killer - User ManualAndrea Rossi Patria100% (2)

- Wbuhs PG ThesisDokument7 SeitenWbuhs PG Thesisgbx272pg100% (2)

- Mini Riset Bahasa Inggris BisnisDokument10 SeitenMini Riset Bahasa Inggris BisnissyahsabilahNoch keine Bewertungen

- Loading and Hauling Dump Truck: DumperDokument2 SeitenLoading and Hauling Dump Truck: DumperRJNoch keine Bewertungen

- CV LeTranNguyen enDokument4 SeitenCV LeTranNguyen enLe Tran NguyenNoch keine Bewertungen

- MoveInSync Native Android Mobile AppDokument12 SeitenMoveInSync Native Android Mobile AppRismaNoch keine Bewertungen

- 107 01 Covers and Side Doors A SideDokument38 Seiten107 01 Covers and Side Doors A Sideben vervuurtNoch keine Bewertungen

- Brochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Dokument2 SeitenBrochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Fernanda RizaldoNoch keine Bewertungen

- Definition, Scope and Nature of EconomicsDokument29 SeitenDefinition, Scope and Nature of EconomicsShyam Sunder BudhwarNoch keine Bewertungen

- Michael S. Lewis-Beck-Data Analysis - An Introduction, Issue 103-SAGE (1995)Dokument119 SeitenMichael S. Lewis-Beck-Data Analysis - An Introduction, Issue 103-SAGE (1995)ArletPR100% (1)

- Embargoed: Embargoed Until April 24, 2019 at 12:01 A.M. (Eastern Time)Dokument167 SeitenEmbargoed: Embargoed Until April 24, 2019 at 12:01 A.M. (Eastern Time)Las Vegas Review-JournalNoch keine Bewertungen

- Galaxy A8 User ManualDokument193 SeitenGalaxy A8 User ManualHüseyin ACARNoch keine Bewertungen

- Renaissance QuestionsDokument3 SeitenRenaissance QuestionsHezel Escora NavalesNoch keine Bewertungen

- Product-Oriented Learning Competencies: (Beginner)Dokument4 SeitenProduct-Oriented Learning Competencies: (Beginner)Kri S ELNoch keine Bewertungen

- Experiment #3 Venturi Meter: Home Unquantized ProjectsDokument7 SeitenExperiment #3 Venturi Meter: Home Unquantized ProjectsEddy KimathiNoch keine Bewertungen

- THDP-3 Worm Gear Manual Interchangeable Single Punch Tablet PressDokument8 SeitenTHDP-3 Worm Gear Manual Interchangeable Single Punch Tablet Pressdibimrane13Noch keine Bewertungen

- NAAC 10.12.1888888 NewDokument48 SeitenNAAC 10.12.1888888 Newచిమ్ముల సందీప్ రెడ్డిNoch keine Bewertungen

- 2 Design Thinking - EN - pptx-ALVDokument18 Seiten2 Design Thinking - EN - pptx-ALVSalma Dhiya FauziyahNoch keine Bewertungen

- 3949-Article Text-8633-1-10-20180712Dokument10 Seiten3949-Article Text-8633-1-10-20180712Volodymyr TarnavskyyNoch keine Bewertungen

- Business Design Thinking - Nguyễn Quang MinhDokument39 SeitenBusiness Design Thinking - Nguyễn Quang MinhbuikimhoangoanhtqkNoch keine Bewertungen

- Quotation Request Form: Customer DetailsDokument1 SeiteQuotation Request Form: Customer DetailsAmanda RezendeNoch keine Bewertungen

- Oracle Pac 2nd KeyDokument48 SeitenOracle Pac 2nd KeyKrishna Kumar GuptaNoch keine Bewertungen

- AKIM Mühendislik - Primavera Türkiye - Earned Value Analysis - v2Dokument1 SeiteAKIM Mühendislik - Primavera Türkiye - Earned Value Analysis - v2Ece GürtekinNoch keine Bewertungen

- El Nido RW 33 Headwind 1120 + CLWDokument2 SeitenEl Nido RW 33 Headwind 1120 + CLWRanny LomibaoNoch keine Bewertungen

- KIT REQUEST FORM - GradDokument2 SeitenKIT REQUEST FORM - Graddamie aadamsNoch keine Bewertungen