Beruflich Dokumente

Kultur Dokumente

Manual, Stepdrive For 290

Hochgeladen von

David WesnerOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Manual, Stepdrive For 290

Hochgeladen von

David WesnerCopyright:

Verfügbare Formate

PRM Marine Transmissions StepDrive

Installation & Service Manual

Installation & Service Manual

2-Speed Automatic Transmission for retro fitting to: Volvo 290DP drive leg, versions C, D and E.

Newage Transmissions Ltd, 2004. All rights reserved. No part of this publication may be reproduced without the written Permission of the copyright owner.

PRM Marine Transmissions StepDrive

Installation & Service Manu al

Congratulations on your purchase of

Foreword The PRM StepDrive has been specifically designed for retro fitting to the Volvo Penta 290-DP drive leg, issues C, D and E. Provided it is correctly installed and maintained it should provide a long and trouble free life, and giving the owner the following advantages over the existing single speed drive: ? ? ? ? Improved acceleration Reduced creep speed Smoother FWD / REV selection Improved fuel economy, less smoke and less vibration.

This Workshop Manual is intended primarily for StepDrive dealers and therefore assumes a basic knowledge of marine drive systems and electrical competence with Volvo engine installations. It is of utmost importance that the instructions are followed to ensure that the unit operates as intended. Newage Transmissions Ltd continuously develops its products, and as such reserves the right to modify StepDrive as required; any amendments deemed pertinent to the Manual will be introduced via service bulletins. Newage Transmissions Ltd can accept no responsibility under warranty or otherwise for any loss or damage resulting from failure to observe these instructions. To avoid prejudicing your rights under war ranty, do not undertake any repair or other work on the gearbox during the warranty period without first contacting Newage Transmissions Ltd or an authorised distributor for advice. In the event of failure, you should do this via the StepDrive distributor who supplied the gearbox; if this is not possible, you should notify Newage Transmissions Ltd. direct, quoting the serial number.

ii

PRM Marine Transmissions StepDrive

Installation & Service Manu al

Content 1 GENERAL INFORMATION ........................................................................................................................... 1 1.1 SERVICE PARTS............................................................................................................................................... 1 1.2 PRE -DELIVERY TEST....................................................................................................................................... 1 1.3 IDENTIFICATION .............................................................................................................................................. 1 1.4 TECHNICAL OVERVIEW OF STEP DRIVE ....................................................................................................... 2 1.4.1 Control.................................................................................................................................................... 2 1.4.2 Hydraulics.............................................................................................................................................. 3 1.4.3 StepDrive Layout...................................................................................................................................5 2 INSTALLING STEPDRIVE ............................................................................................................................. 6 2.1 REMOVING THE STERNDRIVE ........................................................................................................................ 6 2.2 PARTS REQUIRED............................................................................................................................................. 7 2.3 DISASSEMBLY OF DRIVE LEG........................................................................................................................ 7 2.4 SHIMMING FOR THE STEP DRIVE ................................................................................................................... 8 2.5 BUILDING STEP DRIVE INTO THE LEG .......................................................................................................... 9 2.5.1 Assembling to the Lower Section........................................................................................................ 9 2.5.2 Assembling to the Upper Section......................................................................................................10 2.5.3 Joining the StepDrive.........................................................................................................................11 2.5.4 Refitting the Sterndrive.......................................................................................................................12 2.6 ONBOARD.......................................................................................................................................................14 2.6.1 Helm Controls......................................................................................................................................14 2.6.2 Switch Box............................................................................................................................................15 2.6.3 Engine Compartment..........................................................................................................................17 2.6.4 Outside the boat...................................................................................................................................19 3 TESTING..............................................................................................................................................................20 3.1 4 POST ASSEMBLY TESTING ............................................................................................................................20

WARRANTY .......................................................................................................................................................21 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 VALIDITY PERIOD.........................................................................................................................................21 STEP DRIVE PRODUCT ...................................................................................................................................21 LIMITATION OF LIABILITY ...........................................................................................................................22 ITEMS NOT SUPPLIED BY NEWAGE..............................................................................................................22 A DVICE ...........................................................................................................................................................22 ILLUSTRATION OF WARRANTY COVER......................................................................................................22 TRANSFERABLE WARRANTY.......................................................................................................................23 STOLEN STEP DRIVE UNIT............................................................................................................................23

5 6

SERVICING ........................................................................................................................................................24 PARTS LIST........................................................................................................................................................25 6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8 6.9 6.10 6.11 6.12 STEP DRIVE GENERAL ASSEMBLY MAIN GEARBOX .............................................................................25 STEP DRIVE GENERAL ASSEMBLY TOP MANIFOLD ..............................................................................27 M AINSHAFT A SSEMBLY...............................................................................................................................29 LAYSHAFT A SSEMBLY .................................................................................................................................30 SOLENOID HOUSING A SSEMBLY.................................................................................................................31 PUMP M ANIFOLD A SSEMBLY......................................................................................................................32 NON-RETURN VALVE SUB-A SSEMBLY .....................................................................................................33 SOLENOID COVER A SSEMBLY.....................................................................................................................33 RELIEF VALVE A SSEMBLY ..........................................................................................................................34 FILTER KIT (MT0516-KIT).........................................................................................................................34 INSIDE THE BOX .............................................................................................................................................35 STEP DRIVE FAULT FINDING CHART ..........................................................................................................38

iii

PRM Marine Transmissions StepDrive

Installation & Service Manu al

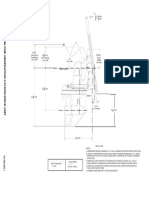

Table of Figures Figure 1 Serial Plate ______________________________________________________________ 1 Figure 2 Control Box ______________________________________________________________ 2 Figure 3 Hydraulics Schematic_______________________________________________________ 3 Figure 4 Cooling Flow Schematic ____________________________________________________ 4 Figure 5 Power Flow through StepDrive _______________________________________________ 5 Figure 6 Ratio equation ____________________________________________________________ 5 Figure 7 O rings for Volvo Bottom Gear Housing _______________________________________ 9 Figure 8 Photo showing even spreading of Loctite 518 sealant _______________________________ 9 Figure 9 O Rings for Volvo Top Gearbox_____________________________________________ 10 Figure 10 Photo showing even spreading of Loctite 518 sealant_____________________________ 10 Figure 11 O rings for StepDrive joining______________________________________________ 11 Figure 12 Photo showing even spreading of Loctite 518 sealant_____________________________ 11 Figure 13 Painted and Anti-fouled Drives. _____________________________________________ 13 Figure 14 Example of Switch box location._____________________________________________ 15 Figure 15 - Connecting the plug for the Switch Box________________________________________ 16 Figure 16 - Template for Switch Box ___________________________________________________ 16 Figure 17 Installation guide________________________________________________________ 17 Figure 18 Alternator wiring (diesel engines) ____________________________________________ 18 Figure 19 Example of cable run, P clips and gland mounting. _____________________________ 19 Figure 20 Copy of Warranty Registration Form - send to Newage ___________________________ 23

iv

PRM Marine Transmissions StepDrive

Installation & Service Manu al

1 1.1 Service Parts

General Information

The comprehensive illustrated parts list found at the back of this manual gives full information and ordering procedure. 1.2 Pre-delivery Test

Before the StepDrive leaves the factory, every gearbox is subjected to a final test and inspection which includes the following: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 1.3 Flush clean. Pressurise the StepDrive assembly, and check for deterioration of pressure to Volvos recommendation, inc vacuum test. Fill with oil. Check for noise levels. Check drag torque during running. Record oil flow in cooling circuit. Record time to working temperature. Activate gear change solenoid. Reverse rotation. Record oil pressure @ 1500rpm in forward & reverse, reduction & direct drive.

Identification

Every PRM Marine Transmission is fitted with an identification plate before it leaves the factory, which on StepDrive is located on the back face of the main gearcase. It will be observed that there are two lines of numbers, the top line being the serial number & works order number and the bottom line being the product structure number (the serial number and order number below are examples).

NEWAGE

PRM

COVENTRY

C919400 SD290C

MADE IN

R01162

ENGLAND

Figure 1 Serial Plate

PRM Marine Transmissions StepDrive

Installation & Service Manu al

1.4

Technical Overview of StepDrive

The automatic two-speed gearbox will always start off in the low gear (reduction), which has an exact ratio of 1.31 to 1 (in addition to the standard drive ratio). This reduction gear will reduce the creep/idle speed of the boat, and hence give more thinking and manoeuvring time, with the added benefit of less vibration as the engine is under reduced load, and not labouring. As the boat begins to accelerate, the reduction gear reduces the amount of engine torque required to rotate the prop, hence taking the load off the engine and allowing it to accelerate at a greater rate. When the boat is planing and the drag forces reduce, the gearbox then changes gear automatically taking the drive back to the original leg ratio, hereon referred to as direct drive. This has the advantage of not only better acceleration, but also better fuel economy as the duration of time under acceleration is reduced; as is the load on the engine during this inefficient time period. It has also been noticed that with less over fuelling there will also be less black smoke. It is also possible that on some installations the pitch of the propeller can be increased to achieve a higher top speed. NOTE: This is only possible if the original prop selection was a compromise of top speed against acceleration, typically on pre-KAD engines. 1.4.1 Control

The gear change itself is controlled by a 2-position, 4-way solenoid spool valve and coil that is triggered by the electrical control system (one control system per boat). When the ignition is turned on, the gearbox will automatically receive a signal to move the spool valve to the reduction position, however StepDrive gear selection is not physically activated until the gearbox has system pressure. The pressure is provided by the internal gear pump, which is rotated when the Volvo cone clutch gearbox has been engaged (Fwd or Rev). This design feature allows the cone clutch gearbox to be used without the inertia of the prop magnifying any backlash/noise, with the hydraulics then giving a smoother take up.

Cable attachment for helm mounted On/Off Switch Box with indicator light

Engine Compartment mounted Control Box featuring: - Fault light (RED) - On/off indicator (GREEN / ORANGE) - Change point adjuster: - Clockwise = increase rpm - Anti-clockwise = decrease rpm (Approx 100rpm = 1 turn)

StepDrive Signal Cables

Alternator terminal connectors

Figure 2 Control Box The control system requires a simple 12-volt electrical supply (taken from the alternator) and a signal from the alternator pulse terminal (on twin installations only a single reading is required). This should generally be set to change gear at maximum engine power (max rpm), although this is slightly variable dependent upon each vessel (mass, beam displacement etc).

PRM Marine Transmissions StepDrive

Installation & Service Manu al

1.4.2

Hydraulics

StepDrive is a hydraulic gearbox, which is fitted after the Volvo cone clutch gearbox, and driven by the output of the cone clutch drive. This allows the forward / reverse mechanism to be selected without the inertia of the propeller, reducing the lurch that can be present, with the hydraulics then giving a smooth take-up. Fundamentally the hydraulics serve two main functions: 1. To give the required clutch pressure to either the reduction or direct drive multi plate wet clutches. This pressure is set by Newage Transmissions at the factory. The oil circuit consists of a 100? m suction strainer (that should be cleaned when the leg is serviced), a series of non-return valves (NRV), a two-gear pump, pressure relief valve (530-550psi), 25? m pressure filter (to be replaced when serviced) and 4way solenoid spool valve (12 volt). T excess oil is then passed from the relief he valve to the cooling circuit.

Figure 3 Hydraulics Schematic

PRM Marine Transmissions StepDrive

Installation & Service Manu al

2.

The cooling circuit is vital to the longevity of the gearbox; cold oil is pumped (via strainer, NRVs and relief valve) from below the water line/cavitation plate, directly in to the bottom bearing of the Volvo cone clutch gearbox (or top box). There is also an additional oil flow circuit that cools the StepDrive gearbox itself. Both these circuits join a common path back below the water level as illustrated below:

Figure 4 Cooling Flow Schematic

PRM Marine Transmissions StepDrive

Installation & Service Manu al

1.4.3

StepDrive Layout

The StepDrive is a twin parallel vertical axis layshaft design gearbox. It comprises of two constant mesh Clutch gears and two constant mesh Pinion gears. The Mainshaft clutch gear is driven from the Volvo cone clutch output shaft, with the layshaft continuously driving the StepDrive hydraulic pump.

INPUT TO STEPDRIVE PUMP DRIVE

LAYSHAFT CLUTCH GEAR

MAINSHAFT CLUTCH GEAR

LAYSHAFT PINION GEAR

MAINSHAFT PINION GEAR

STEPDRIVE OUTPUT

Figure 5 Power Flow through StepDrive When the StepDrive reduction is engaged (at low rpm), the Layshaft clutch is actuated, locking the layshaft clutch gear to the layshaft pinion gear; the power is therefore transmitted via the reduction ratio on the pinion gears, as indicated b the white arrow. Direct drive is y achieved by locking the mainshaft clutch gear to the mainshaft pinion gear, as shown with the black arrow. This effectively locks the shaft solid and hence has no gearing losses/transmission errors. The 4-gear mesh sets the overall reduction ratio of the gearbox, and is calculated as follows:

LayshaftClutch Gear MainshaftClutch Gear

MainshaftPinion Gear LayshaftPinion Gear

45T 44T

50T 39T

? 1 .31 : 1

Figure 6 Ratio equation

PRM Marine Transmissions StepDrive

Installation & Service Manu al

2 2.1 Removing the Sterndrive

Installing StepDrive

This should be done in accordance with the guidelines in the Volvo Penta Workshop Manual, but the procedure has been summarised below: 1. 2. 3. 4. 5. 6. 7. 8. 9. Disconnect the power to prevent accidental starting Move the control lever to reverse Loosen the propeller cone lock bolt Move the control lever to forward gear Remove the aft line cutter, forward propeller nut, and forward propeller. Return the shift control to neutral. Remove the shift linkage cover on the leg. Remove the cotter pin and washer from the shift cable end, and remove the end pivot pin from the cable. Loosen the screw holding the shift cable clamp and release shift cable. Remove the 2 screws holding the steering pin to the upper gear head. Using 2 M6 screws 30mm long (or longer), install into the threaded holes of the steering pin. As the screws are turned in, the steering pin will be forced out of the steering pin socket and steering helmet bushing. Using Volvo tool (884573), remove the clamp around the u-joint bellows. Remove the cotter pin on the trim cylinder pins. Remove the trim cylinder pins. Raise the drive manually and insert Volvo tool onto the H bracket (885143). Remove the exhaust bellows from the drive. Remove the clamp on the raw water hose. Remove the raw water hose. Now remove the H bracket support tool and lower the drive. Install Volvo Penta support bracket (885146) and remove the sterndrive from the transom shield (remove pivot pins with bolts).

10. 11. 12. 13. 14.

This is based on units not fitted with the Hook -up mechanism. It is not possible to directly fit StepDrive to these types of stern drives (without modifications) for the following reasons: ? ? ? The output bearing of the early Volvo cone clutch gearbox is not compatible with the StepDrive. * The Vertical drive shaft to the lower section is a different length and not compatible with StepDrive. * The StepDrive exhaust ducting is located where the Hook -up mechanism fits, i.e. a new H bracket and ram set is required.

* Depending upon demand, the necessary modifications will be made to the StepDrive to allow installation on DP drives preceding model C.

PRM Marine Transmissions StepDrive

Installation & Service Manu al

2.2

Parts required

The StepDrive gearbox replaces the centre section of the 290DP drive leg. To complete the installation the drive must be removed from the boat and moved to a clean and dry area. In addition to the Volvo 290DP drive to be converted, the following parts will be required: ? StepDrive Gearbox, inc: - StepDrive Gearbox and plastic top cover - General Parts kit - O ring kit - Assembly kit Volvo shims for the Cone Clutch output ball bearing (not supplied) Volvo shims for the lower leg input tapered roller bearing (not supplied) Consumables such as Paint, Anti-foul, grease, medium strength thread lock, silicone etc (not supplied). In addition to these essential items, it is recommended that the normal service items be replaced as required (anodes, bellows etc).

? ? ? ?

In the event of the small electrical box mounted on the top of StepDrive becoming damaged, or failure of the spool valve or coil; Loctite Super Lube (available from Newage Spares Dept) will be required when assembling to protect the internals against water ingress. An installer for a new build should not require this grease. 2.3 Disassembly of Drive leg

Once the sterndrive has been removed from the boat in accordance with the guidelines set by Volvo Penta, the drive leg can now be disassembled as follows: 1. Place a suitable container under the sterndrive, remove the dipstick and remove the oil drain plug from the bottom of the duo-prop housing. Reinstall the drain plug after the oil has been drained. Examine the condition of the oil for signs of excessive heat (black), which may indicate the drive has been slipping, or has significant wear. If the oil is of white colour, it is likely that the drive was not sealed correctly, or has sustained damage to the joint faces. This will need investigating and curing prior to fitting StepDrive. Remove the cotter pin and washer from the gearshift linkage, and remove the linkage. This should be stored in a suitable container for the owner, as it will not be required for the StepDrive installation. Remove the two 3/8 UNC nuts from the upper gear head studs, and the two 3/8 UNC cap head bolts to remove the gear head, using a rubber mallet if required. NOTE: Retain all shims, as these will be required to calculate the new shims for the StepDrive. Remove the seven bolts fixing the lower gear housing to the intermediate housing (retaining all washers if present), and lift apart using a rubber mallet if required. The internal splined shear tube should be removed and placed with the linkage (see point 3). Again, all shims must be retained. The intermediate housing will not be required, however the H bracket, steering spindle, hose connection (and gasket), sealing rings and needle roller bearings/washers are retained for the StepDrive installation. Remove the two bolts fixing the plastic hose connection, and remove with gasket. Remove the yoke by driving out the steering spindle using Volvo Penta tools (884311 & 9991801).

2.

3.

4.

5.

6.

7. 8.

PRM Marine Transmissions StepDrive

Installation & Service Manu al

2.4

Shimming for the StepDrive

With the Volvo 290DP drive spit into the three fundamental parts, remove the bearing cup from the underside of the centre section (using pinch bars), and measure the bearing bore depth (ensuring the shims have been removed) with a depth-micrometer. Then measure the depth of the same bearing bore on the StepDrive g earcase. The StepDrive depth should be same or greater than the original housing; the difference should be made up by the addition of shims. If the exact shimming size is not available, up to 0.002 pre-load is acceptable, but there should be no float.

1) Old centre section bottom bearing bore depth 2) StepDrive bottom bearing bore depth x-w

=w =x

= Additional Shim size required

Repeat the above procedure for the output bearing of the Volvo top box by measuring the depths of the old and new bores. As this bearing is a ball bearing, if the exact size cannot be achieved, 0.002 (2 thou) float is acceptable.

1) Old centre section top bearing bore depth 2) StepDrive top bearing bore depth z-y

=y =z

= Additional Shim size required

Note, this shimming procedure is identical to replacing a standard Volvo 290DP centre section, and requires no additional special tooling. See your Volvo Penta drive workshop manual for further shimming details.

PRM Marine Transmissions StepDrive

Installation & Service Manu al

2.5

Building StepDrive into the Leg

Once the shimming has been calculated, the gearbox can now be assembled to the remaining Volvo components. Firstly, remove the H bracket from the old centre section, and fit to the StepDrive gearbox as described in the Volvo workshop manual. Note it is possible that this may need to be re-shimmed to minimise free play using Volvo shims (0.7, 0.8 and 0.9mm). 2.5.1 ? ? ? ? ? ? Assembling to the Lower Section

Clean the surfaces with an oil repellent solvent, and check for any lumps, bumps or burrs. Starting with the Volvo lower housing, insert the two studs (04805125S from Fastener Kit MT0518) into the housing to meet with the holes marked X on StepDrive (illustration), using a medium strength thread locking agent (not supplied). Using Loctite 518, create a continuous thin bead around the bearing, mounting holes and oil return hole, and also around the exhaust ducting (all on the Volvo lower unit). Using a brush, dab and spread this evenly to create the gasket, see figure 9. Place O rings into position with grease; one in StepDrive gearbox recess, and one in Volvo lower unit groove. Lower the StepDrive gearbox assembly on to the top of the Volvo lower housing, taking care not to disturb/move the O rings. Tighten the 5 cap screws and 2 nuts to the recommended Volvo tightening torque. NOTE: Actual O rings are not coloured, but are refereed on page 34.

Figure 7 O rings for Volvo Bottom Gear Housing

Figure 8 Photo showing even spreading of Loctite 518 sealant

PRM Marine Transmissions StepDrive

Installation & Service Manu al

2.5.2 ? ? ?

Assembling to the Upper Section

The existing Volvo studs (2 off) attached to the cone clutch gear housing should be retained, and checked that they do not protrude further than 39mm from the mounting face. Clean the mating surface with an oil repellent solvent, and check for any lumps, bumps or burrs. Use the O rings provided (within MT0519; 04309930V & 04302530V), and grease into position as shown below (colours refer to actual size colour chart in section 6.11). NOTE: Actual O rings are not coloured

Figure 9 O Rings for Volvo Top Gearbox ?

Morse cable shown for later reference only

? ? ?

Apply the Loctite 518 sealant with a continuous thin bead around the underside of the Volvo cone clutch gearbox, around the bearing, mounting holes and oil return aperture. Care should be taken to ensure that the sealant makes no contact with the bearing. Spread this evenly by using a brush to dab and spread the gasket. Lower the manifold onto the Volvo gear housing, using the studs for guidance, and ensuring that the O ring remain in the correct position. NOTE: The original Volvo bush/insert is not required in the hole marked Y. Insert the two new cap screws, and fit the new washers and nuts to the studs (supplied in the fastener kit MT0518) Tighten in standard opposite pattern to the correct tightening torque (specified by Volvo).

Figure 10 Photo showing even spreading of Loctite 518 sealant

10

PRM Marine Transmissions StepDrive

Installation & Service Manu al

2.5.3 ? ? ?

Joining the StepDrive

Check pump spline Check faces clear from lumps bumps and burrs and oil contamination Place O rings using grease NOTE: Actual O rings are not coloured; colours refer to section 6.11

Figure 11 O rings for StepDrive joining ? ? ? Apply a thin bead of Loctite 518 to the face around the O ring apertures, and spread evenly by dabbing with a brush, as illustrated below. Lower the top assembly onto the main gearbox, using the rear-mounting stud as a guide. Fasten the seven bolts and single nut to the correct tightening torque (28Nm)

Figure 12 Photo showing even spreading of Loctite 518 sealant

11

PRM Marine Transmissions StepDrive

Installation & Service Manu al

2.5.4 ? ?

Refitting the Sterndrive

Check for casting flash on exhaust bellow location groove. Repeat Volvo refitting instructions as normal. Take care not to damage the electrical cable in the process.

Mask off the transom, bellows etc, wash off any oil, grease or dirt using thinners or similar and paint the StepDrive with Volvo paint and or anti-foul. There is no necessity for priming as the gearbox is chromated. Assemble the linkage parts as illustrated below, using a Loctite thread locking agent on the ball joint thread (as indicated ), and ensure the split pin on the Volvo selector mechanism is bent to secure fitment. o The pivot bolt and nyloc nut A (for the fwd/rev crank; MT9041) should be done up sufficiently to ensure rotation, but not give any axial movement or wobble of the crank. Screw the loose clevis B onto the end of the Morse cable thread, to approximately the correct position, NOTE this will need to be adjusted and attached after section 2.6 of this manual.

Once the Morse cable has been slid to the top of the slot in the bracket (C), and the bracket securely fastened to the gearbox, use one of the M6 button head screws (3 supplied loose) and stainless steel nut to stop it from sliding out of position. Upon completion of section 2.6, assembled all remaining linkage parts (in neutral), check both split pins, and grease all pivot points and push/pull rod of the cable. Fit top cover with the two remaining M6 button head screws, and securely tighten. The gearbox top cover can now also be anti-fouled (optional), and the protective film over the serial plate removed; this should be grease for protection. The Volvo Penta sticker maybe purchased and added to the top cover (at additional cost).

A B

12

PRM Marine Transmissions StepDrive

Installation & Service Manu al

NOTE: Do not fill with oil until the unit has been air tested (see section 3). Props should only be installed when all dynamic testing has been completed.

Figure 13 Painted and Anti-fouled Drives.

13

PRM Marine Transmissions StepDrive

Installation & Service Manu al

2.6

Onboard 2.6.1 Helm Controls

Due to the configuration of the StepDrive gearbox, the actuation point on the brass crank of the Volvo cone clutch gearbox has been swapped to operate on the opposite end. For this reason the helm control will need to be changed to ensure that the cable follows the following rule: Cable PULL = Forward Cable PUSH = Reverse This will usually entail removing the helm lever body from the boat, and swapping the point of cable attachment to the opposite side of the fulcrum.

NOTE: Failure to complete this will result in the boat going in the opposite direction relative to the lever position

14

PRM Marine Transmissions StepDrive

Installation & Service Manu al

2.6.2

Switch Box

As seen in section 1.4.1 (Control), a switch box is supplied for turning StepDrive on and off (this is not essential to the operation of the gearbox, and should not be confused with manual control of ratio selection). Note, when in the Off position the sterndrive will have the same ratio as standard, and draw no electrical current. The location of this switch panel is not important but for simplicity and easy access Newage Transmissions Ltd recommend that it is fitted to the dashboard where possible. If this is not possible it can be mounted remotely, but this is dependent upon the cable length (cable is approximately 10 meters) and should be checked first. The switch box features water resistant switches, and the electrical circuit is sealed in a potting compound to ensure reliability. The panel itself is Aluminium and has been protected to limit oxidation in salt-water environments. The design of the switch box dictates that it must be mounted on a flat surface, and when completed it will be 3mm proud of the mounting surface (the thickness of the Aluminium plate). This will require an area where the dashboard can be drilled to create an aperture (see template below) for the electrical box and cabling. The panel should be secured to the dashboard using the fasteners supplied (2.8mm pilot hole), or suitable alternatives. (To avoid accidental switching, allow sufficient clearance from other controls).

NOTE: Ensure the area below the mounting surface is clear from obstruction/electrical cables.

Figure 14 Example of Switch box location.

15

PRM Marine Transmissions StepDrive

Installation & Service Manu al

Connecting the electrical plug (after feeding through hull to the control box)

Note: the cable colours should correspond to the mating plug on the Control Box.

The electrical contacts should be orientated so that the two location flats are pointing downwards with the black plastic plug in the shown position.

Rubber grommets

Figure 15 - Connecting the plug for the Switch Box

--------------------------------------------------------------------------------------------------------------------------

Template fo r hole

Figure 16 - Template for Switch Box

16

PRM Marine Transmissions StepDrive

Installation & Service Manu al

2.6.3

Engine Compartment

The gearbox control system can be mounted anywhere on the boat provided that there is sufficient cable length (within approximately 3-4 meters from the alternator). However, it is intended that the control unit will be located on the rear transom board, which is strengthened and suitable for screwing the controller to. This is also ideal for the connections to both the gearbox(s) and the alternator. The StepDrive control box will need to be firmly attached to the structure (via 2 screws, pilot hole 2.8mm), and although it is protected against water ingress, it should be kept dry, i.e. a safe distance from (and not directly below) fluid reservoirs, exhaust pipes water jackets etc. The StepDrive unit receives an electrical signal (12v in reduction, 0v in direct drive) from the control box to actuate the gear change. This will require drilling a 16mm hole (using a hole saw to limit damage to the gel coat) in the back of the boat, above the water line and to the right of the drive (viewed from astern) for the electrical cable (see section 2.6.4). The cable itself is then fed through the gland supplied and routed to the control box. It is worth noting that the drive leg is likely to be removed when servicing, so the StepDrive signal cable will need to be unplugged, and fed back through the hole; the cable routing should therefore be simple and easy to remove. The illustration below shows the recommended installation for a twin-engine boat with the helm on the starboard side:

Engine 1 Engine 2

Alternator Feed Control Box Figure 17 Installation guide

Switch Panel

17

PRM Marine Transmissions StepDrive

Installation & Service Manu al

NOTE: Always ensure that the battery has been disconnected before starting any of the electrical work.

The diagram below shows the electrical feed, signal and earth terminals from the alternator. With this configuration the system will only be On when the corresponding engine isolator is on, and hence if only one engine is to be used on a twin installation then the correct isolator must also be on to achieve the reduction gear. Note, this engine does not need to be running to achieve the reduction gear, but the StepDrive will not change gear automatically if the engine the control is connected to is not running.

Red = StepDrive Feed Black = Common earth Blue = Common earth Yellow = Signal feed

Figure 18 Alternator wiring (diesel engines)

Notes: Common installation fault: If the yellow signal wire is not connected to the W terminal, the gearbox will not change gear (out of reduction). Do not attach to the D terminal adjacent to it. Spanner sizes for reference: Positive Negative Signal = = = 10mm spanner & 10mm socket 10mm spanner & 8mm socket (deep) 10mm spanner & 7mm socket (deep)

18

PRM Marine Transmissions StepDrive

Installation & Service Manu al

2.6.4

Outside the boat

It is essential that the cable has sufficient length between the gearbox and gland to enable full steering lock to be achieved, and that the cable does not get trapped when trimming the leg to its extremities. The gland is attached using the screws supplied; drill a 2. 8mm pilot hole to a depth of approx 10mm and a 3mm hole through the gel coat to avoid the screw from splitting the outer surface. The cable should be P clipped to the hull as illustrated below, using a sealing agent around the screws:

Note: Vertical tube is Speedo Figure 19 Example of cable run, P clips and gland mounting.

19

PRM Marine Transmissions StepDrive

Installation & Service Manu al

3 3.1 Post assembly testing

Testing

As with all PRM gearboxes, StepDrive is tested after manufacture to the specification listed in section 1.3 of this manual. For this reason the extent of post-build testing is limited to proving the successful installation of StepDrive to the 290DP sterndrive. As highlighted in the Volvo Pentas Drive workshop manual, the complete assembly should be pressure and vacuum tested prior to being filled with oil to ensure that no water can enter the drive during use. This should be done using Volvo Penta Part numbers 3810152 and 3858578, and following their guidelines, however, the procedure has been summarised below: 1) Pressure Test: ? ? With no oil in unit pressurise the assembly to 21-35KPa (3-5psi), turn the input and output shafts and observe any pressure loss. If passed: Increased the pressure to 110-124KPa (16-18psi). No more than 7KPa (1psi) must be lost ove r a 3-minute test.

If the test fails, use a soapy water solution or dip the drive in water to find the leak point. Do the necessary repairs and repeat the test. 2) Vacuum Test ? ? Evacuate the drive through the drain hole to 10-17KPa (1.5-2.5psi), turn the input and output shafts and observe vacuum loss. If passed: Increased vacuum to 47-54KPa (7-8psi) and monitor decay, no more than 3.4KPa (0.5psi) must be lost over a 3-minute test.

On completion of the above tests the StepDrive may be filled with oil (approximately 4 litres, GL-5 synthetic oil). It is important that the oil level is to the top of the dipstick mark, and as such should only be filled in the vertical position to avoid creating air locks within the StepDrive. For this reason do not fill with oil at an angle as described in the Volvo manual for the standard leg.

NOTE: The following testing should be completed with the Propellers removed. This work should never be completed alone.

When attached to the transom shield, the drive should be tested up to a speed of approximately 1500rpm in forward gear (by using the tap water muffs for cooling). The gearbox may take a second or two to prime for the first time, but if the output fails to rotate increase the engine speed to 2500prm. Under no circumstances should the output shaft be touched during this process. Repeat in reverse and leave running for approximately 1 minute at 1500rpm. Once the gearbox has been spun up and the hydraulics primed, the drive should be left for approximately 2 minutes to allow the oil to settle. Then re-check the oil level and top up as required (to the top of the dipstick mark). For reference: 3800rpm is 886Hz (Approximate gear change point from reduction to direct drive) 1500rpm is 350Hz (Approximate gear change point back to reduction)

20

PRM Marine Transmissions StepDrive

Installation & Service Manu al

Warranty

The product you have purchased comes with a limited warranty from Newage Transmissions Ltd; the terms of are which are listed below. The warranty statement contains a description of what is covered, what is not covered, the duration of coverage, how best to obtain warranty coverage, important disclaimers and limitations of damages, and other related information. The purpose of this section is to help eliminate some of the more common misunderstandings regarding warranty coverage. Keep in mind that warranty covers repairs that are needed within the warranty period because of defects in material and manufacture. Installation errors, normal wear and a variety of other causes that affect the product are not covered. Warranty is limited to defects in material or manufacture, but only when the customer purchases from a distributor authorised by us, or otherwise agreed in writing by Newage. Should you have any questions concerning warranty coverage contact your authorised distributor. 4.1 Validity Period

Newages Conditions of Sale set out Newages standard warranty. You will note that the standard warranty period is two years from the date of commission or 1000hrs operation for pleasure use only. We may vary the standard warranty by notice to you in writing. 4.2 StepDrive Product

Where the Step Drive does not comply with its warranty then Newage will, at its option, either replace the defective product or take such steps as it deems necessary to render the product free from such defects, provided that: a) The units have been stored, installed, used and maintained properly and carefully, and in accordance with the instruction issued by Newage; and the warranty registration form has been completed & returned to Newage. b) The problem is related to parts supplied by Newage as part of a Step Drive gearbox. Problems arising from oil leaks at the interface of the Step Drive and the Volvo drive leg are not covered by this agreement. c) Newage has received notice in writing of the alleged defect within fourteen days of its discovery. d) Newage is given a reasonable opportunity to inspect the product which, if required by Newage, will be returned to Newage's works at Coventry, England, for inspection. e) The owner/operator makes no further use of the product that is alleged to be defective after the defect is discovered or ought to have been discovered.

21

PRM Marine Transmissions StepDrive

Installation & Service Manu al

4.3

Limitation of Liability

Your attention is drawn to the various exclusions and limitations of liability of Newage set out in Newages Conditions of Sale. 4.4 Items not supplied by Newage

For the avoidance of doubt, parts or components not supplied by Newage as an integral part of, or for use with its products, do not have the benefit of a warranty from Newage. 4.5 Advice

All recommendations and advice given by or on behalf of Newage as to the methods of installing or using the products or the purposes to which the products may be applied are given without liability on the part of Newage, its servants or agents. Newage does not include any liability for death or personal injury arising from Newages negligence. 4.6 Illustration of Warranty Cover

By way of illustration only, the following non-exhaustive list of services and expenses are not covered by Warranty: a) b) Damage or loss related to shipping and handling. Lift out and launch fees, towing charges, dockage, storage fee telephone calls, fuels, loss of revenue, transportation charges, overtime pay, loss of or damage to personal property, cost of oils and lubricants, medical expenses. Costs of preparatory work related to warranty work, such as costs of moving furniture and removing carpet or other installations or fittings. Failure caused by use of improper lubricant. Failure caused by inadequate cooling. Failure caused by non-observance of recommended operation and maintenance procedures detailed in Newage's owners handbook or workshop manual. Cost of repairs caused by misuse, accident, neglect or racing. Cost of repairs made necessary by installations that do not meet the minimum standards set out in Newage's workshop manual, including failures due to misalignment, ingress of foreign matter etc. Repeat failures when the distributor performs repair. Warranty will not be allowed on any unit that fails after being used in any application outside the ratings and classification approved by the factory. Newage Transmissions Limited will provide all possible information and assistance to help find solutions to torsional problems, but it is the ultimate responsibility of the person assembling the drive and driven equipment to ensure that they are torsionally compatible.

c)

d) e) f)

g) h)

i) j)

k)

These items, together with non -reimbursable materials and labour supplied by a distributor are exclusively the responsibility of the distributor who performs such work.

22

PRM Marine Transmissions StepDrive

Installation & Service Manu al

4.7

Transferable Warranty

The product warranty is transferable to a subsequent purchaser, but only for the remainder of the unused portion of the limited warranty. This will not apply for commercial applications. The second owner can be registered as the new owner and retain the unused portion of the limited warranty by sending a copy of the bill of sale to Newage Transmissions Ltd. to show proof of ownership. 4.8 Stolen StepDrive Unit

If your StepDrive is stolen, immediately advise the local authorities and Newage Transmissions Ltd of the serial number(s) and to whom the recovery is to be reported. The Stolen StepDrive information is placed into a file at Newage Transmissions Ltd to aid authorities and distributors in recovery of stolen units Claims for replacement of parts under warranty must always be submitted with the gearbox serial number to the distributor who supplied the gearbox; if this is not possible, application may be made to Newage Transmissions Ltd, who must be advised of the supplier's name and address. REMEMBER TO RETURN YOUR WARRANTY REGISTRATION This is supplied loose, and an example of which is shown below. Failure to do so may invalidate warranty

Figure 20 Copy of Warranty Registration Form - send to Newage

23

PRM Marine Transmissions StepDrive

Installation & Service Manu al

5 Yearly, or every 200 hours: ? ? ? ? ?

Servicing

Suction strainer cleaned and refitted (use existing O ring) Replace pressure filter kit MT0516-KIT (tighten to 55Nm) Replace the Oil (approx 4 litres of synthetic GL-5). Note the hydraulics will need to be primed, and the oil level check after testing. Grease linkages Anti foul as required

Drive unit oil capacity - approx 4.0 litres, SAE 75W/90, GL-5 synthetic transmission oil Volvo Penta Part Number: 1141634 1 litre Plastic Bottle 1141635 5 litre Plastic Bottle 1141636 20 litre Metal Drum

If the StepDrive is split to gain access to the Volvo top box, or is removed from the Volvo lower section, the Loctite 518 flange sealant will need to be scraped off using a flat scraper without damaging the joint face. To reassemble the gearbox, repeat the relevant instructions from above and fit with new O rings (Part number MT0519-KIT). The gearbox should also be pressure tested before commissioning. Other service parts available: MT9058: Loctite 518 flange sealant (50ml). MT9059: Loctite Super Lube (85g). MT9060: Pressure gauge adaptor To be used on all joint faces (except pump face). To be used in MT9004 potting box. To use with MT4733 pump pressure gauge (taken from the top manifold by removing the pressure plug; item 10 in section 6.5).

For all serviceable parts and consumables please contact your StepDrive dealer, or StepDrive Sales Newage Transmissions Ltd Barlow Rd Coventry CV2 2LD England

24

PRM Marine Transmissions StepDrive

Installation & Service Manu al

6 6.1

Parts List

StepDrive General Assembly Main Gearbox

Note: 518 Sealant used on joint face

25

PRM Marine Transmissions StepDrive

Installation & Service Manu al

ITEM NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

QTY. 1 2 1 1 1 2 1 1 1 1 n/a n/a n/a n/a 2 1 1 1 4 1 4 1 1 3 1 2 1

NEWAGE PART No. MT9002 092065SA MT9009SA 04302025V MT9033 09303AV MT9015SA MT9016SA MT9001 MT9034 MT1075/02 MT1075/10 MT9053/02 MT9053/10 0210815 04908080S 0191006S 0050801S 0081435ZP 0081320S 0430072V 0430623V 002-0320V 002-0340V 04308030V 04302530V 04309930V

DESCRIPTION Lee Plug Suction Strainer 'O' Ring Oil Return Tube Zero Leak -3 Plug MainShaft Assembly Layshaft Assembly Maincase Oil Collection Tube Layshaft Shim (0.002") Layshaft Shim (0.010") Mainshaft Shim (0.010") Dowel Stud M8 x 80 M8 Washer (plain) M8 Nut (std) M8 Cap Screw (Zinc & Clear) M6 Cap Screw 'O' Ring - Solenoid Ports O' rings MT0519-KIT 'O' Ring - Mainshaft brg 'O' Ring - Lub ports 'O' Ring - Volvo bottom joint face 'O' Ring - Volvo lub joint faces 'O' Ring - Volvo top joint face Parts not shown: Item 27 (See 5.2) 'O' Ring - Layshaft Brg Misc Parts Mainshaft Shim (0.002") Parts not shown: 0890620 - Helicoil M6x12 (1 off) 0890815 - Helicoil M8x12 (12 off) 0900320 - Helicoil 3/8" UNCx3/4" (4 off) 09304AV - Zero Leak plug -4 (1 off) Manifold Assy Manifold

26

PRM Marine Transmissions StepDrive

Installation & Service Manu al

6.2

StepDrive General Assembly Top Manifold

From section 5.1

27

PRM Marine Transmissions StepDrive

Installation & Service Manu al

ITEM NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

QTY. 1 1 1 1 1 1 1 2 2 2 1 1 5 2 2 1 1 2 2 2

NEWAGE PART No. MT9038 MT9041 MT9043 MT9044 Mt9042 MT9045 MT9061 0771312 W102 0060656 0050801S 0191006S 0081465S 0081485S 0083310S 0081435S 0050806S 0060555S 0191006S 04805125S

DESCRIPTION General Parts Fasteners StepDrive Cover Fwd/Rev Crank Linkage Assy Clevis Assy Morse Bracket Control System (Not shown) Signal Cable Assy 3/8 UNC Cap Screw 3/8 UNC Washer 3/8 UNC Nut (Nyloc, Type 'T') M8 Nut (std) M8 Washer (plain) M8 Cap Screw (65 long) M8 Cap Screw (85 long) M6 Button Screw M8 Cap Screw (35 long) M8 Nut (Nyloc, Type 'T') 5/16 UNC Nut (Nyloc) M8 Washer (plain) 5/16 UNC Stud x 38 long * * * * * * * * * * * *

* Items supplied loose as parts required for assembly.

28

PRM Marine Transmissions StepDrive

Installation & Service Manual

6.3

Mainshaft Assembly

ITEM NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

QTY. 1 1 2 1 2 2 1 1 1 1 1 1 1 7 7 1 1 1 1 1

NEWAGE PART No. MT9019 MT9015 MT9024 MT9022 04307415V 0540455 04307030V 04303530V MT9025 MT9026 MT9048-MC 0603001 0593001 MT9014 MT9013 MT9012 0250800 0270500 0535041 MT9017

DESCRIPTION Clutch Gear Insert Mainshaft Clutch Gear Piston Ring Mainshaft Clutch Feeder O' Ring (Viton) Tapper Roller Bearing O' Ring (Viton) O' Ring (Viton) Clutch Piston Crest-To-Crest Spring Thrust Washer Thrust Bearing Thrust Washer Clutch Mating Plate Sintered Clutch Plate Reaction Plate Circlip Brg Retaining Ring Cylindrical Roller Bearing Mainshaft Pinion Short (C, D & E)

29

PRM Marine Transmissions StepDrive

Installation & Service Manual

6.4

Layshaft Assembly

ITEM NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

QTY. 1 1 2 1 2 2 1 1 1 1 1 1 7 7 1 1 2 2 2 1 1 1

NEWAGE PART No. MT9020 MT9016 MT9024 MT9023 04306215V 0540251 04307030V 04303530V MT9025 MT9026 MT9048-MC 0603001 MT9014 MT9013 MT9012 0250770 0300250 0562504 MT1600 MT9018 0602801 0592501

DESCRIPTION Layshaft Layshaft Clutch Gear Piston Ring Layshaft Clutch Feeder O' Ring (Viton) Tappered Roller Bearing O' Ring (Viton) O' Ring (Viton) Clutch Piston Crest-To-Crest Spring Thrust Washer Thrust Bearing Clutch Mating Plate Sintered Clutch Plate Reaction Plate Circlip External Spring Ring Needle Roller Bearing Spacer Layshaft Pinion Gear Thrust Bearing Thrust Washer (REF AS2542)

30

PRM Marine Transmissions StepDrive

Installation & Service Manu al

6.5

Solenoid Housing Assembly

ITEM NO. 1 2 3 4 5 6 7 8 9 10

QTY. 1 1 4 2 1 1 1 1 1 1

PART NO. MT9003 MT9004SA MT9006SA MT9008 MT9027 MT9028 MT9051 092065A MT9054SA 09303SA

DESCRIPTION Solenoid Housing Manifold Potting Box Assy NRV Sub Assy NRV Plug Solenoid Spool Valve Solenoid Coil (12v) M4 Cheese Head (70 long) Lee Plug Relief Valve Assy Pressure plug (-3)

Note: Hydraulic sealant (Loctite 542) to be used on M24 threads (items 4 and 9)

31

PRM Marine Transmissions StepDrive

Installation & Service Manu al

6.6

Pump Manifold Assembly

ITEM NO. 1 2 3 4 5 6 7 8 9 10 11

QTY. 1 2 1 1 1 1 3 1 2 3 4

NEWAGE PART No. MT9005 MT323 MT1496 MT9032 MT9037SA 0430712V 0560801 0560901 022D304 0081320S 0081416S

DESCRIPTION Pump Manifold Pump Gear Secondary Pump Spindle Pump Drive Spindle Filter Bowl Assy O' Ring (Viton) Needle Roller Brg Needle Roller Brg Dowel (3/16" x 1/2") M6 Cap Screw (Stainless) M8 Cap Screw (Stainless)

Note: Pump faces and filter bowl thread to be smeared with grease when assembled.

32

PRM Marine Transmissions StepDrive

Installation & Service Manu al

6.7

Non-Return Valve Sub-Assembly

ITEM NO. 1 2 3 4 5 6

QTY. 1 1 1 1 1 1

NEWAGE PART No. MT9006 066M140 0311055 MT9007 0250180 04301915V

DESCRIPTION NRV Cassette NRV Steel Ball NRV Ball Spring NRV Spring Seat NRV Circlip O' Ring (Viton)

Note: NRV Steel Ball to be seated into NRV Cassette when assembled. 6.8 Solenoid Cover Assembly

Note: Potting box to be filled with Loctite Super Lube (available through spares MT9059)

ITEM NO. 1 2 3 4

QTY. 1 1 1 1

NEWAGE PART No. MT9004 MT9040 MT9046 0050601S

DESCRIPTION Solenoid Cover Grease Nipple Grommet M6 Nut (SS)

33

PRM Marine Transmissions StepDrive

Installation & Service Manu al

6.9

Relief Valve Assembly

ITEM NO. 1 2 3 4 5

QTY. 1 1 1 2 1

NEWAGE PART No. MT9055 MT9054 MT9057 04301915V MT9056

DESCRIPTION Piston Housing Piston Spring (550psi) O' Ring (Viton) Spring Housing

Note: Piston to be seated into the piston hsg when assembled, and should be free moving within the bore. Shims available from Newage Spares for pressure setting. 6.10 Filter Kit (MT0516-KIT)

34

PRM Marine Transmissions StepDrive

Installation & Service Manu al

6.11

Inside the box 1) 2) 3) 4) 5) 6) 7) StepDrive Gearbox, including signal lead & top cover Gland Electrical Control Box (MT9045). O ring kit, see above (MT0519-KIT). Loctite 518 sealant (MT9058) Switch panel, optional (MT9062). Assembly Parts shown over page.

Switch Box (MT9062) Gland

Control Box (MT9045)

50ml

NOTE: The StepDrive gearbox has been supplied with 4 rubber bungs to limit the oil (used for testing at the factory) from leaking. These should be removed and returned to Newage Transmission Ltd.

35

518 FLANGE SEALANT

Loctite 518 Sealant (MT9058)

PRM Marine Transmissions StepDrive

Installation & Service Manu al

Assembly Parts 0083310S

MT9052 0050601S Morse Cable Lock MT9041 Pivot Bolt & Nut

MT9065

MT9043

0081435S

MT9044 0050806S

0060555S

0771312 0191006S

W102 04805125S

0060656

Upper leg mounting 36

Lower leg mounting

PRM Marine Transmissions StepDrive

Installation & Service Manu al

O Rings (MT0519-KIT)

x2

04302530V

x3

002-0340V

04309930V

x1

04308030V

x1

002-0320V

x1

0430623V

x1

0430072V

x4 37

PRM Marine Transmissions StepDrive

Installation & Service Manu al

6.12

StepDrive Fault Finding Chart

Symptom

Reason

Cause Not in gear - Broken/incorrect cable installation No input rotation - Damaged Volvo cone clutch g/box Low oil level StepDrive not priming through NRV's Damaged pump

Remedy Check morse cable operation Check yoke joint etc, repair as required Top up as required (drive vertical) Follow procedure in manual Contact Newage PRM Top up as required (drive vertical) Remove, clean strainer/replace filter Contact Newage PRM Contact Newage PRM Contact Newage PRM Use 'O' ring kit and repair Remove, clean and re-seat Contact Newage PRM Contact Newage PRM Use 'O' ring kit and repair Remove, clean and re-seat Contact Newage PRM See above Contact Newage PRM Fill to correct level See above Contact Newage PRM Check relevant engine isolator Check alternator terminals Damaged electrical cable Contact Newage PRM Check tacho is operative Check charging circuit voltage

No Drive ahead or astern No internal oil pressure

Prop speed does not increase with engine speed ahead or astern

Low oil pressure

Low oil level Blocked oil strainer and/or filter Jammed PRV Damaged/worn pump

Prop does not increase with engine speed in reduction

Slipping clutch

Worn clutch feeder ring Damaged joint face 'O' ring NRV's not seating Worn Clutch plates Worn clutch feeder ring Damaged 'O' ring NRV's not seating Worn Clutch plates Low oil pressure Over load through hitting forign bodies Over filled Low oil pressure Blocked oil way No power to alternator No power to control box No power to solenoid Solenoid coil/valve inoperative

Prop does not increase with engine speed in direct drive

Slipping clutch

Excessive oil temperature

Internal damage Too much oil Clutch slip

Drive will not start in reduction

Electrical fault

Drive will not change to direct drive

No input signal to control box

Failed alternator Low boat battery voltage Incorrect cable instalation

Check yellow lead is 'W' terminal Damged signal cable from alternator Check yellow cable for damage

38

PRM Marine Transmissions StepDrive

Installation & Service Manu al

Approved Installation Centres

Berkshire DB International Ltd Cookham Bridge Cookham-on-Thames SL6 9SN Cornwall Marine Engineering Looe The Quay East Looe PL13 1AL Essex VOLSPEC LTD Woodrolfe Road Tollesbury Maldon CM9 8SE Hampshire RK MARINE LTD Hamble River Boatyard Bridge Road Swanwick Southampton SO3 7EB Sussex BA Peter Plc Peters Shipyard Chichester Marina Chichester PO20 7EJ Wales Abersoch Land & Sea Royal Garage Abersoch Pwhelli

Tel: 01628 526 032 Fax: 01628 520 564 E- mail: sales@dbmarine.co.uk

Tel: 01503 262 887 Fax: 01503 264 722 E- mail: paullyle@melooe.co.uk

Tel: 01621 869756 Fax: 01621 868859 E- mail: sales@volspec.co.uk

Tel: 01489 583572 & 583585 Fax: 01489 583172 E- mail: parts.rkmarine@btinternet.com

Tel: 01243 512 831 Fax: 01243 511 447 E- mail: willmarrs@petersplc.com

Tel: 01758 713 434 Fax: 01758 713 150 E- mail: aberlandandsea@hotmail.com

39

Das könnte Ihnen auch gefallen

- VP Sterndrive Manual 280285290Dokument180 SeitenVP Sterndrive Manual 280285290ronny_tomren100% (1)

- Owner S ManualDokument88 SeitenOwner S ManualvladaukiNoch keine Bewertungen

- SX-M Drive Workshop ManualDokument270 SeitenSX-M Drive Workshop ManualcarylangleyNoch keine Bewertungen

- Volvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi Sez.8-9Dokument35 SeitenVolvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi Sez.8-9Luciano LiuzziNoch keine Bewertungen

- Installation Reference, Volvo Penta IPS Propulsion Unit and EngineDokument2 SeitenInstallation Reference, Volvo Penta IPS Propulsion Unit and Engineakhil9182100% (1)

- Ham International 3 Series Service Manual PDFDokument18 SeitenHam International 3 Series Service Manual PDFbobbyunlockNoch keine Bewertungen

- Instruction Book: 31, 32, 41, 42, 43 SeriesDokument74 SeitenInstruction Book: 31, 32, 41, 42, 43 SeriesIvan HorakNoch keine Bewertungen

- XT0425 Parts ManualDokument105 SeitenXT0425 Parts ManualG SNoch keine Bewertungen

- M.atelier Model NC 1996 - Mfi Diagnostic (7.4gi Gsi 8.2gsi) - GM - Pages.1 20Dokument20 SeitenM.atelier Model NC 1996 - Mfi Diagnostic (7.4gi Gsi 8.2gsi) - GM - Pages.1 20MichałNoch keine Bewertungen

- Merc Gas EnginesDokument181 SeitenMerc Gas EnginesyamyrulesNoch keine Bewertungen

- Simrad CX34/44/54: Installation ManualDokument62 SeitenSimrad CX34/44/54: Installation ManualVasile NicolaeNoch keine Bewertungen

- Mercruiser Sterndrive Drive Shaft Housing Components Exploded View Diagram and PartsDokument8 SeitenMercruiser Sterndrive Drive Shaft Housing Components Exploded View Diagram and PartsGerardo Espinola Cardozo100% (1)

- Workshop Manual: Technical Data 31, 32, 41, 42, 43, 44, 300-Series BDokument32 SeitenWorkshop Manual: Technical Data 31, 32, 41, 42, 43, 44, 300-Series BVOLVO VPVN100% (1)

- DP SM DP SM 1.68 DP SM 1.78 DP SM 1.95 DP SM 2.32 DP SMTD 1.95 DP SMTD1 1.95 DP SMTD3 2Dokument41 SeitenDP SM DP SM 1.68 DP SM 1.78 DP SM 1.95 DP SM 2.32 DP SMTD 1.95 DP SMTD1 1.95 DP SMTD3 2Michael Kashiotis100% (1)

- Preliminary: Engine and Control SystemsDokument24 SeitenPreliminary: Engine and Control SystemsAnderson VulczakNoch keine Bewertungen

- EVC-D Calibration and Settings Aquamatic Installations D3, D4, D6Dokument2 SeitenEVC-D Calibration and Settings Aquamatic Installations D3, D4, D6Николай АксёновNoch keine Bewertungen

- Mercury Verado V8, SeaPro V8 Operation and Maintenance Manual (PDF, EnG, 5.42 MB) - CompressedDokument123 SeitenMercury Verado V8, SeaPro V8 Operation and Maintenance Manual (PDF, EnG, 5.42 MB) - Compressedlee sampsonNoch keine Bewertungen

- Workshop Manual Engine 43Dokument262 SeitenWorkshop Manual Engine 43Michael TombergerNoch keine Bewertungen

- Accessories Catalog PDFDokument92 SeitenAccessories Catalog PDFDaniel OOWNoch keine Bewertungen

- Alpha One Gen IIDokument1 SeiteAlpha One Gen IIWanda MarthaNoch keine Bewertungen

- Volvo Penta 3.0 4.3 5.0 5.7 WiringDokument28 SeitenVolvo Penta 3.0 4.3 5.0 5.7 Wiringso full of HHONoch keine Bewertungen

- EN - Operators Manual TAMD74CL, TAMD75P PDFDokument84 SeitenEN - Operators Manual TAMD74CL, TAMD75P PDFDmitryNoch keine Bewertungen

- Raymarine Type 150 & 400 Autopilot System Manual PDFDokument64 SeitenRaymarine Type 150 & 400 Autopilot System Manual PDFfbeasby100% (1)

- Alpha Transom Assembly & ServiceDokument73 SeitenAlpha Transom Assembly & ServiceDave Lamers100% (1)

- Alarmes SmartcraftDokument52 SeitenAlarmes SmartcraftEdgar PinheiroNoch keine Bewertungen

- tp5982 PDFDokument64 Seitentp5982 PDFVincent RadityaNoch keine Bewertungen

- Chaparral 290 Part ListDokument55 SeitenChaparral 290 Part ListVincent RadityaNoch keine Bewertungen

- By Engine ManualDokument392 SeitenBy Engine ManualDmitry100% (1)

- Minicommand: Operation, Installation & Troubleshooting ManualDokument183 SeitenMinicommand: Operation, Installation & Troubleshooting ManualBoris ZhilkinNoch keine Bewertungen

- How To Identify A Volvo Penta Gas EngineDokument4 SeitenHow To Identify A Volvo Penta Gas EngineUmar ShamsudinNoch keine Bewertungen

- Volvo Penta Aquamatic 280Dokument181 SeitenVolvo Penta Aquamatic 280Rodrigo Perez100% (2)

- 3126B Marine Engines: Maintenance IntervalsDokument38 Seiten3126B Marine Engines: Maintenance IntervalsjoelsanchezcamachoNoch keine Bewertungen

- Saildrive 130 150 Workshop Manual 7742984Dokument100 SeitenSaildrive 130 150 Workshop Manual 7742984Simon100% (2)

- 2003 200 Bow RiderDokument36 Seiten2003 200 Bow Riderbbenz62Noch keine Bewertungen

- Cola VolvoDokument102 SeitenCola Volvovicente100% (1)

- Service Manual enDokument116 SeitenService Manual enMartin Roger100% (1)

- D C A B: Installation Electronic Vessel Control D4, D6 EVC - CDokument2 SeitenD C A B: Installation Electronic Vessel Control D4, D6 EVC - Csivan_sg1800Noch keine Bewertungen

- 4.3L/5.0L Mpi Ect Mercury Mercruiser: Operation Maintenance & Warranty ManualDokument149 Seiten4.3L/5.0L Mpi Ect Mercury Mercruiser: Operation Maintenance & Warranty ManualDrazenNoch keine Bewertungen

- 8m0133411 PDFDokument115 Seiten8m0133411 PDFcharlesNoch keine Bewertungen

- Workshop Manual: EGC DiagnosticsDokument316 SeitenWorkshop Manual: EGC DiagnosticsThan MinZawNoch keine Bewertungen

- Volvo Penta Installation Checklist D4/D6/D8/D11/D13 Inboard (Version 3.7)Dokument28 SeitenVolvo Penta Installation Checklist D4/D6/D8/D11/D13 Inboard (Version 3.7)Boris Sitorus100% (1)

- Alpha One Generation Ii Stern Drive: IndexDokument37 SeitenAlpha One Generation Ii Stern Drive: IndexNicholas Ribic100% (1)

- Owner'S Manual: Ilmor EnginesDokument60 SeitenOwner'S Manual: Ilmor EnginesBill MontgomeryNoch keine Bewertungen

- Mercruiser 4.5L Alpha BravoDokument102 SeitenMercruiser 4.5L Alpha BravoLucas Oliveira100% (1)

- Dometic QHT Control User ManualDokument24 SeitenDometic QHT Control User ManualLin LinNoch keine Bewertungen

- M.atelIER-Model NC 1996-Electrical & Ignition - Pages.1 20Dokument20 SeitenM.atelIER-Model NC 1996-Electrical & Ignition - Pages.1 20Anonymous M0OEZEKoGi100% (1)

- Accessories CatalogDokument92 SeitenAccessories CatalogDavid PomaNoch keine Bewertungen

- Accessories Catalog PDFDokument96 SeitenAccessories Catalog PDFSanti Al ElricNoch keine Bewertungen

- MD 2040D-BT Workshop ManualDokument96 SeitenMD 2040D-BT Workshop ManualChris Wooley100% (4)

- Daedong DT100NS Power Tiller Operator's ManualDokument15 SeitenDaedong DT100NS Power Tiller Operator's ManualLisakolyNoch keine Bewertungen

- 5.7 GS Volvo Penta Owners ManualDokument88 Seiten5.7 GS Volvo Penta Owners ManualJerryMartin100% (1)

- TAD 734 GE Manual OperadorDokument70 SeitenTAD 734 GE Manual OperadorMauricio BozzoNoch keine Bewertungen

- Volvo Tad741ge OpmDokument64 SeitenVolvo Tad741ge OpmIvica Karas50% (2)

- Mercruiser Stern Drive Service ManualDokument14 SeitenMercruiser Stern Drive Service ManualDes Stirling0% (1)

- Principles of Operatiom Po4016enDokument116 SeitenPrinciples of Operatiom Po4016enSherzad Chem100% (2)

- DFA1101GZ5AD6J-907 Operational Manual-200606 - English PDFDokument92 SeitenDFA1101GZ5AD6J-907 Operational Manual-200606 - English PDFKemal Lisnik ArnautovicNoch keine Bewertungen

- Volvo TAD 952 VE - enDokument78 SeitenVolvo TAD 952 VE - enidelfonsoNoch keine Bewertungen

- GBM 1325g Pilot Tube Lubrication Pump OmDokument115 SeitenGBM 1325g Pilot Tube Lubrication Pump OmItzhak SchwartzmanNoch keine Bewertungen

- Workshop Manual Engine ComponentsDokument384 SeitenWorkshop Manual Engine Componentsfreeze595988% (34)

- Final Drive UnitDokument8 SeitenFinal Drive UnitIsaiah Lule100% (5)

- Our Comprehensive Offering For The Dairy Industry: With Totally Integrated AutomationDokument18 SeitenOur Comprehensive Offering For The Dairy Industry: With Totally Integrated AutomationStancu AlexandruNoch keine Bewertungen

- D101NLB - D102NLB Service GB - 10 - 2012Dokument124 SeitenD101NLB - D102NLB Service GB - 10 - 2012hoiNoch keine Bewertungen

- Decanter Alfa LAval ALDEC 30Dokument134 SeitenDecanter Alfa LAval ALDEC 30Antonio Duarte83% (6)

- Columbus Calling: Gear Expo 2017 Preview Booth Previews, Part IDokument110 SeitenColumbus Calling: Gear Expo 2017 Preview Booth Previews, Part IMAKINONoch keine Bewertungen

- CHAPTER 8 Engine Lubrication and CoolingDokument30 SeitenCHAPTER 8 Engine Lubrication and CoolingRushabh PatelNoch keine Bewertungen

- Worms Worm Gears-Formulas Self Locking PDFDokument1 SeiteWorms Worm Gears-Formulas Self Locking PDFalexdisu4510Noch keine Bewertungen

- User Manual Commercial Mixer Planetary Mixer With Meat Grinder Attachment 20 Liters Ce Gear Transmission b20f4Dokument10 SeitenUser Manual Commercial Mixer Planetary Mixer With Meat Grinder Attachment 20 Liters Ce Gear Transmission b20f4becosmeNoch keine Bewertungen

- LF90D Tech DataDokument6 SeitenLF90D Tech DataJose VidalNoch keine Bewertungen

- Magazine Farmax enDokument24 SeitenMagazine Farmax enAbdi LadiantoNoch keine Bewertungen

- Gear Geometry & Profile TheoryDokument24 SeitenGear Geometry & Profile Theoryansh1983100% (2)

- MDSP - February 2022Dokument7 SeitenMDSP - February 2022Joshua Gagate100% (1)

- Nagapattinam - 611002.: E.G.S. Pillay Engineering CollegeDokument35 SeitenNagapattinam - 611002.: E.G.S. Pillay Engineering CollegePrasath MurugesanNoch keine Bewertungen

- Ae - MTRLDokument30 SeitenAe - MTRLHemanth KumarNoch keine Bewertungen

- Swarnandhra College of Engineering & Technology Department of Mechanical Engineering Course Information SheetDokument9 SeitenSwarnandhra College of Engineering & Technology Department of Mechanical Engineering Course Information SheetMurali VangalapatiNoch keine Bewertungen

- Unified Mechanical Engineering Lab-2Dokument38 SeitenUnified Mechanical Engineering Lab-2sharmashnNoch keine Bewertungen

- SDSF Datasheet 120808Dokument2 SeitenSDSF Datasheet 120808Rex LinNoch keine Bewertungen

- 13 1964 CH-Auto TransDokument32 Seiten13 1964 CH-Auto TransJose LaproviteraNoch keine Bewertungen

- Weatherford Pumping Unit AmpscotDokument15 SeitenWeatherford Pumping Unit AmpscotMostafa AlamirNoch keine Bewertungen

- Design and Performance Analysis of Helical Gear For Al and Steel Material by Using AnsysDokument10 SeitenDesign and Performance Analysis of Helical Gear For Al and Steel Material by Using AnsysankNoch keine Bewertungen

- Industrial Chain Sprocket Suppliers and Exporters in MumbaiDokument7 SeitenIndustrial Chain Sprocket Suppliers and Exporters in MumbaiSubbuNoch keine Bewertungen

- Catia-Interface For KisssoftDokument1 SeiteCatia-Interface For KisssoftrezaNoch keine Bewertungen

- 3.1 GL For Selection of Turbine and Governing PDFDokument96 Seiten3.1 GL For Selection of Turbine and Governing PDFPablo German TouriñanNoch keine Bewertungen

- Gear Geometry For Reduced and Robust Transmission Error and Gearbox NoiseDokument21 SeitenGear Geometry For Reduced and Robust Transmission Error and Gearbox Noiseranim najibNoch keine Bewertungen

- Final Project Design Report FinalDokument18 SeitenFinal Project Design Report Finalrock starNoch keine Bewertungen

- B16,18,20X-7 Sb1189e00Dokument472 SeitenB16,18,20X-7 Sb1189e00Ricardo VieiraNoch keine Bewertungen

- 2018 Dewalt Power Tools CatalogDokument17 Seiten2018 Dewalt Power Tools CatalogLady HolguinNoch keine Bewertungen

- 02 Design of Clutch and BrakesDokument29 Seiten02 Design of Clutch and BrakesCholan PillaiNoch keine Bewertungen

- Accessories Catalog Precision Measuring Centers BROCH en 01Dokument40 SeitenAccessories Catalog Precision Measuring Centers BROCH en 01adi utomoNoch keine Bewertungen

- Big Gear Inspection Is Booming: Oil Additives Can International CalculationDokument68 SeitenBig Gear Inspection Is Booming: Oil Additives Can International CalculationmapalptsNoch keine Bewertungen