Beruflich Dokumente

Kultur Dokumente

18 Process Plant Layout Engineering - Course Syllabus

Hochgeladen von

afraz_xecOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

18 Process Plant Layout Engineering - Course Syllabus

Hochgeladen von

afraz_xecCopyright:

Verfügbare Formate

Process Plant Piping Layout Engineering and Piping Design

Certification Course

Course Title

Process Plant Piping Layout Engineering and Piping Design

Duration of Course : One Months 30 Days ( 100 Hours Power Point Presentation ) Daily Classes Venue Eligibility Criteria : Two Hours Per Day ( by PowerPoint Presentation ) : SEA , Hyderabad, Andhra Pradesh, India : Mechanical Engineer , Chemical Engineers , Petroleum Engineer and Draftsmans

Overview This Certification Course on Process Plant Piping Layout and Piping Design is integrated with Process Plant Layout & Equipments, per ASME B31.3 , Process Piping Drafting, Hydraulic Design of Piping Systems etc. Process Piping is the piping that convey fluids under pressure or vaccum inside the boundaries of a Chemical plant, Petroleum refinery, Gas Processing plant, Petrochemical, Pharmaceutical, Textile, Paper, Semiconductor & Cryogenic Plants falls under the scope of ASME B 31.3 It is a complex arrangement of pipes, valves, support clamps, other related components and control instrumentation. The Certification Course comprehensively focuses from fundamentals of Process Piping Systems , Layout of Piping Systems , Mechanical / Process Equipments , Process Piping Drafting.

ASME B 31.3 Provides requirements for design, erection, materials, inspection, fabrication, testing for process piping in Petroleum refineries, chemical plants, pharmaceutical plants, textile plants, paper plants, Semiconductor Plants, Cryogenic Plants process plant.

COURSE SYLLABUS

PART - 1

PIPING SYSTEMS DETAILED ENGINEERING LAYOUT OF PIPING SYSTEMS & PIPING DRAFTING MECHANICAL AND PROCESS EQUIPMENT Module 1 Fundamentals of piping Module 2 ASME codes and standards Module 3 Classification of pipe Module 4 Piping Material Specifications ASME / ASTM Module 5 Calculation of standards property of piping materials Module 6 Pipe Fittings Module 7 Types of Flanges Module 8 Types of Valves Module 9 Mechanical and Process Equipment Module 10 Flow Diagrams

Module 11 Piping Isometric Module 12 Module 13 Piping and Equipment Layout Pipe Supports

PART - 2

PIPING SYSTEMS DESIGN Module 14 Design of process piping requirements per ASME B31.3

Module 15 Design pressure integrity Module 16 Typical wall thickness calculation for Oil and Gas , Petrochemical , Refineries ( eg. Saudi Aramco )

Module 17 Module 18 Module 19

Hydraulic Design of Piping Systems Design Calculations of Piping sizing Pump Calculations

DETAILED COURSE SYLLABUSOUTLINE PART - 1

PIPING SYSTEMS DETAILED ENGINEERING LAYOUT OF PIPING SYSTEMS & PIPING DRAFTING MECHANICAL AND PROCESS EQUIPMENT

Module 1 Fundamentals of piping

Definition and Application of Piping Pipe Manufacturing Pipe Fabrication Pipe Designations

Module 2 ASME codes and standards

ASME Boiler and Pressure vessels Codes ASME Pressure Piping Design Codes. API Codes Other Codes & Standards

Module 3 Classification of pipe

Manufacturing Methods Weight and Size Standards STD , Extra Strong XS , Double Extra Strong XXS etc. Applications or Uses Pressure Temperature Rating System

Module 4 Piping Material Specifications ASME / ASTM

Ferrous Material Specifications

Non Ferrous Material Specifications

Module 5 Calculation of Sandards Properties of Commercial Piping Materials

Several Examples of Calculation of Standards Properties of Commercial Piping Materials

Module 6 Pipe Fittings

Types of Fitting - Butt Weld , Threaded and Socket Weld _ Elbow 90 degree (LR & SR), 45 degree, Reducing Ell. , _ Branch Connections Straight & Out let Tees Reducers Concentric & Eccentric, Reducer Offsets. Fabricated Branch Connections Stub In & Stub On, Branch Reinforcements Reinforcing Pad, Welding Saddle Olets. _ Olet Fittings Weldolets, Sockolets, Threadolets, Latrolets, Elbolets

Module 7 Types of Flanges

Definition of Flange. Types of Flanges based on Face and Application,-. Forged Steel and Cast Iron Flanges. Threaded Flanges , Slip-on Flanges, Socket-Welded Flanges , WeldedNeck Flanges , Blind Flanges Gaskets Types, Thickness, Bolts & Nuts.

Module 8 Types of Valves

Definition & basic function Valve Types Gate, Globe, Ball, Check, Butterfly, Angle, PRV/PSV, & Plug , Automatic Control , Needle , Diaphragm , Safety Pop Application of Check Valve Valve Storage Procedure Valve Testing Control Valve Manifold. Layout Representation & Requirements.

Module 9 Mechanical and Process Equipment

Static Equipment Horizontal Vessels, Vertical Vessels, Storage Tanks, Heat Exchanger , Reboiler., Towers and Columns Rotary Equipment Pumps, Compressor, Fans, & Steam Turbines.

Module 10

Flow Diagrams

Process Flow Diagram PFD Piping & Instrumentation Diagram P & ID. Utility Flow Diagram Line Numbering P& ID Requirements Flow Diagram Exercises. Symbols & Abbreviations. Instrument Types & Symbols Flow, Temp, and Pressure & Level. Flow Plan arrangement etc.

Module 11 Piping Isometric

Definition Drawing Piping Isometrics Isometric Dimensions, Notes & Callouts. Isometric Offsets. Exercises on Creation of Isometrics form Piping Plans and Sections.

Module 12 Piping and Equipment Layout (Plot Plan, Equipment

Layout, & Piping GA Drawings ) Plot Plan Development & Requirements. Equipment Layout Terminology, Control Point & Battery Limits Preparation of Equipment Layout. Piping GA Drawing Requirements and Layout Procedure. Pump GA Drawing and Layout Consideration. Tank & Vessel Layout Consideration .etc.

Module 13 Pipe Supports

Types and Functions of Supports Anchors Pipe Guides Limit Stops Pipe Shoe Dummy Leg / Trunion Field Support / Base Support Rigid Hangers Flexible or Resilient Supports - Variable & Constant Load Pipe Rack and Yard Piping Design

PART - 2

PIPING SYSTEMS DESIGN

Module 14 Design of process piping requirements per ASME B31.3

Scope of ASME B 31.3, B31.1 Design Pressure & Design Temperature for Piping Systems. Ratings of Flanges etc. Reinforcement of Branch Connection

Module 15 Design pressure integrity

Concept of Pressure Integrity Pressure Design of Straight Pipe under Internal Pressure. Wall thickness Calculations

Module 16 Typical wall thickness calculation for Oil and Gas , Petrochemical , Refineries ( eg. Saudi Aramco )

Several Examples of wall thickness calculation for Oil and Gas , Petrochemical , Refineries ( eg. Saudi Aramco )

Module 17

Hydraulic Design of Piping Systems

Fluid Flow Sizing Pipe Sizing Recommended Velocities for Water and Steam Piping etc. Reynolds Number Types of Flow in Piping Pressure Drop due to Friction / viscosity Darcy Weisbach Equation Friction Factor Moody Diagram Minor Losses in Piping Equivalent Length Method & Loss Coefficient Method

Module 18 Design Calculations of Piping sizing

Several Examples of Calculation of Pipe Sizing

Module 19

Pump Calculations

Head Section and Flooded Lift Velocity Head Total Dynamic Section Head , Total Dynamic Discharge Head , Total Systems Head Cavitation in Pumps NPSH Required & NPSH Available for Pumps. Several Examples of Design of Pump Calculations

Das könnte Ihnen auch gefallen

- Piping Plot Plan and Layout EngineeringDokument12 SeitenPiping Plot Plan and Layout EngineeringKagira Drawing SoltuionNoch keine Bewertungen

- Piping ArticlesDokument187 SeitenPiping Articlesdhanu1308Noch keine Bewertungen

- Offshore Piping Design: Technical Design Procedures & Mechanical Piping MethodsVon EverandOffshore Piping Design: Technical Design Procedures & Mechanical Piping MethodsNoch keine Bewertungen

- Process Piping Drafting Course Outlines (FINAL)Dokument13 SeitenProcess Piping Drafting Course Outlines (FINAL)andrew myintmyatNoch keine Bewertungen

- PIPING ENGINEERING MAN-HOUR ESTIMATEDokument14 SeitenPIPING ENGINEERING MAN-HOUR ESTIMATEShabeer KiblaalamNoch keine Bewertungen

- SP3D Equipment S4 Practice LabDokument9 SeitenSP3D Equipment S4 Practice LabKrishna KNoch keine Bewertungen

- Check List For Piping LayoutsDokument5 SeitenCheck List For Piping LayoutsThiruThirunavukkarasu100% (3)

- Piping Training - Typical Project TypesDokument12 SeitenPiping Training - Typical Project TypesDinesh Hande100% (2)

- Introduction To Piping DepartmentDokument25 SeitenIntroduction To Piping DepartmentAmir RazmiNoch keine Bewertungen

- Autocad ShortcutsDokument20 SeitenAutocad ShortcutsKing YungNoch keine Bewertungen

- Sp3D Start Smartplant 3DDokument37 SeitenSp3D Start Smartplant 3DJigy100% (2)

- C1 The Basic of Plant Layout Design - Process Plant Layout and Piping DesignDokument81 SeitenC1 The Basic of Plant Layout Design - Process Plant Layout and Piping Designdung100% (1)

- To Be A Piping Designer You Should KnowDokument7 SeitenTo Be A Piping Designer You Should KnowQusroo AhmedNoch keine Bewertungen

- Rolta Piping GuideDokument224 SeitenRolta Piping GuideSudhesh Rajamoorthy100% (3)

- Piping Engineering Course OverviewDokument2 SeitenPiping Engineering Course Overviewmayur_lanjewar0% (1)

- Plot Plan & Equipment LayoutDokument6 SeitenPlot Plan & Equipment LayoutTejas PatelNoch keine Bewertungen

- Pipin StudyDokument81 SeitenPipin StudyRaju NaiduNoch keine Bewertungen

- Siddhesh Updated Sp3dDokument4 SeitenSiddhesh Updated Sp3dSiddhu DudwadkarNoch keine Bewertungen

- Typical Piping Project SequenceDokument23 SeitenTypical Piping Project SequenceJackNoch keine Bewertungen

- 1722 Piping Drafting Instruc GuideDokument26 Seiten1722 Piping Drafting Instruc GuideRizwan Ashraf100% (2)

- BN-DG-C01K Plant Layout PumpsDokument16 SeitenBN-DG-C01K Plant Layout Pumpshalder_kalyan9216Noch keine Bewertungen

- AutoPIPE vs Caesar user interface guideDokument7 SeitenAutoPIPE vs Caesar user interface guidelimin zhangNoch keine Bewertungen

- Equipment Selection & Plant LayoutDokument11 SeitenEquipment Selection & Plant LayoutFebio DalantaNoch keine Bewertungen

- TR Diss 6736 PDFDokument166 SeitenTR Diss 6736 PDFmohammed ramzi CHAHBINoch keine Bewertungen

- Check List For Piping LayoutsDokument3 SeitenCheck List For Piping LayoutskarunaNoch keine Bewertungen

- Chemical Plant Process PrincipleDokument29 SeitenChemical Plant Process PrincipleDanish Iqbal100% (1)

- Thumb RuleDokument42 SeitenThumb RuleShabeer KiblaalamNoch keine Bewertungen

- Mechanical Engineering Drawing: SR KaleDokument22 SeitenMechanical Engineering Drawing: SR KaleAdnan RanaNoch keine Bewertungen

- Layout of Piping Systems and Process EquipmentDokument452 SeitenLayout of Piping Systems and Process Equipmentjumkung67% (3)

- Lecture 2 Process Engineering-1Dokument95 SeitenLecture 2 Process Engineering-1ahmed.ayoob.abdNoch keine Bewertungen

- Piping DocumentsDokument12 SeitenPiping Documentskomail0% (1)

- Process Plant Layout - Becoming A Lost ArtDokument7 SeitenProcess Plant Layout - Becoming A Lost ArtRajendraNoch keine Bewertungen

- Piping in Plant Design, Construction and MaintenanceDokument226 SeitenPiping in Plant Design, Construction and MaintenanceEfren Ibanez100% (18)

- Piping Engineering - Piping Layout Procedure and Pipe Rack - XyntechDokument14 SeitenPiping Engineering - Piping Layout Procedure and Pipe Rack - XyntechKeiko DavilaNoch keine Bewertungen

- DWP For Piping EngineeringDokument83 SeitenDWP For Piping Engineeringlin kin100% (3)

- Equpment LayoutDokument6 SeitenEqupment LayoutdasubhaiNoch keine Bewertungen

- PFD P&id PDFDokument431 SeitenPFD P&id PDFSONWALYOGESH100% (1)

- Engineered Packaging Center A Global ProviderDokument6 SeitenEngineered Packaging Center A Global ProviderLTE002Noch keine Bewertungen

- Learn Basic of Piping EngineeringDokument43 SeitenLearn Basic of Piping Engineeringkaruna100% (1)

- Piping Design and Layout NotesDokument225 SeitenPiping Design and Layout NotesMohnish KashyapNoch keine Bewertungen

- Introduction to Piping Materials Department ActivitiesDokument23 SeitenIntroduction to Piping Materials Department Activitiesvikas2510100% (1)

- ICARUS ReferenceDokument66 SeitenICARUS Referencerylar999Noch keine Bewertungen

- Plant Layout and IsometricDokument46 SeitenPlant Layout and IsometricJenny Azzahra100% (1)

- Piping Material Take Off-MTO, BOM, BOQ & MTO Stages (With PDFDokument5 SeitenPiping Material Take Off-MTO, BOM, BOQ & MTO Stages (With PDFDhiren PatelNoch keine Bewertungen

- Equipment and Piping LayoutDokument39 SeitenEquipment and Piping Layoutvaitlixar100% (2)

- Piping Model Review ProcedureDokument8 SeitenPiping Model Review Procedurekad-7Noch keine Bewertungen

- Design Practice General PipeDokument8 SeitenDesign Practice General PipedevNoch keine Bewertungen

- Wavistrong Product CatalogueDokument114 SeitenWavistrong Product CatalogueBINODH DNoch keine Bewertungen

- Piping Design CourseDokument17 SeitenPiping Design CourseImran Shaik33% (3)

- 19 P G Diploma in Piping Design - Course SyllabusDokument19 Seiten19 P G Diploma in Piping Design - Course Syllabusprince_lal100% (1)

- Piping Design Concepts & Caesar : Pipe Stress AnalysisDokument3 SeitenPiping Design Concepts & Caesar : Pipe Stress AnalysisGerry Malapitan100% (1)

- Sylabus For Piping TrainingDokument5 SeitenSylabus For Piping TrainingDilip YadavNoch keine Bewertungen

- CEASAR and PDMS SoftwareDokument10 SeitenCEASAR and PDMS Softwarehayatmdazhar100% (1)

- Master process piping design and stress analysisDokument13 SeitenMaster process piping design and stress analysisGaurav PanjwaniNoch keine Bewertungen

- Piping DesignDokument4 SeitenPiping DesignTerry YongNoch keine Bewertungen

- Process Piping Design & EngineeringDokument4 SeitenProcess Piping Design & Engineeringtibi1000Noch keine Bewertungen

- Piping Engineer SyllubusDokument3 SeitenPiping Engineer SyllubusbalajivangaruNoch keine Bewertungen

- Summary of Experience Work Profile:: Curriculum VitaeDokument2 SeitenSummary of Experience Work Profile:: Curriculum VitaeSuthan SelvarajNoch keine Bewertungen

- Water Parameters NeededDokument1 SeiteWater Parameters Neededafraz_xecNoch keine Bewertungen

- Waste WaterDokument31 SeitenWaste Waterafraz_xec100% (1)

- GSAS Technical Guide V2.1Dokument90 SeitenGSAS Technical Guide V2.1Laras Fadillah100% (1)

- GCC Reuse Regulations: GE Power & Water Water & Process TechnologiesDokument37 SeitenGCC Reuse Regulations: GE Power & Water Water & Process TechnologiesRashid Al GaoudNoch keine Bewertungen

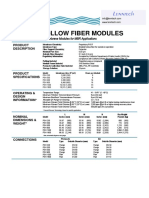

- Puron Technical Bulletin Modules 300 600 1800 PVDF Rev 11-2 FinalDokument2 SeitenPuron Technical Bulletin Modules 300 600 1800 PVDF Rev 11-2 Finalafraz_xecNoch keine Bewertungen

- GRP Water Tank SpecsDokument4 SeitenGRP Water Tank Specsafraz_xecNoch keine Bewertungen

- Heat Loss and Gain CalculationDokument84 SeitenHeat Loss and Gain Calculationafraz_xecNoch keine Bewertungen

- DBSP Design Basis ScopingDokument23 SeitenDBSP Design Basis ScopingMuneer YousofNoch keine Bewertungen

- DBSP Design Basis ScopingDokument23 SeitenDBSP Design Basis ScopingMuneer YousofNoch keine Bewertungen

- SustainabilityAssessment System - AM PDFDokument35 SeitenSustainabilityAssessment System - AM PDFafraz_xecNoch keine Bewertungen

- GCC Reuse Regulations: GE Power & Water Water & Process TechnologiesDokument37 SeitenGCC Reuse Regulations: GE Power & Water Water & Process TechnologiesRashid Al GaoudNoch keine Bewertungen

- Ashghal StandardsDokument26 SeitenAshghal Standardsafraz_xecNoch keine Bewertungen

- GRP Water Tank SpecsDokument4 SeitenGRP Water Tank Specsafraz_xecNoch keine Bewertungen

- Hydaranautics MembraneDokument3 SeitenHydaranautics Membraneafraz_xecNoch keine Bewertungen

- 16 L200 LHD +GCC-E SpecDokument2 Seiten16 L200 LHD +GCC-E Specafraz_xecNoch keine Bewertungen

- Cat 6 S-FTP 4 CableDokument2 SeitenCat 6 S-FTP 4 Cableafraz_xecNoch keine Bewertungen

- Mechanical-Engineering Gate2016.InfoDokument3 SeitenMechanical-Engineering Gate2016.InfoHenryNoch keine Bewertungen

- Epa Water Treatment Manual Filtration 1Dokument80 SeitenEpa Water Treatment Manual Filtration 1alkemeya100% (1)

- Mechanical-Engineering Gate2016.InfoDokument3 SeitenMechanical-Engineering Gate2016.InfoHenryNoch keine Bewertungen

- All Polypropylene String Wound CartridgesDokument1 SeiteAll Polypropylene String Wound Cartridgesafraz_xecNoch keine Bewertungen

- HILTI Direct - FasteningDokument2 SeitenHILTI Direct - Fasteningafraz_xecNoch keine Bewertungen

- Auditing HealthcareDokument82 SeitenAuditing Healthcareafraz_xecNoch keine Bewertungen

- Flexible Conduit SpecsDokument10 SeitenFlexible Conduit Specsafraz_xecNoch keine Bewertungen

- List of Materials For GRP TankDokument1 SeiteList of Materials For GRP Tankafraz_xecNoch keine Bewertungen

- Koch Puron PSH 300 LDokument2 SeitenKoch Puron PSH 300 Lafraz_xecNoch keine Bewertungen

- Cable Tray Support SpecsDokument3 SeitenCable Tray Support Specsafraz_xecNoch keine Bewertungen

- Tank Foundation DrawingDokument1 SeiteTank Foundation Drawingafraz_xecNoch keine Bewertungen

- Ebara 3 Series Centrifugal Pumps Selection GuideDokument0 SeitenEbara 3 Series Centrifugal Pumps Selection GuideMaida AgićNoch keine Bewertungen

- Inspection Form For New Construction: Project NameDokument1 SeiteInspection Form For New Construction: Project Nameafraz_xecNoch keine Bewertungen

- Control Cables SpecsDokument4 SeitenControl Cables Specsafraz_xecNoch keine Bewertungen

- Electromagnetic Braking SystemDokument14 SeitenElectromagnetic Braking SystemTanvi50% (2)

- Sulzer MC EquipmentDokument12 SeitenSulzer MC EquipmentsnthmlgtNoch keine Bewertungen

- Saes H 201Dokument9 SeitenSaes H 201heartbreakkid132Noch keine Bewertungen

- Hyd Schematic 2658487205 - 005Dokument3 SeitenHyd Schematic 2658487205 - 005Angelo Solorzano100% (2)

- Tutorial Sim MechanicsDokument840 SeitenTutorial Sim MechanicsHernan Gonzalez100% (4)

- E Requisition SystemDokument8 SeitenE Requisition SystemWaNi AbidNoch keine Bewertungen

- COP Oil: For Epiroc Components We Combine Technology and Environmental SustainabilityDokument4 SeitenCOP Oil: For Epiroc Components We Combine Technology and Environmental SustainabilityDavid CarrilloNoch keine Bewertungen

- Mock PPT 2023 TietDokument22 SeitenMock PPT 2023 Tiettsai42zigNoch keine Bewertungen

- MAPEH 6- WEEK 1 ActivitiesDokument4 SeitenMAPEH 6- WEEK 1 ActivitiesCatherine Renante100% (2)

- DC CheatsheetDokument2 SeitenDC CheatsheetRashi SinghNoch keine Bewertungen

- 6.1.3 Final Exam - Exam (Exam)Dokument8 Seiten6.1.3 Final Exam - Exam (Exam)parker3poseyNoch keine Bewertungen

- 230kv Cable Sizing CalculationsDokument6 Seiten230kv Cable Sizing Calculationsrajinipre-1Noch keine Bewertungen

- Cygnus 4plus Operating ManualDokument141 SeitenCygnus 4plus Operating Manualdzul effendiNoch keine Bewertungen

- I2E: Embedding Innovation as Organizational StrategyDokument11 SeitenI2E: Embedding Innovation as Organizational StrategyDeepak PanditNoch keine Bewertungen

- Catalogue: Product Offering 51Dokument56 SeitenCatalogue: Product Offering 51Bruno MartinsNoch keine Bewertungen

- Ethanol: Safety Data SheetDokument19 SeitenEthanol: Safety Data SheetNitika SinhaNoch keine Bewertungen

- Empowerment Technology - Week 2Dokument3 SeitenEmpowerment Technology - Week 2yahgieNoch keine Bewertungen

- Laser Module 5Dokument25 SeitenLaser Module 5Luis Enrique B GNoch keine Bewertungen

- IPA Assignment Analyzes New Public AdministrationDokument8 SeitenIPA Assignment Analyzes New Public AdministrationKumaran ViswanathanNoch keine Bewertungen

- Understanding Power Dynamics and Developing Political ExpertiseDokument29 SeitenUnderstanding Power Dynamics and Developing Political Expertisealessiacon100% (1)

- Sea Cities British English Teacher Ver2Dokument6 SeitenSea Cities British English Teacher Ver2Kati T.Noch keine Bewertungen

- REFLEKSI KASUS PLASENTADokument48 SeitenREFLEKSI KASUS PLASENTAImelda AritonangNoch keine Bewertungen

- QUIZ 2 BUMA 20013 - Operations Management TQMDokument5 SeitenQUIZ 2 BUMA 20013 - Operations Management TQMSlap ShareNoch keine Bewertungen

- CalculationDokument24 SeitenCalculationhablet1100% (1)

- The Production and Interpretation of Ritual Transformation Experience: A Study on the Method of Physical Actions of the Baishatun Mazu PilgrimageDokument36 SeitenThe Production and Interpretation of Ritual Transformation Experience: A Study on the Method of Physical Actions of the Baishatun Mazu PilgrimageMinmin HsuNoch keine Bewertungen

- Lab 1 Handout Electrical MachinesDokument23 SeitenLab 1 Handout Electrical Machinesvishalsharma08Noch keine Bewertungen

- 9-Lesson 5 Direct and Indirect SpeechDokument8 Seiten9-Lesson 5 Direct and Indirect Speechlaiwelyn100% (4)

- Materials Technical Specification.: Stainless SteelDokument6 SeitenMaterials Technical Specification.: Stainless SteelMario TirabassiNoch keine Bewertungen

- Wiley Wesleyan UniversityDokument36 SeitenWiley Wesleyan UniversityBirunda SilvaNoch keine Bewertungen

- TSR Cyl Tilt Cab LD 110Dokument2 SeitenTSR Cyl Tilt Cab LD 110Ferry AndisNoch keine Bewertungen

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureVon EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Operational Amplifier Circuits: Analysis and DesignVon EverandOperational Amplifier Circuits: Analysis and DesignBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Understanding Automotive Electronics: An Engineering PerspectiveVon EverandUnderstanding Automotive Electronics: An Engineering PerspectiveBewertung: 3.5 von 5 Sternen3.5/5 (16)

- CNC Trade Secrets: A Guide to CNC Machine Shop PracticesVon EverandCNC Trade Secrets: A Guide to CNC Machine Shop PracticesNoch keine Bewertungen

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryVon EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryBewertung: 4 von 5 Sternen4/5 (5)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsVon EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNoch keine Bewertungen

- The Cyanide Canary: A True Story of InjusticeVon EverandThe Cyanide Canary: A True Story of InjusticeBewertung: 4 von 5 Sternen4/5 (51)

- Design for How People Think: Using Brain Science to Build Better ProductsVon EverandDesign for How People Think: Using Brain Science to Build Better ProductsBewertung: 4 von 5 Sternen4/5 (8)

- The Rights of Nature: A Legal Revolution That Could Save the WorldVon EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldBewertung: 5 von 5 Sternen5/5 (1)

- Electrical Principles and Technology for EngineeringVon EverandElectrical Principles and Technology for EngineeringBewertung: 4 von 5 Sternen4/5 (4)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsVon EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNoch keine Bewertungen

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionVon EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionBewertung: 3 von 5 Sternen3/5 (1)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableVon EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNoch keine Bewertungen

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tVon EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tBewertung: 4.5 von 5 Sternen4.5/5 (27)

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorVon EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorBewertung: 4 von 5 Sternen4/5 (7)

- Introduction to Ecology and Environmental Laws in IndiaVon EverandIntroduction to Ecology and Environmental Laws in IndiaNoch keine Bewertungen

- Design Is The Problem: The Future of Design Must Be SustainableVon EverandDesign Is The Problem: The Future of Design Must Be SustainableBewertung: 1.5 von 5 Sternen1.5/5 (2)

- Iconic Advantage: Don’t Chase the New, Innovate the OldVon EverandIconic Advantage: Don’t Chase the New, Innovate the OldBewertung: 4 von 5 Sternen4/5 (1)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessVon EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessNoch keine Bewertungen

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceVon EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceBewertung: 4 von 5 Sternen4/5 (19)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationVon EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationBewertung: 4.5 von 5 Sternen4.5/5 (2)