Beruflich Dokumente

Kultur Dokumente

Simplified Model For Damage in Squat RC Shear Walls

Hochgeladen von

Fadhila FadiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Simplified Model For Damage in Squat RC Shear Walls

Hochgeladen von

Fadhila FadiCopyright:

Verfügbare Formate

Engineering Structures 31 (2009) 22152223

Contents lists available at ScienceDirect

Engineering Structures

journal homepage: www.elsevier.com/locate/engstruct

Review article

Simplified model for damage in squat RC shear walls

Edward D. Thomson

a

, Mara E. Perdomo

b,

, Ricardo Picn

b

, Mara E. Marante

b

, Julio Flrez-Lpez

c

a

Structural Engineer, Fluor Canada Ltd, Suite 700, 1075 W Georgia St,Vancouver, Canada

b

Department of Structural Engineering, Lisandro Alvarado University, Barquisimeto, Venezuela

c

Department of Structural Engineering, University of Los Andes, Mrida, Venezuela

a r t i c l e i n f o

Article history:

Received 5 December 2008

Received in revised form

29 March 2009

Accepted 28 May 2009

Available online 21 June 2009

Keywords:

Shear walls

Reinforced concrete

Earthquake damage

Fracture mechanics

Finite elements

Lumped plasticity

Elastoplasticity

a b s t r a c t

In this paper, a newsimplified model for simulating damage of squat RC shear walls under lateral loads is

proposed. This simplified model is based on damage and fracture mechanics. It describes the reduction in

stiffness and strength due to diagonal cracking, permanent deformations due to yielding of transverse

reinforcement and sliding across shear cracks. First, the analytical expressions are developed for the

particular case of monotonic loading. Ayield function to describe permanent deformations due to yielding

of transverse reinforcement is proposed. Then, a crack resistance function, based on the Griffith criterion,

is introduced and experimentally identified. Finally, the necessary analytical expressions are developed

for hysteretic behavior. The proposed numerical model is implemented in a commercial finite element

program and validated against experimental results. It is shown that the model can predict well the

response of RC shear walls.

2009 Elsevier Ltd. All rights reserved.

Contents

1. Introduction.................................................................................................................................................................................................................... 2216

2. Model of monotonic behavior ....................................................................................................................................................................................... 2216

2.1. Element flexibility matrix ................................................................................................................................................................................. 2216

2.2. Evolution law of the permanent deformations................................................................................................................................................ 2217

2.3. Evolution law of the damage ............................................................................................................................................................................ 2217

2.4. Identification of the crack resistance function ................................................................................................................................................ 2217

2.5. Computation of the model parameters ............................................................................................................................................................ 2218

2.6. Numerical simulation........................................................................................................................................................................................ 2219

3. Model for hysteretic behavior ....................................................................................................................................................................................... 2219

3.1. Unilateral behavior ............................................................................................................................................................................................ 2219

3.2. Pinching effects in shear walls.......................................................................................................................................................................... 2220

3.2.1. Sliding function of a shear crack........................................................................................................................................................ 2220

3.2.2. Computation of sliding shear parameters......................................................................................................................................... 2221

4. Numerical implementation and model validation....................................................................................................................................................... 2221

4.1. A finite element for squat RC shear walls ........................................................................................................................................................ 2221

4.2. Numerical simulations ...................................................................................................................................................................................... 2222

5. Conclusions..................................................................................................................................................................................................................... 2222

Acknowledgements........................................................................................................................................................................................................ 2223

Appendix. Notations ................................................................................................................................................................................................. 2223

References....................................................................................................................................................................................................................... 2223

Corresponding author. Tel.: +58 251 2529279; fax: +58 251 2592173.

E-mail address: mariaperdomo@ucla.edu.ve (M.E. Perdomo).

0141-0296/$ see front matter 2009 Elsevier Ltd. All rights reserved.

doi:10.1016/j.engstruct.2009.05.020

2216 E.D. Thomson et al. / Engineering Structures 31 (2009) 22152223

1. Introduction

Simulation models of shear wall nonlinear behavior can be

classified into three groups: lumped plasticity models, distributed

plasticity models, and multi-layer models.

Lumped plasticity models are easier to implement because

inelastic effects are considered concentrated on nonlinear springs

or plastic hinges of zero length. The nonlinear behavior of these

hinges is described by complicated rules. Most used typical

models are those reported by Riyadh et al. [1] Williams et al. [2],

Reinhorn et al. [3], Bazant and Bhat [4] and Ma et al. [5]. The

weakness of these models results from the difficulty in choosing

appropriate model parameters. These models usually represent

real behavior when applied to laboratory specimens and using

appropriate parameters. However, when they are used to simulate

real structure behavior, many uncertainties in the correct choice of

adequate parameters appear.

Distributed plasticity models are slightly more complicated, as

they take into account the distribution of inelastic effects along

a finite length as described by Kunnath et al. [6]. They are less

popular than the lumped plasticity models, because they have the

same shortcomings of these models with an added uncertainty

when estimating the length along which inelastic effects are

distributed.

Multi-layer models are based mainly on the finite element

method. These models use discretization of elements for structure

representation. Material behavior is represented by constitutive

relations that are usually well known. In general, the results ob-

tained withthese models are suitable; however, the computational

cost and the time consumed in the preparation of the necessary in-

put data make these models of limited use when large shear wall

structures are to be modeled. Vulcano [7] analyzes several models

which fall into this last category comparing analytical simulations

withexperimental results. Models based onVulcanos macroscopic

approach are more effective than those based on a microscopic ap-

proach. Other authors such as Colotti [8] and Ghobarah [9] report

multi-component models that include some refinements allowing

a better representation of the nonlinear behavior, but there is ba-

sically no improvement in computational cost.

In this paper, a newsimplified model for simulating the damage

of squat RC shear walls under lateral loads is proposed. This

simplified model is based on damage and fracture mechanics. It

can be classified in the group of lumped plasticity models that

describes the reduction in stiffness and strength due to diagonal

cracking, permanent deformations due to yielding of transverse

reinforcement and sliding across shear cracks.

This paper is organized as follows; in Section 2 a model of

the monotonic behavior of shear walls is proposed; in Section 3

the model is extended to the more general case of walls

subjected to cyclic loading; the numerical implementation of the

model is briefly described in Section 4 and some simulations of

experimental tests are presented in order to showthe performance

of the model.

2. Model of monotonic behavior

2.1. Element flexibility matrix

Consider a shear wall as a deep beam, the damage model of RC

frame members is adapted for members subjected to high shear

forces. The model is based on methods of continuum damage

mechanics and fracture mechanics; see Flrez-Lpez [10].

The generalized stresses and deformations matrices of a wall

member are: {M}

t

= (M

i

, M

j

, N) and {}

t

=

_

i

,

j

,

_

respec-

tively.

The mechanical interpretation of the components in those

matrices is present in Figs. 1 and 2.

Fig. 1. Generalized stresses.

Fig. 2. Generalized deformations.

In this paper, permanent deformation due to flexural effects is

neglected; only plastic deformations due the shear effects are con-

sidered. Therefore, a new variable denoted generalized plastic de-

formation matrix is introduced:

_

P

_

t

= (

p

s

,

p

s

, 0), where

p

s

represents the plastic deformations due tothe yielding of the trans-

verse reinforcement and is represented in Fig. 3. This assumption

restricts the use of the model to the case of squat elements.

Generalized stresses and deformations in an elastoplastic shear

wall are related by:

_

p

_

= [F

o

] {M} (1)

where [F

0

] is the flexibility matrix in local coordinates whose

expression is:

[F

0

] =

_

F

a

o

_

+

_

F

f

o

_

+

_

F

s

o

_

. (2)

The matrices

_

F

a

o

_

,

_

F

f

o

_

and

_

F

s

o

_

represent the flexibility due to

axial forces, flexure effects, and shears respectively. These matrices

have the following expressions:

_

F

a

o

_

=

l

EA

_

0 0 0

0 0 0

0 0 1

_

(3a)

_

F

f

o

_

=

l

3EI

_

1 1/2 0

1/2 1 0

0 0 0

_

(3b)

_

F

s

o

_

=

1

GA

v

l

_

1 1 0

1 1 0

0 0 0

_

(3c)

E.D. Thomson et al. / Engineering Structures 31 (2009) 22152223 2217

Fig. 3. Plastic rotation in a shear wall.

where E is the modulus of elasticity, A is the total area of cross

section, A

v

is the effective shear area, I is the moment of inertia,

G the shear modulus and l the length of the member. It can be seen

that for large values of l, the shear term becomes small while the

flexure termincreases. This is the case for slender members where

shear deflections can be neglected.

Another significant inelastic phenomenon is concrete cracking.

This effect produces a reduction of the element stiffness. The goal

of this paper is the inelastic analysis of RCshear walls; therefore the

latter termin expression (2) is modified by introducing the damage

variable (d

s

) that can take values between zero and one:

_

F

s

(d

s

)

_

=

1

GA

v

l(1 d

s

)

_

1 1 0

1 1 0

0 0 0

_

. (4)

Physically, the damage variable measures the degree of con-

crete cracking in the wall, i.e. d

s

= 0 indicates that there is no

concrete cracking, d

s

= 1 represents a cracked wall that has no

shear stiffness at all (see Fig. 4). The flexibility matrix of a degrad-

able shear wall has the following expressions:

[F(d

s

)] =

_

F

a

o

_

+

_

F

f

o

_

+

_

F

s

(d

s

)

_

. (5)

Therefore, the state law of a member with shear deformations,

damage and plastic rotations is:

_

p

_

= [F (d

s

)] {M} . (6)

The internal variables in the shear wall model as the permanent

deformations (

p

) and damage (d

s

) are obtained from evolution

laws.

2.2. Evolution law of the permanent deformations

When actions on the member exceed some critical value,

permanent or plastic deformations appear in the member. As

aforementioned only shear plastic effects are considered. In order

to compute the evolution of the plastic rotation, a yield function f

y

is introduced:

f

y

=

V

1 d

s

c

s

p

s

V

y

(7)

where V = (M

i

+M

j

)/l is the shear force on the member, c

s

and V

y

are parameters of the model that depend on the properties of the

element. There may be plastic rotation evolution only if the yield

function is equal to zero:

p

s

> 0 only if f

y

= 0. (8)

Fig. 4. Physic representation of damage variable by shear.

2.3. Evolution law of the damage

The Griffith criterion, which is the basis of Fracture Mechanics,

states that there may be crack propagation only if the energy

release rate equals the crack resistance of the wall:

d

s

> 0 only if G

s

= R(d

s

) (9)

where R = R(d

s

) is the crack resistance of the wall that is assumed

to be a function of the damage state of the wall.

The energy release rate of a damaged shear wall can be defined

as:

G

s

=

W

d

s

=

V

2

l

2GA

v

(1 d

s

)

2

(10)

where W

is the complementary strain energy of a damaged wall

that can be written as: W

= 1/2{M}

t

[F(d

s

)]{M}.

As in Fracture Mechanics, the crack resistance function has to

be identified from experimental results, as described in the next

section.

2.4. Identification of the crack resistance function

The model that describes the behavior of a shear wall is com-

posed by the state law (6), the plastic rotation evolution law (8)

with yield function (7), and the Griffith criterion (9). It can be no-

ticed that only the crack resistance termneeds experimental iden-

tification. In order to carry out this identification an experimental

program of shear walls was carried out at in Laboratory of Struc-

tural Mechanics at the Lisandro Alvarado University.

The shear walls were designed according to ACI Code 318-05

[11]. A relationship l/d (d is the effective depth) less than 2.5

was used in order to obtain a shear dominant failure mode.

Reinforcement of the specimens where chosen so that damage

or cracking due to bending are negligible. A RC non-slender

element with a high percentage of longitudinal reinforcement

and a low concrete resistance allows a further degradation of the

strength and stiffness to achieve shear failure [12]. The geometric

characteristics of shear walls are shown in Table 1. These walls

were tested under cyclic loading and zero axial force, see Fig. 5.

Fig. 6 shows a shear wall built in as a cantilever. The boundary

and kinematic conditions of the test are: M

i

= V l; M

j

= 0;

i

=

t

l

where t is the lateral displacement at the top of the wall.

2218 E.D. Thomson et al. / Engineering Structures 31 (2009) 22152223

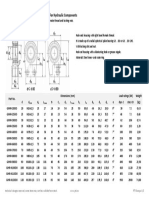

Table 1

Geometry of shear wall specimens.

Specimen w (mm) e (mm) l (mm) d (mm) l/d

v

(%)

s

(%) f

c

(MPa) F

y

(Mpa) F

su

(Mpa)

SW-M01 500 125 600 475 1.26 6.25 0.50 16.7 389.3 630.0

SW-H02 600 100 850 575 1.48 3.29 0.73 16.5 461.0 630.0

SW-H03 585 100 700 560 1.25 0.33 0.26 37.0 607.8 759.7

w = wide of wall

e = thickness of wall

l = length of wall

d = effective depth

s

= percentage of transverse reinforcement

v

= percentage of longitudinal reinforcement

f

c

= nominal resistance of concrete

F

y

= yield stress of transverse steel

F

su

= ultimate stress of transverse steel

Fig. 5. Shear wall specimen geometry and loading.

The relationship between force and displacement can be obtained

from the state law (6) and those conditions.

(t t

p

) =

_

l

3

3EI

+

l

GA

v

(1 d

s

)

_

V (11)

where, t

p

=

p

s

.l is the plastic deflection.

The slope of an elastic unloading in the test (see Fig. 6), denoted

as Z, is:

Z =

V

(t t

p

)

. (12)

Therefore, after (11)(12) the following relationship between

shear damage d

s

and the slope Z is obtained:

Z =

1

l

3

3EI

+

l

GA

v(1d

s)

(13)

Then

d

s

= 1

l

GA

v

_

1

1

Z

l

3

3EI

_

. (14)

It can be noted that this procedure to measure shear damage

is a modification of the stiffness variation method of continuum

damage mechanics, Lemaitre [13].

The energy release rate can be computed from Eq. (10) with

the experimental values of V and d

s

. Fig. 7 shows the energy

release values for specimen SW-M01. An expression for the crack

resistance function is:

R (d

s

) = G

crs

+ q

s

ln (1 d

s

)

(1 d

s

)

. (15)

Two member dependent parameters are necessary to define the

crack resistance of the wall: G

crs

and q

s

. A plot of this function with

appropriate values of the parameters can also be seen in Fig. 7.

A good correlation is observed between the experimental results

and the proposed crack resistance function. A similar analytical

expression was proposed by Cipollina et al. [14] for RC frames.

2.5. Computation of the model parameters

The proposed model has four parameters: G

crs

, q

s

, c

s

, V

y

; they

depend on the cross-section of the wall, the horizontal and

Fig. 6. Representation of the variable Z.

E.D. Thomson et al. / Engineering Structures 31 (2009) 22152223 2219

Fig. 7. Damage variable vs. Energy release rate for shear wall SW-M01.

vertical reinforcement, and the material properties. The direct

determination of these parameters is not convenient; instead they

can be computed by the resolution of the following system of

equations:

V = V

cr

implies d

s

= 0 (16a)

V = V

p

implies

p

s

= 0 (16b)

V = V

u

implies dV/dd

s

= 0 (16c)

V = V

u

implies

p

s

=

p

us

(16d)

where, V

cr

is the shear that produces the first diagonal crack, V

p

is the shear that lead to yielding of transverse reinforcement, V

u

is the ultimate shear resisted by the wall, and

p

us

is the ultimate

plastic rotation. All these wall properties can be computed from

conventional reinforced concrete theory.

The cracking shear of a RC member, when the member is sub-

jected to shear and axial loads can be obtained by the expression

of ACI 318-05 [11]:

V

cr

=

_

1 +

P

14A

g

_

_

_

f

c

6

_

0.8A

g

(17)

where A

g

is the total area of the wall cross section, f

c

is the nominal

resistance of the concrete inMPa, andP is the axial loadonthe wall.

The shear load that leads to yielding of transverse reinforce-

ment can be obtained by the expression of ACI 318-05 [11]:

V

p

=

_

A

v

F

y

Cot

s

_

d (18)

where A

v

is the transverse reinforcement area of the wall, d is the

effective depth of the wall, F

y

is the yielding stress of transverse

reinforcement in MPa, s is the separation between stirrups, and

is the angle between the compression strut and the longitudinal

axis of the shear wall.

The ultimate shear can be obtained by the expression proposed

in Sezen and Moehle [15]:

V

u

=

A

v

F

y

d

s

+

_

0.5

_

f

c

l/d

_

1 +

P

0.5

_

f

c

A

g

_

0.8A

g

. (19)

The ultimate plastic rotation for a shear load can be computed by

the expression proposed by Park and Paulay [16]:

P

us

=

(F

su

F

y

)A

v

E

s

ts

_

1

s

+

E

s

E

c

_

0.25l (20)

where the F

su

is the ultimate stress of the transverse reinforcement

in MPa, E

s

is the modulus of elasticity of the reinforcement in

MPa, E

c

is the modulus of elasticity of concrete in MPa,

s

is the

percentage of transverse reinforcement.

Table 2

Computed properties of the Specimen SW-M01.

Specimen V

cr

V

p

V

u

P

us

SW-M01 34.05 50.75 170.60 0.0066

V

cr

= shear force that produces the first diagonal crack (kN)

V

p

= shear force that yields the horizontal reinforcement (kN)

V

u

= the ultimate shear force resisted by the wall (kN)

P

us

= the ultimate plastic rotation in a member due to shear

Table 3

Model parameters of the Specimen SW-M01.

Specimen V

y

c

s

G

crs

q

s

SW-M01 51.72 61371 3.73 253.46

V

y

= parameter for yield function (kN)

c

s

= parameter for yield function (kN)

G

crs

= parameter for crack resistance function (kN mm)

q

s

= parameter for crack resistance function (kN mm)

2.6. Numerical simulation

A simulation of the SW-M01 test was carried out. The results

of this simulation are shown in Fig. 8(b). As it can be seen,

the proposed model represents adequately the evolution of the

damage due to shear and the accumulation of plastic deformations

in the wall. The wall properties used for the simulation are

presented in Table 2 and the corresponding model parameters are

shown in Table 3.

The envelope of the numerical result can be seen, together with

the experimental results, in Fig. 8(a). It can be observed that the

model represents correctly the experimental behavior of the wall.

3. Model for hysteretic behavior

3.1. Unilateral behavior

During cyclic loadings, two distinctive sets of shear cracks can

appear inthe wall (see Fig. 9). Eachset is mainly relatedto a specific

direction of the shear load. In continuum damage mechanics,

similar phenomena are represented by the introduction of two

damage variables. One of them is related to microcracking density

due to positive stress (positive damage) and the other represents

damage due to negative stress (negative damage), see [17]. When

the shear force changes sign, one set of cracks tends to close and its

presence has a reduced effect in the wall behavior while the other

set of cracks tends to open and became the dominant stiffness

reduction phenomenon. This class of behavior is called unilateral

in the damage mechanics literature.

The model described in this paper can include the concept to

unilateral damage as described in Flrez-Lpez [10]. There are now

two damage variables for shear: d

+

s

and d

s

, which characterize

the state of damage due to positive and negative shear forces,

respectively (see Fig. 9).

The elasticity law (1) can be generalized as:

_

P

_

=

_

F(d

+

s

)

_ _

M

+

_

+

_

F(d

s

)

_ _

M

_

(21)

where, {M

+

} represents the positive part of the elements of

matrix {M} and {M

} is the negative part of the elements of {M};

i.e.

M

i

+

= M

i

if M

i

> 0 and M

i

+

= 0 otherwise (22a)

M

i

= M

i

if M

i

< 0 and M

i

= 0 otherwise. (22b)

The flexibility matrices have the same basic form of Eq. (5)

substituting d

s

by d

+

s

andd

s

:

_

F(d

+

s

)

_

and

_

F(d

s

)

_

. It canbe noticed

that for a positive shear force the flexibility terms are increased

2220 E.D. Thomson et al. / Engineering Structures 31 (2009) 22152223

Fig. 8. Shear wall SW-M01 (a) Experimental results (b) Numerical simulation.

only by the damage variable d

+

s

and negative cracks are assumed

totally closed with no influence at all in the wall behavior.

The evolution of shear damage is described according again to

the Griffith criterion:

d

+

s

> 0 only if G

+

s

= R(d

+

s

) (23a)

s

> 0 only if G

s

= R(d

s

). (23b)

The plastic evolution law is similar to the one for the model of

monotonic behavior, but the yield function has now two expres-

sions: one for positive actions and another for negative ones.

f

y

=

V

(1 d

+

s

)

X Q; if

_

V

(1 d

+

s

)(1 d

s

)

c

s

p

s

_

0

f

y

=

V

(1 d

s

)

+ X Q otherwise (24)

where X is a kinematic hardening term, and Q is an isotropic hard-

ening term, which are defined as follows:

X = 0.60c

s

P

s

(25)

Q = 0.40c

s

p

s

+ V

y

. (26)

The variable p

s

is the maximum plastic rotation at any given time

of the entire plastic deformation history.

3.2. Pinching effects in shear walls

The so called pinching effect in the hysteretic behavior curves

was observed during the experimental analyses. This phenomenon

is due to some sliding between the cracked surfaces before they

come in full contact [18]. The basis for the modeling of this

phenomenon is explained below.

Consider an interface between two different continuum bodies

as is shown in Fig. 10(a) and let and be the normal and

shear stresses on the interface. If the surface is characterized by

a Coulomb friction criterion, the relative horizontal displacement

h between the blocks obeys the following law:

_

h > 0 if ||

s

() = 0

h = 0 if ||

s

() < 0

(27)

where the term

s

is the slide resistance that depends on the

normal stress. The non-slide domain, for an arbitrary resistance,

is represented in Fig. 10(b). It can be noted that slide occurs when

the shear stress reaches the slide resistance. The latter value is not

constant but depends on the normal stress. For higher values of the

compressive normal stress, higher values of the slide resistance are

obtained. A general presentation of interface behavior can be seen

in plasticity textbooks (see for instance Salenon [19]).

Fig. 9. Representation of positive and negative shear damage.

Fig. 10. (a) Interface between two media. (b) Non-slide domain.

3.2.1. Sliding function of a shear crack

The process of slide across a shear crack can also be explained

in terms of Coulomb friction criterion. Consider a shear crack

in a shear wall which has been formed under positive load.

As the load is reduced to zero, the crack remains open. Once

the load starts to be applied in the negative direction, friction

across the crack is small, but as the crack begins to close, friction

increases gradually, which can be seen as a gradual increase in

the normal stress and consequentially in the slide resistance.

Additionally, if reinforcement yielding has occurred as the crack

opens, it is evident that in order to close the crack completely, the

reinforcement must be yielded in compression. Therefore, there is

an interaction between two phenomena: slide across shear cracks

and yield of the reinforcement. Both phenomena generate plastic

rotations in the wall.

Ageneralizationof the concept of Coulomb frictioncriterioncan

be used to describe the behavior of an inelastic shear wall with

slide. Thus, the following slide function is introduced:

f

s

= |V| k

s

. (28)

Expression (28) allows one to define the evolution of plastic rota-

tions as follows: there will be increments of the plastic rotations

due to slide across shear cracks if the shear force reaches the crit-

ical value k

s

, otherwise these increments are null.

In the case of Coulomb friction criterion, it is accepted that

the slide critical value depends on the normal stresses on the

interface. For slide across shear cracks, it will be assumed that the

E.D. Thomson et al. / Engineering Structures 31 (2009) 22152223 2221

Fig. 11. Interaction between yield and slide functions.

critical value k

s

corresponds to a hardening function. The analytical

determination of the hardening function is a very complex

problem, therefore the following phenomenological expression is

proposed:

k

s

= V

o

e

sign(V)

p

s

. (29)

An exponential function of the plastic rotation has been chosen so

that the typical pinched curves are obtained when slide is present

in the wall. The term V

o

will be called slide resistance which is

a concept similar to the yield shear force in plasticity, i.e., V

o

is

the shear force that produces slide when no plastic rotations have

occurred yet. The computation of the parameters V

o

and will be

discussed in a following section.

To model sliding shear together with damage due to cracking,

a slide function due to sliding shear is proposed, similar to that

proposed by Picn et al. [20] for a similar phenomenon observed

in beams with bond failure. This slide function (f

s

) is defined as

follows:

if

_

V

(1 d

+

s

)(1 d

s

)

c

s

p

s

_

0

then f

s

=

V

(1 d

+

s

)

V

o

e

sign(V)

p

s

else f

s

=

V

(1 d

s

)

V

o

e

sign(V)

p

s

. (30)

Now, there are two yield functions which interact, one due to

actual yielding of horizontal reinforcement and the other due to

sliding shear.

The function which controls the evolution of plastic deforma-

tions will be the one with the largest value at any given time as is

illustrated in Fig. 11.

This function takes into account the fact that on closure of the

shear cracks, there are two competing effects: friction between

crack faces and compression forces acting on the horizontal rein-

forcement.

3.2.2. Computation of sliding shear parameters

In expressions (29) and (30), two new parameters are intro-

duced: V

o

and . Where V

o

represents the value of shear force

which produces slide across a crack for zero plastic rotation and

is a parameter which can be calculated by solving the following

equations:

if f

y

or f

s

= 0 then

_

G

+

s

= R(d

+

s

) for positive actions

G

s

= R(d

s

) for negative actions.

(31)

As a result, the following expression is obtained for positive ac-

tions:

=

(1 d

+

s

) ln

_

2GA

v

R(d

+

s

)

lV

2

0

_

2

_

2GA

v

(1d

+

s

)

2

R(d

+

s

)

l

(1 d

+

s

)V

y

(1 )(1 d

+

s

)c

s

p

s

(32)

Fig. 12. Effect of parameter.

Fig. 13. Generalized displacements {q} and internal forces {Q}.

and, for negative actions:

=

(1 d

s

) ln

_

2GA

v

R(d

s

)

lV

2

0

_

2

_

2GA

v

(1d

s

)

2

R(d

s

)

l

(1 d

s

)V

y

(1 )(1 d

s

)c

s

p

s

. (33)

The effect of the parameter on the hysteretic curves can be seen

in Fig. 12.

4. Numerical implementation and model validation

4.1. A finite element for squat RC shear walls

The model can be included in conventional structural analysis

programs as a new finite element. The generalized displacements

(degrees of freedom) and internal forces of the element are

given, respectively, by {q}

t

= (q

1

, q

2

, . . . , q

6

) and {Q}

t

=

(Q

1

, Q

2

, . . . , Q

6

) as indicated in Fig. 13. A finite element is defined

as the set of equations that relate the generalizeddisplacements {q}

with the internal forces {Q}. A finite element for a RC shear wall is

composed by the proposed model and two additional equations.

The first one is denoted kinematic equation and relates the

generalized deformations {} with the generalized displacements

{q}. The second one is the element equilibrium equation that

relates the element internal forces {Q} with the generalized

stresses {M}.

The kinematic equation is

{} = [B] {q}

[B] =

_

_

_

_

sec

l

cos

l

1

sec

l

cos

l

0

sec

l

cos

l

0

sec

l

cos

l

1

cos sec 0 cos sec 0

_

_

(34)

where [B] is called transformation matrix and is the angle

betweenthe chordof the element andthe global axis X (see Fig. 13).

The member equilibrium equation can be expressed as

{Q} = [B]

t

{M} . (35)

2222 E.D. Thomson et al. / Engineering Structures 31 (2009) 22152223

Fig. 14. Specimen SW-H02 (a) Experimental results (b) Numerical simulation.

Fig. 15. Specimen SW-H03 (a) Experimental results (b) Numerical simulation.

Table 4

Computed properties of the specimens SW-H02 and SW-H03.

Specimen V

cr

V

p

V

u

P

us

SW-H02 32.50 145.47 193.04 0.0162

SW-H03 47.44 74.15 154.84 0.0053

V

cr

= shear force that produces first diagonal crack (kN)

V

p

= shear force that yields horizontal reinforcement (kN)

V

u

= ultimate shear force resisted by a shear wall (kN)

P

us

= ultimate plastic rotation in a member due to shear

The finite element for squat RC walls was included in the library of

a commercial FE program [21]. The numerical implementation of

the model was carried out in a similar way as is described in [22].

4.2. Numerical simulations

In order to validate the model some additional tests were

carried out. The specimens are similar to the one described

in Section 2. They were called SW-H02 and SW-H03 and its

geometry is presented in Table 1. The specimens were subjected

to cyclic lateral loading of increasing amplitude and zero axial

force. Figs. 14 and 15 show the experimental results and the

numerical simulations of those tests. The shear wall properties

for the simulation are presented in Table 4 and the corresponding

model parameters are shown in Table 5.

It can be noticed that two degrees of pinching can be observed

in these tests. This difference might be related to the percentage

of transversal reinforcement in both specimens (0.73 % for SW-

H02 and 0.26 % for SW-H03). In the model the degree of pinching

is controlled by the parameter V

o

in Eq. (30). So far there is no

validated procedure to compute this parameter as a function of the

wall characteristics and this is a limitation of the model.

Table 5

Model parameters of the specimens WW-H02 and SW-H03.

Specimen V

y

c

s

G

crs

q

s

V

o

SW-H02 189.70 20427 6.99 668.18 103.52

SW-H03 78.53 63076 11.27 322.18 45.95

V

y

= parameter for yield function (kN)

c

s

= parameter for yield function (kN)

G

crs

= parameter for shear damage function (kN mm)

q

s

= parameter for shear damage function (kN mm)

V

o

= parameter for shear slide function (kN)

The envelope of the numerical results can be seen, together

with the experimental results, in Fig. 14(a) and Fig. 15(a). It can

be observed that the model represents correctly the experimental

behavior of squat RC shear walls.

5. Conclusions

A model for the simulation of damage in squat RC shear walls

under cyclic lateral loads has beenproposed. It is basedonconcepts

and methods of damage and fracture mechanics. It allows, at

least in a qualitative manner, a representation of the following

effects: stiffness and strength degradation due, mainly, to diagonal

cracking of the concrete; plastic deformations due to yield of the

horizontal reinforcement; and sliding shear across diagonal cracks

(pinching effect).

A good correlation between experiment and model can be

appreciated. Most parameters of the model can be determined

from conventional reinforced concrete theory.

In its present state, the model does not account for the

combined damage due to shear and bending, as in tall shear walls,

where cracking due to bending may be more significant than

cracking due to shear.

E.D. Thomson et al. / Engineering Structures 31 (2009) 22152223 2223

Acknowledgements

The experimental investigation presented in this paper was

carried out in the Laboratory of Structural Mechanics at the

Lisandro Alvarado University. The research work was sponsored by

FONACIT and CDCHT Lisandro Alvarado University, Venezuela.

Appendix. Notations

The following symbols are used in this paper:

A total cross section area

A

g

gross area of concrete section

A

v

effective shear area of cross section

c

s

parameter for yield function

d effective depth

d

s

shear damage variable

d

+

s

shear damage variable for positive actions

d

s

shear damage variable for negative actions

E

c

modulus of elasticity of concrete

E modulus of elasticity

E

s

modulus of elasticity of steel

f

c

nominal resistance of the concrete

f

s

shear slide function

F

su

ultimate stress of transverse steel

f

y

yield function

F

y

yield stress of transverse steel

[F

o

] flexibility matrix of member

[F

a

o

] flexibility matrix due to axial forces

[F

f

o

] flexibility matrix due to flexure effects

[F

s

o

] flexibility matrix due to shear effects

[F

s

(d

s

)] shear flexibility matrix of a damaged wall

[F(d

s

)] flexibility matrix of a damaged wall

G shear modulus

G

crs

parameter for shear damage function

G

s

energy release rate of damaged shear wall

G

+

s

energy release rate of a damaged shear wall for positive

actions

G

s

energy release rate of a damaged shear wall for negative

actions

h relative displacement between two blocks of an interface

k

s

critical shear force that produces slide

l length of wall

M

i

, M

j

flexural moments at nodes i and j of a member

M

+

positive part of the elements of matrix {M}

M

negative part of the elements of matrix {M}

N axial force in a member

P axial load

p

s

maximum plastic rotation achieved

q

s

parameter for shear damage function

Q isotropic hardening term for yield function

s

percentage of transverse reinforcement

v

percentage longitudinal reinforcement

R, R(d

s

) crack resistance function

e thickness of wall

V shear force in a member

V

cr

shear force that produces first diagonal crack

V

o

parameter for shear slide function

V

p

shear force that yields horizontal reinforcement

V

u

ultimate shear force resisted by a shear wall

V

y

parameter for yield function

w wide of wall

W

complementary strain energy of a damaged wall

X kinematic hardening term for yield function

Z slope of elastic unloading

parameter of yield function

axial elongation of the member cord

t horizontal displacement at top of shear wall

t

p

plastic horizontal displacement at top of wall

i

,

j

total rotation at nodes i and j of member

P

s

plastic rotation in a member due to shear

P

us

ultimate plastic rotation in a member due to shear

parameter for shear slide function

normal stress across an interface

shear stress across an interface

s

shear slide resistance

References

[1] Riyadh H, Mohamad M, Murat D. Prediction of damage in R/C shear panels

subjected to reversed cyclic loading. J Earth Eng 2005;9(1):4166.

[2] Williams MS, Villernure I, Sexsmith RG. Evaluation of seismic damage indices

for concrete elements loaded in combined shear and flexure. ACI Struct J 1997;

94(3):31522.

[3] Reinhorn AM, Kunnath SK, Mander JB. In: Fafjar P, Krawinkler yH, editors.

Seismic design of structures for damage control in nonlinear seismic analysis

and design of reinforced concrete buildings. London: Elsevier Applied Science;

1992. p. 6376.

[4] Bazant ZD, Bhat PD. Prediction of hysteresis of reinforced concrete members.

J Struct Eng, ASCE 1977;103(1):15380.

[5] Ma SM, Bertero VV, Popov EP. Experimental and analytical studies on the

hysteretic behavior of reinforced concrete rectangular and T-beams. Report

No. EERC 76-2, Berkeley: Earthquake Engineering Research Center, University

of California, 1976.

[6] Kunnath SK, Reinhorn A, Park YJ. Analytical modeling of inelastic seismic

response of R/C structures. J Struct Eng, ASCE 1990;116(4):9961017.

[7] Vulcano A. In: Fafjar P, Krawinkler yH, editors. Macroscopic modeling for

nonlinear analysis of rc structural walls in nonlinear seismic analysis and

design of reinforced concrete buildings. London: Elsevier Applied Science;

1992. p. 81202.

[8] Colotti V. Shear behavior of RCstructural walls. J Struct Eng, ASCE 1993;119(3):

72846.

[9] Ghobarah A, Youssef M. Modelling of reinforced concrete structural walls. Eng

Struct, Elsevier Science 1999;21(10):91223.

[10] Flrez-Lpez J. Simplified model of unilateral damage for RC frames. J Struct

Eng, ASCE 1995;121(12):176572.

[11] American Concrete Institute (ACI). Building code requirement for structural

concrete. ACI Committee 318, Farmington Hills, Mich, 2005.

[12] Woodward KA, Jirsa JO. Influence of reinforcement on RC short columns

resistance. J Struct Eng, ASCE 1984;110(1):90104.

[13] Lemaitre J. A course on damage mechanics. Germany: Springer-Verlag; 1992.

[14] Cipollina A, Lpez-Inojosa A, Flrez-Lpez J. A simplified damage mechanics

approach to nonlinear analysis of frames. Comput Struct 1995;54(6):111326.

[15] Sezen H, Moehle J. Shear strength model for lightly reinforced concrete

columns. J Struct Eng, ASCE 2004;130(11):1692703.

[16] Park R, Paulay T. Reinforced concrete structures. New York: John Wiley and

Sons; 1975.

[17] Ladeveze P. On an anisotropic damage theory. In: Proc. of the CNRS

international colloquium of failure criteria of structural media. France: Villard

de Lans; 1983.

[18] Saatcioglu M, Humar JM. Dynamic analysis of buildings for earthquake-

resistant design. J Civ Eng Can 2003;30:33859.

[19] Salenon J. Calcul la rupture et analyse limite. Presses de lcole nationale des

ponts et chausses, Paris, France, 1983.

[20] Picn-Rodrguez R, Quintero-Febres C, Flrez-Lpez J. Modeling of cyclic bond

deterioration in RC beam-column connections. Struct Eng Mech 2007;26(5):

56989.

[21] Abaqus users manual Version 6.2. Pawtucket, RI: Hibbitt, Karlson &

Sorensen, Inc; 2001.

[22] Marante ME, Flrez-Lpez J. Three dimensional analysis of reinforced concrete

frames based on lumped damage mechanics. Int J Solids and Struct 2003;

40(19):510923.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Equipos John DeereDokument1 SeiteEquipos John DeereGustavo GonzalezNoch keine Bewertungen

- Introduction Portable ToiletsDokument1 SeiteIntroduction Portable ToiletsShrestha Hem100% (1)

- Machine Design - LDokument2 SeitenMachine Design - LNilesh Mistry (Nilesh Sharma)Noch keine Bewertungen

- WMS For Pipe Supports ErectionDokument17 SeitenWMS For Pipe Supports ErectionRamaraju RNoch keine Bewertungen

- 07 - Boom Module 550 801 00 - TamrockDokument98 Seiten07 - Boom Module 550 801 00 - Tamrockcarlos mouraNoch keine Bewertungen

- Standard dimensions and data for steel and stainless steel pipe sizesDokument7 SeitenStandard dimensions and data for steel and stainless steel pipe sizesRSGatesNoch keine Bewertungen

- Copper Bonded Steel Earth RodDokument9 SeitenCopper Bonded Steel Earth Rodemmanuel_nyirendaNoch keine Bewertungen

- NVC - Tutorial Sheet No.1 Without SolutionDokument23 SeitenNVC - Tutorial Sheet No.1 Without SolutionPrabhpreet singhNoch keine Bewertungen

- High Temperature Tensile Strength TestingDokument4 SeitenHigh Temperature Tensile Strength TestingWalter RuedaNoch keine Bewertungen

- Hand & Mechanical Directional Valves: ISO 4401 Sizes 06, 10, 16 and 25Dokument6 SeitenHand & Mechanical Directional Valves: ISO 4401 Sizes 06, 10, 16 and 25aaaNoch keine Bewertungen

- Ruukki Load Bearing Profiled Sheet Installation InstructionsDokument20 SeitenRuukki Load Bearing Profiled Sheet Installation InstructionsEmanuel PopaNoch keine Bewertungen

- MasterFlow - 400 v1 - 2Dokument2 SeitenMasterFlow - 400 v1 - 2Vivek GaurNoch keine Bewertungen

- Electrical Estimation and Costing 15ee553 NotesDokument113 SeitenElectrical Estimation and Costing 15ee553 Notessriram70% (20)

- Detail Ground TankDokument1 SeiteDetail Ground TankRully SaputraNoch keine Bewertungen

- New Power Supply Installation for 8 Aircon UnitsDokument2 SeitenNew Power Supply Installation for 8 Aircon UnitsJohn Ralph VegaNoch keine Bewertungen

- Design of FootingDokument18 SeitenDesign of Footingrumylo f. agustin100% (1)

- PENOLIOplumbing Design AnalysisDokument2 SeitenPENOLIOplumbing Design Analysisrrpenolio86% (7)

- Akpark: Cover Sheet - ElectricalDokument10 SeitenAkpark: Cover Sheet - ElectricalEngr M.Arshad KhalidNoch keine Bewertungen

- MT 25 BFB1Dokument74 SeitenMT 25 BFB1Meritz DanNoch keine Bewertungen

- Fort Jadhavgadh Urban Design Case StudyDokument8 SeitenFort Jadhavgadh Urban Design Case StudyAishwarya KambleNoch keine Bewertungen

- CONSEAL 300 Pure Bitumen WaterproofingDokument2 SeitenCONSEAL 300 Pure Bitumen WaterproofingGodwin IwekaNoch keine Bewertungen

- High Performance Louvers For Curtain Wall SystemsDokument8 SeitenHigh Performance Louvers For Curtain Wall Systemszeynepuzunoglu6Noch keine Bewertungen

- EML e BrochureDokument21 SeitenEML e BrochureECCSNoch keine Bewertungen

- GIHR-K..DO - Rod Ends For Hydraulic ComponentsDokument1 SeiteGIHR-K..DO - Rod Ends For Hydraulic ComponentsQuintrae DelfinNoch keine Bewertungen

- Ch17 ArchesDokument45 SeitenCh17 ArchesErnie ErnieNoch keine Bewertungen

- 4 Regular Design Services of The ArchitectDokument2 Seiten4 Regular Design Services of The ArchitectHaruno AknecsNoch keine Bewertungen

- Rev 1.1Dokument123 SeitenRev 1.1Muhammad Irfan ButtNoch keine Bewertungen

- Innvo8 Squash Court Panel System: Specification InformationDokument5 SeitenInnvo8 Squash Court Panel System: Specification InformationDaniil TriznoNoch keine Bewertungen

- Maintenance of Railway TrackDokument39 SeitenMaintenance of Railway TrackvennillaNoch keine Bewertungen

- Earthing Structures SystemsDokument72 SeitenEarthing Structures SystemsIsaac AppiagyeiNoch keine Bewertungen