Beruflich Dokumente

Kultur Dokumente

Weekly Fire Pump Inspection Test Procedures

Hochgeladen von

Jay T. YongOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Weekly Fire Pump Inspection Test Procedures

Hochgeladen von

Jay T. YongCopyright:

Verfügbare Formate

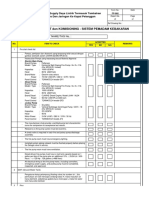

WEEKLY FIRE PUMP INSPECTION & TEST PROCEDURES

The purpose of the weekly fire pump inspection and test is to ensure the fire pump is in an operating condition free of physical damage and is capable of providing continuous delivery for required fire protection demands. An additional purpose of the weekly test is to detect deficiencies that may not be obvious by visual inspection. To prevent false alarms, notification should be provided to the alarm monitoring facility prior to and after completion of the weekly fire pump test. After the test verify that all fire pump supervisory signals were received by the alarm monitoring facility. The weekly inspection of the fire pump is a visual examination of the fire pump and its assemblies to verify that the pump appears to be in an operating condition and is free of physical damage. The weekly inspection procedure should be completed prior to starting the weekly churn test. The weekly churn test verifies the operational status of fire pump and identifies deficiencies that may not be evident by visual examination. WEEKLY INSPECTION PROCEDURE Check the power indicating light on the controller to verify that there is power to the pump Check to make sure there is adequate heat in the fire pump room (not less than 40F and 70F for diesel pumps without engine heaters) during colder months Check to make sure ventilating louvers are free to operate Check to make ensure the pump suction, discharge and bypass valves are open Examine piping, fitting, and connections for any physical damage or leakage Check to make sure the suction and discharge gauge pressure reading is normal Check the system pressure gauge to ensure the system pressure reading is normal Electric Fire Pumps Check to make sure the transfer switch pilot light is illuminated Make sure the isolating switch is closed Check to make sure the reverse phase alarm pilot light is off or normal phase pilot light is on Diesel Fire Pumps Make sure fuel tank is full Check the controller and verify the selector switch is in the automatic position Check to ensure voltage readings on both sets of batteries is normal Check and verify charging current readings are normal on both sets of batteries If provided, check oil level in right angle gear drive Check and verify crankcase oil level is normal

Check and verify proper electrolyte levels in batteries Check to ensure battery terminals are free of corrosion and connections are tight Check to make sure cooling water level is normal If provided, check to ensure the water jacket heater is operating Check to ensure that antifreeze in cooling system heat exchanger is adequate Check all hoses, fuel lines, and cooling line connections for any leakage and to ensure they are in a good condition

ELECTRIC FIRE PUMP WEEKLY TEST PROCEDURE

Verify start and stop settings on the pressure maintenance pump (jockey pump) by dropping the pressure in the jockey pump sensing line. After completion of all inspection procedures, start the pump automatically by slowly dropping the pressure in the controller sensing line. After starting, the pump should be run at least 10 minutes. Record the pressure at which the pump automatically started. Record the pump suction and discharge pressures. Check the pump packing glands to ensure proper tightness and adequate lubrication (should be a slow drip approximately 1 drip per second adjust glands if necessary with pump off). Check and verify proper operation of the circulation relief valve (this will usually be located on a 1 inch line off the discharge side of the pump should be discharging a steady stream of water). Check the pump shaft bearings, packing gland stuffing box, and casing for any signs of overheating (bearings and stuffing box should be warm to the touch casing should be cool to the touch). Check for any unusual noise or vibration. If the pump is equipped with a main relief valve, check to ensure proper operation. Verify operation of all supervisory signals (i.e., pump running, loss of power, phase reversal, etc.) Verify that pump is left in the automatic start mode upon completion of the test.

Note: If any abnormal operation or condition is noted during the weekly churn test, the pump should be shut down and left in the automatic start position until repairs are made. Repairs should be completed as soon as possible and the pump retested.

2 of 3

DIESEL FIRE PUMP WEEKLY TEST PROCEDURE

Verify start and stop settings on the pressure maintenance pump (jockey pump) by dropping the pressure in the jockey pump sensing line. After completing all inspection procedures, start the pump by slowly dropping the pressure in the controller sensing line. The pump should be run a minimum of 30 minutes. Record the pressure at which the pump automatically started. Observe how long it takes the engine to crank and once started how long it takes to reach running speed. Record the pump suction and discharge pressures. Check the pump packing glands to ensure proper tightness and adequate lubrication (should be a slow drip approximately 1 drip per second adjust glands if necessary with pump off). Check for any unusual noise or vibration. Check the pump shaft bearings, packing gland stuffing box, and casing for any signs of overheating (bearings and stuffing box should be warm to the touch casing should be cool to the touch). Verify proper operation of pressure relief valve. Check the heat exchanger for cooling water flow. Record cooling system temperature. Check engine speed and record rpms. Check oil pressure (should conform to manufacturers recommendation) and record. Record amp reading (should be +2 to +5 amps after 5 minutes of running time). Verify that engine will start off of both sets of batteries. Verify operation of all supervisory signals (i.e., pump running, pump off, etc.) Verify that pump is left in the automatic start mode upon completion of the test.

Note: If any abnormal operation or condition is noted during the weekly churn test, the pump should be shut down and left in the automatic start position until repairs are made. Repairs should be completed as soon as possible and the pump retested. 3 of 3

Das könnte Ihnen auch gefallen

- Fire Pumps - Inspection, Testing and MaintenanceDokument2 SeitenFire Pumps - Inspection, Testing and Maintenancesunilarora9999Noch keine Bewertungen

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFDokument3 SeitenTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid ShaikhNoch keine Bewertungen

- P8217 Checklist Fire Pump PDFDokument7 SeitenP8217 Checklist Fire Pump PDFQuynh NguyenNoch keine Bewertungen

- Maintenance Instruction V03Dokument18 SeitenMaintenance Instruction V03Farooq AhmadNoch keine Bewertungen

- FM Fire Pump Inspection Checklist and FormDokument4 SeitenFM Fire Pump Inspection Checklist and Formkrunalb@inNoch keine Bewertungen

- Duty Pump TestDokument1 SeiteDuty Pump TestMohd Aliff Mohd YunosNoch keine Bewertungen

- SOP of Automatic Water Sprinkler SystemDokument1 SeiteSOP of Automatic Water Sprinkler SystemShahnawaz KazmiNoch keine Bewertungen

- FM Fire Pump Inspection Checklist and Form-DikonversiDokument24 SeitenFM Fire Pump Inspection Checklist and Form-DikonversiMochammad Maulana Suwardo100% (1)

- Diesel FP Weekly Inpection ChecklistDokument2 SeitenDiesel FP Weekly Inpection ChecklistElaine Aubrey Bardelosa100% (2)

- Fire Pump Hydrant Inspection ChecklistDokument2 SeitenFire Pump Hydrant Inspection Checklistkukuh nugNoch keine Bewertungen

- Fire Pump Test Form: (Sign Here)Dokument2 SeitenFire Pump Test Form: (Sign Here)Sofiq100% (1)

- Sprinkler PDFDokument4 SeitenSprinkler PDFAntony JebarajNoch keine Bewertungen

- Fire Pump Checklist PDFDokument2 SeitenFire Pump Checklist PDFJhe InibamNoch keine Bewertungen

- Weekly Fire Pump Test Form: (Sign Here)Dokument1 SeiteWeekly Fire Pump Test Form: (Sign Here)khalid_ghafoor6226100% (1)

- Fire Pump Test FormDokument3 SeitenFire Pump Test FormSdferwste SrqreNoch keine Bewertungen

- Automatic Sprinkler Systems Acceptance Test Checklist NFPA 13Dokument3 SeitenAutomatic Sprinkler Systems Acceptance Test Checklist NFPA 13duchoang5000100% (1)

- Report of Inspection, Testing & Maintenance of Standpipe SystemsDokument8 SeitenReport of Inspection, Testing & Maintenance of Standpipe SystemsCubzlookNoch keine Bewertungen

- Fire Pump Routine Checklist NFPA 20Dokument2 SeitenFire Pump Routine Checklist NFPA 20Mouayed ZeadanNoch keine Bewertungen

- FS AnnualFirePumpTestingProcedureDokument4 SeitenFS AnnualFirePumpTestingProceduresyamsul bahri100% (3)

- Monthly Fire Pump Testing FormDokument1 SeiteMonthly Fire Pump Testing FormFerdinand M. Turbanos100% (4)

- HVWS System SOPDokument11 SeitenHVWS System SOPVishal Sanas100% (1)

- Testing & Commissioning Checklist Fire HydrantDokument2 SeitenTesting & Commissioning Checklist Fire HydrantTorre 11 Departamento 1808Noch keine Bewertungen

- Diesel Fire Pump Inspection ChecklistDokument2 SeitenDiesel Fire Pump Inspection ChecklistShabaaz Mohammed Abdul100% (1)

- Fire Sprinkler System Testing FormDokument2 SeitenFire Sprinkler System Testing FormDaniel Flores100% (1)

- Automatic Sprinkler Systems Acceptance Test Checklist NFPA 13 PDFDokument3 SeitenAutomatic Sprinkler Systems Acceptance Test Checklist NFPA 13 PDFanon_299280009Noch keine Bewertungen

- Fire Pump Itm ChecklistDokument4 SeitenFire Pump Itm ChecklistImranNoch keine Bewertungen

- Fire Alarm MaintenanceDokument2 SeitenFire Alarm Maintenancesamantha1966Noch keine Bewertungen

- Fire Pump ChecklistDokument4 SeitenFire Pump Checklistsbalu12674100% (2)

- Sprinkler System ChecklistDokument2 SeitenSprinkler System ChecklistJhe Inibam100% (3)

- AFSA Inspection Form - Water Based PDFDokument4 SeitenAFSA Inspection Form - Water Based PDFMYSTerB100% (2)

- Appendix - Fire Protection Preventive Maintenance ScheduleDokument5 SeitenAppendix - Fire Protection Preventive Maintenance Schedulemohamed attiaNoch keine Bewertungen

- Maintenance ManualDokument16 SeitenMaintenance ManualAbdul HakkimNoch keine Bewertungen

- Check List Test Dan Komisioning - Sistem Pemadam Kebakaran: Equipment Name/Tag No.Dokument8 SeitenCheck List Test Dan Komisioning - Sistem Pemadam Kebakaran: Equipment Name/Tag No.Rudy HarahapNoch keine Bewertungen

- Check List - Fire Protection Inspection Untuk KomisioningDokument4 SeitenCheck List - Fire Protection Inspection Untuk KomisioningRudy Harahap100% (1)

- Fire Pumps Testing & CommissioningDokument6 SeitenFire Pumps Testing & CommissioninggitaNoch keine Bewertungen

- Check List For Ul Pumps Standard Set D+e+jn PDFDokument6 SeitenCheck List For Ul Pumps Standard Set D+e+jn PDFdesign sseNoch keine Bewertungen

- Fire Pump Check ListDokument1 SeiteFire Pump Check ListArafat RobinNoch keine Bewertungen

- Report of Inspection, Testing & Maintenance: of Fire Pump AssembliesDokument6 SeitenReport of Inspection, Testing & Maintenance: of Fire Pump AssembliesMatel Franklin AnastaNoch keine Bewertungen

- Fire Hydrant System Test QCDD FormDokument1 SeiteFire Hydrant System Test QCDD FormMahmoud HassanNoch keine Bewertungen

- Sprinkler and SystmesDokument4 SeitenSprinkler and SystmesridwanNoch keine Bewertungen

- Diesel Fire Pump Inspection ChecklistDokument2 SeitenDiesel Fire Pump Inspection ChecklistRamadan Rashad100% (11)

- Sprinkler System - General InformationDokument5 SeitenSprinkler System - General InformationshahidenterNoch keine Bewertungen

- NFPA ChecklistDokument4 SeitenNFPA ChecklistAhmed Sayed Abdel Tawab100% (1)

- Fire PUMPS T&C ChecklistDokument6 SeitenFire PUMPS T&C ChecklistUmair BaBerNoch keine Bewertungen

- NFPA 25 Fire Protection Equipment Testing Recommendations and Frequencies PDFDokument2 SeitenNFPA 25 Fire Protection Equipment Testing Recommendations and Frequencies PDFMatthewNoch keine Bewertungen

- Stacker Preventive Maintenance Weekly: Clean and InspectDokument1 SeiteStacker Preventive Maintenance Weekly: Clean and InspectFabio Gonzalez100% (1)

- Fire Hydrant ChecklistDokument1 SeiteFire Hydrant ChecklistTushar BabarNoch keine Bewertungen

- Simplex 4100ES Operating InstructionsDokument2 SeitenSimplex 4100ES Operating InstructionsRaviNoch keine Bewertungen

- Dust Collector Service ChecklistDokument1 SeiteDust Collector Service ChecklistFatemeh AziziNoch keine Bewertungen

- Testing and Commissioning Method Statement For Fire Fighting PumpsDokument2 SeitenTesting and Commissioning Method Statement For Fire Fighting PumpsHumaid Shaikh100% (1)

- Inspection Form For Fire PumpDokument6 SeitenInspection Form For Fire PumpRonny Aja100% (1)

- Inspection and Testing Requirements For Fire Sprinkler SystemsDokument3 SeitenInspection and Testing Requirements For Fire Sprinkler Systemsalan100% (1)

- Electric Fire Pump Inspection ChecklistDokument1 SeiteElectric Fire Pump Inspection ChecklistSabaw Sa Bowl90% (10)

- Inspection and Testing 05Dokument12 SeitenInspection and Testing 05Nasrul AdliNoch keine Bewertungen

- Fire Sprinkler System Maintenance ChecklistDokument2 SeitenFire Sprinkler System Maintenance ChecklistKevin Pagayaman100% (2)

- Novec 1230 Fire Suppression SystemDokument1 SeiteNovec 1230 Fire Suppression SystemvivekvpsfeNoch keine Bewertungen

- Checklist For Pressure Testing Safely 2Dokument2 SeitenChecklist For Pressure Testing Safely 2Jonathan CambaNoch keine Bewertungen

- Weekly Fire Pump Inspection & Test ProceduresDokument6 SeitenWeekly Fire Pump Inspection & Test ProceduresShabaaz Mohammed AbdulNoch keine Bewertungen

- Fire Pumps SopDokument7 SeitenFire Pumps SopPankaj PandeyNoch keine Bewertungen

- Fire Pump Testing - Periodic Operational TestDokument5 SeitenFire Pump Testing - Periodic Operational TestToa Suhandita100% (1)

- IndicatorsDokument60 SeitenIndicatorsJay T. YongNoch keine Bewertungen

- Summary ActivityDokument1 SeiteSummary ActivityJay T. YongNoch keine Bewertungen

- Fact Book 2007Dokument241 SeitenFact Book 2007Jay T. YongNoch keine Bewertungen

- Storm PackerDokument38 SeitenStorm PackerJay T. Yong100% (1)

- Compressor Dry Gas SealsDokument12 SeitenCompressor Dry Gas SealsRajeev Domble100% (3)

- HVACRStarDokument7 SeitenHVACRStarAli_Mochtar_5165Noch keine Bewertungen

- An Introduction To AeroacousticsDokument64 SeitenAn Introduction To Aeroacousticslax_doraNoch keine Bewertungen

- Volume-I - (Coal) 2014636129985100886136 PDFDokument153 SeitenVolume-I - (Coal) 2014636129985100886136 PDFAzhar KhanNoch keine Bewertungen

- 02 - Hammarby SjostadDokument24 Seiten02 - Hammarby SjostadShorbanNoch keine Bewertungen

- Blowdown Strainer DesignDokument2 SeitenBlowdown Strainer DesignElias EliasNoch keine Bewertungen

- Test Report G60 - 2BDokument21 SeitenTest Report G60 - 2BMr IlchamNoch keine Bewertungen

- Sewage Sludge CombustionDokument62 SeitenSewage Sludge CombustionJoão Diego FeitosaNoch keine Bewertungen

- VMC Ideo 325Dokument9 SeitenVMC Ideo 325Patrick CarapinhaNoch keine Bewertungen

- SyllabusDokument8 SeitenSyllabusSameer SolankiNoch keine Bewertungen

- compliance sheet of euroclima加承包商Dokument9 Seitencompliance sheet of euroclima加承包商Li Liu100% (1)

- Sigrity Flextronics Power Integrity System Design CPDokument26 SeitenSigrity Flextronics Power Integrity System Design CPDURGASI JYOTHINoch keine Bewertungen

- Instruction Manual Professional Timing Light Instruction Manual Professional Timing LightDokument1 SeiteInstruction Manual Professional Timing Light Instruction Manual Professional Timing LightJohn DePNoch keine Bewertungen

- Studying The Operation of A Smart Grid With The MyGrid MiniSystem For NI MyDAQ (Piomeer Release)Dokument4 SeitenStudying The Operation of A Smart Grid With The MyGrid MiniSystem For NI MyDAQ (Piomeer Release)Jobin VargheseNoch keine Bewertungen

- Form 2 Chapter 2 Nutrient CycleDokument13 SeitenForm 2 Chapter 2 Nutrient CycleMohd Amiruddin Malek100% (1)

- Module 3 First Half (1339)Dokument3 SeitenModule 3 First Half (1339)Ibrahim FareedNoch keine Bewertungen

- Solar TrackingDokument18 SeitenSolar Trackingkoti519100% (1)

- Boiler Tubular Air Pre-Heater - TaphDokument18 SeitenBoiler Tubular Air Pre-Heater - TaphsbmmlaNoch keine Bewertungen

- Research Paper On Magnetic Refrigeration Sourabh SInghDokument9 SeitenResearch Paper On Magnetic Refrigeration Sourabh SInghersourabh75% (4)

- DatasheetDokument8 SeitenDatasheetinalambricNoch keine Bewertungen

- Design and Working of Pedal Operated Flour MillDokument2 SeitenDesign and Working of Pedal Operated Flour MillEditor IJTSRDNoch keine Bewertungen

- Envirable: Induction Heater CatalogDokument23 SeitenEnvirable: Induction Heater CatalogAamirMalikNoch keine Bewertungen

- Lesson 5 Packed Tower ScrubbersDokument20 SeitenLesson 5 Packed Tower ScrubbersinsomniaticstatNoch keine Bewertungen

- General Physics 2 LAS Quarter 3Dokument450 SeitenGeneral Physics 2 LAS Quarter 3Eff100% (6)

- Fault MVA Calc - PPT (Compatibility MDokument20 SeitenFault MVA Calc - PPT (Compatibility MK.T.100% (1)

- Cobra's Messages Another Way of Explaining .Dokument18 SeitenCobra's Messages Another Way of Explaining .Dustin Thomas100% (1)

- Advances in Water Research - Vol32no1Dokument40 SeitenAdvances in Water Research - Vol32no1LeilNoch keine Bewertungen

- PB0101-2 Raymond HP BM Coal Pet CokeDokument2 SeitenPB0101-2 Raymond HP BM Coal Pet CokeswatkoolNoch keine Bewertungen

- H&MT - Lesson 9. Types of Fins, Fin Applications, Heat Transfer Through Fin of Uniform Cross-SectionDokument6 SeitenH&MT - Lesson 9. Types of Fins, Fin Applications, Heat Transfer Through Fin of Uniform Cross-SectionadimeghaNoch keine Bewertungen

- Air Conditioner: Parts ListDokument4 SeitenAir Conditioner: Parts ListDavid Lemos SanchezNoch keine Bewertungen

- Energy Attacks: Energy Manipulation Attack PowersDokument3 SeitenEnergy Attacks: Energy Manipulation Attack PowersSunčica NisamNoch keine Bewertungen