Beruflich Dokumente

Kultur Dokumente

Foamed Glass

Hochgeladen von

Deepta RaoOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Foamed Glass

Hochgeladen von

Deepta RaoCopyright:

Verfügbare Formate

Table Of Contents

Topics

page No.

Abstract ................................................................................................................................................... 2 Introduction ............................................................................................................................................. 3 Figure 1. Soap foam bubbles .............................................................................................................. 3 Foamed glass........................................................................................................................................... 4 Figure 2 Foamed Glass ....................................................................................................................... 5 Production Process .................................................................................................................................. 5 Figure 3 Porous Foamed Glass ........................................................................................................... 5 Figure 4 Processing of Foamed glass .................................................................................................. 6 Properties of foamed glass ...................................................................................................................... 6 Figure 5. Foamglass in different shapes.............................................................................................. 8 Strength and deformation properties ....................................................................................................... 8 Table 1.Deformation/settlements (short term/day 1) in foam glass material ...................................... 9 Table 2.Estimated creep deformations after day 1 at stress level* 300 kN/m2 permanent load......... 9 Foamed Glass In Road Projects .............................................................................................................. 9 Figure 6.Installing Steel Tube ........................................................................................................... 11 EXAMPLES WHERE FAOMGLASS IS USE IN ROAD PROJECTS .............................................. 11 Advantages of Foamed glass ................................................................................................................ 12 Disadvantages of Foamed glass ............................................................................................................ 15 Conclusion ............................................................................................................................................ 15 References ............................................................................................................................................. 17

Abstract Granulated foamed glass is produced by recirculating waste glass. It is also known as cellular glass. It is a light weight, opaque glass material having a closed-cell structure. It is an excellent bulk material for civil construction and insulation purposes. It is a lightweight, extremely fine-pored expanded glass with millions of pores. Since no diffusion can take place, the material is watertight and achieves an efficient barrier against soil humidity. Foamed glass is produced using an environ-mentally friendly recycling technology for contaminated and toxic material. The normal grain size is in the range 10 60 mm. When placed and compacted in a drained fill the least unit density will be 300 350 kg/m3 depending on the compaction machinery and compaction efforts. Besides the outstanding mechanical and thermal properties of the product, foamed glass manufacture is an exemplary process for waste recycling on an industrial basis. Foam glass can be manufactured fully out of waste glass, with only a minimum of additives. The material may be used as a lightweight fill material, as frost protection layer/thermal insulation in roads , insulation in buildings, especially suitable for thin-walled thermal insulations, such as for window frames, cement bricks and insulating plasters or other civil engineering applications. Foam glass can also provide very effective fire protection.The material is very advantageous and is being extensively used in construction thses days. This Report basically presents the manufacture, usage, advantages , disadvantages and other engineering aspects of Foam glass.

Introduction A foam is a substance that is formed by trapping pockets of gas in a liquid or solid. A bath sponge and the head on a glass of beer are examples of foams. In most foams, the volume of gas is large, with thin films of liquid or solid separating the regions of gas. An important division of solid foams is into closed-cell foams and open-cell foams. In a closed-cell foam, the gas forms discrete pockets, each completely surrounded by the solid material. In an opencell foam, the gas pockets connect with each other. A bath sponge is an example of an opencell foam: water can easily flow through the entire structure, displacing the air. A camping mat is an example of a closed-cell foam: the gas pockets are sealed from each other, and so the mat cannot soak up water. Foams are examples of dispersed media. In general, gas is present in large amount so it will be divided in gas bubbles of many different sizes (the material is polydisperse) separated by liquid regions which may form films, thinner and thinner when the liquid phase is drained out of the system films.[1] When the principal scale is small, i.e. for a very fine foam, this dispersed medium can be considered as a type of colloid. The term foam may also refer to anything that is analogous to such a foam, such as quantum foam, polyurethane foam (foam rubber), XPS foam, Polystyrene, phenolic, or many other manufactured foams. The same concept is used in the process of Foamed glass.

Figure 1. Soap foam bubbles

Foamed glass The study of thermodynamics in the late 19th century included the heat-transfer properties of materials and led to the concept of thermal insulationthat is, a material that has a relatively low rate of heat transfer. As building atmospheres became more carefully controlled after 1900, more attention was given to the thermal insulation of building enclosures . One of the best insulators is air, and materials that trap air in small units have low heat-transfer rates; wool and foam are excellent examples. The first commercial insulations, in the 1920s, were mineral wools and vegetable-fibreboards; fibreglass wool appeared in 1938. Foamed glass, the first rigid insulating foam, was marketed in the 1930s, and after 1945 a wide variety of plastic foam insulations was developed. Since the 1970s most building codes have set minimum requirements for insulation of building envelopes, and these have proved to be very cost-effective in saving energy. Foamed glass is A light, black, opaque, cellular glass made by adding powdered carbon to crushed glass and firing the mixture which acts as a cellulating agent.These components are mixed, placed in a mold, and then heated to a temperature of approximately 950 oF. During the heating process, the crushed glass turns to a liquid. Decomposition of the cellulating agent will cause the mixture to expand and fill the mold. The mixture creates millions of connected, uniform, closed-cells and form at the end a rigid insulating material. It is widely used as light weight fill material, thermal insulation in roads and buildings, and insulation under the floor slab as well because of its light weight, low parameters of heat conductivity. It is also used in the petroleum and chemical industries as well as underground engineering and military projects for heat insulation, temperature conservation, cold storage and sound insulation.

Figure 2 Foamed Glass

Production Process Foamglass is produced using an environmentally friendly recycling technology for contaminated and toxic waste ranging from mercury lamps, industrial slag and flyash, PC and TV-tubes, and laminated glass to batteries. The process is based on the concept of transforming finely ground glass powder from different glass sources mixed with an activator like silica carbide into glass foam. In the grinding process heavy metals are separated out and recycled to metal melting plants.

Figure 3 Porous Foamed Glass

The powder is spread on a steel belt conveyor running through high temperature ovens whereby the powder expands about 4 times leaving the oven as a glass foam material. When

5

the product leaves the oven it will crack and separate into smaller units due to the temperature shock. Normal grain size will be in the range of 10 60 mm .The production process is free of dust and any harmful gases and does not need water at any stage.

The principles behind this system are very simple: To separate and to clean the waste in fractions for further treatment down the process line. During this process the toxic components are reduced below the detecting limits. In this connection a certificate has been obtained for the material confirming that possible leaching products from a fill will have toxic contents well below normal environmental requirements. Foamed glass generally consists of 8 per cent of glass by volume and 92 per cent gas bubbles.

Figure 4 Processing of Foamed glass

Properties of foamed glass

Waterproof Foamglass insulation is resistant to water and vapour . As an all-glass, 100% closed cell material it retains all the water-resistant properties of glass. Thus there is no moisture

6

absorption, no condensation, no swelling of foamglass insulation , and it helps prevent corrosion under insulation.

Non-combustible Foamglass insulation is made of pure glass, and is non-combustible and also non-absorbent. As an inorganic material foamglass insulaton will not burn or support combustion. It ensures fire protection; inflammable liquids and gases cannot pass through Foamglas insulation .

Resistant To attack Since Foamglass insulation is inorganic, it is resistant to birds or vermin and has an unusually long term life cycle. Insulation of buried pipes and underground constructions is safe as foamglass insulation provides no food or nesting source for birds or vermin and does not support the growth of micro-organisms and bacteria.

High Compressive strength Cellular glass insulation gives exceptionally high compressive strength without deformation under permanent load. The insulation will not compress or settle and provides full support to tank bases and pipe supports, without thermal bridges.

Dimensionally Stable Cellular glass insulation is dimensionally stable, as glass does not shrink or swell. No warping or buckling with foamglass insulation . It remains stable since it has a similar expansion/contraction coefficient to steel piping and equipment. This gives a minimum of stress to the insulation system, joints and coverings as temperature changes. Preventing excessive expansion/contraction of insulation materials is the best way to ensure that the system remains sealed against moisture.

Acid resistant / chemical resistant Foamglass insulation is resistant to organic solvents and nearly all acids, since it is made of pure glass. No destruction of the insulation by sour gas or other corrosive media and aggressive plant conditions. The chemical resistance of glass is universally recognized.

Easily Cut to shape Foamglass insulation can be easily cut and installed on site or Prefabricated and preassembled components are available: segments, T-piece, elbows, half pipe-shells, valve boxes, vessel dome, ends and cones. Depending on project requirements, cellular glass insulation can be easily cut on site using a hard-point saw and other simple tools.

Figure 5. Foamglass in different shapes

Strength and deformation properties In Norway for a road project the foamed glass material was tested in a large cyclic loading triaxial apparatus with diameter 300 mm to find the resistance to develop permanent deformation when exposed to repeated loading. The results are relevant for designing road applications where the material is used in the road structure as part of the base layer or the sub-base layer. For use in road structures the material has elastic properties comparable to ordinary gravel commonly used as a roadbase material. It is, however, important that the stress level is kept below a level that will result in crushing and permanent material deformations. For repeated loading applications the cyclic stress is recommended limited to 75 kPa to reduce the permanent deformations. A large oedometer with diameter 500 mm was used to measure deformations in the material when exposed to permanent loading. The results are shown in Table 3. The test programme was expanded to include long term creep tests to find characteristic values for possible long term deformation. The typical use until now has been up to approximately 100 kN/m 2 base

8

pressure and the experience show no damaging long term deformations for any projects. The long term creep tests will make it possible to estimate the long term deformation for different loading conditions. The already performed oedometer tests are used to estimate the amount of long term creep assuming a linear time resistance development. Results are shown in Table 4. However, long term creep test have to be performed to verify these estimates.

Table 1.Deformation/settlements (short term/day 1) in foam glass material Quality & compaction level \ Stress level Light Light Standard 1% 0.25% 0.3% 4% 1.3% 1.1% >15% >11% >10.5% 50 kN/m2 100 kN/m2 300 kN/m2

Table 2.Estimated creep deformations after day 1 at stress level* 300 kN/m2 permanent load Compaction level 1.25 1.34 2.9% 2.0% 3.8% 2.6% 4.6% 3.1% 5.3% 3.5% 1 year 5 years 25 years 100 years

Thermal Conductivity The material is very suitable as thermal insulation and frost protection in both building and road application. The insulating properties have been tested in laboratory and for dry, compacted material a thermal conductivity of 0.11 W/mK at +10 C has been found.

Foamed Glass In Road Projects The amount of glass products used in the western hemisphere is huge. This comprises various

9

sorts of glass waste originating from light bulbs and other lighting fixtures like mercury lamps, bottles, windowpanes, car windshields etc. and industrial waste. In Europe the average annual glass consumption is about 30 40 kg/per inhabitant. At the same time as being a waste product it also constitutes a raw material for possible reuse. Some of the glass waste may be used directly in the production of bottles and other products but some of the glass waste also contains toxic materials that need to be removed in the recycling process. In this connection a production process has been initiated based on the recycling of waste glass in the middle region of Norway. In Norway about 4 million mercury lamps are used every year and the aim is to recycle about 40 % amounting to an annual production of some 50,000 m 3 of foamglass. In the production process lighting fixtures and other toxic glass waste is treated in order to remove heavy metal components and other environmentally difficult matter. The product has now been used as a lightweight filling material on about 25 road projects in Norway and a monitoring program has been initiated in order to evaluate the material properties and the structural performance.

With its light weight and good drainage and insulating properties the material may both be used as a lightweight fill material and/or frost insulating layer. A continuous work to improve the material since the start of production has resulted in a material that has a different pore structure, density and strength today with improved structural performance compared to the original product.In order to investigate physical and mechanical properties various monitoring programmes have been initiated both for field and laboratory testing.

In Norway a test is conducted on existing foamglass fills by inserting and vibrating a thin walled steel tube (with typical diameter 400-570 mm) into the foamglass (Figure 6). The particles contained within the steel tube are removed and the excavated material weighed wet and dry. This test is often conducted to find out changes in deformations, water content and density. The average density of foamed glass is found to be 300kg/m3.

10

Figure 6.Installing Steel Tube

EXAMPLES WHERE FAOMGLASS IS USE IN ROAD PROJECTS A cut and cover concrete tunnel of about 600 m length was constructed as a part of the relocation of the main highway E6. In order to keep the traffic running during the construction period a temporary diversion road with an embankment height of more than 15 m was constructed above the concrete tunnel. The upper 6 m of the embankment consisted of lightweight fill materials to reduce the weight on the culvert and to improve stability and reduce settlement problems. Both light weight aggregates (9000 m3) and foamglass (1000m3) are used. The diversion road was in service for one year until March 2004. The lightweight fill materials are reused as backfill against bridge abutments and in other parts of the road. Placing and compaction was performed in 1 to 1.5 metre thick layers using crawler mounted dozers with track loads 40 kN/m2 performing some 3 passes over the area per layer. A volume reduction of 25 % was observed. Another 5 % reduction in volume was anticipated due to transport on site from local storage areas. No covering soils were placed on the foamglass slopes on the temporary fill. Density and water content measurements were performed throughout the construction period both on loose material delivered on site and on compacted material in the fill. Plate bearing tests and falling weight measurements (FWD) were also performed. Settlements were observed and was found to be very less.

11

Foamglass insulation used at Ayers Rock Resort. Named after the soaring white sails that crown its roof tops, Sails in the Desert Hotel at Voyages Ayers Rock, located in the central Australian outback, is part of a worldclass resort surrounded by the Uluru-Kata Tjuta National Park, in Australias Northern Territory. With a desert climate that has average temperatures ranging from 19 C (66 F) in winter to 40 C (104 F) in summer, effective and efficient heating and cooling for the five hotels and multiple resort structures is a major task for the facility management engineers at the Voyages Ayres Rock Resort. In total, over 20,000 linear meters of foamglass insulation is currently being used at the Voyages Ayers Rock Resort. In addition to the outstanding longterm thermal performance and compressive strength qualities, several environmental concerns and regulations also played a role in the decision to use foamglass insulation. n. Because foamglass insulation is made from sand and is 100% natural and inorganic, it is the ideal choice for environmentally sensitive areas. Foamglass insulation contains no toxic chemicals or blowing agents and poses no environmental risks.

Advantages of Foamed glass Foamed glass makes buildings inaccessible for temperature shocks but permeable for vapor. so it creates comfortable and stable conditions for work and rest. Moreover foamed glass is very durable material and there is no need of making wearisome repairs of insulation. Foamed glass is also good for reconstruction of old buildings because it is absolutely safe and handy for use. The basic advantages of foam glass 1. Life cycle The guaranteed foam glass blocks life cycle with preservation of physical characteristics values is equal to term of building operation and exceeds 100 years. Experimental researches of the objects warmed with foam glass more 50 years ago have shown absence of essential changes in a foam glass structure. The factor of preservation of heat-shielding properties during all building existence is especially important in view of

12

inaccessibility heat-insulated material after the end of works. Foam glass is not subject to ageing for some reasons since its unique properties resist to active factors showing themselves eventually:

Oxidation: The active oxygen containing in atmosphere does not render influence on foam glass for the reason that this material consists exclusively of the higher oxides silicon, calcium, sodium, magnesium, aluminium;

Erosion: As foam glass has no soluble components in its structure, there is no dissolution and washout of a material with water;

Temperature drops: Foam glass has very low coefficient of linear expansion that allows to transfer daily and annual temperature perturbation without damage for structure of a material;

Freezing of water: At freezing water extends and can destroy even such strong minerals as basalt and granite, flowing in cracks. The surface of foam glass consists of hemispheres, the material represents closed cells at all excluding hit of water inside, therefore expansion of water does not destroy foam glass;

Deformation: Cellular glass is not deformable absolutely and very strong material for its density, that completely excludes an opportunity of its shrinkage, whipping, etc. consequences of gravity and mechanical long influence;

Activity of biological forms: Foam glass is not a nutrient medium for a fungus, mould and microorganisms, it is not damaged with roots of trees, therefore activity of biological forms does not harm to a material structure during the time.

2. Strength Foam glass is the strongest of all effective heat-insulated materials. Foam glass is unique that is not compressed material absolutely. Moreover, less strong than foam glass heat-insulated material demands anchoring to a bearing structure of a construction. 3. Stability of physical parameters Foam glass is the material consisting from hermetically closed hexagonal and spherical cells. Such structure of a material excludes interaction of the gas environment of cells with an atmosphere and causes invariance in time of materials characteristics. That is, there is no change of such parameters of foam glass blocks as heat conductivity, strength, stability, form,

13

etc. Eventually a factor of keeping heat-insulated materials properties is important especially at upkeep of buildings and constructions in view of inaccessibility of a material after end of works. 4. Chemical and biological action stability Glass of which foam glass consists by 100 % , is not decomposed with chemical reagents, is not nutrient medium for fungus, mould and microorganisms, is not damaged with roots of plants, is absolutely impassable for insects and rodents and represents an ideal barrier to similar pests. Foam glass in addition is very good abrasive material. This feature of foam glass is used actively at a heat-shielding of granaries, industrial food refrigerators, warehouses since foam glass is reliable barrier on a way of wreckers besides a heat-protection layer. 5. Incombustibility and fire resistance Foam glass is completely non-inflammable material as it does not include oxidized or organic components. The "know-how" of foam glass is such, that a finished article is fabricated as a result of manufacturing in furnaces at the temperature close to 1000C, therefore at foam glass heating up to warm temperature it only melts as usual glass without extraction of gases or vapor. This factor is important for fire-prevention properties of a construct. 6. Moisture resistance, water resistance and non hygroscopic property Water does not render on foam glass any influence for two reasons. First it consists of hermetically closed cells which walls` material is usual silicate glass. Secondly it does not absorb moisture and does not pass it, and it is an additional hydro barrier at use in a building envelope. At damage of a waterproofing distribution of water is not supposed both in vertical and in horizontal directions. Water resistance of foam glass allows it to prevent ice formation for long, to provide overall protection against corrosion and excellent thermoregulation. Foam glass is steady to action both fresh and salty water.

14

7. Ecological and sanitary safety Ecological and sanitary safety of foam glass allows to warm filler structures not only for housings in which the raised cleanliness of the air is necessary (buildings of educational and medical function, sports constructions; museums; hi-tech manufactures, etc.), but also for buildings with special sanitary-and-hygienic requirements (the food and pharmacological industry; baths and saunas; pools; cafe, restaurants, dining room, etc.) Most foam glass is made by grinding glass from a glass melt into small particles and then mixing it with a carbon containing material and then reheating it up above the melting point of the glass in a box mold. The carbon material reacts with the glass to make carbon dioxide to make the foam. The glass used is mostly recycled glass, but the double heating and the grinding process makes the product expensive, but the product has as very long life compared to organic products and more durability.

Disadvantages of Foamed glass Foam glass to the maximum extent satisfies all requirements imposed. A method for production of this material was developed as early as the ends of 1930s by I.I Kitaigorodskii and B.Long. Unfortunately, despite obvious advantages of foamglass it did not find wide application. However interest in this material in our country has been growing lately. Possibilities of buying cellular glass has appear not very long ago. But for such a short time it has gain a market because of it's unique properties. Everyday, more and more people begin to warm their houses, flats with a cellular glass, again making sure that this material is totally environmental, safe, secure and absolutely incombustible. The base of this material is glass, so it can't be strike by fungus and bacterium. Besides it doesn't maintain burning, doesn't send off toxic substances and smoke. Cellular glass is acidproof and steamproof. The one and only disadvantage of cellular glass is it's price. During the production there are a lot of power inputs, that's why the prise is so high. And with the prices rise on a energy resourses, the price on a cellular glass will rise too.

Conclusion The material is believed to be an interesting alternative as lightweight fill material and Thermal insulation for a number of civil engineering applications. Foamglass granulate has light weight and good insulating and drainage properties. The design densities for foamglass

15

are found to be be 3.5 kN/m3 for the light quality and 4.0 kN/m3 for the standard quality. Foamglass may be used as light weight fill in embankments to improve stability and or reduce settlements and as frost insulation layer. The material is believed to be fully resistant to possible chemical degrading agents in a road structure. The mechanical strength of the light quality material may require some special handling in order to prevent excessive crushing. Observations so far indicate that fairly light machinery should be used on site for placement, distribution and compaction. The material is also being used in Our country for insulating residentital and other buildings . Foamed glass has found an important place in construction of buildings and road and tunnel projects because of its favourable properties. It is a good fire resistant and does not have any environmental impact.\

16

References 1) Aabe Roald, 1980, Lette fyllmasser I vegbygging (lightweight filling materials in road construction text in Norwegian), Intern rapport 954, Norwegian Road Research Laboratory, Oslo 2) S. Basak, S. S. Mukherjee, S. N. Mandal, Rama Das, A. K. Majumdar, J. K. Mondal, R. Samaddar, S. Mondal and Dipali Kundu* Interlaboratory proficiency testing: Intercomparison in relation to the measurement of alumina, iron(III) oxide and titania present in homogenised china clay, in MAPAN-Journal of Metrology Society of India (in press), 2010 3) http://www.mendeley.com 4) www.google.com

17

18

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- RomerDokument20 SeitenRomerAkistaaNoch keine Bewertungen

- 3700 RES 5.5.1 Install GuideDokument38 Seiten3700 RES 5.5.1 Install Guidejlappi100% (1)

- How Convert A Document PDF To JpegDokument1 SeiteHow Convert A Document PDF To Jpegblasssm7Noch keine Bewertungen

- Database Programming With SQL 12-3: DEFAULT Values, MERGE, and Multi-Table Inserts Practice ActivitiesDokument2 SeitenDatabase Programming With SQL 12-3: DEFAULT Values, MERGE, and Multi-Table Inserts Practice ActivitiesFlorin CatalinNoch keine Bewertungen

- Unit-3 BPDokument48 SeitenUnit-3 BPShreyas ShreyuNoch keine Bewertungen

- Finches Statistics Student-1Dokument7 SeitenFinches Statistics Student-1api-319172404Noch keine Bewertungen

- Iot Lab RecordDokument33 SeitenIot Lab RecordMadhavan Jayarama MohanNoch keine Bewertungen

- Lecture-7 - Line CodingDokument14 SeitenLecture-7 - Line CodingFahim Hasan AlifNoch keine Bewertungen

- Product Specifications: Handheld Termination AidDokument1 SeiteProduct Specifications: Handheld Termination AidnormNoch keine Bewertungen

- GMS60CSDokument6 SeitenGMS60CSAustinNoch keine Bewertungen

- Hindu Temples Models of A Fractal Universe by Prof - Kriti TrivediDokument7 SeitenHindu Temples Models of A Fractal Universe by Prof - Kriti TrivediAr ReshmaNoch keine Bewertungen

- L4 Subdivision of PlotsDokument20 SeitenL4 Subdivision of PlotsKenny BoatNoch keine Bewertungen

- Question IARDokument4 SeitenQuestion IARAryan jay vermaNoch keine Bewertungen

- 5R55W-S Repair DiagnosisDokument70 Seiten5R55W-S Repair Diagnosisaxallindo100% (2)

- Dual Inverter Gate: Features DescriptionDokument19 SeitenDual Inverter Gate: Features DescriptionYaju JotosNoch keine Bewertungen

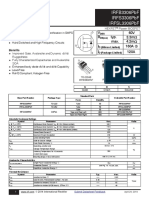

- Irfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADokument12 SeitenIrfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADirson Volmir WilligNoch keine Bewertungen

- F3 Chapter 1 (SOALAN) - RespirationDokument2 SeitenF3 Chapter 1 (SOALAN) - Respirationleong cheng liyNoch keine Bewertungen

- Driver LCI 150W 500-850ma FlexC NF h28 EXC3 enDokument7 SeitenDriver LCI 150W 500-850ma FlexC NF h28 EXC3 enMoustafa HelalyNoch keine Bewertungen

- The Big TEGO. Products Services Data Sheets-75-150-16!76!31-61Dokument31 SeitenThe Big TEGO. Products Services Data Sheets-75-150-16!76!31-61DWI RAHMASARI FATMAWATINoch keine Bewertungen

- Serie W11 PDFDokument2 SeitenSerie W11 PDFOrlandoNoch keine Bewertungen

- SR-X Script Reference - EDokument24 SeitenSR-X Script Reference - EDomagoj ZagoracNoch keine Bewertungen

- Illiquidity and Stock Returns - Cross-Section and Time-Series Effects - Yakov AmihudDokument50 SeitenIlliquidity and Stock Returns - Cross-Section and Time-Series Effects - Yakov AmihudKim PhượngNoch keine Bewertungen

- Famous MathematicianDokument116 SeitenFamous MathematicianAngelyn MontibolaNoch keine Bewertungen

- Heat Fusion of Ice ReportDokument8 SeitenHeat Fusion of Ice Reporthasifah abdazizNoch keine Bewertungen

- 10 2Dokument26 Seiten10 2cristinatubleNoch keine Bewertungen

- Servodisc CatalogDokument87 SeitenServodisc CatalogEstebanRojasKrustofskyNoch keine Bewertungen

- FI Printing Guide Vinyl-303Dokument1 SeiteFI Printing Guide Vinyl-303tomasykNoch keine Bewertungen

- MX3Dokument154 SeitenMX3Dung Nguyen0% (1)

- V. Activities: A. Directions: Do The Activity Below. (20 PTS.) Note: Work On This OfflineDokument7 SeitenV. Activities: A. Directions: Do The Activity Below. (20 PTS.) Note: Work On This OfflineKeith Neomi CruzNoch keine Bewertungen

- M. Fatur - H1C018040 - PETROLOGIDokument15 SeitenM. Fatur - H1C018040 - PETROLOGIFaturrachmanNoch keine Bewertungen