Beruflich Dokumente

Kultur Dokumente

ABC Fuel Injection

Hochgeladen von

hasindu123Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ABC Fuel Injection

Hochgeladen von

hasindu123Copyright:

Verfügbare Formate

THE

fo'," 12.(8 I.r.s.

',int.d II. U. S.A.

OF

FUEL INJECTION

A ROCHESTER SERVICE TRAINING TEXT Roche.ter Products Dlv.

Gen. Motors Corp.

Rochester, N. Y.

www.Arbumor-mlnUII.com

file:///C|/Documents%20and%20Settings/Tim/Desktop/carburetor-manual-welcome/index.htm[4/25/2009 11:42:20 AM]

w w w .car bur et or - manual .com

Would you like some Free Manuals?

ht t p: / / carburet or- manual. com/ free- shop- manual- club- t - 13. ht ml

Also visit ht t p: / / freeshopmanual. com for more Free Manuals

Al so Vi si t my w ebsi t e f or 7 FREE Dow nl oad Manual s st ar t i ng

w i t h t hi s one.

" The ABC' s of Car bur et i on"

Cl i ck Her e Now

WHAT

IS

FUEL

INJECTION

F uel [nject ion is a means of supplying fuel and ai c

to a n engine. T hough its job is simil ar 10 ca rburet ion

it is much more effi Cie nt in many ways. From the

illustration you call see that the most notable difference

from carbureti on is that the fuel is not mixed with the

air until the ai r has very nearly reached the cylinder,

In the carburetor fuel and air are mixed in the venturi

and the inta ke manifold t ra nsports the mi xture to the

cylinders: in a fuel injection system the manifold carries

only a ir a nd t he fuel is sprayed under pressure into t he

ai r stream. either at the intake valve port or in the

cylinder itself . The big di ffer ence is in the fact

that the manifold is not required to transport fuel/alr

mixture. It has been manifold limitations which have

ca used many carburetion problems and which led GM

engi neers to develop a new fuel injection system.

CARBURETl QN

!

FUEL FLOWS

DIREC1L'Y.'"T"O, uu. ,. ,,Jl ;,.1:-_1'"

VENTURI'

FUEL INJECTION

POINT OF

MIXTURE

111

111 11 lil t> wlty F.l?

Carburetors have come a

long way over the past years.

and engi neering and produc-

tion methods have combined

FUEL DISTRIBUTION

One of the most important advantages of fuei

jection is its abili ty to divide the fuel equally between

a ll cylinders. From the illustration showing an

aggerated manifold, it can be seen. that when

the ma nirold carries fuel/air mixture to a variety of

sizes 3 11 d lengths of passages. it is very diffi cult to feed

eac h cylinder in equal ilmounts. As a martel' of fact .

it would not be uncommon to have 15 0/0 difference in

Iuel /air ratio between the leanest cylinder and the

richest cylinder of a given engi ne with a carbureted

fu el system. The mOl in difficulty is that air is quite

ing to How around corn.ers and through various shaped

passages but the fuel. being heavier. is bot hered by

obst ruct ions. curves, etc. In fuel injection fuel can be

fed under pressure through a set of calibrated nozzles.

one fOr each cylinder so that t he fuel charge for

cylinder is virt ually equal.

YOll c.an see that i n. the carburet ed system it would

be necessary to supply mixtures rich enough so that no

cylinders were too lea n. which means tha t t here would

be waste in the cylinders which We fe a lready rich

enough. T he en9ine equi pped wit h fuel inj ection can

often be r un as much as 10';'(; leaner than it would

have to be with a ca rburetor and manifold.

ti ons which ca n be

CARBURET10f<

to produce carburetors which

get the most possible out of

an engi ne. Carburet ion does,

however. have some limita-

overcome ,by fuel injection.

IFUEl DISTRIBUTION I

www.CI!rburetor-m.nu.l.com

AIR FLOW

In a carbureted fuel system the intake manifold

must strike a happy medium between low and high

speed requiremeDts. At idle for " instance. air flow is

very slight and in order to keep the gasoline mjxed with

the air, it is necessary to have small passages to keep

up the air velocity. On Ibe other hand. when power is

required. we would like to have as big a manifold

passage as possible. to allow ma ximum breathing of the

engine. Naturally. to suppl y both of these requirement s,

the maJ1.ifold mUSt be a compromise between small and

large passages and results -in passages of medium size Q

which limit both the low and high speed performance.

but provide enough of each to get by.

In the case of fuel injection, the manifold does not

have to carry a fuel/air mixture and. therefore, can be

designl'd to give the best breathing possible .. In fact

the manifold can be made to actually supercharge the

engine at certain speeds. This is done by haVing a

ram pipe for each cylincfer so that the air on its way to

the cylinder will be traveling in a long column.

while the val ve is open and air is entering the cylinder,

the air flow gets quite a lot of momentum in the ram

pipe. As the piston reaches bottom dead center and

starts back up. air will continue to Bow into the cylinder

because of air velocity in the ram pipe. At the particular

engine speed where the va lve just closes as the air stops

flowing. an ext ra cha rge of air has heen trapped in the

cy linder. This effect is caHed dynamic super charging;

by design of the ram tubes a particular engine speed

can be picked fOf this effect to occur and quite a boost

in torque results at that pa rticular point .

MIXTURE HEATING

In a carburetor. mixture temperature is a problem

during cold operation and it is necessary to bring

exhaust heat through the heat riser in the exhaust

manifold up to the base of the carburetor during r\

up. The unfortunate part is that this heat remains even II

when the engine is warm and often leads to vapor

troubl e, in addition to requiring periodic service to

clean out the heat passages.

In fuel injection. on the other hand. fuel and air are

actually mi xed in a very warm part of the engine and

no extra heat is required during warmup.

HORSEPOWER

Many engineers fee l ,hat we are approaching

practical limits of carburetion in size of venturi , number

of cores. etc., and of course the fartbe.f we go in th.is

direction the more diffi cult it becomes to maintain

ciency in the. part throttle operation. r\

Since a fue.l injection system could supply almost II

unlimited quantities of fuel and air. more efficient

engine pert"ormance can be reali zed with today's

engines. This allows considerable room for further

advances in engine design .

C"' !!8UI'I!TlON

fIJJ-

7r

.Cfu.ol MUI' C'I.O II ..

IDCr l'OWU

CARIIURETION

tu" UU.'KIHI

CAUl " V"'O.

'UEL INJECTION' R ... '" EFHCT

aUDIlE VALYE

CLOSEt

FUEL INJECTION

HORSEPOWER

CAf'leUIt(TIOM FUEl. IN.lECTtON

IIIUC" tREATER FllliL AND .. IR

C.'ACITY

www.clrburetor-mlnull.com

HEIGHT

Styling of todays car has obviously become a very

important factor and one of the trends is toward lower

hood lines. Carburetor and air cleaner heights have

been reduced year a fter year until it seems almost L(

possi ble to build them any lower, 5i n<;e fuel inje<:tion

does not require a down draft of ai r intake, it olfers

interesting possibilities in being able to reduce height

for future styling requirements.

OTHER ADVANTAGES OF FUEL INJECTION

Since fuel delivery does not depend on level of fuel

in a bowl. operation of the fuel injection system is very

little affected by maneuvers like tight turns and sleep

bill climbing.

Since the fuel is sprayed into the wa rm part of 'the

engine. much less extra fuel is required before the

system is operating at normal performance.

Response to the throttle is instantaneous since the

fuel is under pressure at al1 times and needs only to

be released for acce.Jeration.

Another possibility in fuel injection is that fuel.

si nce it is suppli ed separately from the air. can be shut

off completely durng deceleration if des ired. This could "-

reduce the amount of unburned hydrocarbons exhausted L{

to the air and could also offer some improvement in fuel

economy.

TYPES OF FUEL INJECTION SYSTEMS

Different fuel injection systems can be described in

two ways by where the fuel is injected and by

whether it is timed or continuous in flow.

O ne system which has been in use for many years

Is the timed direct cylinder injection such as used in a

Diesel engine, where the nozzle is right in the

bustion chamber and sprays fuel into the chamber when

the piston reaches top dead center on compression. This

system has been success full y used on Diesel engines

but involves rather complicated and expensive timing

deVices and pump equipment.

A second system is timed port injection which is

currently offered by several manufacturers. The nozzle

is located in the intake port and sprays fuel toward the

intake valve whenever the val ve is open. The ti ming

equipmem required is still rather and there is

some question as 10 whether the timing of the discharge

has enough advantages to offset the additional cost.

Continuous flow port injection has been used for

some time as an accessory for racing application. Fuel

is sprayed continuously into the intake port at such a

rate that a full charge is delivered over a complete cycle

oE the engine. Since. injection oE this type involves a "-

nozzle with no valve. of any sort. vacuum effects on the V

fuel spray have been a problem. With. pressure behind

the nozzle and a variety of vacuum values ahead of the

nozzle. it has been very difficult to control fuel BoW',

particularly at idle and low speeds.

After testing all the current systems at this time.

GM engineers concluded that continuous flow port in-

jecti on was the most practical system lor American

automobiles. for no system on the market had been

able. to provide the. necessary full range in performance.

Therefore. the GM Technical Center Engineering stan

set to work to design a new continuous flow fuel in-

jection system.

HEIGHT

\

FUEL INJECTION'

MANEUVERABII .. ITY

FASTER WARMUP

INSTANT RESPONSE

COASTING SHUTOFF

ElI"ECT TIMED I_CTION

INJECTIDN

SYSTIII vno n mill)

,

www.Cllriluretor-m.nu.l.com

GM SYSTEM FEATURES

The new fuel injection system is unique in several

respects. The system contains a float controlled fuel

reservoir for the high pressuregea! pump, which

inates the need for a pump overflow line to the gas tank.

With this design there is always fuel available for

starting. Since the gear pump is in the reservoir, no

pump plumbing is required.

To avoid vacuum effects on the nozzle orifice which

have caused previous trouble with continuous flow sys-

tems a vented fuel nozzle was designed in which the

fuel is sprayed directly into atmosphere, across an air

duct and through a small hole into the intake manifold.

With this type of nozzle, vacuum effects arc nearly nil

and positive fuel control at all speeds is possible. Other

features include mechanical simplicity, instantaneous

response, and outstanding performance from low idle

to full power,

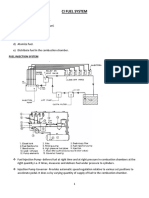

HOW DOES THE GM SYSTEM WORK

The GM system will be explained in the following

text, first by basic principles, in simplified form, then by

tracing each actual system of operation in a typical

fuel injection unit. Since there are minor differences in

various models for different cars, this will be a general

discussion of a typical unit. On the last page of this

booklet is a complete schematic drawing, with all the

systems in their proper place and each important part

identified.

FUEL INJECTION REQUIREMENTS

The fuel injection system has the same old job to

do that the carburetor has been doing so well for so

many years. It is basically a matter of supplying com-

bustible fuel/air mixture at the cylinder for ignition

with a minimum of waste. To be a satisfactory fuel r\

system it must be able to change mixture ratios for L(

power and economy and to provide full performance

throughout the range of cold operation, hot operation.

and all driving conditions. The chief difference be-

tween fuel injection and carburetion is that fuel in-

jection is able to do all these things more efficiently with

potential incrcc.ses in bOth economy and performance.

NOZZLE PRINCIPLE

In the injection system for a typical 8 cylinder

engine, fuel is supplied through 8 matched nozzles, each I)

of which contains a calibrated orifice. Fuel flow at the

nozzle depends on the pressure pushing the fuel; there-

fore. the control system for combining fuel with air will

be a matter of regulating the fuel pressure to match the

amount of air flowing.

6

G M SYSTEM FEATURES

FUEL RESERVOIR

NO RETURN LINE NEEDED

VENTED FUEL NOZZLE

ELIMINATES VACUUM EFFECTS

OM

MECHANICALLY SIMPLE

INSTANTANEOUS RESPONSE

OUTSTANDING

CURB IDLE TO fUll POWER

BASIC JOB - FUEL lAIR MIXTURE

REQUIREMENTS- COMBUSTIBLE MIXTURE

- POWER 6 ECONOMY CONTROL

- FULL PERFORMANCE RANGE

INJECTION NOZZLE PRINCIPLE

DEPENDS ON

THE PRESSURE

www.Cllrbumor-m.nu.l.com

BASIC FUEL CONTROL

Air entering the system passes through a venturi

and causes a vacuum which indicates directly the

amount of air flow. This venturi vacuum, plus the load

on the engine, as indicated by manifold vacuum,

vides a control signal which indicates how much fuel r\.

pressure should be supplied for the correct fuel/air L{

ratio. If air flow increases fuel pressure must increase.

If engine load increases fuel pressure must increase.

When air flow or engine load decreases, pressure is

decreased also so that fuel flow is less. Therefore, fuel

flow will always be in relation to the amount of air that

is flowing and the load on the engine.

The GM system has three basic parts - (1) the

air meter, which must supply air in answer to the

driver's foot and send a control signal to the fuel meter:

(2) the fuel meter which pressurizes the fuel and feeds

the correct pressure to the nozzles in answer to the

control signal from the air meter; (3) the intake

fold supplies air from, the air meter to the engine and

contains a ram pipe for each cylinder. The following

is a description of these basic parts.

FUEL SUPPLY

As shown in the drawing, the fuel meter contains Q

a float controlled fuel bowl. very similar to those used

in carburetion. Fuel is supplied to the fuel meter by a

conventional diaphragm type pump and passes through

a ten micron filter before it reaches the fuel meter. Fuel

from the fuel valve splashes directly into the inlet cup

where it spills over more evenly into the fuel bowl to

avoid getting bubbles in the fuel which might be picked

up by the gear pump. Float level although important

is not as critical as in carburetion because the reservoir

is merely a supply for the gear pump.

HIGH PRESSURE GEAR PUMP

In the fuel bowl is a close tolerance gear pump

which is driven by a flexible drive shaft from the Q

trical distributor at 1/2 engine RPM. The gear pump

can supply pressures as high as 400 P.S.I, and has

about twice the capacity of normal engine require-

ments at any speed. Fuel which is not supplied to the

nozzles by the metering system, is spilled back into

the bowl.

VENTURI VACUUM MEASURES AIR FLOW;

FUEL PRESSURE IS REGULATEO TO FIT

AIR FLOW a LOAD CONDITIONS

BASIC FUEL CONTROL

FUEL. INL.ET""""'-::

FROM SUPPL.Y

PUMP

FUEL. INLET

VAL.VE

GEARS DRIVEN

BY SHAFT FROM

DISTRIBUTOR

GEAR

PUMP

FUEL BOWL

INTAKE

GEAR PUMP

FL.OAT

PRESSURE

TO NOZZLES

7

WWW.Cllrburetor-m.nu.l.com

I I

FUEL

PRESSURE

CONTROL

I I

FUEL PRESSURE

CONTROL

Pressure from the gear pump must be regulated to

provide the right flow at the nozzles. Fuel in the meter-

ing system can go either io the nozzles or through

another passage back to the bowl. through spill ports.

The quantity delivered is controlled by a plunger which

moves vertically to close or open the spill ports. In

other words, if high spill is allowed delivery pressure

is lowered or if low spill is allowed delivery pressure

is raised. For high fuel flow high pressure would he

needed and the spill plunger would be moved down to

cover the spill ports and force more fuel through the

THROTTLE

HIGH SPILL :

J .- PRESSORE

TO NOZZLES

.4\\\\ HEAVY THROTTLE

,

,

,

LOW ____ HIGH

SPilL

....... TO NOZZLES

nozzles. For low flow the spill plunger would be raised

so that more fuel is allowed to spill and there is less

pressure to the nozzle3. As shown in the illustration

you could imagine the spill plunger position as being

a direct result of the driver's foot on the accelerator

pedaL When the driver pushes the accelerator and

asks more power, the plunger moves downward to raise

the fuel pressure. On the other hand. when the driver

lets up on the accelerator. the spill plunger rises and

decreases the fuel pressure.

Fun CONTROL

DI .... PH" ... G ..

CONTROL SIGNAL

VACUUM

I I

CONTROL

LINKAGE

I I

RATIO

LEVER

SPILL

I

II

___

I

CONTROL

LlNI(

CONTROL

LINKAGE

COUNTRWEIGHT

FUEL CONTROL

LEVER

LINIC 110\1[$

"'

I FUEL CONTROL SYSTEM I

Of course the accelerator pedal is not directly

nected to the spill plunger. Fuel control is accomplished

by a very precise linkage system which is shown in the

illustration. One end of the fuel control lever rests

directly on the spill plunger and controls spill plunger

position. The other end of the lever is connected by

a link to the control diaphragm and the lever pivots

around another part which is called the ratio lever.

When the diaphragm pulls the link upward, the lever

end pushes downward on the spill plunger to increase

fuel pressure. When the diaphragm allows the link to

fall, fuel pressure forces the spill plunger upward to

open the spill ports and lower fuel pressure. This

age system is so deSigned that it will balance at the

particular point where the fuel pressure is correct for

the amount of pull on the diaphragm. The linkage

system is carefully counter-balanced so that the only

forces acting are fuel pressure and diaphragm vacuum.

The small counterweight balances the weight of the

fuel control lever itself. The large counterweight

pensates for the weight of the entire system including

the diaphragm. This precise balance is necessary if

there is to be a quick reaction to slight vacuum changes

on the diaphragm. The ratio of diaphragm vacuum to

fuel pressure and thus the fuel/air ratio, can be

trolled by the location of the pivot point or the ratio

lever. Moving the ratio lever changes the mechanical

advantage of the linkage system. For normal driving

the ratio lever is in a fixed position and fuel pressure

is a result of control diaphragm vacuum When mixture

enrichment is required the ratio lever is moved to

change the mechanical advantage of the fuel control

lever and thus change the fuel/air ratio .

www.Cllrbumor-m.nu.l.com

AIR METER

The two main parts of the air meter are the throttle

and the venturi. The throttle controls' the flow of air

into the system and is connected directly to the aceel

era tor through linkage. The venturi is a little different rl\

from the familiar type in which air enters through the L,I

center. It is a very high efficiency venturi and consists

of a cone shaped diffuser suspended in the bore of the

a ir meter. so that air can pass between the outside of

the cone a nd the inside of the a ir meter bore. This

type of venturi has hardly any restrktion to air Row

which is a vital factor in breathing capacity.

CONTROL SIGNAL

Around the venturi is a groove which is open to

venturi vacuum. Venturi vacuum is a measure of air

flow and is used as a control signal, through a tube [)

to the control diaphragm of the fuel meter. Since the

ventuti vacuum will always be a direct measure of the

amount of air Bowing, the metering system can be

calibrated to feed a certain fuel pressure for a certain

venturi vacuum, t hereby get the correct fuel/air

rat io to t he cylinders.

AIR FOR IDLE

For idle the throttle valve is left closed in the bore

and ai r is taken through a bypass around the valve

and this idle air is regulated by a large idle air [)

ment screw. Engine idle speed then can be controlled

by turning this screw in or out to decrease or increase

engine speed. In addition to the ai r through this bYF

pass. a portion of the idle air enters directly through

the air duct io each nozz le.

AIR TO

MANlfOLO

---------1

,

,

,

THROTTLE I

VALVE

SIGNAL TO

FUEL METER

lAIR!

IFUEL CONTROL SIGNAL I

"'"

, 1 V r "'" """

"" '" /

BY"''''' --

VAl.V' 10L Alit

'''''' 'f.iIlilA

NOllL[ AlII

TO Io1ANIfOLO

TtlIltAMIFOLD

-c:>-

I IDLE AIR FLOW I

,

www.Cllrbumor-m.nu.l.com

LOW AIR FLOW ---- LOW SIGNAL

FUEL METER ,-__

IDLE SIGNAL IDLE CONTROL SIGNAL

IDLE CONTROL SIGNAL

At idle speeds and low thrcttle opening. air flow through the venturi is

so slight that there is very little venturi signal. Since we must supply slightly

richer mixtures for idle operation. additional vacuum is introduced into the

signal system to increase the fuel pressure slightly. The passages shown in

the air meter very much resemble the idle system in a carburetor. Below the

throttle valve the idle system is opened to manifold vacuum. The amount of

vacuum allowed to affect the system is controlled by an idle Just above

the throttle valve is a small hole which acts as a bleed at idle and as a vacuum

source when the throttle valve is slightly open. Vacuum in the idle system

is supplied to the diaphragm through a signal tube. The venturi signal and

idle signal come together in a "T" fitting at the control diaphragm. At idle

and very low speeds the idle signal system provides most of the control signal.

As the throttle valve opens manifold vacuum drops and venturi- vacuum

creases so that the venturi control signal becomes the more important signaL

IDLE CONTROL SIGNAL DECREASES

FLOW INCREASES

RESTRICTION

DELAYS IDLE

SIGNAL DROP,

BOOSTS TOTAL

SIGNAL

MANIFOLD VACUUM

ON IDLE PORTS ____ -'

DECREASES

VALVE

OPENS QUICKLY

MOMENTARY

PRESSURE

INCREASE FOR

I ACCELERATION I ACCELERATION

ACCELERATION

At normal driving speeds acceleration is instantaneous. To

prevent any possible lag at lower speed the signal system contains

a restriction in the idle signal line which retains a momentary high

signal at the diaphragm whenever the throttle is opened quickly.

As the throttle is opened the venturi signal increases immediately

and the idle signal drops off. The restriction in the idle signal

line forces the signal to stay higher momentarily until it bleeds

through the restriction so that there is a slight boost in signal

for acceleration.

"

www.Cllrbumor-m.nu.l.com

,- --------------

POWER

..

HIGH

'==" ... LOW MANIFOLD '-__ -'

VACUUM -

FOR POWER

THROTTLE VALVE

WIDE OPEN

I POWER ENRICHMENT I

For power operation richer mixtures are necessary and can be obtained

by moving the ratio lever. SiDce manifold vacuum is the best indication of /' ./

power requirements, the ratio lever is connected to a diaphragm which reacts ./

to manifold vacuum. When the "load is light and the vacuum is high. the ratio, /' fi" c

lever remains in economy position. When the vacuum drops with an increase !f

in engine load, a calibrated spring behind the diaphragm moves the ratio lever .. (

to power position. The mixture limits of economy and power ratios arc

at the factory by stop screws which limit the movement of the enrichment

linkage.

THROTTLE VALVE

CLOSED DURING

DECELERATION

COASTING SHUT-OFF

MANIFOLD VACUUM

HIGHER THAN USUAL

PUMP DISCHARGE

RETURNS TO

FUEL BOWL

I COASTING SHUT-OFF I

In those units which use the coasting there is a spring loaded

valve in the high pressure gear pump. During normal operation the spring

keeps the valve closed so that full pressure is delivered to the metering system.

Whenever deceleration causes higher than normal vacuum, a diaphragm

comes the spring and lifts the valve and allows gear pump delivery to return

to the bowl so that there is no pressure on the metering system. Thus fuel

can be cut off completely except when power is actually required from the

engine.

FUEL

NOZZLES

"

www.Cllrbumor-m.nu.l.com

THERMOSTATIC

COIL

)

ROTATION OF

IOLE SIGNAL

CONTROL SIGNAL IS

INCREASED "::Y.NR"jOcOi;jS,Ti,wf

FROM COLD t.1

SYSTEM

VACUUM

'"U'RlN:. OFF

o COLD

OPERATION, SO

DIAPHRAGM STAYS

IN RICH POSITION

FUEL PRESSURE IS

INCREASED DURING WARMUP

LEVER DURING WARMUP

I COLD ENRICHMENT I

COLD ENRICHMENT

In the lue! inject ion system there is no choke as

such. Cold enrichment is obtained by adding more

fud rat her t ha n chokingoff t he air. In the GM system

two methods are used for cold enrichment : one simply

shuts off vacuum to the power enrichment diaphragm

so t ha t power mixtures are used until the ca r is w;]fmed

up; the ot her introduces manifold vacuum into the

Signal system for a n additional signal boost during cold

operati on. In various applicati ons bath systems are

used separately or together. The illustration shows a

system which will use a signal boost and power enrich-

ment . If one Of the other only were used it would

simply be a matter of eliminating one valve and one

tube. In t he sys tem shown. vacuum for starting the

"

. - . - ~ -

engi ne would fi rst pull the piston completely down and

hold it there, which would index the lever to open t he

boost va lve just the r ight a mount and would a lso move

the externa l linkage to set the fast idle calJl on t he

s.cond step posi tion. Ge nerator current heats a re-

sistance element in t he thermostat cover which heats

the t her mostati c coil until it begins to relax. As the coil

rel axes the leve r graduall y moves until the hleed is

closed. At this poi nt there is no further signal boost but

power enrichment is st ill used because manifol d vacuum

to the enric hme nt diaphragm is blacked by the spring

loaded check ball . As the coil warms up still more.

the lever opens the ball check va lve to allow vacuum to

the enri chmenl dia phragm and return the system to

normal economy opera tion .

WWW.CIIrburetor-m.nu.l.com

BYPASS LINE

AT fU PUMP

PLUNGER fORCED DOWN,

SHUTS OFF SPILL

STARTING SYSTEM

PRES

PLUNGER MOVING

'-..... DOWN OPENS FUEL

VALVE TO ADMIT

FUEL FROM BYPASS

LINE

Por cold starting u tra fuel is needed to make up for poor

fuel evaporat ion. At cranking RPM [he gear pump deli very is

often not enough for cold starting, so fuel pump prl"!.'isu.re is taken

directly from the fuel inlet to the fuel meter through a tube to

the fuel metering system. A solenoid energized by the starter

circuit pushes the spill plunger down to eliminate all spills and

also open the fuel valve itself so that the starting bypass line can

supply fuel directly to the metering system. As soon as the

engine- starts, the system reverts to normal operation.

ENERGIZED

STARTER CIRCUIT

FUEL TO

NOZZLES

AT fUEL PUMP

PRESSURE

I COLD STARTING I

NO CURRENT TO BYPASS SOLENOID

TO STARTER

CIRCUIT

""--1" \ t <0

THROTTLE OPEN

OPEN THROTTLE

OPERATES SWITCH,

BREAKS CIRCUIT TO

BYPASS SOLENOID

HOT STARTING AND UNLOADING

UNLOADING

,

ONLY GEAR PUMP

PRESSURE TO

NOZZLES

For hot starting extra fuel is definitely not needed

or desi rable, To keep the solenoid from operating, a

micro switch is provided so tha t when the throttle valve

is open there is no current to the solenoid. With this

particular type of starting mechanis m it is important

that proper procedure be used for both cold starts and

hot starts. For cold starts the. accelerator should be

depressed once and then released. allowing the throttle

to be pre-set for starting by the fast idle cam. Further

opening of the throttle would de-choke the system and

prevent starting. For hot starting, the throttle s hould

be opened until the micro switch breaks the circuit to

the starting solenoid so that ext ra fuel is not ' int roduced

into the system, On t he following two pages are

complete d!:':tails of a typical GM fuel injection system.

Each important part is numbered and each number is

li sted on the opposite page with the part name and

function.

"

www.carburctor-m.nu com

INDEX FOR COMPLETE SCHEMATIC DRAWING

ON NEXT PAGE

1. Fuel Inlet Strainer 21. Starting Solenoid Lever 41. Off-Idle Port

2. Needle and Seat 22. Signal Line Restriction 42. Venturi Diffuser Cone

3. Splash Cup 23. Enrichment Control Rod 43. Idle Signal Needle

4. Coasting Shutoff Valve 24. Power Mixture Limit Stop 44. Idle Signal Tube

5. Gear Pump 25. Enrichment Lever 45. Venturi Signal Tube

6. Starti ng Bypass Fuel Line 26. Economy Mixture Limit Stop 46. Airflow Sensing Groove

7. Coasting Shutoff Diaphragm 27. Enrichment Control Spring 47. Manifold Vac. to Vent & C.S.O.

8. Bowl Vent to Manifold 28. Enrichment Control Diaphragm 48. Vacuum to Enrichment Diaphragm

9. High Pressure Fuel Valve 29. Starting Bypass Solenoid 49. Unloadee Switch

10. Fuel Valve Inlet Strainer 30. High Pressure Fuel Line 50. Throttle Levee

11 . Metering Linkage 3 I . Fuel Distributol' 51. Vacuum to Air Meter Passages

12. An ti-percolation Check Ball 32. Nozzle Lines 52. Fast Idle Cam

13. Spill Return to Bowl 33. Solenoid Wire 53. Signal Boost Tube

14. Spill Port 34. Fuel Nozzle 54. Locating Piston

15. Spill Plunger 35. Ram Tube 55. Signal Boost Valve

16. Ratio Lever 36. Intake Manifold 56. Thermostatic Coil

17. Control Diaphragm Link 37. Idle Air Bypass 57. Enrichment Vacuum Valve

18. Control Linkage Counterweight 38. Idle Air Adj. Screw 58. Cold Enrichment Lever

19. Fuel Control Lever 39. Venturi 59. Wire to Starting Circuit

20. Fuel Control Diaphragm 40. Idl e Signal Port

-

1

2 11r:

" -

5

II

"

7

50 ~

,

51-

,

6

ROCHESTER - G M

FUEL INJECTION SYSTEM

TYPICAL SCHEMATIC

5

8

Das könnte Ihnen auch gefallen

- Marvel-Schebler Carburetor Repair ManualDokument21 SeitenMarvel-Schebler Carburetor Repair Manualbedford24100% (14)

- Fiat 126 BIS General InformationDokument291 SeitenFiat 126 BIS General InformationUmur GüngorNoch keine Bewertungen

- Bosch - Efi Fuel Injection Systems - Ingles - 140pgsDokument142 SeitenBosch - Efi Fuel Injection Systems - Ingles - 140pgsreleitefNoch keine Bewertungen

- How MRD Fuel Injection WorksDokument6 SeitenHow MRD Fuel Injection WorksMichael MespreuveNoch keine Bewertungen

- Instruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionDokument42 SeitenInstruction and Maintenance Manual For Alfa Romeo 2000 Fuel Injection Models U.S.A. VersionVladimirNoch keine Bewertungen

- 001 - Common Rail Diesel 1Dokument25 Seiten001 - Common Rail Diesel 1Encik Rafa BenitezNoch keine Bewertungen

- Combined Ignition and Fuel Control System, Petrol EnginesDokument16 SeitenCombined Ignition and Fuel Control System, Petrol EnginesNandakumar BasavarajNoch keine Bewertungen

- Upvc Door: Side View ElevationDokument1 SeiteUpvc Door: Side View ElevationSNEHA DEVARAJU100% (1)

- 29 Junet Babu CRDi 3Dokument20 Seiten29 Junet Babu CRDi 3Jaiveer YadavNoch keine Bewertungen

- Fuel Injection SystemsDokument37 SeitenFuel Injection SystemsKaran Umralkar100% (4)

- Fuel Injection System of Diesel EngineDokument26 SeitenFuel Injection System of Diesel EngineAbdul MannanNoch keine Bewertungen

- Stanadyne Pump Diagnostic Troubleshooting PDFDokument3 SeitenStanadyne Pump Diagnostic Troubleshooting PDFOctavio RamosNoch keine Bewertungen

- AKTraining DesbloqueadoDokument61 SeitenAKTraining DesbloqueadoJUAN JOSE LOPEZ LOJANoch keine Bewertungen

- Stanadyne Pump Diagnostic Troubleshooting PDFDokument3 SeitenStanadyne Pump Diagnostic Troubleshooting PDFOctavio RamosNoch keine Bewertungen

- Common Rail ReportDokument4 SeitenCommon Rail Reportnuwan_nishaNoch keine Bewertungen

- Car PartsDokument12 SeitenCar PartsSemir Nadzakovic100% (1)

- Training Program For Automotive Technolog y 2019 - 2020: Southeast AsiaDokument11 SeitenTraining Program For Automotive Technolog y 2019 - 2020: Southeast AsiaJanne PuhakkaNoch keine Bewertungen

- AT 43 CH 24 Fuel Injection System DiagnosisDokument30 SeitenAT 43 CH 24 Fuel Injection System DiagnosisGODNoch keine Bewertungen

- Makalah Wirausahawan SuksesDokument6 SeitenMakalah Wirausahawan SuksesSurya IrawanNoch keine Bewertungen

- The C.I. Fuel System: OutlineDokument51 SeitenThe C.I. Fuel System: OutlineDanang Aji NugrohoNoch keine Bewertungen

- Diesel Engine Vs Petrol EngineDokument5 SeitenDiesel Engine Vs Petrol EngineAshutosh SinghNoch keine Bewertungen

- Operation 1Dokument9 SeitenOperation 1Wbamlak AshebrNoch keine Bewertungen

- Solenoid Valve Colis For Siemens Continental VDO Common Rail Injector A2C59517051 BK2Q9K546AG and Other Vdo InjectorDokument8 SeitenSolenoid Valve Colis For Siemens Continental VDO Common Rail Injector A2C59517051 BK2Q9K546AG and Other Vdo InjectorWinston Wolf0% (1)

- Fuel InjectionDokument37 SeitenFuel InjectionBence M ZoltanNoch keine Bewertungen

- High-Pressure Common-Rail Fuel InjectionDokument6 SeitenHigh-Pressure Common-Rail Fuel InjectionAndi Anzar0% (1)

- Fuel Injection SystemDokument22 SeitenFuel Injection SystemAlkaf Quraishi100% (2)

- Qip Ice 12 Fuel Injection SystemsDokument40 SeitenQip Ice 12 Fuel Injection SystemsAnonymous eyxVFR100% (1)

- Common RailDokument11 SeitenCommon RailnitishghosalNoch keine Bewertungen

- Repair VP 44 PumpDokument11 SeitenRepair VP 44 PumpBenji Guardo100% (1)

- Turning Up A P7100 PumpDokument8 SeitenTurning Up A P7100 Pumpadam_nell_1100% (1)

- Ci Fuel System Notes PDFDokument19 SeitenCi Fuel System Notes PDFNduati JohnNoch keine Bewertungen

- Parts Bulletin: Technical Support Group Product Support DepartmentDokument7 SeitenParts Bulletin: Technical Support Group Product Support DepartmentUserfabian215Noch keine Bewertungen

- 2.fuel SystemDokument41 Seiten2.fuel SystemMech DTUNoch keine Bewertungen

- Diesel in Line Fuel Injection Pumps PDFDokument3 SeitenDiesel in Line Fuel Injection Pumps PDFDavid Spears100% (3)

- Electronic Multipoint Fuel Injection SystemDokument15 SeitenElectronic Multipoint Fuel Injection SystemDIPAK VINAYAK SHIRBHATE100% (1)

- Study Unit - Automotive Cooling SystemsDokument104 SeitenStudy Unit - Automotive Cooling SystemsWalter SarajevoNoch keine Bewertungen

- CRDiDokument18 SeitenCRDiSuhel InamdarNoch keine Bewertungen

- AA Training Programme Guide - 2016 Building Competence For The FutureDokument60 SeitenAA Training Programme Guide - 2016 Building Competence For The FutureAnonymous wpUyixsjNoch keine Bewertungen

- Unit Injector SystemDokument3 SeitenUnit Injector SystemEdidjo Darwin100% (1)

- Fuel Injection SystemDokument20 SeitenFuel Injection Systemjass_dhaliwal92100% (2)

- Fuel Injection SystemDokument9 SeitenFuel Injection SystemJM PraveenNoch keine Bewertungen

- 1995 Model Series NSX/NSX-T Body Repair Manual: WarningDokument1 Seite1995 Model Series NSX/NSX-T Body Repair Manual: WarningCristian CernaNoch keine Bewertungen

- DENSO Diesel Common Rail Sell Sheet D1070 PDFDokument2 SeitenDENSO Diesel Common Rail Sell Sheet D1070 PDFCesar Bayes RamosNoch keine Bewertungen

- Test BenchesDokument7 SeitenTest BenchesAnderson LondonNoch keine Bewertungen

- 1-3-1. Internal View of Bosch A PF 1CQ Fuel PumpDokument44 Seiten1-3-1. Internal View of Bosch A PF 1CQ Fuel PumpAbdallah MansourNoch keine Bewertungen

- Multi Point Fuel InjectionDokument15 SeitenMulti Point Fuel Injectionಶಿವರಾಜ್ ಎನ್Noch keine Bewertungen

- Bosch MaquinasDokument13 SeitenBosch MaquinasnomecNoch keine Bewertungen

- vp44 Pump Detail Schematic PDF FreeDokument7 Seitenvp44 Pump Detail Schematic PDF Freepablo pérezNoch keine Bewertungen

- DFGHJDokument18 SeitenDFGHJsmsm7000Noch keine Bewertungen

- Chapter 1Dokument61 SeitenChapter 1anup chauhanNoch keine Bewertungen

- Fuel InjectionDokument18 SeitenFuel InjectionsavitagupNoch keine Bewertungen

- Theory of Compression EngineDokument3 SeitenTheory of Compression EngineAshokNoch keine Bewertungen

- RET045 SampleDokument9 SeitenRET045 SampleJacob MelladoNoch keine Bewertungen

- Dellorto Carburador Manual Principios Basicos - InglesDokument34 SeitenDellorto Carburador Manual Principios Basicos - InglesDani-meganeboyNoch keine Bewertungen

- Diesel Engine and Steam BoilerDokument0 SeitenDiesel Engine and Steam BoilerChathuranga ManukulaNoch keine Bewertungen

- Unit-Iii Engine Auxiliary Systems: Fuel Feed SystemDokument26 SeitenUnit-Iii Engine Auxiliary Systems: Fuel Feed SystemMuthuvel MNoch keine Bewertungen

- Lecture No5Dokument20 SeitenLecture No5Vishnu SrivastavaNoch keine Bewertungen

- Air-Fuel Requirement in SI Engines: Unit Ii Fuel SystemsDokument62 SeitenAir-Fuel Requirement in SI Engines: Unit Ii Fuel SystemsdurgapriyaNoch keine Bewertungen

- Carburetor ReportDokument7 SeitenCarburetor ReportAly MohamedNoch keine Bewertungen

- IC Engine QuestionsDokument18 SeitenIC Engine QuestionswasemNoch keine Bewertungen

- Basic AcousticsDokument35 SeitenBasic Acousticsw56100% (4)

- ACOUSTICSDokument19 SeitenACOUSTICSWalaa Mohsen MadkourNoch keine Bewertungen

- Strategic Planning A Ten-Step GuideDokument14 SeitenStrategic Planning A Ten-Step Guideearl58100% (1)

- Sanyo - cm21lx8c - (ET) Service ManualDokument33 SeitenSanyo - cm21lx8c - (ET) Service Manualhasindu123100% (2)

- Smart Lighting Product Catalogue 2020 Final SDokument118 SeitenSmart Lighting Product Catalogue 2020 Final SarminsarajevoNoch keine Bewertungen

- Lighting BOQ Offer 14.11.19Dokument3 SeitenLighting BOQ Offer 14.11.19Akd Deshmukh100% (1)

- Question Bank EeeDokument12 SeitenQuestion Bank EeePRASAD MALINoch keine Bewertungen

- Rate ListDokument13 SeitenRate ListUsamaQadirNoch keine Bewertungen

- BSR 2012 Sri LankaDokument82 SeitenBSR 2012 Sri LankaRanga Lakmal Dissanayaka75% (16)

- Dimming of The Light BulbDokument3 SeitenDimming of The Light BulbJayati AgrawalNoch keine Bewertungen

- INV - ReportDokument88 SeitenINV - ReportFincera Home Decor PakistanNoch keine Bewertungen

- 773 e Part BookDokument912 Seiten773 e Part Bookeko sunaryo100% (3)

- Solenoid Coils For Proportional Valves (Solenoid Operated) Types 40-1836 50-1836Dokument2 SeitenSolenoid Coils For Proportional Valves (Solenoid Operated) Types 40-1836 50-1836Dew บุรุษสุดตีนNoch keine Bewertungen

- Gear Tooth Speed SensorsDokument3 SeitenGear Tooth Speed SensorsKartik GvrNoch keine Bewertungen

- KERYS Descripcion PDFDokument33 SeitenKERYS Descripcion PDFHalit Yalçınkaya100% (1)

- IS310 - IS320 Data SheetDokument2 SeitenIS310 - IS320 Data SheetATM SRINIVASANNoch keine Bewertungen

- Chint Serie JXBDokument2 SeitenChint Serie JXBVentas MogroMercNoch keine Bewertungen

- Haynes Fuses FabiaDokument4 SeitenHaynes Fuses FabiadramicaninNoch keine Bewertungen

- Fuji CBDokument1 SeiteFuji CBReymark ClamonteNoch keine Bewertungen

- Introduction of VFD and Its Programming, Faults, Troubleshooting and MaintenenceDokument27 SeitenIntroduction of VFD and Its Programming, Faults, Troubleshooting and MaintenenceDigvijay singhNoch keine Bewertungen

- Manitou MLT 740h LsuDokument14 SeitenManitou MLT 740h LsuCalin SilviuNoch keine Bewertungen

- Disconector enDokument16 SeitenDisconector enSandaruwan DhananjayaNoch keine Bewertungen

- EATON Vol04 - Tab03Dokument135 SeitenEATON Vol04 - Tab03Anonymous Ot5Wg7yAFNoch keine Bewertungen

- Bushings AbbDokument3 SeitenBushings Abbariel celaNoch keine Bewertungen

- New Single Family Home at Nevada Avenue - TakeoffDokument4 SeitenNew Single Family Home at Nevada Avenue - TakeoffMukhtar Case2022Noch keine Bewertungen

- Construction of Syn GeneratorDokument9 SeitenConstruction of Syn Generatorsuresh2700% (1)

- Mexican Beetle 1600i Engine Bay 28 Pin Connector Information:-Connector LocationDokument3 SeitenMexican Beetle 1600i Engine Bay 28 Pin Connector Information:-Connector LocationLuis Mendez GuerreroNoch keine Bewertungen

- Harness Data: Section C - ElectricsDokument1 SeiteHarness Data: Section C - ElectricsIonut GrozaNoch keine Bewertungen

- Catalogo Completo Cooper LightingDokument130 SeitenCatalogo Completo Cooper LightingWilliam Dante Mescco SaireNoch keine Bewertungen

- CTs & VTsDokument48 SeitenCTs & VTssulemankhalid100% (1)

- Concrete Construction Article PDF - Largest Inverted Umbrella RoofDokument2 SeitenConcrete Construction Article PDF - Largest Inverted Umbrella RoofWilson Andres Echeverri GutierrrezNoch keine Bewertungen

- Automatic Trunk Lid Retrofit BMW F10 BJDokument13 SeitenAutomatic Trunk Lid Retrofit BMW F10 BJNick Nott0% (1)