Beruflich Dokumente

Kultur Dokumente

Air Pollution Control Systems Analysis

Hochgeladen von

antiokiaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Air Pollution Control Systems Analysis

Hochgeladen von

antiokiaCopyright:

Verfügbare Formate

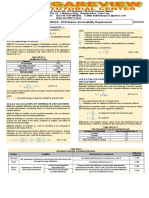

CATALYTIC COMBUSTION

Air Pollution Control Systems Analysis

Technology Equipment Equipment Type Process Description Recommended Applications Application Advantages Application Disadvantages

Rotary Concentrator

Zeolite-based adsorption wheel used with a small thermal or catalytic oxidizer to destroy a higher LEL concentrated air stream. Capable of 95-99% total DRE of the process stream.

Collection of VOCs from high volume, low loading air streams by adsorption. The air stream is then concentrated into a reduced volume, high loading concentrate stream. Typically 8:1 to 24:1 concentration ratios are used.

Ideal for paint booth, oven production lines, circuit boards, semi-conductors, composites, fiberglass, halogenated vapors Most high volume low VOC process air streams

Hydrophobic/non-flammable Very low operational cost Long life expectancy for wheel Small operational footprint Easy future expansion Easy to maintain and service

Not for high LEL air streams Not for use with liquids/aerosols Requires lower process stream inlet temperature typically below 150F

Regenerative Thermal Oxidizer

Thermal oxidation system capable of 95% heat recovery and 99%+ DRE of almost all process air streams.

Ceramic media used as a heat exchanger for high heat transfer efficiency. Ceramic media consists of structured packing or random saddles.

5000 cfm > air streams 0 10% lower explosive limit Pharmeceutical, wood finishing, OSB manufacture, corrosive organics, chemical processing, paper coating, paint booth, web offset

Very low operational/ maintenance cost High heat transfer effectiveness ideal for high volume, low VOC air streams Capable of handling high temperature at the inlet process streams

Higher capital cost Not for high LEL process airstreams Two-chamber design typically yields only 98% max destruction efficiency

Regenerative Catalytic Oxidizer

Catalytic oxidation system capable of 95% heat recovery and 99% DRE of select process air streams.

Precious metal catalyst used to destroy VOCs at low operating temperatures. Ceramic media used as a heat exchanger for high heat exchange efficiency. Ceramic media consists of structured packing or random saddles.

5000 cfm > air streams Capable of handling 0 10% LEL process streams Flexography, rotogravure, chlorinated compounds, circuit boards, electronics

Very low operational cost High heat transfer effectiveness ideal for high volume, low VOC air streams Capable of handling high temperature inlet air streams Low NOx, CO generation

Medium capital cost Susceptible to precious metal catalyst poisons (silicon, heavy metals, SO2 )

Recuperative Thermal Oxidizer

Thermal oxidation system that consists of a stainless steel heat exchanger with a high temperature oxidation chamber for 99%+ DRE.

Capable of achieving 70% heat transfer effectiveness with a shell and tube heat exchanger. One (1) second retention time at operating temperature (1400F) typically guarantees 99% DRE of VOCs.

0 100,000 scfm Ideal for air streams containing over 15% LEL of VOCs. Can handle air streams with up to 40% LEL with heat exchanger bypass. Adhesive coating, metal decorating, semi-conductor, heat offset printing, custom coating

Low capital cost Can handle high LEL air streams Liquids, aerosols or particulate are not a problem Good heat recovery options High silicon loading design available

High operating cost if air stream LEL is below 15%

Recuperative Catalytic Oxidizer (Monolith)

Catalytic oxidation system that consists of a stainless steel heat exchanger and precious metal catalyst on a monolith substrate.

Oxidizes VOCs through a chemical reaction between the hydrocarbons and precious metal. Capable of achieving 70% heat transfer effectiveness and 99% DRE.

0 100,000 scfm Flexible in handling varying process stream applications while offering low operating costs Graphic arts, fiberglass, paint finishing, composites, bakeries, coffee roasting, soil remediation, wire enameling, PTA/PE, chemical processing, chlorinated compounds

Low capital cost Low operating costs for process streams with low LELs and VOC loading Good range of flexibility Low NOx and CO generation

Typically not capable of handling sustained operation with process streams above 25% LEL Susceptible to catalyst poisons

Recuperative Catalytic Oxidizer (Spherical)

Catalytic oxidation system that consists of a stainless steel heat exchanger and precious metal catalyst on a spherical (bead) catalyst.

Spherical catalyst offers greater poison resistance to phosphorus, silicon, heavy metals and such due to greater surface area of ceramic media and better dispersion of precious metals.

0 100,000 scfm Flexible in handling varying process stream applications while offering low operating costs Heat offset printing, fiberglass, composites, soil remediation, paint finishing, bakeries, coffee roasting, wire enameling, PTA/PE, chemical processing, chlorinated compounds

Excellent poison resistance Low capital cost Low operating costs for process streams with low LELs and VOC loading Good range of flexibility Low NOx and CO generation

Typically not capable of handling sustained operation with process streams above 25% LEL

709 21st Avenue Bloomer, Wl 54724 U.S.A. Phone: 715.568.2882 Fax 715.568.2884

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Unit Weight of Materials Used at Construction SiteDokument5 SeitenUnit Weight of Materials Used at Construction SiteJames Mcguire100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Pipeline Repair Procedure Final MR 050112Dokument35 SeitenPipeline Repair Procedure Final MR 050112Sadam Bin Muzammal100% (5)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- FurnacesDokument7 SeitenFurnacesChirag PatelNoch keine Bewertungen

- Review MODULE - RCD Beams: Serviceability Requirements: 419.2.3 Modulus of Rupture of ConcreteDokument2 SeitenReview MODULE - RCD Beams: Serviceability Requirements: 419.2.3 Modulus of Rupture of ConcreteJoseph Lanto100% (1)

- Plate Heat Exchanger Gaskets WEBSITEDokument2 SeitenPlate Heat Exchanger Gaskets WEBSITESHAKEEL ISMAIL LAMBAYNoch keine Bewertungen

- Structural Design of Drainage ChannelDokument8 SeitenStructural Design of Drainage ChannelMikaheel AdesanyaNoch keine Bewertungen

- Corn Starch PDFDokument12 SeitenCorn Starch PDFMostafa Hussein AbdouNoch keine Bewertungen

- Lubrication Failure AnalysisDokument59 SeitenLubrication Failure AnalysisMahaveer Singh100% (1)

- Design-Coordination-Checklist Architectural Verfeb252020Dokument5 SeitenDesign-Coordination-Checklist Architectural Verfeb252020KunnalNoch keine Bewertungen

- SANTOS GLNG LNG Plant StandardsDokument4 SeitenSANTOS GLNG LNG Plant StandardsantiokiaNoch keine Bewertungen

- Refinery Furnace DesignDokument27 SeitenRefinery Furnace DesignGuillermoNoch keine Bewertungen

- Macho Laminador: M DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 Unc Asme B1.1Dokument2 SeitenMacho Laminador: M DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 Unc Asme B1.1emerson.mineiro100% (1)

- Screw CompressorDokument12 SeitenScrew Compressorantiokia100% (2)

- Corrected Differential Pressure CalculationsDokument1 SeiteCorrected Differential Pressure CalculationsantiokiaNoch keine Bewertungen

- Extreme Sport Good For HealthDokument11 SeitenExtreme Sport Good For HealthantiokiaNoch keine Bewertungen

- Rich List 2018Dokument4 SeitenRich List 2018antiokiaNoch keine Bewertungen

- OGP Draft 118683 - Guidelines For Systems and Installations For Supply of LNG As Fuel To ShipsDokument52 SeitenOGP Draft 118683 - Guidelines For Systems and Installations For Supply of LNG As Fuel To ShipsjomafebaNoch keine Bewertungen

- Utility Flares TemplateDokument2 SeitenUtility Flares TemplateantiokiaNoch keine Bewertungen

- KimSize TutorialDokument21 SeitenKimSize TutorialantiokiaNoch keine Bewertungen

- GLT Forged Steel Check ValveDokument2 SeitenGLT Forged Steel Check ValveantiokiaNoch keine Bewertungen

- DHU-Major Equipment SpecificationDokument2 SeitenDHU-Major Equipment SpecificationantiokiaNoch keine Bewertungen

- IP ClassDokument1 SeiteIP ClassantiokiaNoch keine Bewertungen

- Determination of Traces in Natural GasDokument34 SeitenDetermination of Traces in Natural GasDr. Wisam Al-Shalchi100% (6)

- Involute Gear Tooth Contact Stress AnalysisDokument17 SeitenInvolute Gear Tooth Contact Stress AnalysisCelsoNoch keine Bewertungen

- 5f72776f3e12c83107dc0f2e 56 ANSI Flange Access FittingDokument8 Seiten5f72776f3e12c83107dc0f2e 56 ANSI Flange Access Fittingiyandaseun8846Noch keine Bewertungen

- Atul 30,36-LoescheDokument16 SeitenAtul 30,36-LoescheSales ITANoch keine Bewertungen

- Proceedings of Spie: High-Field Electrostriction of Elastomeric Polymer Dielectrics For ActuationDokument14 SeitenProceedings of Spie: High-Field Electrostriction of Elastomeric Polymer Dielectrics For ActuationrajainrushNoch keine Bewertungen

- FP200 FR Expanding Foam: AbescoDokument2 SeitenFP200 FR Expanding Foam: AbescoIrfan AliNoch keine Bewertungen

- Flow Measurement (Compatibility Mode)Dokument11 SeitenFlow Measurement (Compatibility Mode)NRNiloyNoch keine Bewertungen

- Le - CorbusierDokument34 SeitenLe - CorbusierPavani KajaNoch keine Bewertungen

- Review Questions For 2nd Midterm Exam - Apr 14 2022Dokument10 SeitenReview Questions For 2nd Midterm Exam - Apr 14 2022nonameNoch keine Bewertungen

- Newcombe, 2010, Multistorey TimberDokument86 SeitenNewcombe, 2010, Multistorey Timberprisciliano1Noch keine Bewertungen

- Lubricants and LubricationDokument57 SeitenLubricants and LubricationJako MishyNoch keine Bewertungen

- CE 302 - Conc - Lecture 4 - Wk4Dokument18 SeitenCE 302 - Conc - Lecture 4 - Wk4IsraelNoch keine Bewertungen

- Metallurgy Practicum ModuleDokument9 SeitenMetallurgy Practicum ModuleJundi AbdillahNoch keine Bewertungen

- Joule-Thomson Coefficient: Experiment T9 Chemistry 114Dokument4 SeitenJoule-Thomson Coefficient: Experiment T9 Chemistry 114truffeloveNoch keine Bewertungen

- Time Schedule RIIMDokument4 SeitenTime Schedule RIIMBayu KurniawanNoch keine Bewertungen

- 6312 Open Product Comparison - SKFDokument1 Seite6312 Open Product Comparison - SKFWahyuNoch keine Bewertungen

- General Notes: (Roads, Drainage and Structures) I. at SpecificationsDokument1 SeiteGeneral Notes: (Roads, Drainage and Structures) I. at SpecificationsDarren ValienteNoch keine Bewertungen

- Tong Hop BuiddingDokument122 SeitenTong Hop BuiddingTrần ViệtNoch keine Bewertungen

- CXVB Engineering Data: Connection Side: Air Inlet End: Air Inlet EndDokument7 SeitenCXVB Engineering Data: Connection Side: Air Inlet End: Air Inlet EndJohnnybacsiNoch keine Bewertungen

- SB Unimax EnglishDokument6 SeitenSB Unimax Englishmohsen_267Noch keine Bewertungen