Beruflich Dokumente

Kultur Dokumente

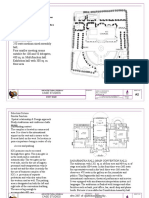

Design Criteria Report For 7 State Capitals

Hochgeladen von

OngeriJOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design Criteria Report For 7 State Capitals

Hochgeladen von

OngeriJCopyright:

Verfügbare Formate

Project Name:

Provision of Consultancy Services for Feasibility Studies, Detailed Designs and

Tender Documents for Urban Water and Sanitation Facilities in Seven State Capi-

tals of Bentiu, Bor,Torit, Aweil, Kuajok, Rumbek and Yambio.

Project Number: 5096004 and 5096005

Report for: Ministry of Water Resources and Irrigation, Republic of South Sudan

PREPARATION, REVIEW AND AUTHORISATION

Revision # Date Prepared by Reviewed by Approved for Issue by

1 06.01.2012 Bwahama Nteko

2

3

ISSUE REGISTER

Distribution List Date Issued Number of Copies

Ministry of Water Resources and Irrigation

SMEC Republic of South Sudan

SMEC, Kenya

SMEC Project File

SMEC COMPANY DETAILS

SMEC International Pty Ltd.

3rd Floor, Kipro Plaza, Sports Road (Westlands)

P.O. Box 14094 00800, NAIROBI, Kenya.

Tel:

+254 20 2016958

Fax:

Email:

rmafricak@smecafrica.com; www.smec.com

Republic of South Sudan

Ministry of Water Resources and Irrigation, Juba

MULTI DONOR TRUST FUND (MDTF) SOUTHERN SUDAN (SS)

WATER SUPPLY AND SANITATION PROJECT (WSSP)

MDTF GRANT TF096197, PROJECT ID P111061

CONTRACTS NOS MWRI/WSSP/SER/01/2011 AND MWRI-SER-007/2010

FOR

PROVISION OF CONSULTANCY SERVICES FOR FEASIBILITY STUDIES, DETAILED

DESIGNS AND TENDER DOCUMENTS FOR THE URBAN WATER AND SANITATION

FACILITIES IN SEVEN STATE CAPITALS OF BENTIU, BOR, TORIT, AWEIL, KUAJOK,

RUMBEK AND YAMBIO

Draft Design Criteria Report

06 January 2012

SMEC International Pty Ltd.

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

TABLE OF CONTENTS

Provision of Consultancy Services for Feasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report | PAGE I

TABLE OF CONTENTS

1 INTRODUCTION ....................................................................................................... 1-1

1.1 Project Background ................................................................................................... 1-1

1.2 Project Objectives ...................................................................................................... 1-1

1.3 Expected Results of the Project ................................................................................. 1-1

1.4 Main Objectives of the Design Criteria Report ........................................................... 1-1

2 PROJECT DESIGN CRITERIA ................................................................................. 2-1

2.1 General ...................................................................................................................... 2-1

2.2 Design Horizons ........................................................................................................ 2-1

2.3 Technical Standards .................................................................................................. 2-1

2.4 Guidelines on Level of Water Supply Services ........................................................... 2-1

2.5 Guidelines on Level of Sanitation Services ................................................................ 2-2

2.6 Basis for Design of Sanitation Services ..................................................................... 2-2

2.7 Population and Water Demand .................................................................................. 2-2

2.8 Fire fighting ................................................................................................................ 2-7

2.9 Peak Factors ............................................................................................................. 2-7

3 DESIGN OF WATER SUPPLY SYSTEMS ................................................................ 3-1

3.1 Water Quality ............................................................................................................. 3-1

3.2 Raw Water Abstraction .............................................................................................. 3-1

3.2.1 Groundwater Abstraction ........................................................................................... 3-1

3.2.2 Surface Water Abstraction ......................................................................................... 3-1

3.3 Transmission Mains ................................................................................................... 3-2

3.3.1 General ...................................................................................................................... 3-2

3.3.2 Gravity Mains ............................................................................................................. 3-2

3.3.3 Pressure Mains .......................................................................................................... 3-2

3.3.4 Pipe Fittings and Valves ............................................................................................ 3-2

3.3.5 Surge Protection ........................................................................................................ 3-3

3.4 Water Pump Stations ................................................................................................. 3-3

3.4.1 Pumping Capacity...................................................................................................... 3-3

3.4.2 Pump Materials .......................................................................................................... 3-3

3.4.3 Suction Mains ............................................................................................................ 3-3

3.4.4 Instrumentation .......................................................................................................... 3-3

3.5 Storage Tanks ........................................................................................................... 3-4

3.5.1 Water Treatment Reservoirs ...................................................................................... 3-4

3.5.2 Water Distribution Reservoirs .................................................................................... 3-4

3.5.3 Reservoir Design ....................................................................................................... 3-4

3.6 Dimensioning of Water Distribution Systems ............................................................. 3-4

3.6.1 Pressure Requirements ............................................................................................. 3-4

3.6.2 Hydraulic Design of Distribution Mains ....................................................................... 3-4

3.7 Design of Water Distribution Networks ....................................................................... 3-5

3.7.1 System Design of Distribution Network ...................................................................... 3-5

3.7.2 Flow Metering ............................................................................................................ 3-5

3.7.3 Zoning and District Metering ...................................................................................... 3-5

4 DESIGN OF WATER TREATMENT FACILITIES ...................................................... 4-1

4.1 General ...................................................................................................................... 4-1

4.2 Screening .................................................................................................................. 4-1

4.3 Desilting ..................................................................................................................... 4-2

4.4 Aeration ..................................................................................................................... 4-2

4.4.1 Spray Aerators ........................................................................................................... 4-2

4.4.2 Multiple Tray Aerators ................................................................................................ 4-2

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

TABLE OF CONTENTS

Provision of Consultancy Services for Feasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report | PAGE II

4.4.3 Cascade Aerator ........................................................................................................ 4-2

4.5 Coagulation ............................................................................................................... 4-2

4.5.1 Rapid Mixing .............................................................................................................. 4-2

4.5.2 Coagulant Chemicals ................................................................................................. 4-4

4.6 Flocculation ............................................................................................................... 4-4

4.6.1 General ...................................................................................................................... 4-4

4.6.2 Horizontally Baffled Flocculation (Sinuous Channel) .................................................. 4-4

4.6.3 Mechanical Flocculation (Mixing) ............................................................................... 4-4

4.7 Clarification ................................................................................................................ 4-5

4.7.1 Conventional Settling Tanks ...................................................................................... 4-5

4.7.2 Lamellae Settlers ....................................................................................................... 4-5

4.8 Filtration ..................................................................................................................... 4-5

4.8.1 General ...................................................................................................................... 4-5

4.8.2 Rapid Sand Filtration ................................................................................................. 4-6

4.8.3 Slow Sand Filters ....................................................................................................... 4-6

4.9 Disinfection ................................................................................................................ 4-7

4.9.1 Ultraviolet radiation .................................................................................................... 4-7

4.9.2 Ozone ........................................................................................................................ 4-7

4.9.3 Chlorination ............................................................................................................... 4-7

4.10 Sludge Treatment ...................................................................................................... 4-8

5 DESIGN OF SANITATION SYSTEMS ...................................................................... 5-1

5.1 On-Site Sanitation Systems ....................................................................................... 5-1

5.1.1 Overall Sanitation Strategy ........................................................................................ 5-1

5.1.2 Septic Tanks .............................................................................................................. 5-1

5.1.3 Treatment of Septic Tank Sludge ............................................................................... 5-1

5.2 Sludge Treatment Facilities ....................................................................................... 5-2

5.2.1 Waste Stabilisation Ponds ......................................................................................... 5-2

5.2.2 Influent Design Parameters ....................................................................................... 5-2

5.2.3 Effluent Quality Requirements ................................................................................... 5-2

5.2.4 Screening .................................................................................................................. 5-3

5.2.5 Anaerobic Ponds ....................................................................................................... 5-3

5.2.6 Facultative Ponds ...................................................................................................... 5-3

5.2.7 Maturation Ponds ...................................................................................................... 5-3

6 ECONOMIC CRITERIA ............................................................................................. 6-1

6.1 Selection of PipeLine Materials .................................................................................. 6-1

6.2 Economic Life and Maintenance Costs ...................................................................... 6-1

6.3 Economic Benefits of Project ..................................................................................... 6-2

LIST OF TABLES

Table 1: Guidelines on Level of Water Supply Services........................................................... 2-1

Table 2: Domestic Water Demand ........................................................................................... 2-3

Table 3: Institutional Water Demand ........................................................................................ 2-4

Table 4: Industrial Water Demand ........................................................................................... 2-4

Table 5: Commercial Water Demand ....................................................................................... 2-4

Table 6: Assumed Base Population and Population Breakdowns ............................................ 2-6

Table 7: Peak Factors ............................................................................................................. 2-7

Table 8: Minimum Washout Sizes ........................................................................................... 3-3

Table 9: Septic Tank Sizing ..................................................................................................... 5-1

Table 10: Standards for Effluent from Sewage Treatment Works ............................................ 5-3

Table 11: Economic Working Life and Annual Maintenance Costs .......................................... 6-1

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

LIST OF ABBREVIATIONS

Provision of Consultancy Services for Feasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report | PAGE I

LIST OF ABBREVIATIONS

DUWS Department of Urban Water and Sanitation

DWS Department of Water Supply

EDR Equalizing Discount Rate

EIA Environmental Impact Assessment

GIS Geographic Information System

GOSS Government of Southern Sudan

GRSS Government of the Republic of South Sudan

GWh Giga-Watt hours

ha Hectare

HMIS Hydro-meteorological Information System

IA Implementing agencies (ID, MASL, CEB, NWSDB, WRB, MD, DMC)

ID Internal Diameter (diameter of pipe or bore casing)

IDP Internally Displaced Person(s)

km kilometre

L/sec Litres per Second (Flow rate)

m Metre

m

3

/day Cubic Metres per day (Flow rate)

MCA multi-criteria analysis

MCM Million Cubic Meters

MD Meteorological Department

MDTF Multi Donor Trust Fund

MENR Ministry of Environment and Natural Resources (Bentiu)

MFP Ministry of Finance and Planning

MIWM Ministry of Irrigation and Water Management

MW mega Watt

MWRI Ministry of Water Resources and Irrigation

NAWAM National Water Management Implementation Project

ND Nominal Diameter (of pipe or bore casing)

NGO Non Governmental Organization

SMEC SMEC International Pty Ltd

TOR Terms of Reference

UNDP United Nations Development Program

UNESCO United Nations Educational & Scientific Organization

USOM United States Operations Mission

WASH Water and Sanitation Hygiene

WB World Bank

WRAS Water Resources Assessment Study

WRD Water Resources Department

WRM Water Resources Management

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 1

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 1-1

1 1 I IN NT TR RO OD DU UC CT TI IO ON N

1.1 PROJECT BACKGROUND

The Republic of South Sudan is the worlds newest country; inaugurated on the 9th July 2011

after a referendum on independence held from 9th to 15th January 2011.

The Project, Feasibility Studies, Detailed Designs and Tender Documents Consultancy services

for Urban Water and Sanitation for the Seven State Capitals facilities, is the first project to be

awarded under the new government. It is to be undertaken within the seven state capitals of

Bentiu (Unity State), Bor (Jonglei State), Torit (Eastern Equatoria State), Aweil (Northern Bahr

el-Ghazel State), Kuajok (Warrap State), Rumbek (Lakes State) and Yambio (Western Equato-

ria State).

The result of the Project will be feasibility studies, detailed design reports and tender documents

for improving and extending the water supply and sanitation facilities of the seven towns.

1.2 PROJECT OBJECTIVES

As stated in the Terms of Reference (ToR), the objectives of the study are to:

- Investigate and determine a technically viable intervention for rehabilitating or providing

new water supply and sanitation systems in the three state capitals of Bentiu (Unity

State), Bor (Jonglei State) and Torit (Eastern Equatoria State);

- Investigate and determine economically feasible intervention for rehabilitating or provid-

ing new water supply and sanitation systems in the three towns; and

- Investigate and determine environmentally sound and socially responsive intervention

for rehabilitating or providing new water supply and sanitation systems.

1.3 EXPECTED RESULTS OF THE PROJECT

The expected results and outputs of the consulting services for the Project seven State Capitals

under this assignment comprise:

- Feasibility studies for water supply coverage in defined supply area and implementa-

tion of appropriate on-site sanitation strategies (Project Horizon: 20 Years; 2032);

- Detailed design of required water supply and sanitation measures;

- Preparation of tender documents for all required investments;

- Conduct water resources assessment for both surface and ground water; and

- Inclusion of MWRIs Technical guidelines such as distribution network, drinking water

treatment plant, etc.

1.4 MAIN OBJECTIVES OF THE DESIGN CRITERIA REPORT

This Design Criteria Report is intended to establish standards and criteria for:

- specific and total water demand;

- design of storage, pumping, treatment and effluent and sludge disposal facilities;

- dimensioning of water supply and sanitation works;

- materials and methods for civil construction, valves, fittings and accessories, pumps,

equipment, etc; and

- prioritised on-site sanitation.

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 2

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 2-1

2 2 P PR RO OJ JE EC CT T D DE ES SI IG GN N C CR RI IT TE ER RI IA A

2.1 GENERAL

The Design Criteria is primarily based on the MWRIs Technical Guidelines for Drinking Water

Distribution Networks and for Construction and Management of High Capacity Water Yard, April

2009. Where the design guideline is silent, other design standards, guidelines or previous ex-

perience of project specialists have been used in consultation with appropriate stakeholders.

Where appropriate, the design criteria may deviate from the above-mentioned guidelines to fit

the realities of South Sudan.

The design basis will be applied for the specific conditions for the preparation of the seven indi-

vidual feasibility studies.

The approved Design Criteria Report will provide the basis for both the conceptual (preliminary)

designs as will be reported in the feasibility study reports, and the detailed designs as will be

reported in the detailed design reports, for each individual town.

2.2 DESIGN HORIZONS

The Consultant recommends that the phasing of investments will be based on design horizons

as follows:-

- Phase I (2013 2022): Under Phase I the water and sanitation requirements up to year

2022 will be provided, while provision will be made for upgrading to year 2032 in all

components of the system (but any work that is not integral to meeting demand of 2022

will be deferred to phase II).

- Phase II (2023 2032): The infrastructure constructed in phase I will be upgraded to

meet the water and sanitation requirements up to year 2032.

Multiple Phase investments will consider conditions forecasted for Year 2013 - 2022, but be co-

herent with development concepts to Year 2032.

2.3 TECHNICAL STANDARDS

All locally or imported goods will conform to the British Standards (BS). The standards may be

complemented by other standards such as those issued by the American Water Works Associa-

tion (AWWA), Germany (DIN) and South Africa (SABS).

2.4 GUIDELINES ON LEVEL OF WATER SUPPLY SERVICES

Water supply services should be available to all people living within the designated urban area

of the service area. Guidelines on the levels of service to be provided within the main urban

area are presented in Error! Reference source not found..

Table 1: Guidelines on Level of Water Supply Services

Service Aspect Guideline

Hours of service Continuous 24 hours per day.

Water quality Water supplied should comply with World Health Organisation (WHO)

Guidelines for drinking water. Deviations may be made where the

standards are difficult to achieve, provided such deviations are not inju-

rious to health, and provided that customers are notified of any precau-

tions to be taken.

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 2

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 2-2

Reliability To provide a service to all customers for at least 99% of the time and

limit interruptions to the supply to no more than 12 hours for any one in-

terruption occurring.

Metering All production, treatment and customers should have a metered supply.

2.5 GUIDELINES ON LEVEL OF SANITATION SERVICES

An overall sanitation strategy for the main urban area would determine the need for piped sew-

erage services. Such services would be provided where on site sanitation services are unsatis-

factory due to factors such as unsuitable underlying geology or high water tables.

Sewerage services would be integrated with other sanitation facilities, including the provision of

public toilets, and collection and disposal of sludge from septic tanks.

Major industries that are outside the central area covered by the sewer network should general-

ly be expected to treat and dispose of their own waste water in accordance with WHO stand-

ards. For industrial estates, separate wastewater collection and disposal systems may be pro-

vided that are independent of any municipal system. Urban Water Authorities may take-over

and operate these systems.

All Urban Water Authorities would establish standards for industrial waste water discharges to

sewers, which prohibit any toxic materials, excessive oil and grease and substances likely to

adversely affect the operation of the wastewater treatment plant. There would also be a limit on

the BOD and suspended solids (SS) loads of the effluent, and charges should be related to the

quality as well as the quantity of effluent discharged. Industries should be liable for any costs

incurred by the Urban Water Authority where industrial effluents that do not comply with the

standards, or for any damages to the sewers or the treatment process.

Where a piped sewerage system is provided, wastewater collected should be treated and dis-

posed in accordance with WHO standards. Provision should be made for the acceptance and

treatment of septic tank sludge at any waste water treatment plant.

2.6 BASIS FOR DESIGN OF SANITATION SERVICES

The sanitation infrastructure shall comply with the following:

- All wastewater within the service area shall be contained in a manner consistent with

safe disposal of wastewater as per WHO Guidelines.

- All effluent from wastewater generated in the service areas shall meet the WHO Guide-

lines when it is discharged outside the service area.

2.7 POPULATION AND WATER DEMAND

For the population projections the following growth rate are adopted:

- The assumed intensive returnee influx period (2009-2013) a growth rate of 5%

- Assumed intensive urbanisation period (2014-2022) a growth rate of 4%

- Assumed urban growth stabilisation period (2023-2032) a growth rate of 3%

The same rates are used for the estimation of growth of the institutions and commercial activi-

ties in the town for the purpose of estimating water demand.

The 2008 census data have been disputed by the 7 State Authorities and therefore the State

Government Authorities provided the current population (2011) which have been used as Base

population to project population up to 2032.

The residential housing categories for the 7 Town are divided into the following categories:

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 2

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 2-3

- First Class housing with a plot size 30m by 35m;

- Second class housing with a plot size of 25m by 30m; and

- Third class housing with plot size of 20m by 25m.

It is envisaged that majority of the town dwellers shall live in the third class housing.

Per capita water demand has been agreed with the client to be as follows:

- Kiosk Public Tap consumers located in Third class housing type is 20 l/capita/day;

- Yard Tap consumers located in Second class housing type is 40 l/capita/day; and

- House connection consumers located in First class housing type is 80 l/capita/day.

Projection of per capita consumption, population percentage distribution and projected average

per capita domestic water demand as given in Table 1.

Non domestic water demand has been computed as follows:

- Institutional demand: 10% of domestic demand;

- Industrial water demand: 10% of domestic demand;

- Commercial water demand: 10% of domestic demand;

- Total water demand: 130% of domestic demand;

- System losses: 25% of Total flow;

- Average Day demand: (30 x(1+1/0.75) = 173% of domestic demand;

- Operational Consumption of Water Treatment Plant (WTP): 7% of raw water inflow.

Net maximum day demand excluding WTP demand is for the purpose of sizing storage and dis-

tribution system. Gross maximum demand includes WTP demand for the purpose of sizing raw

water sources and raw water transmission.

Tanzania Design Manual suggests that capacities of raw water and treatment facilities include

an operational demand of 5% for water treatment and a further 2% for other operational de-

mands. For the purpose of this study we shall assume that the treatment plant will consume 7%

of the raw water will be used for the water treatment plants internal demand (including back-

washing and other operational requirements).

Table 2: Domestic Water Demand

Consumer Category Per Capita Water Demand

(l/ca/d)

Tanzania Kenya Ethiopia Design Basis for this

Project

People using kiosks/public tap 25 20 20 20

People using yard tap 50 - 30-35 40

People with house connection 250 250 60 -150 80 (recommended by

client)

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 2

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 2-4

Table 3: Institutional Water Demand

Consumer Unit Tanzania Kenya Ethiopia Design Basis

for this Project

Remark

Day schools l/std/d 25 25

10% of

Domestic

Demand

10% of Domes-

tic Demand

With WC

Boarding

schools

l/std/d 70 50 With WC

Health care

dispensaries

l/visitor/d 10 - Out-patients

only

Health care

dispensaries

50 l/bed/d 5,000 l/d No modern

facilities

Health care

dispensaries

100 l/bed/d 5,000 l/d With WC

and sewer

Hospitals, dis-

trict

l/bed/d 200 200 With WC

and sewer

Hospitals, re-

gional

l/bed/d 400 400 With sur-

gery unit

Administrative

offices

l/worker 70 25 With WC

Table 4: Industrial Water Demand

Industry Type

Water Demand

Tanzania Kenya Ethiopia Design Basis for

this Project

Medium Scale

(water intensive)

50

m

3

/ha/d

20 m

3

/ha/d

Responsibility of Establish-

ment to develop own supply

10% of Domestic

Demand

Medium scale

(medium water

intensive)

20

m

3

/ha/d

Responsibility of Establish-

ment to develop own supply

Small scale (dry) 5

m

3

/ha/d

10% of Domestic Demand

Table 5: Commercial Water Demand

Consumer Unit Tanzania Kenya Ethiopia Design Basis

for this Project

Remarks

Hotels l/bed/d 70

200

400

50

300

600

10% of

Domestic

Demand

10% of Domes-

tic Demand

Low class

Medium class

High class

Bars l/bar/d 70

100

300

-

-

500

Low class

Medium class

High class

Shops 1/shop/d

70

130

-

100

Low and medium

class

High class

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 2

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 2-5

Real losses mainly comprise physical leakages from pipelines and service connections, but also

leakages and overflows at storage tanks. Reductions of real losses should relate to the cost of

the water saved. For each system, there is an economic level of leakage, beyond which the cost

of saving the water exceeds the cost of producing additional supplies.

A loss of around 30% of production would be seen as the maximum acceptable level for system

losses, 25% as a normally acceptable level, and 15% probably being the practical minimum

achievable level in most African towns. For the purpose of this project, given that the systems

will be mostly new installations, we shall assume a system loss of 25%.

In order to get viable figures for physical losses i.e. Non Revenue Water (NRW) in the produc-

tion, treatment, pumping and storage facilities, the transmission and distribution networks and

the house connections, spot / basic leak detection investigations has to be executed for the

analysis and assessment of physical NRW.

The following approach recommended:

- comparison of meter readings at significant points of the water supply system balanc-

ing the out- and inflows (production, treatment, transmission, storage and distribution),

- on-site inspections: the inspection concentrated on the trunk mains; knowing the bigger

impact of leakages on big sized pipes and on the appurtenances, as most leakages in

the network occur at network appurtenances like valves, fire hydrants and service con-

nections.

- comparison of flow readings at outflows and inflows of the production site and reser-

voirs can be done using ultrasound flow meters plus readings on bulk meters installed

in the system. Measurements can be done on the transmission mains as well as for in-

flows and outflows for reservoirs within the distribution system.

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 2

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok,

Rumbek and Yambio| Design Criteria Report| PAGE 2-6

Table 6: Assumed Base Population and Population Breakdowns

State

Capital Population Data

Assumed Base

Population

Growth

Rate to

Base

Year of

2012

Assumed

population

Year 2012

Consumption Types

2012

Consumption Types

2022

Consumption Types

2032

Pop. Year 1 2 3 1 2 3 1 2 3

Yambio

Census 2008: 105,881

Estimated 2011: 105,881 105,881 2008 5% 128,699 95% 4% 1% 55% 30% 15% 30% 45% 25%

Rumbek

Census 2008: 70,534

Estimated 2011: 120,650 120,650 2011 5% 126,683 85% 10% 5% 55% 30% 15% 30% 45% 25%

Kuajok Estimated 2011: 60,000 60,000 2011 5% 63,000 100% 0% 0% 55% 30% 15% 30% 45% 25%

Aweil

Census 2008: 59,217

Estimated 2011: 120,460 120,460 2011 5% 126,483 100% 0% 0% 55% 30% 15% 30% 45% 25%

Bor

Census 2008: 61,716

Estimated 2011: 100,000 100,000 2011 5% 105,000 40% 30% 30% 30% 35% 35% 20% 35% 45%

Bentiu

Census 2008: 61,331

Estimated 2011: 95,000 95,000 2011 5% 99,750 40% 30% 30% 30% 35% 35% 20% 35% 45%

Torrit

Census 2008: 33,660

Estimated 2011: 54,045 54,045 2011 5% 56,747 40% 30% 30% 30% 35% 35% 20% 35% 45%

Consumer Categories

1 Kiosk Public Tap Consumers

2 Yard Tap Consumers

3 House Connection Consumers

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 2

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 2-7

2.8 FIRE FIGHTING

Project Towns are classified as Urban areas, and thus fire fighting requirements will be consid-

ered for design of water distribution networks.

The location of fire hydrants will be finalized after consultation with the stakeholders and ap-

proval of the client.

This project adopts the following Tanzania design manual criteria for fire fighting:

- Minimum Flow at hydrant: 10 l/s

- Minimum residual pressure at hydrant: 15 m

- Number of Simultaneous Fires: 2

2.9 PEAK FACTORS

Peak factors will be used for establishing design capacities for dimensioning of facilities and

pipelines. These peak factors comprise peak day factor and peak hour factor.

Average daily demand multiplied by the peak day factor represents the maximum daily demand,

which will be used for design of intakes, transmission mains and treatment plants.

Maximum daily demand multiplied by the peak hour factor represents the maximum hourly de-

mand, which is used for design of water distribution systems. Fire fighting requirements are

added to the maximum daily demand.

Fire fighting reserve requirements are added to the maximum daily demand as 10% of the vol-

ume of the balancing reservoirs.

Table 7: Peak Factors

Population Tanzanian Design Manual

Range of Peak Factors

Design Basis for this Project

Peak Day Factor Peak Hour

Factor

Peak Day Factor Peak Hour Factor

10,000 1.80 1.50 2.40 -2.0 1.7 2.3

10,000 30,000 1.50 1.40 2.0 1.70 1.5 1.9

30,000 -100,000 1.50 -1.30 1.70 -1.60 1.4 1.7

More than 100,000 1.30 1.60-1.50 1.3 1.6

Water distribution networks will be dimensioned for fire fighting requirements for maximum day

demand conditions.

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 3

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 3-1

3 3 D DE ES SI IG GN N O OF F W WA AT TE ER R S SU UP PP PL LY Y S SY YS ST TE EM MS S

3.1 WATER QUALITY

Water supply systems will be designed to achieve the WHO Standards latest edition: Guidelines

for Drinking Water Quality, 3

rd

Edition incorporating 1

st

and 2

nd

Addenda Vol1, Recommenda-

tions, 2008.

3.2 RAW WATER ABSTRACTION

3.2.1 Groundwater Abstraction

Drilling of a borehole will be completed to just lower than the bottom of the lowest aquifer to be

exploited. Boreholes will be cased to protect the hole and the pump rising main in the borehole.

Ductile Iron (DI) or PVC or Steel casings will be used depending on the type of formation and

quality of the groundwater. A pump will be installed at 2/3rd the depth of the water column or 1m

below the stabilised cone of depression. Groundwater abstraction will be limited to 80% of the

yield of the maximum pumping test.

Well casings will be installed:

- to be placed such that it finishes about 50cm above the ground surface,

- to be placed at all non-water bearing zones,

- to be placed about 1.5 or 2m from well bottom.

Blind casings will be used in the impervious formation, and slotted screens will be used in the

aquifer formation. Size of casing is determined by size of borehole and the annular space be-

tween casing and pump. The annular space between the borehole and filter casing will be filled

with washed and well-rounded gravel taken from a river bed.

The Consultant recommends the following specifications for gravel pack and screens:

- Thickness of gravel pack: minimum 100 mm,

- Grain size: 1.5 2mm, achieved through sieving of river sand,

- Material: Only quartz gravel will be accepted. The gravel must be clean and washed

(no dirt must enter the borehole). Crushed rocks will not be accepted,

- Shape of the grains: The grains must be well rounded; crushed rocks will be rejected,

- Slot widths of screens: 1mm.

The Consultant recommends the use of stainless steel for pump casing, impeller and motor for

borehole pumps for sources of groundwater with corrosive characteristics, depending on the pH

of the groundwater and the amount of corrosive compounds such as chlorides in the water.

3.2.2 Surface Water Abstraction

Intakes in rivers will preferably be 3 to 4m below the surface but at least 1m above the river bot-

tom. In rivers with bilharzia risk, the intake point will be a minimum of 80m from the shoreline

with a connecting underwater pipeline.

Gravity intake pipes will be designed for a flow equal to 120 percent of the pump capacity with a

self-cleaning velocity of at least 0.7m/s.

A strainer will be mounted on the inlet and will be at least 1.0m below water level and at least

1.0m above the bottom. The velocity through the strainer will be less than 0.7m/s. The width of

strainer slits will preferably be less than 5mm and of strainer holes 5 10mm. The design of

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 3

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 3-2

the strainer will allow for 30% clogging. Total opening of the strainer will be 2 3 times the

cross-area of the intake pipe.

3.3 TRANSMISSION MAINS

3.3.1 General

Transmission mains will be designed to have minimum slopes of 0.3% for DN 200 mm and

0.2% for DN > 200 mm.

Flow velocities in transmission mains will be between 0.6 2m/s and will be lower in smaller

diameter pipes and higher in larger diameter pipes. The maximum operating velocity will be

2m/s to ensure safe operation of the pipeline.

Minimum pipe cover will be 1m unless the Engineer authorizes a shallower installation, in which

case, special measures may be specified. Pipes above ground will be coated Steel or Ductile

Iron (DI) pipe materials.

Transmission mains will be sized using the Hazen Williams formula for pipe head losses. The

Consultant recommends a C-value of 100 for existing pipelines, 140 for new Steel or Ductile

Iron (DI) pipe materials, and 140 for new PVC and HDPE pipe materials. Given that the pipes

will have to perform according to the required demand for 20 years, the following C factors are

recommended to be used for this project:

- Steel or Ductile Iron (DI) pipe materials: C=100

- PVC and HDPE pipe materials: C=130

Minor head losses will be calculated by assuming a loss of 10% above pipe friction losses (i.e.

increasing the length of the pipes by 10% of actual for the purpose of distribution modelling).

3.3.2 Gravity Mains

Gravity mains will be sized so that the total quantity required for the future forecasted maximum

daily demand can flow through the pipe in 24 hours.

3.3.3 Pressure Mains

Pressure mains will be sized so that the total quantity required for the future forecasted maxi-

mum daily demand can flow through the pipe in 16 hours.

PVC pipe materials will not be used for pressure mains. The Consultant recommends this crite-

rion for long transmission mains, because PVC pipes are susceptible to ovaling from negative

pressure surges. PVC pipes are also susceptible to uneven soil settlement. The combination of

these two conditions can result in high leakages at socketed joints.

3.3.4 Pipe Fittings and Valves

All throttling valves will be gate valves. Isolating valves up to and including DN 300 will be gate

valves, and valves larger than DN 300 will be butterfly valves except where otherwise specifical-

ly required.

All valves will be designed for a maximum permissible differential working pressure of 16 Bar

except where higher pressures are necessary.

Air valves will be fitted at all high points and at significant changes in downward slope. Distance

between air valves will not exceed 1000m for long transmission mains, and will not exceed

600m for transmission mains of minimum slope in flat areas.

Washouts will be fitted at all low points. For large diameter mains the washout tee will be an in-

vert tee to evacuate water and any settled deposits from the pipeline. Error! Reference source

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 3

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 3-3

not found. presents criteria for minimum washout branch diameters of washouts (from Tanza-

nian Design Manual).

Table 8: Minimum Washout Sizes

Main Pipeline Diameter Washout Branch Diameter

Up to 300 mm 80 mm

400 - 600 mm 100 mm

700 - 1000 mm 150 mm

1100 - 1400 mm 200 mm

1600 mm & greater 250 mm

3.3.5 Surge Protection

Surge pressures will be considered when designing transmission mains. Maximum surge pres-

sures will be calculated when assessing the risk of system failure. Special attention will be given

to negative pressures in rising mains. Appropriate surge protection will be provided for systems

where system failure is likely to happen.

Simple Guide for Design of Air Vessels for Water Hammer Protection of Pumping Lines (ASCE

Journal of Hydraulic Engineering, August 2002) will be referred as appropriate.

3.4 WATER PUMP STATIONS

3.4.1 Pumping Capacity

For electrically driven pumps, the Consultant recommends that intake pump stations are de-

signed with a capacity to operate for 22 hours per day.

Where the reliability of electrical power supply is questionable, a standby diesel generator unit

will be included to provide for at least 50% of the maximum pumping capacity of the station.

For diesel engine powered pumps, the pumping capacity will be fixed in accordance with the

stipulation above, but based on a pumping period of not more than 14 hours per day.

The Consultant recommends that the incoming flow to any booster pump station would not be

less than 110% of the capacity of the booster pump station.

3.4.2 Pump Materials

The Consultant recommends the use of stainless steel for pump casing and impeller for raw wa-

ter sources with both corrosive and erosive characteristics, depending on the pH of the water

and the amount of corrosive and erosive compounds such as chlorides and grit in the water.

3.4.3 Suction Mains

The Consultant recommends that the flow velocity in suction mains will not exceed 1.5m/s. Site

average NPHS will be kept greater than the required NPSH by at least 1m. Raw water submers-

ible pumps will be considered instead of above surface pumps.

3.4.4 Instrumentation

Pressure gauges will be provided to monitor suction and delivery pressures for each pump.

Voltmeters and ammeters will be provided for each switch-gear and each motor starter panel.

For large motors above 200 kW, a thermometer should be incorporated to monitor the motor

bearing temperature under running conditions. Hour-meters on larger but not on smaller rotating

assemblies should be provided to monitor the total period of use of such items.

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 3

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 3-4

3.5 STORAGE TANKS

3.5.1 Water Treatment Reservoirs

For water treatment facilities using pumped backwashing of rapid sand filters: the Consultant

recommends that reservoirs at these facilities will be designed with two compartments. The first

compartment will function as a sump for backwash pumps, and store a sufficient amount of fil-

tered and chlorinated water for two backwashes, while also providing a chlorine contact time of

at least 30 minutes to ensure sufficient disinfection. The second compartment will be used ex-

clusively for storage of final treated water.

3.5.2 Water Distribution Reservoirs

The Consultant recommends that storage tanks, which also provide pressure balance within the

distribution system, have total cumulative capacity equivalent to 30% of maximum daily demand

for each design phase. This capacity is used for the sum of demand balancing, emergency and

fire fighting reserve. In these cases any distribution pumping from WTPs would not exceed the

maximum daily demand for each design phase (excluding stand-by pumps).

The following storage capacities shall be used in this project:

- Balancing Storage: 35% of Maximum Day Demand

- Fire Storage: 10% of Maximum Day Demand

- Emergency: 5% of Maximum Day Demand

- Total Storage Capacity: 50% of Maximum Day Demand

3.5.3 Reservoir Design

Ground reservoirs and elevated tanks may either be reinforced concrete or steel. At or near the

coast, concrete structures will be used because of the salt laden atmosphere.

Ground reservoirs will have heights not less than 3 metres and not higher than 6 metres.

The most economic plan shape for a two-compartment rectangular reservoir is usually obtained

when its length at right-angles to the division wall is 1.5 times its breadth.

The Consultant recommends that flat-roofed concrete reservoirs will be covered with earth and

grassed, but a gravel topping would also be considered.

3.6 DIMENSIONING OF WATER DISTRIBUTION SYSTEMS

3.6.1 Pressure Requirements

Consultant recommends minimum residual pressure of 10m for distribution mains unless ap-

proved by the Engineer. Maximum pressure for distribution mains will be 60m. Storied buildings

would make their own arrangements for boosting the water where the pressure is not sufficient

for upper stories of these buildings.

3.6.2 Hydraulic Design of Distribution Mains

Distribution networks will be dimensioned for two demand scenarios which represent critical op-

erating conditions of the network. First scenario represents maximum hourly demand conditions

based on lowest water levels in service reservoirs. Second scenario represents minimum hourly

demand conditions based on maximum water levels in service reservoirs. Minimum hourly de-

mand would be based on the inverse of the peak hourly factor.

The Consultant recommends that velocity in pipes will be limited as follows:

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 3

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 3-5

- 50 100 mm diameter = 0.6 1.0 m/s

- 150 250 mm diameter = 1.0 1.5 m/s

- 300 600 mm diameter = 1.2 2.0 m/s

Distribution mains will be sized using the Hazen Williams formula for pipe head losses. The

Consultant recommends a C-value of 100 for Steel or Ductile Iron (DI) pipe materials, and 130

for PVC and HDPE pipe materials.

3.7 DESIGN OF WATER DISTRIBUTION NETWORKS

3.7.1 System Design of Distribution Network

No service connection will be taken from primary distribution mains. Where a service main

draws water directly from a primary distribution main, a valve will be placed straight on to the

branch of the tee. Similarly, where a service main branches from another, the branch will be

provided with a valve.

All individual connections will consist of a pipe of HDPE material of minimum 15 mm diameter

which shall be taken from the nearest distribution pipe by a ferruled saddle or reducing tee, de-

pending on the size and material of the distribution pipe. Ferrules alone will not be used. The

service pipe will be laid till just outside or just within the plot boundary, where the stop cock and

meter will be located.

Public kiosks will serve not more than 1,500 people within a walking distance not exceeding

400m. Each kiosk will have taps serving not more than 250 people per tap.

3.7.2 Flow Metering

Flow meters will be provided for outflows at all pump stations, water treatment reservoirs and

public storage tanks.

Bulk flow meters of diameters greater than 150 mm will be inclined in-line turbine type meters.

Domestic (consumer) meters will be of the single jet inferential type.

3.7.3 Zoning and District Metering

Appropriate zoning of the water supply areas will be defined in order to identify the locations for

the installation of bulk water meters and section valves for suitable district metering.

Zones will be defined according to energy source. A pressure zone is normally commanded by

one or several high level reservoirs. If the scheme does not permit construction of a number of

reservoirs due to financial or other constraints, then separate distribution mains can be taken

from the same service reservoir, and each zone will have its own separate distribution system,

but with interlinking between the zones via a normally closed valve.

District metered areas (DMAs) will be defined according to one of the following types:

- Branch DMA: This type has only one possible inflow location to the DMA. This type is

most applicable for towns that have no regular layout of roads.

- Grid DMA: This type has inflow into the DMA from at least two directions. This type is

most applicable for towns that have a rectangular road layout.

- Ring DMA: This type has distribution mains located around the DMA boundaries. The

flow is directed inward from any side and reaches any location inside the DMA.

- Radial DMA: This type has a distribution reservoir placed at the centre of a DMA and

the supply pipes radiate out away towards the DMA boundaries. If a town has a radial

layout of roads, this type may be the most suitable.

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 5

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 4-1

4 4 D DE ES SI IG GN N O OF F W WA AT TE ER R T TR RE EA AT TM ME EN NT T F FA AC CI IL LI IT TI IE ES S

4.1 GENERAL

The following methods of water treatment are considered to be suitable, used in different com-

binations as necessary to achieve the desired results:

- Screening or straining

- Roughing or pre-treatment filters

- Plain sedimentation

- Chemical coagulation, flocculation and settling

- Filtration either by Slow Sand or Rapid Gravity filtration

- Disinfection

- Control of algae

- Taste and odour control

- Softening

- Removal of iron and manganese

- De-fluoridation of water

Minimum treatment will be: disinfection for groundwater sources; and some form of filtration fol-

lowed by disinfection for surface water sources. The most feasible (technically and financially)

option will be developed for each town / source individually.

4.2 SCREENING

The following are typical of surface water screens:

- They should be easily accessible, at least during medium and low flows, and inclined

upwards away from the river or stream.

- Velocity entering the screen not should exceed 0.3m/sec.

- Size of the openings of the screen should be: 10

-2

to 10

-3

m (normally 25mm for coarse

screen and 6mm for fine screen)

Head losses for screening units will be calculated using the following formula:

with: b = Shape factor

w = maximum bar width

b = minimum aperture width

V = velocity in pipe

= the angle of inclination of the bars to the horizontal.

The Consultant recommends two units for any proposed screening, and each one of the two

screen wall openings is designed for the full design flow.

In case larger amounts of suspended solids are expected to be found in the raw surface water:

the Consultant recommends to consider band or drum screens, which are arranged as endless

bands or rotating drums of perforated materials. The screening element (band or drum) is in

u | sin

2

2

3

4

g

V

b

w

h

a

|

.

|

\

|

=

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 5

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 4-2

continuous movement, and is continuously and automatically cleaned by a water jet washing off

the screened material into a trough.

In case the raw surface water contains a considerable amount of zooplankton, algae or other

microscopic-sized particles: microstrainers might be used in addition or as alternative to the

screens. Microstrainers are revolving drums mounted in open tanks with a straining medium

usually being a stainless steel wire fabric of a very fine mesh (apertures of 20 to 50 m).

Microstrainer drums are submerged for about 75% of its diameter and rotates at about 1 to 5

rpm. The raw water enters the drum axially and flows out radially through the fabric. Cleaning is

accomplished by a row of water jets along the full length of the rotating drum. Particulate matter

is thus backwashed into a hopper placed along the full length of the drum.

4.3 DESILTING

Any proposed desilting facilities shall be designed with the following criteria:

- Intake velocity is normally in the range of 1 to 1.5 m/sec

- Velocity entering the chamber is reduced to 0.5 m/sec

- Silt then settles when upward velocity is between 0.15 m/min - 0.90 m/min.

- A means of silt removal is provided, and where possible this would be done by flushing

under gravity flow conditions back to the water source

4.4 AERATION

4.4.1 Spray Aerators

Any proposed spray aerators shall be designed to have diameters 10 40mm. The pressure at

the nozzle head would be 2 9m. Discharge rating per nozzle would be 30 600 l/min. Aerator

areas would be 30 90 m2 per 1,000m3/hr.

4.4.2 Multiple Tray Aerators

Any proposed multiple tray aerators shall have 3 5 trays at intervals of 0.3 0.7m with a head

of 1.5 3m. The area would be 15 to 45 m2 per 1,000 m3/hr per tray, with the total area of the

trays about 70 150 m2 per 1,000 m3/h depending on the number of trays applied.

4.4.3 Cascade Aerator

For any proposed cascade aerators, the efficiency of the aeration process is determined by the

hydraulic loading of the cascade weirs, which shall be in the range of 20 100 m3/h*m.

Exposure time can be increased by increasing the number of steps which shall be between 3

and 10 steps. The fall in each step will be 0.15 0.6 m. The area would be 40 m2 per 1,000

m3/hr per step, with the total area of the steps about 200 400 m2 per 1,000 m3/h depending

on the number of steps applied.

4.5 COAGULATION

4.5.1 Rapid Mixing

For rapid mixing in coagulation processes, operation and maintenance costs are minimized by

using either of the following options:

- Static mixers making use of turbulent flow within a pressure pipeline

- Hydraulic mixers making use of a hydraulic jump (for example at a weir overflow)

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 5

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 4-3

Static mixers are pipeline mixers with radial mixing by employing stationary, shaped diverters

within the pipeline, which forces the liquids (the raw water and the coagulant solution) to mix

themselves. These mixers comprise fixed mixing elements installed in a housing of a diameter

which is the same as the pipe diameter.

Hydraulic mixers provide the power input according to the hydraulic head loss according to the

following formula:

P = Q * * g * h

with: P: power input (W)

Q: water flow (m

3

/s)

: water density (kg/m

3

)

g: gravity acceleration (m/s

2

)

h: hydraulic head loss (m)

Hydraulic mixers are usually suitable where some head loss can be tolerated. When compared

to static mixers, hydraulic mixers have the advantage that the coagulant dosing can be moni-

tored by visual observation (open flow), whereas in static mixers the coagulant solution is dosed

into a pressure pipeline and possible pipe blockage may not easily be observed.

The Consultant recommends that electrically driven stirrers are not used because of potential

maintenance problems.

However, if electrically driven mechanical mixers would be used, the Consultant recommends

the use of high speed flash mixers because optimum coagulation efficiency greatly depends on

the rapid dispersion of the coagulant in the raw water. This may not be fully achieved with pad-

dle type mixers at moderate rotation speed.

Rapid Mixing of Impeller Type

These mixers operate at high rotational speeds from 150 to 1,500 rpm or more and are mounted

on a vertical or inclined shaft. In the design of this type of flash mixer which is usually deep,

circular or square a detention time of 10 to 40 seconds would be provided. The preferred ve-

locity gradient is 300 m/s per metre depth or more.

Power required is 1 3 watts per m

3

/hr flow. Impeller diameter to tank diameter D

i

/D

t

should be

0.2 0.4 where D

i

is impeller diameter and D

t

is tank diameter.

The shaft speed of the propeller would be greater than 100 rpm for imparting a tangential veloci-

ty greater than 3m/s. The preferred ratio of height to diameter of tank is 1:1 3:1. To reduce

vortex and rotational movement of water about the impeller shaft, baffles projecting 1/10 1/12

of the tank diameter at least in four places along the wall of tank would be provided. The mixing

chamber would be placed below the chemical feed flow ensuring short chemical feed lines.

Rapid Mixing of Paddle Type

Any mixing in a tank with paddles would have the following criteria:

- mixing time: 0.2 2 minutes

- circle speed: 0.6 2m/sec

- revolution per minute: 5 20 rpm

- energy: 1 4 Wh/m3

- G = velocity gradient: 700 1000 (s-1)

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 5

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 4-4

4.5.2 Coagulant Chemicals

Aluminium Sulphate (Al

2

(SO

4

)

3

*18H

2

O) (Alum) is the most widely used chemical for water co-

agulation. However, an alternative coagulant Polyaluminium Chloride (PAC) has proven its suit-

ability and has significant advantages when compared to the use of Alum:

- Improved floc formation,

- Significantly reduced coagulant dosing rates (reduction of more than 50% possible),

thus compensating the higher unit price if compared to Alum,

- Low or even no relevant pH-reduction (whereas Alum dosing at common dosing rates

usually requires lime dosing for pH-correction),

- Less sludge production in the sedimentation stage.

The suitability of alternative coagulants and the determination of most appropriate dosing rates

should be subject to water treatability tests (Jar-Tests).

4.6 FLOCCULATION

4.6.1 General

The required power input for moderate mixing in the flocculation stage may be achieved by ei-

ther hydraulic or mechanical means.

Baffled flocculation basins are preferred over other alternatives for reasons of lower operation

and maintenance requirements, and less operation costs, especially because no electrically

driven devices are involved.

Baffled flocculation basins may either be of the horizontally baffled type (sinuous channel with

around-the-end baffles) or of the vertically baffled type (over- and under-baffles). For easiness

of operation (especially cleaning) the horizontally baffled type (sinuous channel) is preferred.

The Consultant recommends the following criteria for the flocculation process:

- G 15 60 s-1

- GT 10,000 100,000

- HRT 15 60 minutes

4.6.2 Horizontally Baffled Flocculation (Sinuous Channel)

Sinuous channels would be designed for flow velocities of 0.25 0.4m/sec and a detention pe-

riod of 20 30 minutes. The head loss over the total channel may range from 0.3 1m. Higher

velocities are preferred for highly turbid water.

The loss of head in bends is computed as 2 3.5 times the velocity head for each 180 degree

bend (half cycle turn) for round-the-end type.

This option does not involve mechanical moving parts, except only fixed staggered baffles to

achieve large and settlable flocs.

4.6.3 Mechanical Flocculation (Mixing)

For very large size plants, mechanical agitators of the paddle type installed in distinct floccula-

tion chambers can be considered.

In case of mechanical flocculation, it is recommended to apply the so-called tapered flocculation

with at least two flocculation chambers in series. The power input in the first chamber would be

significantly higher, whereas it reduces in the second chamber in order not to destroy the flocs.

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 5

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 4-5

The peripheral velocity should be between 0.5 and 0.8m/s in the first tank and between 0.1 and

0.3 m/s in the second tank.

- Detention time = 15 60 minutes

- Paddle area = 10% 20% of area of flocculator

- Head loss in mechanical flocculation is generally of the order of 0.1 0.2m

4.7 CLARIFICATION

4.7.1 Conventional Settling Tanks

Conventional settling tanks may either be horizontal flow clarifiers or vertical flow clarifiers.

Typical surface loading rates for conventional clarifiers are 1m/h for horizontal tanks and 2m/h

for up flow tanks. The latter can be increased to up to 5m/h if polyelectrolytes are used as floc-

culation aid.

Conventional settling tanks would be designed using weir overflow rates of 250 300 m

3

/m

2

/day

and surface loading of 1.0 m

3

/m

2

/h (or 24 m

3

/m

2

/day) calculated on net available surface area.

Effective depth of water would be a minimum of 2.0m allowing for sludge deposits, with the total

net depth at least 2.5m.

Average detention times in conventional settling tanks may range between 2 hours for vertical

flow clarifiers and 4 hours for horizontal flow clarifiers.

To avoid destruction of flocs, the velocity of the flocculated water between flocculation tank and

the settling tank should at no place exceed 0.2m/s.

4.7.2 Lamellae Settlers

Lamellae type clarifiers are settling tanks equipped with inclined parallel plates or tubes in order

to significantly increase the effective settling surface. This configuration allows much higher sur-

face loadings and will thus reduce the overall area required for these clarifiers.

Typical surface loading rates for lamellae type clarifiers are in the range of 5 12m/h, but pur-

pose built units may even attain 20m/h or even higher rates, depending on the raw water char-

acteristics and the flocs produced in the coagulation and flocculation stage. The angle of inclina-

tion to the horizontal is usually 55

o

70

o

.

In order to avoid algae growing enhanced by direct sunlight, the clarifiers should be covered by

an appropriate sun protection roof.

4.8 FILTRATION

4.8.1 General

Rapid gravity sand filters are the most widely used filtration devices, having proven their effi-

ciency for a wide range of different types of water. Rapid gravity sand filters allow operational

flexibility, especially in terms of the frequency and the phasing of the filter backwashing. How-

ever, rapid gravity sand filters have higher operation and maintenance requirements when com-

pared to slow sand filters.

Slow sand filters provide a low operation and maintenance solution for low turbidity waters. This

option represents a static process without any operational flexibility. Due to the smaller grain

size, slow sand filters may tend to clog easier, especially for cases where the water fed to the

slow sand filters contains algae.

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 5

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 4-6

4.8.2 Rapid Sand Filtration

Filters will be constructed in banks of three or more filter units, and each filter unit would have

an individual inlet that can be closed for maintenance and backwashing. The inlet would be de-

signed in such a way that flushing and velocities over 0.4m/s do not occur.

Surface loads would be between 4 and 7 m3/h*m2, and the filter structure would be designed

with a minimum height between the top of the filter media and the bottom of the wash water

channel of at least 30% of the height of the filter media as this expands during backwashing.

The filter bed would be approximately 1.0m thick and preferably consist of well rounded quartz

sand with an effect size of 0.7 1.0mm and uniformity coefficient in the range of 1.3 1.5. The

supporting gravel layer would have a minimum height of 0.1m and grain size of 2 8mm.

The available hydraulic head above the top of the filter bed would be 1.3 1.5m (for constant

head type filters) and around 2.0 2.5m (for constant flow type filters).

The most effective filter backwashing is achieved by the sequence of air scour to loosen the

clogged filter media, followed by a combined air/water sequence and finished by rinsing only

with water.

Backwashing of each filter unit is usually required once within 48 hours, however the design of

the filter backwashing facilities will allow for backwashing of each filter unit once every 24 hours.

The backwash procedure consists of a sequence of three steps:

- Air scour at a rate of 50 60m/h for 3 5 minutes

- Combined air scour (50 60m/h) and wash water (10 20m/h) for 5 10 minutes

- Water rinsing at a rate of 25 to 30 m/h for 5 to 10 minutes.

The required amount of wash water for backwashing of one filter unit will always be available

and will be taken from the treated (disinfected) clear water storage tank.

4.8.3 Slow Sand Filters

Slow sand filters consist of a relatively deep sand bed over a supporting bed of fine gravel and

an under-drain pipe-work system (typically 0.9 1.2m deep on start-up) and are cleaned by pe-

riodically removing the surface layer until the remaining bed depth is not less than 0.6m before

being re-sanded. The sand used is finer than the 1 2mm range that is typical in rapid sand

filters, having typically a mean particle size in the range of 0.15 0.4mm.

For slow sand filtration, the turbidity in the incoming water should not exceed an average of 5

10 NTU, and certain (filamentous) types of algae and organic load must be low. Any temporary

shock-loads by high turbidity waters (e.g. during rainy periods) must also be avoided.

For calculation of total area of slow sand filter beds, a working rate of 0.1 0.15 m3/m2/hr

would be used. When one filter is not operational, the working rate of the remaining filter beds

would not exceed 0.2m3/m2/h.

The chamber outlet should be made large enough to keep the entrance velocity into the slow

sand filter below 0.1m/s.

The grain size distribution of the filter sand should have an effective size 0.15 0.35mm and the

coefficient of uniformity should preferably be about 1.75 but less than 3.

About 1.5m of head of water above the filter bed should be adequate.

The collection pipes beneath the filter zone would be placed at 1m intervals and be perforated

with holes of 3.5mm diameter, or by saw-cuts placed on the underside of the pipe. The distance

between holes or saw-cuts would be about 100mm. Around the collection pipes and up to a lev-

el of about 0.3m above, a bottom layer of broken stones (50 to 100mm) and coarse gravel

(grain size 16 to 23mm) would be placed. Above this layer would be placed a layer of about

7 STATE CAPITALS URBAN WATER AND SANITATION FACILITIES PROGRAMME DESIGN CRITERIA REPORT

CHAPTER 5

Provision of Consultancy Services forFeasibility Studies, Detailed Designs and Tender Documents for Urban Water

and Sanitation Facilities in Bentiu, Bor, Torit, Aweil, Kuajok, Rumbek and Yambio| Design Criteria Report| PAGE 4-7

0.1m finer gravel (grain size 4 to 5.6mm) and a layer of about 0.1m coarse sand (grain size 1 to

4mm) on top of which is placed the actual filter sand.

Filter cleaning, by scraping off a 25mm surface layer of sand, is required at intervals, usually of

between 30 and 100 days depending on the turbidity of the water being filtered. The depth of

sand should not be allowed to become less than 600mm.

The Consultant recommends a minimum of two filter units would be provided for any proposed

slow sand filtration.

4.9 DISINFECTION

4.9.1 Ultraviolet radiation

Light radiation is an effective disinfection method for clear water, but its effectiveness is signifi-

cantly reduced when the water is turbid and contains nitrate, sulphate, and ferrous iron.

In addition, this disinfection method does not produce any residual that would protect the water

against any new contamination that could serve for control and monitoring purpose.

Hence UV disinfection is not recommended for the present Project.

4.9.2 Ozone

Ozone is increasingly used for disinfection of drinking water supplies in industrialized countries

because it is effective in eliminating compounds that give objectionable taste or colour in water.

Like UV disinfection, ozone normally leaves no measurable residual which could serve for moni-

toring the process. The absence of a residual also means that there is no protection against

new contamination of the water after its disinfection.

The high installation and operation costs, and the need for continuous power, make the use of

ozone relatively expensive. Furthermore the operation of ozone generators requires a number

of safety precaution measures, which might not be easily ensured under the operational condi-

tions within the present Project towns.

Hence disinfection using ozone is not recommended for the present Project.

4.9.3 Chlorination

Chlorine and chlorine compounds provide a number of advantages when compared to other dis-

infection methods and disinfection chemicals.

Its ability to destroy pathogens is fair, and its widespread availability makes it well suited for dis-

infection. Its cost is moderate, and for these reasons chlorine is the most widely used disinfect-

ant throughout the world. As a disadvantage, chlorination by-products such as trihalomethanes

are of possible health concern.

Alternative chlorine dosing chemicals comprise the following:

- For large schemes, the use of gaseous chlorine is preferable.