Beruflich Dokumente

Kultur Dokumente

Telecommunication Noatak 000

Hochgeladen von

Khaja Muqeem UddinOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Telecommunication Noatak 000

Hochgeladen von

Khaja Muqeem UddinCopyright:

Verfügbare Formate

NOATAK K-12 REPLACEMENT SCHOOL NORTHWEST ARCTIC BOROUGH SCHOOL DISTRICT

DIVISION 16 ELECTRICAL

Burkhart Croft Architects, LLC

Section 16710 - Page 1 TELECOMMUNICATION DISTRIBUTION

SECTION 16710 TELECOMMUNICATION DISTRIBUTION PART 1 - GENERAL 1.1 SUMMARY A. The intent of this Specification is to place in working order a complete, fully tested and documented telecommunication cabling system consisting of both Category 5e copper and fiber optic cabling complying with the Codes and Standards referenced herein. In addition, horizontal voice cabling and patch capabilities will be provided for the operation of the owner installed telephone system. B. Section includes backboards, pathways, cabinets, racks, termination devices, outlets, and premises wiring to install a structured Category 5e rated telecommunication cabling system. Related Sections: 1. Section 16060 - Grounding and Bonding. 2. Section 16070 - Electrical Hangars and Supports. 3. Section 16075 - Electrical Identification. 4. Section 16123 - Building Wire and Cable. 5. Section 16130 - Raceway and Boxes. 6. Section 16133 Cable Trays. 7. Section 16141 - Floor Boxes.

C.

1.2

REFERENCE CODES AND STANDARDS A. Design, manufacture, test, and install telecommunications cabling networks per manufacturer's requirements and in accordance with NFPA-70 (National Electrical Code), state codes, local codes, requirements of authorities having jurisdiction, and particularly the following standards: 1. ANSI/TIA/EIA-568-B Addendum 1, Draft 10 2. ANSI/TIA/EIA-568-B.1 - General Cabling System Requirements 3. ANSI/TIA/EIA-568-B.2 - Balanced Twisted-Pair Cabling Components 4. ANSI/TIA/EIA-568-B.3 - Optical Fiber Cabling Components Standard 5. ANSI/TIA/EIA-569-A - Commercial Building Standard for Telecommunications Pathways and spaces 6. ANSI/TIA/EIA-606 - Administration Standard for the Telecommunications Infrastructure of Commercial Buildings. 7. ANSI/TIA/EIA-607 - Commercial Building Grounding and Bonding Requirements for Telecommunications 8. Install cabling in accordance with the most recent edition of BICSI publications: a. BICSI - Telecommunications Distribution Methods Manual. b. BICSI - Cabling Installation Manual.

BCA Project No. 0513.03

NWABSD Project No. 542.01

T:\2004.186.1 - Noatak School - Design Development\Specifications\Electrical\16710-Telecommunication-Noatak.doc

NOATAK K-12 REPLACEMENT SCHOOL NORTHWEST ARCTIC BOROUGH SCHOOL DISTRICT

DIVISION 16 ELECTRICAL

Burkhart Croft Architects, LLC

Section 16710 - Page 2 TELECOMMUNICATION DISTRIBUTION

1.3

SYSTEM DESCRIPTION A. Provide the equipment, materials, and labor to install the systems shown on the drawings and specified herein. This shall include (but not be limited to) provision of all trenching and backfill, raceways, sleeves, boxes, gutters, shelves, enclosures, shelf and enclosure supports, backboards, equipment racks, line and low voltage wire and cable, patch cords, pull ropes (in unused conduits), terminal modules, panels, outlets, jacks, splices, connections, cable management, labeling, testing and all other material, equipment, and labor required to make the systems fully operational. B. Service entrance from telecommunications utility company. 1. Telecommunications Utility Company: XXX 2. Service Entrance Pathway: Empty raceways with pull rope from point of Telephone Utility connection at property line to building service terminal backboard in telecommunication closet. Backbone Pathway: Conform to EIA/TIA requirements using fiber cable in innerduct and copper cable, routed in continuous pathway support, J-hooks and conduit sleeves.

C.

D. Horizontal Pathway: Conform to EIA/TIA requirements, using raceway, continuous pathway support, J-hooks and conduit sleeves. E. Backbone Cabling: 1. Data: Complete system of optical fiber backbone cable system from main distribution frame to intermediate distribution frame with all terminations installed in Fiber Connector Housing Units. 2. Voice: Complete system of multi-conductor pair UTP cable from main distribution frame to telecommunication intermediate distribution frame location. Horizontal Cabling: Complete structured cabling system star topology from patch panels to station outlets using unshielded twisted pair (UTP) horizontal cables.

F.

1.4

SUBMITTALS A. Division 1 - Submittals: Submittal procedures. 1. Manufacturer's Catalog Data shall be submitted for the following items. Data shall include a complete list of parts, special tools, and supplies with current unit prices and source of supply. a. UTP Copper Cable. b. UTP Telecommunications Jacks and Faceplates. c. UTP Modular Patch Panel. d. UTP Patch Cables. e. Fiber Cable. f. Fiber Connectors. g. Fiber Connector Housings and Panels.

BCA Project No. 0513.03

NWABSD Project No. 542.01

T:\2004.186.1 - Noatak School - Design Development\Specifications\Electrical\16710-Telecommunication-Noatak.doc

NOATAK K-12 REPLACEMENT SCHOOL NORTHWEST ARCTIC BOROUGH SCHOOL DISTRICT

DIVISION 16 ELECTRICAL

Burkhart Croft Architects, LLC

Section 16710 - Page 3 TELECOMMUNICATION DISTRIBUTION

h. Equipment Racks. i. Cable Management Panels. j. Cable Organizers. k. UTP and Fiber Telecommunications Cable Tester. l. Ladder Racking m. Terminal Modules n. Rack Mounted UPS Device B. Labeling System: Coordinate with Contracting Agency for Owners labeling conventions. Submit Project labeling system for approval. Where room numbers are employed in identification scheme, use room numbers as listed in final room sign schedule. Quality Assurance Plan: Contractor shall prepare a quality assurance plan which provides a detailed outline of all testing to be accomplished. Quality assurance plan shall include, as a minimum, a schedule of when tests will be performed relative to installation milestones, specific test procedures that will be used, a list of test equipment that will be used including manufacturer, model number, calibration certification, range and resolution accuracy. Test plan shall be submitted to the Owner for approval at least 30 days prior to the start of testing.

C.

D. Shop Drawings shall include dimensioned layout of equipment rooms and telecommunication closets, including backboards, patch panels, grounding terminal bus bars, ladder racking, equipment, etc. Layouts shall coordinate with lighting fixtures, HVAC equipment, etc., which affect room layouts. E. Shop Drawings shall include dimensioned layout of major pathways, including j-hooks, sleeves, cable trays, conduits 2 and larger and location of firewall penetrations. Shop drawings shall include riser style diagram of all backbone wiring and terminations and typical horizontal wiring and termination for owner review and approval.

F.

G. Shop drawings shall include labeling documentation. 1.5 CLOSEOUT SUBMITTALS A. Division 1 Contract Closeout: Closeout procedures. B. Project Record Documents: Record actual locations and sizes of pathways and outlets. Include all test report. Provide floor plan with identification of all outlets. Provide 1/16 scale (minimum) laminated floor plan with accurate identification of all outlets served by respective closet in each closet, including a single line representation of the network system.

1.6

WORKMANSHIP

BCA Project No. 0513.03

NWABSD Project No. 542.01

T:\2004.186.1 - Noatak School - Design Development\Specifications\Electrical\16710-Telecommunication-Noatak.doc

NOATAK K-12 REPLACEMENT SCHOOL NORTHWEST ARCTIC BOROUGH SCHOOL DISTRICT

DIVISION 16 ELECTRICAL

Burkhart Croft Architects, LLC

Section 16710 - Page 4 TELECOMMUNICATION DISTRIBUTION

A. Components of the system shall be installed in a neat, workmanlike manner. Wiring color codes shall be strictly observed and terminations shall be uniform throughout the system. Identification markings and systems shall be uniform. TIA/EIA 568B wiring codes as shown on the drawings shall standardize all wiring B. Install materials and equipment in accordance with applicable standards, codes, requirements, and recommendations of national, state, and local authorities having jurisdiction, and National Electrical Code (NEC) and with manufacturer's printed instructions

1.7

QUALIFICATIONS A. Manufacturer: Company specializing in manufacturing products specified in this section with minimum three years documented experience. B. Installer: Specialty telecommunication system contractor primarily engaged in installing products specified in this section with minimum three years documented experience. Installer shall be certified by manufacture of cabling and termination equipment to be installed. Contractor shall include listing of at least three projects of equivalent scope and size, including date of project completion, location of project, and point of contact or reference for each specific project. Testing Agency: Specialty telecommunication system contractor specializing in testing products specified in this section with minimum three years documented experience.

C.

1.8

COORDINATION A. The necessity to coordinate this work with the Owner and the Contracting Agency is emphasized. The Contractor shall be responsible for any omissions, delays and additional cost due to lack of coordination or approval from the same. B. Coordinate all work with lighting, power, ventilation, sprinklers and other systems in the communication rooms to avoid interferences. Coordinate with the utility company for all requirements of service installation.

C. 1.9

TERMINOLOGY A. Backbone Cables - Copper or optical fiber cables connecting main cross-connect facilities or intermediate cross-connect facilities. B. Cable Management Troughs, gutters, management panels, etc., mounted in conjunction with telecommunications distribution equipment and terminal blocks, for the routing of cables and patch cords in a neat and workmanlike manner.

BCA Project No. 0513.03

NWABSD Project No. 542.01

T:\2004.186.1 - Noatak School - Design Development\Specifications\Electrical\16710-Telecommunication-Noatak.doc

NOATAK K-12 REPLACEMENT SCHOOL NORTHWEST ARCTIC BOROUGH SCHOOL DISTRICT

DIVISION 16 ELECTRICAL

Burkhart Croft Architects, LLC

Section 16710 - Page 5 TELECOMMUNICATION DISTRIBUTION

C.

Data Generic term for Structured Telecommunication Distribution System cabling and hardware infrastructure internal and external to a building or buildings used to transmit voice and data, etc.

D. Horizontal Cables Cables connecting patch panels or terminal blocks in the Telecommunications Rooms to the outlet jacks. E. F. Jacks or Ports - Female mechanical termination device for horizontal cables. LEC - Local Exchange Carrier Serving Utility.

G. Outlets - Device plate that contains jacks or ports. H. Patch Panels Rack mounted connecting hardware to connect horizontal or backbone cables to an arrangement of fixed connectors using patch cords or to form cross or interconnections. I. Pathways-refers to conduits, sleeves, cabletrays, distribution rings, etc., which are employed to route backbone and horizontal cables between telecommunication rooms, outlets, etc. for placement, support, and protection of the telecommunication cables. Rack Mounting frame to support telecommunication equipment, patch panels, etc.

J.

K. Telecommunications Rooms (TR) Space for housing telecommunications equipment, cable terminations and cross-connect wiring. L. 1.10 Terminal Blocks - Multiple punch down cable terminations.

ACCEPTABLE MANUFACTURERS A. Provide products of manufacturers as named in individual articles 1. Submittals to be approved by Engineer and NWABSD project manager, before installation. 2. Where no manufacturer is specified, provide products of manufacturers in compliance with requirements. 3. Any item of equipment or material not specifically addressed on the drawings or in this document and required to provide a complete installation shall be provided in a level of quality consistent with other specified items. 4. Provide products that are suitable for intended use, including, but not limited to environmental, regulatory, and electrical requirements. B. Structured cabling system will include copper cable, fiber cable, termination jacks, outlets, patch panels, patch cords, fiber connection panels, and connecting hardware. Provide all equipment from one of the following list of approved manufacturers structured systems: KRONE, Ortronics/Berk-tek, AVAYA Technologies (Lucent).

BCA Project No. 0513.03

NWABSD Project No. 542.01

T:\2004.186.1 - Noatak School - Design Development\Specifications\Electrical\16710-Telecommunication-Noatak.doc

NOATAK K-12 REPLACEMENT SCHOOL NORTHWEST ARCTIC BOROUGH SCHOOL DISTRICT

DIVISION 16 ELECTRICAL

Burkhart Croft Architects, LLC

Section 16710 - Page 6 TELECOMMUNICATION DISTRIBUTION

PART 2 - PRODUCTS 2.1 UNSHIELDED TWISTED PAIR STATION CABLING A. Horizontal Cable and Copper Backbone Cable: Plenum rated, Category 5e, four pair, 24 AWG twisted copper conductors, 350 Megahertz Cable. 1. KRONE #TN5ETP-***02 Plenum Rated. 2. Berk-tek LANmark 350 CMP Plenum Rated. 3. AVAYA #2061 Plenum Rated. 2.2 STATION HARDWARE A. Jacks: Flush mount, 8 pin, 568-B pairing convention with faceplates or connectors. Numbered ports. 1. KRONE K600 #6467-1-081-10 T568A/B. 2. Ortronics TracJack #OR-63750001 T568A/B 3. AVAYA #MPS100E-246 T568B. B. Faceplates: White, match faceplate jack count as shown on drawings. Use of blanks is discouraged. 1. KRONE #6644-1-154-02. 2. Ortronics TracJack # OR-40300546 or EP01-067-01 3. AVAYA #M14L-246. Icons and Labels: 1. KRONE included in the faceplate. 2. Ortronics #OR4030920x; Numbered icons - must be glued in place (x = jack ID, i.e. 1,2,3,4). Numbered icons not required custom numbered faceplate. 3. AVAYA included in the faceplate.

C.

2.3

PATCH PANELS A. Data Patch Panels: 48 Port Category 5e. Install the number of patch panels in each equipment rack as required to terminate all UTP cables at the rack plus twenty five (25) percent spare capacity. Horizontal cable management shall be provided for each patch panels without integrated horizontal cable management. 1. KRONE Enhanced Patch Panel 6653-1-466-48. 2. Ortronics #OR-851004038 2RMS 3. AVAYA Patchmax PM2150PSE-48 with integral horizontal management.

2.4

PATCH CORDS A. Patch Panel Patch Cords: Provide one round seven foot long, Category 5e rated, blue, four pair, 24 AWG twisted stranded copper conductors for each terminated patch panel port. Deliver patch cords to Owner at project site.

BCA Project No. 0513.03

NWABSD Project No. 542.01

T:\2004.186.1 - Noatak School - Design Development\Specifications\Electrical\16710-Telecommunication-Noatak.doc

NOATAK K-12 REPLACEMENT SCHOOL NORTHWEST ARCTIC BOROUGH SCHOOL DISTRICT

DIVISION 16 ELECTRICAL

Burkhart Croft Architects, LLC

Section 16710 - Page 7 TELECOMMUNICATION DISTRIBUTION

1. KRONE TruePatch#TP5ETA-WT07. 2. Ortronics #OR-836GT8007DE06. 3. AVAYA #D8CM-IV7. B. Station Outlet Patch Cords: Provide one round nine foot long (ten foot for Lucent and Krone), Category 5e rated blue 24 AWG twisted stranded copper pair conductors for each terminated station outlet jack plus 25% additional cables for future expansion or replacement cables. 1. KRONE TruePatch #TP5ETA-WT10. 2. Ortronics #OR-836GT8009DE06. 3. AVAYA #D8CM-IV10.

2.5

COPPER BACKBONE CABLE (VOICE BACKBONE) A. Copper Voice Backbone Cable: Plenum rated, Category 3 compliant, copper 24 AWG, multi-pair cable units. (xx + pair count, as indicated on the drawings). 1. KRONE #VXVxx24-1902. 2. Berk-Tek # 230xxx. 3. AVAYA #2010xxxBWH.

2.6

OPTICAL FIBER BACKBONE CABLE A. Optical Fiber Cable: Plenum Rated, tight-buffered multi-mode, dual window graded index optical glass fiber cable with fiber counts as denoted on the drawings. Fiber Dimension: Core: 62.5 micron. Cladding: 125 micron. Coating: 250 micron. Buffering: 900 micron. Cable Minimum Bending Radius: During Installation: 20 times outside cable diameter. After Installation: 10 times outside cable diameter. 1. KRONE #6xx-PTS-CB-62S/SL (xx = fiber count denoted on the plans). 2. Berk-tek GigaLite #PDP0xx-GB3510/25 (xx = fiber count as denoted on the plans). 3. AVAYA OptiSPEED #ABC-)xxD-LPX (xx = fiber count as denoted on the plans). B. Number of fiber shall be two strands to each telecommunication closet receiving 1 to 22 new horizontal cable terminations, plus 4 additional spare strands. An additional two strands of fiber shall be added for every additional 22 new horizontal cables terminated in the respective telecommunication closet. Fiber connector: SC type connector, Non metal

2.7

OPTICAL FIBER CONNECTOR HOUSING

BCA Project No. 0513.03

NWABSD Project No. 542.01

T:\2004.186.1 - Noatak School - Design Development\Specifications\Electrical\16710-Telecommunication-Noatak.doc

NOATAK K-12 REPLACEMENT SCHOOL NORTHWEST ARCTIC BOROUGH SCHOOL DISTRICT

DIVISION 16 ELECTRICAL

Burkhart Croft Architects, LLC

Section 16710 - Page 8 TELECOMMUNICATION DISTRIBUTION

A. Optical Fiber Connector Housing: High Density, front and rear accessible, 19 inch rack mountable, pull out shelf with cable retainers and fiber storage drums. Unit to have clear polycarbonate protective cover with fiber optic cable Duplex SC couplings. 1. KRONE #RMG1-24-SCDMML. 2. Ortronics #OR-615MMC-36P-00./ OR-615SCDSM3-L 3. AVAYA #600B2/ 12SC1 Duplex EW 2.8 OPTICAL FIBER CONNECTORS A. Optical Fiber Connectors: Field installable Type SC with ceramic ferrule and provide maximum 0.3 dB insertion loss. 1. KRONE / Corning #95-100-16. 2. Ortronics/Corning #95-100-16. 3. AVAYA #P6201A-Z-126. 2.9 TERMINATION BACKBOARDS A. Material: Fire retardant Plywood B. C. 2.10 Size: As required, 5/8 inch thick minimum, Grade AC or better Finish: Paint to match adjacent walls.

FLOOR MOUNTED TELECOMMUNICATION EQUIPMENT RACKS A. Open Frame Floor Mounted Equipment Racks: Extruded aluminum 6061-T6, open frame, 19 inch EIA width equipment rack, 7 foot overall height (unless noted otherwise on prints) with flange base, mounting rails drilled front and back and tapped to EIA standards, 40+ RMS minimum, clear finish. Install ground bus on rack near the bottom as shown on the drawings and as specified in Section 16060 Grounding. Install power strip on rack near the bottom, as shown on the drawings. Provide seismic bracing as required by Section 16070 Electrical Hangars and Supports. Seismic support must consist of rigid supports and not use cables or chains. 1. Chatsworth Products 46353-503 or approved equal with rack-mounted ground bar.

2.11

WALL MOUNTED TELECOMMUNICATION RACKS A. Open Frame Wall Mounted Equipment Racks: Aluminum, 35 (20 mounting space) usable mounting height, gate opens 180 degrees, fully wall mountable, 150 pound load capacity, dual locking latches, integral cable management, clear finish. Install ground bus on rack near the bottom as shown on the drawings and as specified in Section 16060 Grounding. Install power strip on rack near the bottom as shown on the drawings. Provide seismic bracing as required by Section 16070 - Electrical Hangars and Supports. 1. Chatsworth Products 11348-519 or approved equal with rack mounted ground bar.

BCA Project No. 0513.03

NWABSD Project No. 542.01

T:\2004.186.1 - Noatak School - Design Development\Specifications\Electrical\16710-Telecommunication-Noatak.doc

NOATAK K-12 REPLACEMENT SCHOOL NORTHWEST ARCTIC BOROUGH SCHOOL DISTRICT

DIVISION 16 ELECTRICAL

Burkhart Croft Architects, LLC

Section 16710 - Page 9 TELECOMMUNICATION DISTRIBUTION

2.12

HORIZONTAL CABLE MANAGEMENT A. For the Berk-Tek/Ortronics and Krone structured cabling system, install horizontal cable management panels in the equipment rack. Unless otherwise noted on the drawings, install one cable management panel between each patch panel and below the last patch panel. 1. Floor Racks: Ortronics # OR-60400057 or approved equal 2. Wall Racks: Ortronics #OR-808004410 or approved equal

2.13

VERTICAL CABLE MANAGEMENT A. Vertical Cable Management: Double sided narrow vertical section 7 feet high by 3.65 inches wide by 12.75 inches deep. Provide vertical cable management on each side of all racks installed with one vertical cable management between multiple adjacent racks. 1. Chatsworth Products #12096-503.

2.14

RACK EQUIPMENT SHELF A. Rack Equipment Self: 19 inch wide heavy duty 20 inch deep and mounting hardware. 1. Chatsworth Products #11164-519.

2.15

POWER PROTECTION STRIP A. Power Protection Strip: Rack mounted UL 1449 330/400 clamping voltage, twelve on/off switch controlled 3 prong 120 Volt outlets with 12 foot cord. Unit protects Normal/Common Modes: 33,000/26,000 Peak Milliamps, 50-60 dB. Provide one power protection strip mounted on each installed rack. 1. Leviton #5500-192. 2.

2.16

EXTRA MATERIALS: A. Furnish to the Owner the following spares. 1. Five (5) percent of each type of UTP telecommunications jacks. 2. Five (5) percent of each type of telecommunications faceplates. 3. If number icons are utilized provide ten (10) percent of each identification icon for each number designation (1 thru 4) on the faceplate.

PART 3 - EXECUTION 3.1 INSTALLATION A. Install pathways in accordance with EIA/TIA 569. B. Install wire and cable in accordance with EIA/TIA 568.

BCA Project No. 0513.03

NWABSD Project No. 542.01

T:\2004.186.1 - Noatak School - Design Development\Specifications\Electrical\16710-Telecommunication-Noatak.doc

NOATAK K-12 REPLACEMENT SCHOOL NORTHWEST ARCTIC BOROUGH SCHOOL DISTRICT

DIVISION 16 ELECTRICAL

Burkhart Croft Architects, LLC

Section 16710 - Page 10 TELECOMMUNICATION DISTRIBUTION

C.

Install termination backboards and racks plumb, and attach securely to building wall at each corner.

D. Provide color coding of all systems equipment in compliance with the Standards outlined in ANSI/EIA/TIA 606. E. Install polyethylene pulling string in each empty conduit over 10 feet in length or containing a bend. Provide engraved plastic nameplates under the provisions of Section 16075. identify all backboards and cabinets.

F.

G. Ground and bond pathways, cable shields, cable tray and equipment under all the provisions of Section 16060. H. Provide patch cord connections between all termination hardware to provide a complete and functional system. I. All cables shall be routed in such a way as to minimize EMI and RFI interference. Cables shall be routed to maintain the following minimum distances from disturbance sources as indicated below: 1. Unshielded power lines or electrical equipment in proximity to open telecommunication systems: 5 inches. 2. Unshielded power lines or electrical equipment in proximity to enclosed telecommunication systems: 2.5 inches. 3. Enclosed power lines or electrical equipment rated at 2.5kVA or greater in proximity to open telecommunication systems: 24 inches. 4. Enclosed power lines or electrical equipment rated at 2.5kVA or greater in proximity to enclosed telecommunication systems: 6 inches. 5. Distance from fluorescent or HID lighting fixtures: 6 inches All open wiring shall be plenum rated. Plenum rated cables may be run exposed in cable tray or above accessible ceiling above classrooms and offices support by suitable cable rings or fasteners. Concealed cabling, such as in walls, above hard ceilings, and through soffits shall be installed in conduit.

J.

3.2

FIELD QUALITY CONTROL A. Division 1 - Quality Controls and Contract Closeout. B. Inspect and test optical fiber cables in accordance with NETA ATS, except Section 4. Perform inspections and tests listed in NETA ATS, Section 7.25. Inspect and test copper cables and terminations in accordance with EIA/TIA 568-A-5, Category 5e.

C.

BCA Project No. 0513.03

NWABSD Project No. 542.01

T:\2004.186.1 - Noatak School - Design Development\Specifications\Electrical\16710-Telecommunication-Noatak.doc

NOATAK K-12 REPLACEMENT SCHOOL NORTHWEST ARCTIC BOROUGH SCHOOL DISTRICT

DIVISION 16 ELECTRICAL

Burkhart Croft Architects, LLC

Section 16710 - Page 11 TELECOMMUNICATION DISTRIBUTION

D. Submit test reports for approval. All equipment not meeting the requirements of these testing standards shall be brought into compliance and retested prior to final acceptance.

END OF SECTION

BCA Project No. 0513.03

NWABSD Project No. 542.01

T:\2004.186.1 - Noatak School - Design Development\Specifications\Electrical\16710-Telecommunication-Noatak.doc

NORTHWEST ARCTIC BOROUGH SCHOOL DISTRICT P.O. BOX 51 KOTZEBUE, AK 99752

January 16, 2007 ADDENDUM NO. 2 TO: SUBJECT: ALL PLAN HOLDERS REQUEST FOR PROPOSALS NOATAK K-12 REPLACEMENT SCHOOL Project No. 524.01 DUE DATE: 2:00 PM, ALASKA STANDARD TIME JANUARY 26, 2007

This Addendum forms a part of the Contract Documents and modifies the original Request for Proposal Documents dated December 19, 2006 as noted below. NOTE TO PROPOSERS: Proposers must acknowledge receipt of this Addendum on the Proposal Form. Failure to do so may subject the Proposer to disqualification. This addendum consists of: nine (9) 8-1/2x 11 pages, one (1) specification section attachment and nine (9) drawing attachments. CHANGES TO PRIOR ADDENDA: AD2-1. Addendum No. 1 Item 7: Section 00300 PROPOSAL FORM (Dated January 4, 2007): ADD the following paragraph after the DEED COST FORMAT LEVEL II table on page 5: Proposer shall submit the DEED COST FORMATL LEVEL II information, in a separately sealed and labeled envelope, to the office of Burkhart Croft Architects no later than 2:00 AST on Tuesday, January 30, 2007.

CHANGES TO PROPOSAL & CONTRACTING REQUIREMENTS: AD2-2. Section 00020 REQUEST FOR PROPOSALS: REVISE date and time noted under RECEIPT OF PROPOSALS to read . 2:00 pm AST on Friday, January 26, 2007.

ADDENDUM-2.DOC

AD2-3.

Section 00100 INSTRUCTIONS TO OFFERORS, Paragraph 1.03(A): REVISE date and time noted in first sentence for receipt of proposals to read 2:00 pm AST on Friday, January 26, 2007, . Section 00700 GENERAL CONDITIONS: REVISE subparagraph 5.2.2 to read: 5.2.2 The Contractor shall not contract with any such Subcontractor, Sub-subcontractor or any such person or entity to whom the Project Manager has made reasonable objection under the provisions of Subparagraph 5.2.1.

AD2-4.

CHANGES TO TECHNICAL SPECIFICATIONS: AD2-5. AD2-6. Division 1 GENERAL REQUIREMENTS: ADD the attached Section 01045 BUILDING PLANT OPERATOR. Section 05521 PIPE AND TUBE RAILINGS: REVISE paragraph 1.1(B) to 1.1(A)(1) and ADD the following paragraph 1.1(A)(2) to read: 2. Woven-wire mesh guardrail panels at stairs and landings. Section 10431 SIGNAGE: ADD the following paragraph: 1.1(A)(3) Plaque Sign. Section 10431 SIGNAGE: ADD the following paragraph: 2.1(A)(3) Manufacturers of Plaque Sign: Metallic Arts, Inc., or equal. Section 10431 SIGNAGE: ADD the following paragraph: 2.7 PLAQUE SIGN A. Type: Cast plaque B. Size: 18 x 30 C. Text: To be determined. Generally with 35 character headline and 12 lines of copy with a total of 225 characters, all in Helvetica style. D. Material and Finish: Cast bronze (pebble texture), background oxidized to a dark statuary color, letters and borders sanded to a satin texture and entire panel finished with two coats of clear lacquer. E. Border Style: Raised Edge F. Mounting Method: PMM-3, toggle bolts with rosettes. AD2-10. Section 15130 PUMPS: ADD the following paragraph: 2.5 SEWAGE EJECTOR PUMPS A. Manufacturers: 1. ITT Flygt. 2. Zoeller. 3. Hydromatic. 4. Substitutions: See Section 01630 Substitution and Product Options.

ADDENDUM-2.DOC

AD2-7. AD2-8. AD2-9.

B. Pumps: Duplex grinder type, heavy duty submersible, cast iron construction, hardened stainless steel stationary and rotary cutters, permanently lubricated upper and lower single-row ball bearings, stainless steel pump and motor shaft. Mechanical seals shall consist of two independent assemblies with tungsten carbide lower primary seal and ceramic upper seal. Pump shall be explosion-proof FM approved. C. Accessories: Guide rails and lifting chain, submersible power cable, check valve, shut-off valve. D. Sump: Fiberglass basin; size as indicated on drawings; 3 side and bottom foam insulation with protective cover; vapor-proof cover with lifting handles and openings for vent, pump discharge, inlet(s), pump access covers, power feed and controls. E. Controller: Intrinsically safe, UL listed, NEMA 3R enclosure for interior Installation, control circuits, pump motor starters and disconnects as required for automatic pump control and operation, H-O-A control switch, pump run pilot lights, high water alarm pilot light, alarm horn, alternator to switch lead pump on each pump cycle, conductance-actuated liquid level probe with multiple sensor points for pump on/off (each pump), high level alarm, contacts for connection to DDC system. AD2-11. Section 15920 BUILDING SYSTEMS CONTROLS, Paragraph 2.7(B): ADD Item 1(K) to read: k. Black and white laser printer. AD2-12. Specification Section 16850 TELEVISION DISTRIBUTION EQUIPMENT: DELETE this Section in its entirety. AD2-13. Specification Section 16421 ENCLOSED CONTROLER: DELETE paragraph 2.3 Magnetic Motor Controllers Two Speed and ADD the following paragraph in its place: AD2-14. 2.3 A. Reduced Voltage Motor Controllers (Soft Start) Manufacturers: These specifications are based on Square D Altistart 48 to set a standard for design and quality. Alternative systems manufactured by GE and Eaton Cutler-Hammer will be considered providing that sufficient documentation is provided to indicate that the equipment meets the requirements of the specification. Note, however, that starters, disconnect switches, pushbutton stations, and pilot control devices of one manufacturer are to be provided throughout this section: 1. Substitutions: Division 1 - Substitutions. Description: Solid state digital controller with combination disconnect and soft start controller for reduced voltage starting. Required for all motors 5 hp and above unless they are to be controlled by a VFD. Control Voltage voltage: 120volts, 60 Hz.

B.

C.

ADDENDUM-2.DOC

D. E. F.

Poles: as required for load served. Wiring: Straight-through wiring with all terminals clearly marked. Overload Relay: NEMA ICS. 1. Solid State: Trip current rating will be established by selection of overload relay and shall be adjustable (3 to 1 current range). The overload shall be self-powered, provide phase loss and phase unbalance protection, have a permanent tamper guard, and be ambient insensitive. It will also be available in Trip Class 10 or 20 and have a mechanical test function. 2. Outputs: Unit will be designed for addition of either a normally open or normally closed auxiliary contact and be field convertible. 3. Reset: Unit shall offer both manual reset and remote reset using an external module. Enclosure: ANSI/NEMA ICS 6, as required to meet conditions. Interior Dry Locations: Type 1, Exterior Locations: Type 3R. Product Features: 1. Auxiliary Contacts: NEMA ICS 2, 2 each field convertible contacts in addition to seal-in contact. 2. Cover Mounted Pilot Devices: NEMA ICS 5, standard duty type. 3. Pilot Device Contacts: NEMA ICS 5, Form Z, rated A150. 4. Pushbuttons: Recessed or Shrouded type. 5. Indicating Lights: LED type. 6. Selector Switches: Hand-Off-Auto Rotary type. 7. Relays: NEMA ICS 2, 8. Control Power Transformers: 120 volt secondary, 50 VA minimum, in each motor starter. Provide fused primary and secondary, and bond unfused leg of secondary to enclosure. 9. Microprocessor based motor thermal protection system. 10. Digital indication of soft start status, motor status, fault status. 11. Digital keypad to configure operating and control parameters. 12. Full Voltage Bypass. Combination Controllers: Combine motor controllers with disconnect in common enclosure, using motor circuit protector or thermal magnetic circuit breaker conforming to NEMA AB 1.

G. H.

I.

ADDENDUM-2.DOC

CHANGES TO DRAWINGS: AD2-15. Sheet C1.2 Site Plan: REVISE note at Shop to read: Relocate existing skid-mounted shop building from existing school to this location. Confirm electrical service connection requirements and provide new electrical service to relocated shop. Sheet F2.1 Details 1and 2: DELETE Details 1 and 2 in their entirety. Sheet F2.1 Notes: DELETE Notes 1 through 8 in their entirety. Sheet F2.1 Detail 3: REPLACE Detail 3 with detail shown on attached Sheet SKC1. Sheet M0.1 Tank Schedule: ADD the following note: The storage capacity of the fire water storage tank FWT-1 indicated on the drawings is for reference only. Final capacity of the tank shall be determined by the Contractors fire protection system engineer as indicated on the tank schedule on this sheet and Specification Section 13910. Sheet A2.2 Fan Room 201: ADD requirement for a for a new IT room to be located in the upper level fan room (exact location to be determined at a later date). Sheet A2.4 Gym 140: ADD requirement for separate gym floor color in main basketball key areas, and mascot logo inlay at center court circle. Details and colors shall be confirmed in final Construction Documents. Sheet A2.4 Principal 148: ADD a floor mounted safe, 1.26 cu. ft. (14-inch H x 12-inch W x 13-inch D) - Gardall Model 1311 or equal, with location to be confirmed in final Construction Documents. Sheet A3.19 Detail 1: REVISE the Front Canopy Assembly to read: Single ply membrane roofing Cover Board Rigid insulation to provide min. slope for drainage plywood Wood joists, see Struc. 5/8 plywood Metal soffit panel, MSP-1 Sheet A5.1 Door Schedule: ADD Note 3 to read: Provide rough-in, wiring, and door hardware required for a complete magnetic card, keyless entry system, at the following locations: Doors 101B, 103, 125A, 126B, 131A, 131B, 138C, 140B, 146, 148, 168A and 180B. Sheet A5.1 Door Schedule, Door 168A: ADD a 1 to the ALT # column.

AD2-16. AD2-17. AD2-18. AD2-19.

AD2-20. AD2-21.

AD2-22.

AD2-23.

AD2-24.

AD2-25.

ADDENDUM-2.DOC

AD2-26.

Sheet A5.3 Finish Schedule: REVISE Finish Schedule as follows: a. Vestibule 101: ADD Remark #6 b. Vestibule 125: ADD Remark #6 c. Vestibule 168: ADD Remark #6 d. Science 113: REVISE Floor to VT-1 e. Prep 114: REVISE Floor to VT-1

AD2-27.

Sheet A5.4 Finish Materials & Color Schedule: REVISE Finish Material and Color Schedule as follows: a. AF-3 Flooring: REVISE to Mondo Highjolt 24x24x5/16 Interlocking tiles (L25 Plum), or equal. b. ST-1 Stainless Steel: DELETE reference to Fry Reglet c. VT-1 Flooring: REVISE to Armstrong Stand Excelon Imperial Texture (color to be selected) d. WO-1 Flooring: REVISE to Lees FirstStep Modular (color to be selected), 24 x 24. e. ADD Remark 6, as follows: At Vestibule 101, extend WO-1 into Commons 102 for a length of 9-0 and full width from wall to wall. At Vestibule 125, extend WO-1 into Corridor 107 for a length of 12-0 (aligned with the east wall of the display case), and full width from wall to wall. At Vestibule 168, extend WO-1 into Corridor 167 for a length of 8-0 (align with locker end wall) and full width from wall to wall.

AD2-28. AD2-29. AD2-30.

Sheet A8.3 Detail 2: REVISE note at guardrail mesh to read: Galvanized woven-wire mesh. Sheet M0.1 Lift Station Schedule: REVISE as indicated on attached Sheet SKM1. Sheet M0.2 Computer Room Air Conditioner Schedule: ADD a second unit, CRU-2, same size and capacity as CRU-1. The location of the second unit will be determined at a later date. Sheet M0.2 Sound Attenuator Schedule: DELETE Sound attenuator SA-2. Sheet M0.2 Pump Schedule: REVISE as indicated on attached Sheet SKM1 adding requirement for soft start motors for pumps CP-2, 3, 4 and adding pumps CP-7 & 8. Sheets M1.1, M1.2, M1.3: REVISE underfloor heating system as indicated on attached Sheets SKM2 - SKM5. System revised to have six heating loops. There shall be a total of 405 feet of type BB-5 bare fintube element on the six loops, spaced at approximately equidistant intervals along the six loops in 135 three-foot sections. See sketches for the number of sections on each loop.

AD2-31. AD2-32. AD2-33.

ADDENDUM-2.DOC

AD2-34.

Sheet M2.1, M2.2, M2.3: ADD sheet note to read: Provide expansion compensation for hydronic piping system using pre-manufactured flexible expansion loops as required. Refer to design narrative and Specification Section 15120. Sheet M3.1: ADD return air ductwork at high school wing classrooms as indicated on attached Sheet SKM6. Sheet M3.2: EXTEND return air ductwork above Administration area ceiling into ceiling plenum space of Corridor 167 in elementary school wing, ADD return air grilles in Administration area, and ADD transfer air boot at Library 180, Admin 147 and Conference 153 as indicated on attached Sheet SKM7. Sheet M4.1 Mechanical Building Plan: REVISE boiler room plan as indicated on attached Sheet SKM8 to show pumps CP-7 & 8 and associated piping serving the hot water generators and mechanical building hydronic unit heaters. Sheet M4.1 Detail 2: REVISE all HWS and HWR references on boiler piping diagram to HGS and HGR. Also CHANGE X-inch HGS to 4-inch HGS (two places) on discharge piping of pumps CP-2, 3, 4. Sheet M4.2 Fan Room Plan: DELETE sound attenuators SA-2 (two places) in return air ductwork serving Air handling unit AHU-3. All return air ductwork to be lined with 1-inch thick sound attenuation insulation as per specifications. See attached Sheets SKM6 and SKM7 for return air ductwork revisions. Sheet M5.1 Detail 4: REPLACE Fuel Oil Tank detail with that shown on attached Sheet SKM-9. Sheet M5.1 Details: ADD a strainer on the inlet side of control valves at all terminal heating equipment such as baseboard radiation, unit heaters, cabinet unit heaters, radiant ceiling panels, and duct coils. Sheet E0.2 Detail 1: DELETE fixture type T (and light pole) shown near the new mechanical building. DELETE one type S fixture (pole and twin floodlights) at the playground and relocate remaining type S fixture and pole to be centered at the playground. Sheets E2.4 Detail 2: ADD lighting and switching controls, as required for a new IT room to be located in the upper level fan room (exact location to be determined at a later date). Sheets E3.1, E3.2, and E3.3: REVISE motor size (in hp) of Sewage Lift Station Pumps and all required connections, breakers, etc for LS-1, LS-2, and LS-3 at 2 hp instead of 1 hp and LS-4 at 3 hp instead of 7.5 hp as indicated by Mechanical SKM1.

7

AD2-35. AD2-36.

AD2-37.

AD2-38.

AD2-39.

AD2-40. AD2-41.

AD2-42.

AD2-43.

AD2-44.

ADDENDUM-2.DOC

AD2-45.

Sheet E3.4 Detail 1: ADD required motor starters, connections, breakers, etc for the newly added CP-7 (3/4hp, 208v, 3 phase) and CP-8 (3/4hp, 208v, 3 phase) as indicated by Mechanical SKM8. Sheet E3.4 Detail 2: RELOCATE VFD from EF-8 to AHU-2. Sheet E3.4 Detail 2: ADD required motor starters, connections, breakers, etc. for CRU-2 (same size as CRU-1), as required for a new IT room to be located in the upper level fan room (exact location to be determined at a later date). Sheet E3.4 Sheet Notes: ADD note 7 to read: All motors 5 hp or greater are to be provided with either electronic soft start motor controller or vfd motor controller. Sheets E4.1, E4.2, E4.3, and E4.4: DELETE all television systems (outlets, jacks, coax. cables, headend equipment, etc.). Sheet E4.4 Detail 2: ADD a Fire Alarm horn/strobe, as required for a new IT room to be located in the upper level fan room (exact location to be determined at a later date). Sheet E5.4 Detail 2: RELOCATE the telecommunication equipment (racks, backboard, etc.) to a new IT room to be located in the upper level fan room (exact location to be determined at a later date). EXTEND cable tray to new IT room. Sheet E5.5 Detail 1 & Specification Section 16710: ADD the following equipment to allow for video distribution through the telecommunication system. The bid for this equipment and installation is to be included in the Universal Services Contract (E-rate) and separate from the price of the rest of the Noatak K-12 School Project. All equipment is to be manufactured by VBrick Systems or equal (equal shall qualify for E-rate reimbursement). Quantity 3 - VBrick #9110-4300-003, MPEG-2 Dual Channel Encoder 10/100BT Ethernet with cable kit and remote control. Quantity 1 VBrick #8000-0049-0004, Ethernetv Portal Server Hardware and Software. Quantity 1 VBrick #8000-0078-0001, Network Video Recorder. Quantity 1 VBrick #8000-0075-0001, VOD Window 300 mbps Video-On-Demand Server with Windows OS. Quantity 6 VBrick #8000-0044-0003, IP Receiver for MPEG 1/2/4. Quantity 2 VBrick #9110-6200-0003, MPEG-2 Encoder/Decoder 10/100BT Ethernet with cable kit and remote control.

AD2-46. AD2-47.

AD2-48. AD2-49. AD2-50. AD2-51.

AD2-52.

AD2-53.

Sheet E5.5 Detail 3: Sheet E5.5 Detail 3: REVISE detail to reflect the design intent for all surface raceway (exterior and interior walls) in finished areas to be run horizontally

8

ADDENDUM-2.DOC

only. The horizontal raceway shown along exterior walls in electrical drawings shall extend to an adjacent interior wall, where elbows, wall box connectors (Wiremold #V4014A or equal), and recessed junction boxes will need to be added as required for the power and data to be run in concealed conduits inside an interior wall.

END OF ADDENDUM NO. 2

ADDENDUM-2.DOC

NOATAK K-12 REPLACEMENT SCHOOL NORTHWEST ARCTIC BOROUGH SCHOOL DISTRICT

DIVISION1 GENERAL REQUIREMENTS

Section 01045 - Page 1 Burkhart Croft Architects, LLC BUILDING PLANT OPERATOR _____________________________________________________________________________________________

SECTION 01045 BUILDING PLANT OPERATOR PART 1 - GENERAL 1.1 SECTION INCLUDES A. This Section includes clarification of the Owners desire for the NWABSDs Building Plant Operator (BPO) to be familiar with new building systems, and the Owners willingness to extend a leave of absence to the BPO during construction of the project. 1.2 RELATED SECTIONS A. Related Sections include the following: 1. Section 01650 Starting of Systems, for start-up and training as required of the BPO for on-going operations and maintenance. 2. Section 01700 Project Closeout, for coordinating closeout of the Contract. 3. Section 01730 Operating and Maintenance Data, for operations and maintenance information required of the BPO for on-going operations and maintenance. 1.3 RELATED DOCUMENTS A. Drawings and general provisions of the Contract, including General and Supplementary Conditions and other Division 1 Specification Sections, apply to this Section. 1.4 DESCRIPTION A. It is important to the Owner that the Noatak School Building Plant Operator (BPO), who will responsible for day-to-day maintenance and repair of the completed project, be very familiar with and knowledgeable of the building system and components, particularly with respect to mechanical and electrical systems. B. The District will grant the Noatak BPO a leave of absence to work for the contractor during the construction of the building. During the period the BPO works for the contractor he will be a contractor employee with responsibilities and benefits as such.

PART 2 - PRODUCTS (Not Used) PART 3 - EXECUTION (Not Used)

END OF SECTION 01045

BCA Project No. 0408.04

I:\0408 - Noatak K-12 School\Doc\Specifications

NWABSD Project No. 524.01

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Introduction To Anglo-Saxon LiteratureDokument20 SeitenIntroduction To Anglo-Saxon LiteratureMariel EstrellaNoch keine Bewertungen

- Shell - StakeholdersDokument4 SeitenShell - StakeholdersSalman AhmedNoch keine Bewertungen

- Jurnal SejarahDokument19 SeitenJurnal SejarahGrey DustNoch keine Bewertungen

- Web Development AgreementDokument3 SeitenWeb Development AgreementRocketLawyer100% (2)

- Architecture AsiaDokument84 SeitenArchitecture AsiaBala SutharshanNoch keine Bewertungen

- EMCEE ScriptDokument3 SeitenEMCEE ScriptSunshine Garson84% (31)

- Module Letter 1Dokument2 SeitenModule Letter 1eeroleNoch keine Bewertungen

- Ifm 8 & 9Dokument2 SeitenIfm 8 & 9Ranan AlaghaNoch keine Bewertungen

- The Approach of Nigerian Courts To InterDokument19 SeitenThe Approach of Nigerian Courts To InterMak YabuNoch keine Bewertungen

- Distribution Logistics Report 2H 2020Dokument21 SeitenDistribution Logistics Report 2H 2020IleanaNoch keine Bewertungen

- NIST SP 800-53ar5-1Dokument5 SeitenNIST SP 800-53ar5-1Guillermo Valdès100% (1)

- Correctional Case StudyDokument36 SeitenCorrectional Case StudyRaachel Anne CastroNoch keine Bewertungen

- E-Conclave Spon BrochureDokument17 SeitenE-Conclave Spon BrochureNimish KadamNoch keine Bewertungen

- Jurisdiction and Kinds of JurisdictionDokument3 SeitenJurisdiction and Kinds of JurisdictionANUKULNoch keine Bewertungen

- Philippine National Development Goals Vis-A-Vis The Theories and Concepts of Public Administration and Their Applications.Dokument2 SeitenPhilippine National Development Goals Vis-A-Vis The Theories and Concepts of Public Administration and Their Applications.Christian LeijNoch keine Bewertungen

- Juegos 360 RGHDokument20 SeitenJuegos 360 RGHAndres ParedesNoch keine Bewertungen

- Remote Lab 1013Dokument3 SeitenRemote Lab 1013cloud scapeNoch keine Bewertungen

- Metaphors of GlobalizationDokument3 SeitenMetaphors of GlobalizationShara Christile ColanggoNoch keine Bewertungen

- 5 15 19 Figaro V Our Revolution ComplaintDokument12 Seiten5 15 19 Figaro V Our Revolution ComplaintBeth BaumannNoch keine Bewertungen

- rp200 Article Mbembe Society of Enmity PDFDokument14 Seitenrp200 Article Mbembe Society of Enmity PDFIdrilNoch keine Bewertungen

- Contemporary World Reflection PaperDokument8 SeitenContemporary World Reflection PaperNyna Claire GangeNoch keine Bewertungen

- Quiet Time Guide 2009Dokument2 SeitenQuiet Time Guide 2009Andrew Mitry100% (1)

- Definition of Social PharmacyDokument7 SeitenDefinition of Social PharmacyShraddha PharmacyNoch keine Bewertungen

- 2016 GMC Individuals Round 1 ResultsDokument2 Seiten2016 GMC Individuals Round 1 Resultsjmjr30Noch keine Bewertungen

- "A Study On Services Offered by State Bank of India": Final ProjectDokument59 Seiten"A Study On Services Offered by State Bank of India": Final ProjectShabana KarimNoch keine Bewertungen

- Narendra Budiman: Professional StatementDokument1 SeiteNarendra Budiman: Professional StatementPratika SariputriNoch keine Bewertungen

- Internship Report Mca Audit Report InternshipDokument33 SeitenInternship Report Mca Audit Report InternshipJohnNoch keine Bewertungen

- Adobe Scan 03-May-2021Dokument22 SeitenAdobe Scan 03-May-2021Mohit RanaNoch keine Bewertungen

- 2015 3d Secure WhitepaperDokument7 Seiten2015 3d Secure WhitepapersafsdfNoch keine Bewertungen

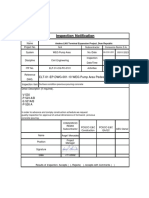

- In-CIV-201 INSPECTION NOTIFICATION Pre-Pouring Concrete WEG Pump Area PedestalsDokument5 SeitenIn-CIV-201 INSPECTION NOTIFICATION Pre-Pouring Concrete WEG Pump Area PedestalsPedro PaulinoNoch keine Bewertungen