Beruflich Dokumente

Kultur Dokumente

Ansi Valve Leakage Standards

Hochgeladen von

SHAHgan1Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ansi Valve Leakage Standards

Hochgeladen von

SHAHgan1Copyright:

Verfügbare Formate

ANSI VALVE LEAKAGE STANDARDS

There are six different seat leakage classifications as defined by ANSI FCI 70-2. The most commonly used by Gemco Valve are CLASS I, CLASS IV and CLASS Vl. CLASS I is also know as dust tight and can refer to metal or resilient seated valves. CLASS IV is also known as metal to metal. It is the kind of leakage rate you can expect from a valve with a metal shut-off disc and metal seat. CLASS Vl is known as a soft seat classification. Soft Seat Valves are those where the seat or shut-off disc or both are made from some kind of resilient material such as Teflon. Control Valve Seat Leakage Classifications - ANSI FCI 70-2 superseding ANSI B16.104 Leakage Maximum Test Test Pressure Testing Procedures Required for Establishing Class Leakage Medium Rating Designation Allowable I XXX XXX XXX No test required provided user and supplier so agree II 0.5% of rated Air or water 45-60 psig or Pressure applied to valve inlet with outlet open to capacity at 50-125 F max. operating atmosphere or connected to a low head loss (10-52C) differential measuring device full normal closing thrust provided whichever is by actuator. lower III 0.1% of rated As above As above As above capacity IV 0.01% of rated As above As above As above capacity V 0.0005 ml per Water at Max service Pressure applied to valve inlet after filling entire body minute of 50to125F pressure drop cavity and connected piping with water and stroking water per inch (10to52C) across valve valve plug closed. Use net specified max actuator of port plug, not to thrust, but no more, even if available during test. Allow diameter per exceed ANSI time for leakage flow to stabilize. psi differential body rating. VI Not to exceed Air or 50 psig or max Actuator should be adjusted to operating conditions amounts nitrogen at rated differential specified with full normal closing thrust applied to valve shown in 50 to 125 F pressure across plug seat. Allow time for leakage flow to stabilize and following table (10to52C) valve plug use suitable measuring device. based on port whichever is diameter. lower.

Control Valve Seat Leakage Classifications

NOMINAL PORT DIAMETER Inches 3 4 6 8 10 12 NOMINAL PORT DIAMETER Millimeters 76 102 152 203 254 305 LEAK RATE ml per Minute 0.9 1.7 4 6.75 9 11.5 LEAK RATE

Bubbles / minute* 6 11 27 45 63 81

*Bubbles per minute as tabulated are a suggested alternative based on a suitable calibrated measuring device, in this case a 0.25-inch OD X 0.032-inch wall tube submerged in water to a depth of from 1/8 to 1/4 inch. The tube end shall be cut square and smooth with no chamfers or burrs. The tube axis shall be perpendicular to the surface of the water. Other measuring devices may be constructed and the number of bubbles per minute may differ from those shown as long as they correctly indicate the flow in milliliters per minute.

Das könnte Ihnen auch gefallen

- 626 9397 CGDokument17 Seiten626 9397 CGErnesto Josue Diaz ObandoNoch keine Bewertungen

- Design of End Plate ConnectionDokument2 SeitenDesign of End Plate ConnectionAndro RebuyasNoch keine Bewertungen

- Valves Valve LeakageDokument5 SeitenValves Valve Leakagearson5646100% (1)

- ANSI HI 14.6-2011 Rotodynamic Pumps For Hydraulic Performance Acceptance Tests PDFDokument91 SeitenANSI HI 14.6-2011 Rotodynamic Pumps For Hydraulic Performance Acceptance Tests PDFLuis DanielNoch keine Bewertungen

- Seat Leakage Classifications in Accordance With ANSI-FCI-70-3-2004 PDFDokument1 SeiteSeat Leakage Classifications in Accordance With ANSI-FCI-70-3-2004 PDFShabir KhanNoch keine Bewertungen

- As 3571.2-2009 Plastics Piping Systems - Glass-Reinforced Thermoplastics (GRP) Systems Based On Unsaturated PDokument8 SeitenAs 3571.2-2009 Plastics Piping Systems - Glass-Reinforced Thermoplastics (GRP) Systems Based On Unsaturated PSAI Global - APACNoch keine Bewertungen

- Fehniger Steve-Pump Vibration UnlockedDokument35 SeitenFehniger Steve-Pump Vibration Unlockedreynaldo figueroa guerreroNoch keine Bewertungen

- Swing Check Valves PDFDokument8 SeitenSwing Check Valves PDFErcan YilmazNoch keine Bewertungen

- Chien1995 PDFDokument6 SeitenChien1995 PDFFelipeMorenoNoch keine Bewertungen

- SERIES 3000: Angle Surge Relief ValveDokument6 SeitenSERIES 3000: Angle Surge Relief ValveMd Aamir AnsariNoch keine Bewertungen

- Tapered Thread Inspection - Tubing, Casing, &: Required EquipmentDokument1 SeiteTapered Thread Inspection - Tubing, Casing, &: Required EquipmentTulio WeverNoch keine Bewertungen

- Methodology ArticleDokument6 SeitenMethodology ArticleItalo AdottiNoch keine Bewertungen

- Plug ValvesDokument14 SeitenPlug Valvesashish.mathur1100% (1)

- Pipeline Acronyms and Classifications GuidelineDokument12 SeitenPipeline Acronyms and Classifications GuidelinelsaishankarNoch keine Bewertungen

- Mov ItpDokument1 SeiteMov ItpMussab Salih100% (1)

- Flushing Water Velocity Calculation MethodologyDokument5 SeitenFlushing Water Velocity Calculation MethodologySrihari KodimelaNoch keine Bewertungen

- Design Requirements For Pressure Safety Relief ValvesDokument5 SeitenDesign Requirements For Pressure Safety Relief Valvesvela vanNoch keine Bewertungen

- Mokveld Company Profile PDFDokument12 SeitenMokveld Company Profile PDFRICARDO3454Noch keine Bewertungen

- T&A Flange Insulation Kits PDFDokument4 SeitenT&A Flange Insulation Kits PDFJuan CarlosNoch keine Bewertungen

- Sand Filters Datasheet PDFDokument2 SeitenSand Filters Datasheet PDFJamesStenhouseNoch keine Bewertungen

- SECTION 02510 Water Distribution Rev 0Dokument46 SeitenSECTION 02510 Water Distribution Rev 0Ahmed Ben HmidaNoch keine Bewertungen

- Asme B 16.34 InterpretacionDokument21 SeitenAsme B 16.34 InterpretacionJuan Manuel Montoya G.Noch keine Bewertungen

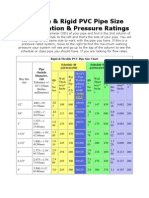

- Flexible & Rigid PVC Pipe Size IdentificationDokument4 SeitenFlexible & Rigid PVC Pipe Size IdentificationAziz Khan KakarNoch keine Bewertungen

- Flow Analysis for Hydrocarbon Pipeline EngineeringVon EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNoch keine Bewertungen

- Valves - AWWA Valves PDFDokument28 SeitenValves - AWWA Valves PDFnilnilen2009Noch keine Bewertungen

- Lateral Tee: What Is The Difference Between Lateral Tee and True WYEDokument2 SeitenLateral Tee: What Is The Difference Between Lateral Tee and True WYEAnonymous 6ZWS6IG2J9Noch keine Bewertungen

- Double Containment EDokument43 SeitenDouble Containment EDavid FonsecaNoch keine Bewertungen

- Zyc120bs GB1Dokument32 SeitenZyc120bs GB1Mel ErphandNoch keine Bewertungen

- List Some Standards ISODokument2 SeitenList Some Standards ISOAnonymous n4bJbeLAqNoch keine Bewertungen

- Valve Leakage ClassificationDokument2 SeitenValve Leakage ClassificationFacundo Argüello100% (1)

- Butterfly Valve Operation Manual PDFDokument16 SeitenButterfly Valve Operation Manual PDFLuis GonzalezNoch keine Bewertungen

- Load-Indicating Externally Threaded Fasteners: Standard Specification ForDokument5 SeitenLoad-Indicating Externally Threaded Fasteners: Standard Specification ForAhmad Zubair RasulyNoch keine Bewertungen

- Avk Saudi National Price ListDokument46 SeitenAvk Saudi National Price Listjanpaul2481Noch keine Bewertungen

- Wiik & Hoeglund Pipe FittingsDokument60 SeitenWiik & Hoeglund Pipe Fittingsliang jasonNoch keine Bewertungen

- Book 2: Chapter 4 - Fluid Flow: Application LimitationsDokument20 SeitenBook 2: Chapter 4 - Fluid Flow: Application LimitationsVaniya GoelNoch keine Bewertungen

- Clamp-On Flow MeterDokument6 SeitenClamp-On Flow MeterHanan Khan100% (1)

- Valve Leakage: Home Glossary ResourcesDokument3 SeitenValve Leakage: Home Glossary Resourcesarkan1976Noch keine Bewertungen

- Testing StandardDokument7 SeitenTesting StandardDiego Fernando Pedroza UribeNoch keine Bewertungen

- FRP TanksDokument1 SeiteFRP TanksMakrand SakpalNoch keine Bewertungen

- 175 012401Dokument2 Seiten175 012401Abu Anas M.Salaheldin100% (1)

- Eadips Manual Engl PDFDokument390 SeitenEadips Manual Engl PDFbkarabasevicNoch keine Bewertungen

- Ipc2012 90308Dokument7 SeitenIpc2012 90308Marcelo Varejão CasarinNoch keine Bewertungen

- Spesifications For Surge VesselDokument9 SeitenSpesifications For Surge VesselAnupamMishraNoch keine Bewertungen

- Booster Pump-TechPart - 2of2 BDokument71 SeitenBooster Pump-TechPart - 2of2 BKatie RamirezNoch keine Bewertungen

- Hydrostatic TestingDokument18 SeitenHydrostatic TestingRicardoNoch keine Bewertungen

- Leakage of Valves - Testing API 598, ANSI FCI 70-2, MSS-SP-61 and ISO Standard 5208Dokument14 SeitenLeakage of Valves - Testing API 598, ANSI FCI 70-2, MSS-SP-61 and ISO Standard 5208anon_9896895680% (1)

- Chilled Water Piping System: SECTION 15/1/6Dokument9 SeitenChilled Water Piping System: SECTION 15/1/6Ahmed Yousri AhmedNoch keine Bewertungen

- IIT-Intake and Exhaust Manifold DesignDokument28 SeitenIIT-Intake and Exhaust Manifold DesignVasudev GuptaNoch keine Bewertungen

- Smith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureDokument8 SeitenSmith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureWong Chung MengNoch keine Bewertungen

- Water Regulations 1999 Summary PDFDokument3 SeitenWater Regulations 1999 Summary PDFAboaliNoch keine Bewertungen

- MSS SP 80 1997 Bronze Gate, Globe, Angle, Check ValvesDokument28 SeitenMSS SP 80 1997 Bronze Gate, Globe, Angle, Check Valvessasan49Noch keine Bewertungen

- APGA Code of Practice For Upstream PE Gathering Lines in The CSG IndustryDokument174 SeitenAPGA Code of Practice For Upstream PE Gathering Lines in The CSG Industrydamian o'connorNoch keine Bewertungen

- 00 AWWA StandardsDokument3 Seiten00 AWWA Standardsliviu_dovaNoch keine Bewertungen

- Bonstrand PipeDokument24 SeitenBonstrand Pipejayhuacat7743Noch keine Bewertungen

- Butterfly Torque Selection GuideDokument3 SeitenButterfly Torque Selection Guidedragon2065Noch keine Bewertungen

- Spe 77 - 307Dokument5 SeitenSpe 77 - 307Dunamis Joe100% (1)

- Butterfly Valve Info PDFDokument14 SeitenButterfly Valve Info PDFCS100% (1)

- 109.08 SEO Domestic Sewage Submersible PumpDokument81 Seiten109.08 SEO Domestic Sewage Submersible Pumpibrahim100% (1)

- Liquid SizingDokument38 SeitenLiquid SizingChetan ChuriNoch keine Bewertungen

- DBB CatalogueDokument28 SeitenDBB CatalogueHeri SetyantoNoch keine Bewertungen

- UCM Ball ValvesDokument22 SeitenUCM Ball ValvesBalakrishna BisoyiNoch keine Bewertungen

- Samson Globe Control ValveDokument12 SeitenSamson Globe Control ValveShishir DwivediNoch keine Bewertungen

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryVon EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Ansi Valve Leakage Standards Gemco ValveDokument1 SeiteAnsi Valve Leakage Standards Gemco ValvenithyaNoch keine Bewertungen

- Assignment On Shaft DesignDokument2 SeitenAssignment On Shaft DesignRitesh SinghNoch keine Bewertungen

- OrganizedDokument34 SeitenOrganizedMochammad Su'udNoch keine Bewertungen

- Hardness TestDokument10 SeitenHardness Testanil chejara100% (1)

- Looking After Your Rotax 912 Series EngineDokument20 SeitenLooking After Your Rotax 912 Series EngineDimitris SarmasNoch keine Bewertungen

- EDWARD ZAMBRANO VALER - Tarea 01-IC252BCIDokument9 SeitenEDWARD ZAMBRANO VALER - Tarea 01-IC252BCILuis ArosteguiNoch keine Bewertungen

- Phase DiagramDokument13 SeitenPhase DiagramJayzl Lastrella CastanedaNoch keine Bewertungen

- Fisher D4 Control Valve Assembly: FeaturesDokument12 SeitenFisher D4 Control Valve Assembly: FeaturesAlberto GuillenNoch keine Bewertungen

- Component Engineering: Installation, Operation & Maintenance ManualDokument1 SeiteComponent Engineering: Installation, Operation & Maintenance ManualrsaimaheshNoch keine Bewertungen

- Outdoor UnitsDokument47 SeitenOutdoor UnitsSayeed AnwarNoch keine Bewertungen

- The Second Law of Thermodynamics: UNIT-3Dokument48 SeitenThe Second Law of Thermodynamics: UNIT-319-810Anitha bhukyaNoch keine Bewertungen

- Guia de FallasDokument348 SeitenGuia de Fallasvicar_27Noch keine Bewertungen

- Air Drilling With MotorsDokument6 SeitenAir Drilling With MotorsGharib HashemNoch keine Bewertungen

- Operating Manual SV 550Dokument14 SeitenOperating Manual SV 550juan manuel sierra solisNoch keine Bewertungen

- Ata 70 Engine Standard Practices: Training ManualDokument41 SeitenAta 70 Engine Standard Practices: Training ManualLuis Enrique La Font FrancoNoch keine Bewertungen

- Models: 1, Condensations in Expanding CosmologicDokument3 SeitenModels: 1, Condensations in Expanding CosmologicsayanNoch keine Bewertungen

- L279-11 Proforma de Venta de Libros Formato Digital - GYM SADokument2 SeitenL279-11 Proforma de Venta de Libros Formato Digital - GYM SAMarco RiveraNoch keine Bewertungen

- Om - S70 Metric - 11 - 2014Dokument30 SeitenOm - S70 Metric - 11 - 2014TucumánElectricidadIndustrialNoch keine Bewertungen

- Hydraulic Control Valve (Manual Controls) (E Series Coil) - S630Dokument5 SeitenHydraulic Control Valve (Manual Controls) (E Series Coil) - S630Edgar SanchezNoch keine Bewertungen

- Tapered Pipe Threads PDFDokument1 SeiteTapered Pipe Threads PDFMoises GarciaNoch keine Bewertungen

- Floating JointDokument2 SeitenFloating JointEDUARDO NICOLASNoch keine Bewertungen

- Electrical InstrumentDokument13 SeitenElectrical InstrumentAYON_MSNNoch keine Bewertungen

- ECA100 Engine Cycle Datasheet 0417Dokument3 SeitenECA100 Engine Cycle Datasheet 0417BKONoch keine Bewertungen

- SR Energy Services: No. 24, 6th Street, Iyyappa Nagar, Madipakkam, Chennai-600091Dokument1 SeiteSR Energy Services: No. 24, 6th Street, Iyyappa Nagar, Madipakkam, Chennai-600091sadhanaNoch keine Bewertungen

- Forced and Free Vibration ProjectDokument4 SeitenForced and Free Vibration ProjectHarshdeep SinghNoch keine Bewertungen

- Charlatte HydrochocDokument1 SeiteCharlatte Hydrochocrizkboss8312Noch keine Bewertungen