Beruflich Dokumente

Kultur Dokumente

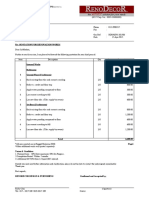

Building Materials Proposal for Damasara Bungalow

Hochgeladen von

Reeve Wong Jing JyhOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Building Materials Proposal for Damasara Bungalow

Hochgeladen von

Reeve Wong Jing JyhCopyright:

Verfügbare Formate

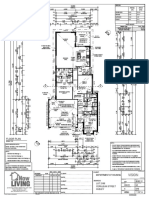

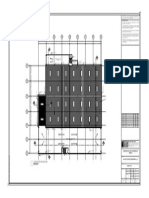

Proposal of Building Materials/ Products

For DoubleStorey Bungalow In Damasara Height

AQS1 (F5)

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

List of Figures

Figure 1 Marble Flooring ........................................................................................................... 1 Figure 2 Marble Flooring ........................................................................................................... 1 Figure 3 Royal White Marble Polished Flooring Living Room ................................................... 3 Figure 4 Royal White Marble Polished Flooring Dining Room .................................................. 4 Figure 5 Royal White Marble Polished Flooring Dry Kitchen .................................................... 4 Figure 6 Unglazed Porcelain Tiles Flooring Bathroom............................................................... 5 Figure 7 Unglazed Porcelain Tiles Flooring Bathroom............................................................... 6 Figure 8 Unglazed Porcelain Tiles Flooring Bathroom............................................................... 7 Figure 10 Antlia Unglazed Porcelain Tiles Flooring Bathroom .................................................. 8 Figure 9 Antlia Unglazed Porcelain Tiles Flooring Wet Kitchen................................................. 8 Figure 11 Engineer Timber Flooring .......................................................................................... 9 Figure 12 Engineered Timber Flooring .................................................................................... 10 Figure 13 Armstrong Engineered Timber Flooring .................................................................. 11 Figure 14 Armstrong Engineered Timber Flooring .................................................................. 11 Figure 15 Ceramic Pattern Tiles Flooring ................................................................................ 12 Figure 16 Ceramic Tiles Flooring ............................................................................................. 12 Figure 17 Ceramic Tiles Flooring Bathroom ............................................................................ 13 Figure 18 Johnson Ceramic Tiles Flooring ............................................................................... 15 Figure 19 Ceramic Wall Tiling .................................................................................................. 16 Figure 20 Ceramic Wall Tiling .................................................................................................. 16 Figure 21 Glazed Ceramic Wall Tiling Type Prismatics (Bath 1, 2 &3) ..................................... 19 Figure 22 Glazed Ceramic Wall Tiling Type Neutral (Master Bath) ......................................... 19 Figure 23 Glazed Ceramic Wall Tiling Type Vivid (Wet Kitchen) ............................................. 20 Figure 24 Glazed Ceramic Wall Tiling Type Vivid (Dry Kitchen) .............................................. 20 Figure 25 Painting Wall Finishes .............................................................................................. 21 Figure 26 Painting Wall Finishes .............................................................................................. 21 Figure 27 Nippon White Colour Painting Wall Finishes........................................................... 23 Figure 28 Nippon Momento Sparkle Silver Painting Wall Finishes ......................................... 23 Figure 29 Modern Gypsum Board Ceiling ............................................................................... 24 Figure 30 Modern Gypsum Board Ceiling ............................................................................... 26 Figure 31 Washable Ceiling Tiles ............................................................................................. 29

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

List of Tables

Table 1 Advantages and Disadvantages of Marble Flooring ..................................................... 2 Table 2 Area Proposed for Marble Flooring .............................................................................. 4 Table 3 Advantages and Disadvantages of Unglazed Porcelain Tiles Flooring .......................... 6 Table 4 Area Proposed for Unglazed Porcelain Tiles Flooring................................................... 8 Table 5 Advantages and Disadvantages of Engineered Timber Flooring ................................ 10 Table 6 Area Proposed for Engineered Timber Flooring ......................................................... 11 Table 7 Advantages and Disadvantages of Ceramic Tiles Flooring ......................................... 13 Table 8 Area Proposed for Ceramic Tiles Flooring .................................................................. 15 Table 9 Area Proposed for Ceramic Wall Tiling ....................................................................... 19 Table 10 Area Proposed for Ceramic Wall Tiling ..................................................................... 20 Table 11 Area Proposed for Painting Wall .............................................................................. 23 Table 12 Area Proposed For Gypsum Ceiling Board ................................................................ 27 Table 13 Area Proposed for Ceiling Tiles ................................................................................. 29 Table 14 Internal Floor Finishes (Ground Floor)...................................................................... 30 Table 15 Internal Floor Finishes (First Floor) ........................................................................... 31 Table 16 Internal Wall Finishes (Ground Floor)....................................................................... 32 Table 17 Internal Wall Finishes (First Floor) ............................................................................ 33 Table 18 Internal Ceiling Finishes (Ground Floor) ................................................................... 34 Table 19 Internal Ceiling Finishes (First Floor) ........................................................................ 35

ii

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

Contents

1 Introduction of Materials/ Products.................................................................................. 1 1.1 Internal Floor Finishes ............................................................................................... 1 Marble Flooring ................................................................................................. 1 Introduction ................................................................................................... 1 Advantages and Disadvantages of Marble Flooring ...................................... 2 Installation of Marble Flooring ...................................................................... 3 Area Proposed for Marble Flooring ............................................................... 4 Porcelain Tiles Flooring Introduction ................................................................ 5 Introduction ................................................................................................... 5 Advantages and Disadvantages of Unglazed Porcelain Tiles Flooring .......... 6 General Installation Guidelines of Unglazed Porcelain Tiles Flooring ........... 7 Area Proposed for Unglazed Porcelain Tiles Flooring ................................... 8 Engineered Timber Flooring .............................................................................. 9 Introduction ................................................................................................... 9 Advantages and Disadvantages of Engineered Timber Flooring ................. 10 Area Proposed for Engineered Timber Flooring .......................................... 11 Ceramic Tiles Flooring ..................................................................................... 12 Introduction ................................................................................................. 12 Advantages and Disadvantages of Ceramic Tiles Flooring .......................... 13 Installation of Ceramic Tiles Flooring .......................................................... 14

1.1.1 1.1.1.1 1.1.1.2 1.1.1.3 1.1.1.4 1.1.2 1.1.2.1 1.1.2.2 1.1.2.3 1.1.2.4 1.1.3 1.1.3.1 1.1.3.2 1.1.3.3 1.1.4 1.1.4.1 1.1.4.2 1.1.4.3 1.2

Internal Wall Finishes .............................................................................................. 16 Ceramic Wall Tiling .......................................................................................... 16 Introduction ................................................................................................. 16 Advantages and Disadvantages of Ceramic Wall Tiling ............................... 17 Installation of Ceramic Wall Tiling ............................................................... 18 Area Proposed for Glazed Ceramic Wall Tiling ............................................ 19 Area Proposed for Glazed Ceramic Wall Tiling ............................................ 20 Painting Wall Finishes ...................................................................................... 21 Introduction and Advantages of Painting Wall Finishes.............................. 21 Painting Steps .............................................................................................. 22 Area Proposed for Painting Wall Finishes ................................................... 23

1.2.1 1.2.1.1 1.2.1.2 1.2.1.3 1.2.1.4 1.2.1.5 1.2.2 1.2.2.1 1.2.2.2 1.2.2.3 1.3

Internal Ceiling Finishes........................................................................................... 24 Gypsum Board Ceiling with Painting ............................................................... 24

1.3.1

iii

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS 1.3.1.1 1.3.1.2 1.3.1.3 1.3.1.4 1.3.2 1.3.2.1 1.3.2.2 1.3.2.3 2

February 22, 2012

Introduction ................................................................................................. 24 Advantages of Gypsum Board Ceiling ......................................................... 25 Installation of Gypsum Board Ceiling .......................................................... 26 Area Proposed for Gypsum Ceiling Board ................................................... 27 Ceiling Tiles ...................................................................................................... 28 Introduction ................................................................................................. 28 Advantages of Ceiling tiles........................................................................... 28 Area Proposed for Ceiling Tiles.................................................................... 29

Proposed Building Material/Products ............................................................................. 30 2.1 2.2 2.3 2.4 2.5 2.6 Internal Floor Finishes (Ground Floor) .................................................................... 30 Internal Floor Finishes (First Floor).......................................................................... 31 Internal Wall Finishes (Ground Floor) ..................................................................... 32 Internal Wall Finishes (First Floor)........................................................................... 33 Internal Ceiling Finishes (Ground Floor) .................................................................. 34 Internal Ceiling Finishes (First Floor) ....................................................................... 35

iv

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1 Introduction of Materials/ Products

1.1 Internal Floor Finishes

1.1.1 Marble Flooring 1.1.1.1 Introduction

Figure 1 Marble Flooring

Marble is a rock resulting from metamorphism of sedimentary carbonate rocks, most commonly lime stone or dolomite rock. Metamorphism causes variable recrystallization of the original carbonate mineral grains. The minerals that result from impurities give marble wide variety of colours. The purest calcite marble is white. Marble containing hematite has a reddish colour. Marble that has limonite is yellow, and marble with serpentine is green. Throughout the years, marble flooring has been regarded as a symbol of prosperity. Ancient architectures used marble flooring to signify wealth and power of a place. A very good example of the splendor of marble flooring is the Taj Mahal, which is considered as one of the ancient wonders of the world. At present, marble flooring is very much still the symbol of wealth and power.

Figure 2 Marble Flooring

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.1.1.2 Advantages and Disadvantages of Marble Flooring Advantages

Disadvantages

Marble is an all natural substance - Marble is a natural stone product. Marble is highly resilient to water and moisture - Marble is a great As such, it is completely biodegradable, making it a favorite among choice for bathrooms and kitchens because of its water and moisture environmentally conscious homeowners. Marble is also bacteria, resistant properties. allergen and moisture resistant when properly sealed.

Marble is durable and long-lasting - Marble is very hard, durable and long lasting. Its also more porous than granite, so its critical to seal any areas that will be exposed to moisture. With proper maintenance, a beautiful marble floor can last a lifetime.

Marble may not fit all budgets - Marble flooring can give your home an aura of richness. It definitely has a natural beauty that quite surpasses most other flooring materials. For this reason, marble is quite expensive.

Marble is a gorgeous addition for home interiors - Marble flooring comes in a great selection of colors, styles and patterns to perfectly Marble should be installed by professionals. Marble requires regular complement and home dcor. Its also highly versatile for a wide cleaning and sealing. variety of applications.

Table 1 Advantages and Disadvantages of Marble Flooring

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.1.1.3 Installation of Marble Flooring

Preparation of sub base: Base coat consisting of cement concrete 1:8:16, 1:5:10 or 1:4:8 should be laid on compacted earth under marble stone flooring. Laying out of marble stone slabs The base concrete or RCC slab on which marble stone slabs are laid should be thoroughly cleaned. The average thickness of bedding mortar under marble stone slab should be 20 mm thick and the ratio of cement mortar should be 1:3 The sand used in mortar should be coarse sand. The thickness of bedding should not be less than 12 mm in any place.

Figure 3 Royal White Marble Polished Flooring Living Room

The top surface of mortar (bedding) should be leveled correctly by adding fresh mortar at hollows if any. The mortar is allowed to harden and cement slurry shall be spread at the rate of 4.4 kg per sq. meter. Marble stone slab to be paved should then be lowered gently back in position and tapped with wooden mallet till it is properly bedded and leveled with adjoining slab. Care should be taken to match the grains of slabs. All stone slabs should be laid in same manner. After lying of each slab surplus cement on the surface of slabs should be cleaned.

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.1.1.4 Area Proposed for Marble Flooring Location Living Room Hallway 1 & 2 Dining Room Dry Kitchen Price(SQFT) RM30 RM30 RM30 RM30 Colour White White White White Size(MM) 450x900x20 450x900x20 450x900x20 450x900x20 Brand Stone Tile Depot Stone Tile Depot Stone Tile Depot Stone Tile Depot Type Royal White Polished Royal White Polished Royal White Polished Royal White Polished

Table 2 Area Proposed for Marble Flooring

Figure 5 Royal White Marble Polished Flooring Dry Kitchen

Figure 4 Royal White Marble Polished Flooring Dining Room

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.1.2 Porcelain Tiles Flooring Introduction 1.1.2.1 Introduction

Porcelain is made similarly to other ceramic, although it is fired at much higher temperature. Porcelain tiles for the floor are made by combining natural products such as crushed China stone and kaolinite with chemicals that give the porcelain strength. Porcelain tiles are fully vitrified, glazed or unglazed and can be made using a white or colored ceramic body composed of a mix of clay and feldspars. They are shaped by pressing a powdered body and the fired product has water absorption less than 0.5% (ISO 10545-3). Unglazed porcelain tiles is the popularity of this type of tile grew rapidly following technology evolution in single firing. Water absorption is 0.1% or less (in order to minimize open porosity after polishing). Glazed porcelain tiles which a key practical implication is that low porosity of porcelain tiles makes them frost resistant. In addition, the higher quality body composition and resultant surface enables the use of a minimum amount of glaze (enough to close surface pores). The high quality surfaces enable a large number of spray and printed color effects (obvious enhancement of aesthetic value). Water absorption is usually less than 0.5%.

Figure 6 Unglazed Porcelain Tiles Flooring Bathroom

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.1.2.2 Advantages and Disadvantages of Unglazed Porcelain Tiles Flooring Advantages Durability - Porcelain tile is the hardest flooring material available, meaning it can withstand even the heaviest foot traffic. Because its 30% stronger than granite, porcelain is perfect for both residential and commercial use. It also offers superior stain resistance. Low Maintenance - Porcelain tiles are easy to maintain. Simply

sweep the floor thoroughly and clean with a damp mop and mild household detergent.

Disadvantages Difficulties to install and handling - Many porcelain tiles are very heavy and cumbersome. Need experts of professionals to install.

Sustainability - Porcelain tiles are smooth and non-porous. Because of its hardness and its resistance to moisture, porcelain is most often used in bathrooms and kitchens. Porcelain tiles are non-porous; theyre water, allergen and bacteria resistant.

Table 3 Advantages and Disadvantages of Unglazed Porcelain Tiles Flooring

Figure 7 Unglazed Porcelain Tiles Flooring Bathroom

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.1.2.3 General Installation Guidelines of Unglazed Porcelain Tiles Flooring

1. Divide the area to be tiled into four even sections, using a level and pencil to make two lines that intersect in the middle of the area. Use your square to ensure that the lines are exactly perpendicular to each other, at 90 degrees. 2. Install your tiles with thinset mortar, spreading it with a mortar trowel over the intersection of the two lines and setting the first four tiles at the intersection. Space them 1/8-inch from each other, using tile spacers. Cut the tiles to fit at the outside edges of the area with your tile cutter. Let the tiles set overnight. 3. Brush penetrating tile sealant over the whole surface of the tiled area. Cover the face (top surface) of each tile completely, but don't let the sealant get into the spaces between the tiles. Let the sealant dry for an hour, and then apply a second coat. Let it dry

Figure 8 Unglazed Porcelain Tiles Flooring Bathroom

overnight. 4. Apply grout to the tiles with your grout float, squeezing it into the spaces and off the tile surface. Wait ten minutes, and then wipe down the tile face with a damp sponge, removing the excess grout. 5. Let the grout set for three to four days. Apply another two coats of tile sealant over the whole tiled area, including the grout. Let the sealant dry for a day before using the area.

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.1.2.4 Area Proposed for Unglazed Porcelain Tiles Flooring Location Wet Kitchen Maids Bath Powder Room/ Toilet Guests Bath Master Bath Bath 1 Bath 2 Bath 3 Price(SQFT) RM16 RM16 RM16 RM16 RM16 RM16 RM16 RM16 Colour Wheat Graphite Graphite Graphite Graphite Graphite Graphite Graphite Size(MM) 600x300x11 600x300x11 600x300x11 600x300x11 600x300x11 600x300x11 600x300x11 600x300x11 Brand Johnson Johnson Johnson Johnson Johnson Johnson Johnson Johnson Type Antlia Antlia Antlia Antlia Antlia Antlia Antlia Antlia

Table 4 Area Proposed for Unglazed Porcelain Tiles Flooring

Figure 9 Antlia Unglazed Porcelain Tiles Flooring Bathroom

Figure 10 Antlia Unglazed Porcelain Tiles Flooring Wet Kitchen

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.1.3 Engineered Timber Flooring 1.1.3.1 Introduction Engineered hardwood flooring offers all the beauty of a real hardwood floor, but adds greater stability due to its many layers. Because theyre more resistant to higher humidity levels, engineered hardwood floors can be installed in more places than traditional hardwood floors, like summer homes and basements. Plus, todays engineered hardwood flooring options are tremendous and available in a wide variety of domestic and hardwood species. Engineered hardwood flooring is a product made up of a core of hardwood or plywood and a top layer of hardwood veneer. The product thus has the natural characteristics of the selected wood species, as opposed to a photographic layer. The main difference between this type of wood and laminate flooring is that laminate flooring contains no actual wood. Engineered flooring is produced by adhering layers of plastic laminate veneer with real wood. The end result is a stunning array of options that are gorgeous, durable and eco-friendly because they require fewer trees to

Figure 11 Engineer Timber Flooring

produce.

Under adverse conditions, solid hardwood floors can warp, cup, swell or split apart. Engineered hardwood flooring overcomes these problems by constructing a multiple-ply plank that counteracts twisting and remains flat and intact. This makes engineered hardwood flooring a better choice for installation over radiant heat sources, over concrete, and in rainy climates. In addition to the top hardwood veneer, engineered wood flooring typically has three or more core layers. Of course, there is greater stability with more layers. The core layers may be plywood, high-density fiberboard, or hardwood. Some engineered flooring has five to seven hardwood core layers. Engineered hardwood floors range in widths from 3-7 inches wide and come in a wide variety of domestic and exotic hardwood species. Some brands of engineered flooring have a thin wear layer that can only be re-coated and cannot be sanded and refinished new again once they get worn. They have an average lifespan of between 30 40 years depending on traffic. Other brands or styles can have a thicker 2 4 mil thick wear layer that can be completely sanded and refinished 2- 5 times. The thicker wear layer engineered floors can last from 40 100 years before having to be replaced, which add to their appeal.

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.1.3.2 Advantages and Disadvantages of Engineered Timber Flooring Advantages Durability - Solid hardwood is among the longest lasting of all flooring types. With todays flooring finishes, these floors are also water resistant. Disadvantages Limited Below Grade Installation - Solid hardwood not recommended for below grade installation due to sensitive to humidity. These floors perform better in humidity controlled environments. ( Below Grade - Pertaining to the location of a finished floor that is in direct contact with the ground or with less than 18 inches of well-ventilated space.) Transitions To Other Floors - A new hardwood floor may be a different height than the floor it adjoins. Thinner profile wood and transition strips will help to equalize the difference.

Appearance - Solid hard wood floors give an elegant aesthetic and high end look. It improves with age because it acquires a desirable patina over time. It also offers warmth, natural look, beauty and value of wood and never goes out of style. Allergy Prevention - Carpets are known May Scratch - A hardwood floors finish is as breeding grounds for mold, mildew, susceptible to scratching from traffic or dust mites, and also hold animal pet nails. dander. These are all undesirable elements for people with allergies and respiratory problems. Hardwood floors do not retain any of these. Suitable For Radiant Heated - Solid Hardwood Floors are suitable for installing over a radiant heated concrete slab. However the slab surface must never exceed 85 F in temperature. Before installing over a radiant heated floor, turn off heat and wait until the floor has reached room Figure 12 Engineered Timber Flooring temperature. After installing the floor return the heat to the previous setting.

Table 5 Advantages and Disadvantages of Engineered Timber Flooring

10

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.1.3.3 Area Proposed for Engineered Timber Flooring Location Guest Room Master Bedroom Bedroom 2 Bedroom 3 Bedroom 4 Family Area Price(SQFT) RM60 RM60 RM60 RM60 RM60 RM60 Colour Peppercorn Peppercorn Peppercorn Peppercorn Peppercorn Peppercorn Size(MM) 900x130x11 900x130x11 900x130x11 900x130x11 900x130x11 900x130x11 Brand Armstrong Armstrong Armstrong Armstrong Armstrong Armstrong Type Hardwood Maple Hardwood Maple Hardwood Maple Hardwood Maple Hardwood Maple Hardwood Maple

Table 6 Area Proposed for Engineered Timber Flooring

Figure 14 Armstrong Engineered Timber Flooring Figure 13 Armstrong Engineered Timber Flooring

11

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.1.4 Ceramic Tiles Flooring 1.1.4.1 Introduction Products that beautify your home, enhance design and dcor, meet your specific comfort, performance and budget needs, are easy to care for, and stand the test of time. Ceramic tile has been around for centuries, and with today's technology manufacturers have created new design and application possibilities that were not available a decade ago. If you have never lived with ceramic tile before or if it has been a long time since you have done so, you will be amazed at the wide selection of colors, sizes, shapes and new textures that are now available. Because of its durability and its resistance to moisture, ceramic flooring is most often used in bathrooms and kitchens. However, it is extremely versatile and can be used in almost any room in the home. A ceramic tile is natural product made up of clay, mineral and water. It has a ceramic coating on the tile body, giving it color and finish so it will be natural choice for your interior floors and walls

Figure 15 Ceramic Pattern Tiles Flooring

Figure 16 Ceramic Tiles Flooring

12

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.1.4.2 Advantages and Disadvantages of Ceramic Tiles Flooring Advantages Durability - Ceramic tile is great for high traffic situations, thanks to its strength and resiliency to staining and wear. While not extremely impact resistant, the wear ability of tile is the reason for its durability. Easy Maintenance - Ceramic tiles are virtually maintenance free and very easy to clean. Simply sweep the floor thoroughly with a broom and clean with a damp mop and mild household detergent. Affordability Low Price

Table 7 Advantages and Disadvantages of Ceramic Tiles Flooring

Disadvantages If not properly installed, ceramic floor tiles develop cracks in a few years ago tiles are fragile.

Ceramic tiles are hard, and therefore feel very stiff under their feet, especially if you work in the kitchen for long hours. To reduce the impact, you can get some rugs in the intervention group areas.

Figure 17 Ceramic Tiles Flooring Bathroom

13

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.1.4.3 Installation of Ceramic Tiles Flooring Step 1 Choosing thinset mortar. Selecting the proper thinset mortar for your ceramic tile installation will add strength and years of life to your new flooring. Avoid using organic mastics adhesives to install ceramic tile to floors. Use a gray thinset mortar if you plan to use a dark colored grout and use a white thinset mortar if you plan to use a light colored grout. Skim coating the Substrate with thinset mortar. Prior to installing your tile, skim a thin coating of thinset mortar onto the substrate using the flat end of your thinset trowel. This will maximize the mechanical bond between the thinset mortar bed and the floor. The tile and mortar bed should be installed while this coating is wet.

Step 2 Applying the thinset mortar to the tile instead of the floor will result in a flatter and cleaner tile floor. Foundations tend to draw moisture away from the mortar causing it to dry very quickly. Beginners will benefit from this technique as they will have more time to work at a slower pace. In addition, because this method of application offers 100% coverage, the risk of air pockets becoming trapped under the tile are significantly reduced and the grout will also have a deeper, more secure base. This technique is most effective for tiles larger than 8" x 8" in size and is highly recommended for most vitrified porcelain tile installations. Mix the thinset mortar mix with water until it has the same consistency of peanut butter. Properly mixed, it should stick easy to the tile and hold it's shape with little or no sagging. Using your trowel, place a softball size portion of thinset on the center of tile. Holding the trowel at a slight angle, push down and away from the center of tile towards each corner. Repeat this process until all corners have been evenly skimmed with thinset. Mix your thinset thoroughly, removing lumps, to the consistency of peanut butter. Properly mixed, it should stick easy to the substrate and hold it's shape with little or no sagging. Holding the trowel at a slight angle, push down and away to spread the thinset mortar. It is important that the thinset be evenly distributed with the ridges of the mortar bed all following the same direction. After the tile has been installed, you will need to use a pencil or other similar device to remove the excess thinset mortar from within the grout joints. This will help to provide a deeper base for the grout to anchor itself in, resulting in a stronger joint.

Step 3 Install your tile making sure it is properly aligned with your guide lines. Push down on tile firmly and evenly to properly seat the tile. A mallet may also be used to tap the tile into place.

14

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.1.4.4 Area Proposed For Glazed Ceramic Tiles Flooring Location Maid Room Store Room Price(SQFT) RM12 RM12 Colour Grey Grey Size(MM) 400x400x9 400x400x9 Brand Johnson Johnson Type Neutral Neutral

Table 8 Area Proposed for Ceramic Tiles Flooring

Figure 18 Johnson Ceramic Tiles Flooring

15

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.2 Internal Wall Finishes

1.2.1 Ceramic Wall Tiling 1.2.1.1 Introduction Ceramic tiles are made of porous body with a coating of white or colored Glaze. These are used extensively in the bathrooms, kitchen in modern buildings and in hospitals and analytical laboratories, toiletries attached to railway platforms. This is because of this products have properties like good resistance to weather and chemicals, having high strength, hard, glossy surface with different colors and pleasing appearance. Ceramic wall tiles in different colours, of the same size, shape and finishing to put together an interesting wall design. In the near future the chances for replacing these items by other materials look very bleak. These tiles are rather cheap, easy to clean, have more life and are available in pleasing colours. Therefore, ceramic wall tiles are highly recommended to install.

Figure 19 Ceramic Wall Tiling

Figure 20 Ceramic Wall Tiling

16

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.2.1.2 Advantages and Disadvantages of Ceramic Wall Tiling

1 Hygienic and Easy to Clean Ceramic wall tile is much easier to maintain than paint, wall paper or other tile materials. You can choose from a range of finishes such as matt, glossy or semi glossy. To keep the tiles clean, all you need to do is wipe them from time to time. Ceramic wall tiles are also highly resistant to abrasive chemicals and cleaners, which makes them easy to keep clean. 2 Moisture Resistant Because ceramic wall tile is resistant to moisture and humidity, it is ideal for damp environments such as bathrooms and kitchens. It does not swell or deform when exposed to high levels of moisture. 3 Fade Resistant Even when subjected to continuous exposure to the sun, ceramic wall tiles do not fade or lose color. The appearance of these tiles will remain the same for many long years with minimal care. 4 Long Lasting Ceramic wall tiles are very durable and long lasting. They do not crack, fade or break under pressure. 5 Odor Resistant Unlike other materials that may absorb and hold on to odors, ceramic wall tile does not absorb smells. It is ideal for use in kitchens. 6 Environmentally Friendly Ceramic wall tile is made in an environmentally friendly process. It is manufactured from natural ingredients obtained from the earth. Unlike some types of paint that emit VOCs and contribute to health problems, ceramic wall tile is totally free of fumes or toxins. It is completely safe to use in your home or office. 7 Cost Effective The purchase and installation of ceramic wall tile may cost you more money initially. However, if you consider the longevity, attractiveness and durability of ceramic wall tile, the cost is worth it. Over time, ceramic wall tile proves itself to be one of the most cost effective options available. Once you install ceramic wall tile, you do not have to worry about repainting or redoing the wallpaper every few years.

17

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.2.1.3 Installation of Ceramic Wall Tiling

Preparing the wall Ceramic tiles can be installed directly on drywall, plaster, or if they are in moist areas, onto "green" drywall or even better cement backer board. Green drywall designed for use in bathrooms. It's as easy (or as hard) to work with as ordinary drywall, but it's specially formulated to resist moisture. Its best use is in a kitchen or bathroom where the environment will get moist, but not where it will actually be exposed to water. Installing the tile Starting in the center, on one side of your reference line, apply a coat of tile setting adhesive to an area about 3' by 3' square. Take care not to cover your lines .Spread the adhesive with the smooth side of your notched trowel and then go over it with the notched side to create ridges in the adhesive. Firmly press each tile in place and give it a slight twisting motion to be sure it makes good contact with the adhesive. As you work your way along, place tile spacers on all four sides of each tile, so your grout lines will be consistent. Take your time and work on the wall in three square foot sections. At the end of a row or around fixtures, you'll probably need to cut some tiles. A rented ceramic tile cutter is the easiest way to make your straight cuts. Using this tool, score the cut line on a full tile and then snap the tile along the scribed line. Smooth the edge with 80 grit sandpaper (the edge of a cut ceramic tile is very sharp). Cutting irregular shaped tiles or around obstructions will require using "tile nippers." These are a heavy duty hand tool that you use to "nip" or bite off little pieces of a tile, one at a time, until you have cut the needed shape.

Grouting

After the tiles have all been installed and the adhesive has set up (probably overnight), it's time to grout the tiles. Depending on the width of your grout lines, you will need to choose either sanded or unsanded grout. If the spaces between the tiles are bigger than 1/8", use sanded grout. (Sanded grout actually contains sand particles that help make the grout joint stronger.) Remove all your tile spacers and mix the grout following manufacturer's directions (it should end up with a peanut butter-like consistency). If you're grouting in a bathroom or kitchen area, be sure your grout includes a waterproofing agent. Ask or read the manufacturer information to be sure you get the right grout. Using a rubber float, apply the grout at a 45-degree angle to the grout lines. Press firmly; you want to get grout all the way down to the bottom of the seams. Work in your 3' x 3' areas to be sure you get uniform coverage of all the grout lines. Wipe off any excess grout with a wet sponge and clear water. After the grout has had about 30 minutes to dry, go back over sections with a soft cloth and buff away any grout haze.

18

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.2.1.4 Area Proposed for Glazed Ceramic Wall Tiling Location Master Bath Guest Bath Powder Room/ Toilet Maid Bath Bath 1 Bath 2 Bath 3 Price(SQFT) RM13 RM13 RM13 RM10 RM10 RM10 RM10 Colour White Black White White White + Various Colour White + Various Colour White + Various Colour Size(MM) 450x150x10 450x150x10 450x150x10 150x150x6 150x150x6 150x150x6 150x150x6 Brand Johnson Johnson Johnson Johnson Johnson Johnson Johnson Type Neutral Neutral Neutral Prismatics Prismatics Prismatics Prismatics

Table 9 Area Proposed for Ceramic Wall Tiling

Figure 22 Glazed Ceramic Wall Tiling Type Neutral (Master Bath) Figure 21 Glazed Ceramic Wall Tiling Type Prismatics (Bath 1, 2 &3)

19

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.2.1.5 Area Proposed for Glazed Ceramic Wall Tiling Location Wet Kitchen Dry Kitchen Price(SQFT) RM13 RM13 Colour Teal Pinstripe + White Pinstripe White Pinstripe Size(MM) 450x150x10 450x150x10 Brand Johnson Johnson Type Vivid Vivid

Table 10 Area Proposed for Ceramic Wall Tiling

Figure 23 Glazed Ceramic Wall Tiling Type Vivid (Wet Kitchen)

Figure 24 Glazed Ceramic Wall Tiling Type Vivid (Dry Kitchen)

20

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.2.2 Painting Wall Finishes 1.2.2.1 Introduction and Advantages of Painting Wall Finishes

Centuries ago until now, painting is the most common finishes applied on the wall because of its low costs and easier to apply on the wall and available of various colour choice. Advantages of painting as a wall finishes. Economical Long-Lasting Protection Good wall paints are easy to clean Good Appearance Short Setting Time Fungus Resistant Anti-Bacterial Environment Friendly Quality wall paints are more durable

Figure 25 Painting Wall Finishes Figure 26 Painting Wall Finishes

21

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.2.2.2 Painting Steps

Prepare the surface Clean the surface The surface must be cleaned of mortar droppings, dirt, dust, grease and other foreign matters such as growth of molds, algae, moss by brushing and washing. Efflorescence deposits must be cleaned also. Repair the patches Patches on painting area must be repaired by plastering followed by application of a coat of waterproofing cement paint on patches after wetting the surface completely. Clean existing paint/whitewash Clean old/existing surface, previously treated with whitewash and color wash thoroughly by scrapping all whitewash, color wash when water proofing cements paint is required to apply on existing surfaces. Do mixing thoroughly Step1: Mix cement paint and water in proper ratio Take 2 parts of cement paint and one part of water and stir thoroughly. Take care to add cement paint gradually to the water and not vice versa. Step 2: Add remaining water Add remaining one part of water to the mixture Step 3: Shake the solution Stir the solution thoroughly to obtain uniform finish. Apply first coat of cement paint Apply the solution Apply prepared solution with brushes or spray machine after cleaning and wetting cement or concrete surface. Hake the solution during application and use it within one hour after mixing otherwise it would be thicken and affect the finish. Getting good finish Take care that the thickness of paint is uniform. Brush out the laps well and dampen the surface after days work. Apply second coat of cement paint After the first coat is set at least for 24 hours, apply second coat by repeating application process of the first coat. Do proper curing Since hardening of paint film depends on the availability of moisture for chemical reaction with cement, the water should be sprinkled on painted surface at least for two days.

22

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.2.2.3 Area Proposed for Painting Wall Finishes Location Living Hall Way 1 & 2 Dinning Maids Room Guest Room Store Family Area Master Bedroom Bedroom 1 Bedroom 2 Bedroom 3 Price (SQFT) RM2 RM2 RM2 RM2 RM2 RM2 RM4 RM4 RM4 RM4 RM4 Colour White White White White White White Reflection Reflection Reflection Reflection Reflection Brand Nippon Nippon Nippon Nippon Nippon Nippon Nippon Nippon Nippon Nippon Nippon Type

Odour-less Premium All-in-1 ( undercoat + 2 premium coat) Odour-less Premium All-in-1 ( undercoat + 2 premium coat) Odour-less Premium All-in-1 ( undercoat + 2 premium coat) Odour-less Premium All-in-1 ( undercoat + 2 premium coat) Odour-less Premium All-in-1 ( undercoat + 2 premium coat) Odour-less Premium All-in-1 ( undercoat + 2 premium coat)

Momento Sparkle Silver (1 Terrace Stone coat + 1 Creek Sand coat) Momento Sparkle Silver (1 Terrace Stone coat + 1 Creek Sand coat) Momento Sparkle Silver (1 Terrace Stone coat + 1 Creek Sand coat) Momento Sparkle Silver (1 Terrace Stone coat + 1 Creek Sand coat) Momento Sparkle Silver (1 Terrace Stone coat + 1 Creek Sand coat)

Table 11 Area Proposed for Painting Wall

Figure 28 Nippon Momento Sparkle Silver Painting Wall Finishes Figure 27 Nippon White Colour Painting Wall Finishes

23

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.3 Internal Ceiling Finishes

1.3.1 Gypsum Board Ceiling with Painting 1.3.1.1 Introduction

Gypsum board is widely used for internal walls and ceilings by the construction industry, and is a material of growing importance in the do-it-yourself sector. It is manufactured by calcining gypsum into a plaster, making slurry from the plaster, and passing the slurry through machines which shape, set, and cut into a board. The addition of Boric Acid to the slurry yields significant improvements in product performance, user convenience, and process efficiency. In gypsum board manufacture, Boric Acid is used to increase the strength of the board, to reduce the board weight by about 10%, to provide better adhesion of the paper backing to the board, to reduce the curing time of gypsum board, to prevent wrinkle formation on the surface of the board, to create a hard gypsum edge that withstands nailing and handling and to enhance fire retardancy.

Figure 29 Modern Gypsum Board Ceiling

24

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.3.1.2 Advantages of Gypsum Board Ceiling Ease of installation Gypsum board building systems are easy to install for several reasons. Gypsum board panels are relatively large compared to other materials. They come in 48and 54-inch wide sheets and in lengths of 8, 10, or 12 feet, so they quickly cover large wall and ceiling areas. Gypsum board assemblies require only a few tools for their construction. Gypsum board can be cut with either a utility knife or a variety of saws, and it can be attached with a variety of fasteners, including screws, nails, and staples. It can also be adhesively attached to many substrates. Gypsum board is a lightweight material. Two workers can easily handle most panels and cover large areas in very short time periods. Gypsum board is easily finished using either a few hand tools or relatively modest machines. Gypsum board installers can quickly learn most application techniques in a few hours. Fire resistance Gypsum board is an excellent fire-resistive building material. In North America, it is the most commonly used interior finish where fire resistance classifications are required. Its noncombustible core contains nearly 21% chemically combined water, as described earlier, which, under high heat, is slowly released as steam. When installed in combination with other materials in laboratory-tested wall and ceiling assemblies, gypsum board serves to effectively protect building elements from fire for prescribed time periods. Sound isolation Preventing the transfer of unwanted sound to adjoining areas is a key consideration when designing a building, specifically when taking into account the intended activities of the occupants in the various parts of the building. For example, a building containing office spaces adjacent to manufacturing facilities requires more noise-reducing features than are typically necessary in a building that has only office space in it. Gypsum board wall and ceilings systems effectively help control sound transmission.

Durability Gypsum board is used to construct strong, high quality walls and ceilings that offer excellent dimensional stability and durability. Surfaces created using gypsum board are easily decorated and refinished.

Versatility Gypsum board satisfies a wide range of architectural requirements for design. Ease of application, performance, ease of repair, availability, and its adaptability to all forms of decoration combine to make gypsum board unmatched by any other surfacing product.

25

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.3.1.3 Installation of Gypsum Board Ceiling

1. Measure the ceiling starting the one end along a wall perpendicular to the joists. Find the joist that's closest to being 8 feet from the wall, without being further than that. Measure from the middle of the joist to the wall. 2. Use your razor knife to score and snap a piece of gypsum board at that length, running the blade alongside your t-square to keep it straight. 3. Set up two ladders, one by the starting wall, the other under the joists to which you measured. With an assistant, hold the gypsum board up to the ceiling, with the cut end facing the wall and the uncut end lining up with the middle of the joist. 4. Shoot drywall screws ever six inches or so along the edge of the board where it is under the joist. Do the same for the rest of the joists above the board. (You will be able to judge the positions of the joists behind the board based on where they come out from the side of it.) Make sure to completely sink the screw heads below the surface 5. Hang the rest of the boards in the same manner, positioning them end to end, in courses, always meeting at the joists. Stagger the positions of the board between courses, so there are no four-way intersections. 6. Presses mesh drywalling tape over all the seams between the boards. Use your drywall knife to spread joint compound over the tape, making a smooth line about 4 inches wide. Also spread a little compound over the sunken screw holes. Let it dry for about 4 hours. 7. Sand the seams and screw holes by hand to smooth out the dried joint compound. Apply another layer of joint compound over the first along the seams, making the seams a little wider. Let it dry, sand it, and apply a third, very thin final coat. Sand it lightly and paint.

Figure 30 Modern Gypsum Board Ceiling

26

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.3.1.4 Area Proposed for Gypsum Ceiling Board

Location Living Room Hallway 1 & 2 Dining Dry Kitchen Wet Kitchen Maids Room Guest Room Store Master Bedroom Bedroom 2 Bedroom 3 Bedroom 4 Family Area

Price (SQFT) RM 8 RM 8 RM 8 RM 8 RM 8 RM 8 RM 8 RM 8 RM 8 RM 8 RM 8 RM 8 RM 8

Color White White White White White White White White White White White White White

Size(mm) 2000x1200x10 2000x1200x10 2000x1200x10 2000x1200x10 2000x1200x10 2000x1200x10 2000x1200x10 2000x1200x10 2000x1200x10 2000x1200x10 2000x1200x10 2000x1200x10 2000x1200x10

Brand Dryco Dryco Dryco Dryco Dryco Dryco Dryco Dryco Dryco Dryco Dryco Dryco Dryco

Table 12 Area Proposed For Gypsum Ceiling Board

27

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.3.2 Ceiling Tiles 1.3.2.1 Introduction Ceiling tiles are lightweight tiles used in the interior of buildings. They are placed in an aluminum grid and they provide little thermal insulation but are generally designed to improve the acoustics of a room. Mineral fibre tiles are fabricated from a range of products; wet felt tiles can be manufactured from perlite, mineral wool, and fibers from recycled paper, stone wool tiles are created by combining molten stone and binders which is then spun to create the tile, or gypsum tiles which are based on the soft mineral and then finished with vinyl, paper or a decorative face. Ceiling tiles very often have patterns on the front face; these are there in most circumstances to aid with the tiles ability to improve acoustics.

1.3.2.2 Advantages of Ceiling tiles

100% Waterproofs Washable Will Never Sag (due to humidity) Mold, Bacteria and Mildew Resistant Impact Damage Resistant Will not Rot, Peel or Flake Flame Retardant Fire Rated: Class A Flame Spread & Smoke Index Fiberglass, Asbestos & Lead Free USDA, FDA, Health Dept & CFIA Compliant UV- Resistant Commercial Recyclable

28

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

1.3.2.3 Area Proposed for Ceiling Tiles Location Master Bath Guest Bath Maid Bath Bath 1 Bath 2 Bath 3 Price(SQFT) RM13 RM13 RM13 RM13 RM13 RM13 Colour White White White White White White Size(MM) 300x300x12 300x300x12 300x300x12 300x300x12 300x300x12 300x300x12 Brand Armstrong Armstrong Armstrong Armstrong Armstrong Armstrong Type Washable Washable Washable Washable Washable Washable

Table 13 Area Proposed for Ceiling Tiles

Figure 31 Washable Ceiling Tiles

29

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

2 Proposed Building Material/Products

2.1 Internal Floor Finishes (Ground Floor)

Location Living Room Hall Way 1 & 2 Dining Room Dry Kitchen Wet Kitchen Maid Bath Guest Bath Powder Room/ Toilet Guest Room Maid Room Store

Table 14 Internal Floor Finishes (Ground Floor)

Types of Floor Finishes Marble Tiles Flooring

Justification Grand and Gorgeous, High Moisture Resistance, Durable, Bacteria Resistance, Allergen Resistance

Unglazed Porcelain Tiles

Anti-Slip, Easy to Clean, High Moisture Resistance, Low Maintenance, Durable

Engineer Timber Flooring Ceramic Tiles

Durable, Good Appearances, Suitable For Radiant Heated, Allergy Prevention, Easy to Clean Easy to Maintenance, Durable, Affordable, Good Appearances, Moisture Resistance

30

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

2.2 Internal Floor Finishes (First Floor)

Location Family Area Master Bedroom Bedroom 2 Bedroom 3 Bedroom 4 Master Bath Bath 1 Bath 2 Bath 3

Table 15 Internal Floor Finishes (First Floor)

Types of Floor Finishes Engineered Timber Flooring

Justification Durable, Good Appearances, Suitable For Radiant Heated, Allergy Prevention, Easy to Clean

Unglazed Porcelain Tiles

Anti-Slip, Easy to Clean, High Moisture Resistance, Low Maintenance, Durable

31

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

2.3 Internal Wall Finishes (Ground Floor)

Location Living Room Hall Way 1 & 2 Dining Room Maid Room Guest Room Store Wet Kitchen Dry Kitchen Maid Bath Guest Bath Powder Room/ Toilet

Table 16 Internal Wall Finishes (Ground Floor)

Types of Wall Finishes Nippon Painting

Justification Good Appearances, Anti-Fungus, Anti-Bacterial, Environment Friendly

Glazed Ceramic Wall Tiles

Easy to Maintenance, Durable, Affordable, Good Appearances, Moisture Resistance

32

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

2.4 Internal Wall Finishes (First Floor)

Location Family Area Master Bedroom Bedroom 2 Bedroom 3 Bedroom 4 Master Bath Bath 1 Bath 2 Bath 3

Table 17 Internal Wall Finishes (First Floor)

Types of Wall Finishes Nippon Painting

Justification Good Appearances, Anti-Fungus, Anti-Bacterial, Environment Friendly

Glazed Ceramic Wall Tiles

Easy to Maintenance, Durable, Affordable, Good Appearances, Moisture Resistance

33

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

2.5 Internal Ceiling Finishes (Ground Floor)

Location Living Room Hallway 1 & 2 Dining Dry Kitchen Wet Kitchen Maids Room Guest Room Store Guest Bath Maid Bath Powder Room/ Toilet Types of Ceiling Finishes Gypsum Board Ceiling with Painting Justification Good Appearances, Durable, Fire Resistance, Sound Insulation

Washable Ceiling Tiles

Waterproof, Durable, Easy to Clean

Table 18 Internal Ceiling Finishes (Ground Floor)

34

PROPOSAL OF BUILDING MATERIALS/ PRODUCTS

February 22, 2012

2.6 Internal Ceiling Finishes (First Floor)

Location Family Area Master Bedroom Bedroom 2 Bedroom 3 Bedroom 4 Master Bath Bath 1 Bath 2 Bath 3

Table 19 Internal Ceiling Finishes (First Floor)

Types of Ceiling Finishes Gypsum Board Ceiling with Painting

Justification Good Appearances, Durable, Fire Resistance, Sound Insulation

Washable Ceiling Tiles

Waterproof, Durable, Easy to Clean

35

Das könnte Ihnen auch gefallen

- Catalog MJT-Office SuppliesDokument8 SeitenCatalog MJT-Office SuppliesmazjayatradeNoch keine Bewertungen

- Drawings and specifications for proposed 40-storey condominium buildingDokument1 SeiteDrawings and specifications for proposed 40-storey condominium buildingGarduque AngreysNoch keine Bewertungen

- Proposed 2 Storey Residential Renovation For MRMRS EduardoDokument13 SeitenProposed 2 Storey Residential Renovation For MRMRS EduardoUwuw8eieieNoch keine Bewertungen

- Residential Building Addition AgreementDokument2 SeitenResidential Building Addition AgreementPonz MadianoNoch keine Bewertungen

- DocDokument27 SeitenDocNana BarimaNoch keine Bewertungen

- Draft Roof Framing Plan Manually (39Dokument41 SeitenDraft Roof Framing Plan Manually (39Jennifer CaliwagNoch keine Bewertungen

- Roof Plan: Rolando F. Vasquez Jr. As Shown As-Built Plan of One Storey Residential BuildingDokument1 SeiteRoof Plan: Rolando F. Vasquez Jr. As Shown As-Built Plan of One Storey Residential BuildingErol VasquezNoch keine Bewertungen

- PV Lighting Systems ExplainedDokument53 SeitenPV Lighting Systems ExplainedRiaz AhmedNoch keine Bewertungen

- Construction of Moiben Sub-County Office BlockDokument152 SeitenConstruction of Moiben Sub-County Office Blockapi-258641606Noch keine Bewertungen

- Contract Addendum Example PDFDokument4 SeitenContract Addendum Example PDFCody TerrellNoch keine Bewertungen

- Table ListDokument16 SeitenTable ListMavelyn TolentinoNoch keine Bewertungen

- Doors, Windows, PaintDokument64 SeitenDoors, Windows, PaintArchana AcchuNoch keine Bewertungen

- USAid Primer Set 2 Story Confined MasonryDokument39 SeitenUSAid Primer Set 2 Story Confined MasonryKevin John Carlo Real0% (1)

- A3 FLOOR PLAN - Layout - 2105Dokument8 SeitenA3 FLOOR PLAN - Layout - 2105Peter WestNoch keine Bewertungen

- R M R A: Eynaldo - Amos & SsociatesDokument9 SeitenR M R A: Eynaldo - Amos & SsociatesluffyNoch keine Bewertungen

- Abrams Cafe PDFDokument4 SeitenAbrams Cafe PDFKresta Ellece LomabaoNoch keine Bewertungen

- Torode Commercial Plans For Enoch Sales House PropertyDokument67 SeitenTorode Commercial Plans For Enoch Sales House PropertyDarren KrauseNoch keine Bewertungen

- Structural FujiDokument6 SeitenStructural Fujichris100% (1)

- Architecture: Schedule of Finishes 1 Schedule of Finishes 2Dokument10 SeitenArchitecture: Schedule of Finishes 1 Schedule of Finishes 2Eunice RosarioNoch keine Bewertungen

- Contract - Owner To ArchitectDokument14 SeitenContract - Owner To ArchitectAlteah BartolomeNoch keine Bewertungen

- Lindenwood Residences Proposal (Ambf X No of Storeys)Dokument8 SeitenLindenwood Residences Proposal (Ambf X No of Storeys)Ponz MadianoNoch keine Bewertungen

- MR.& Mrs. Jun Marc Nobleza South Forbes Properties Sta. Rosa - Silang, TagaytayDokument11 SeitenMR.& Mrs. Jun Marc Nobleza South Forbes Properties Sta. Rosa - Silang, TagaytayAnonymous LQVRIPusNoch keine Bewertungen

- The Planning of Residential Developments The Planning of Residential DevelopmentsDokument30 SeitenThe Planning of Residential Developments The Planning of Residential DevelopmentsFrances MarasiganNoch keine Bewertungen

- Perspective Views: John Louie J. AngDokument1 SeitePerspective Views: John Louie J. AngRenvil PedernalNoch keine Bewertungen

- Company ProfileDokument7 SeitenCompany ProfileGamingVlog Box100% (1)

- Lighting Layout Power Layout: Carza, Ma. Jenselle D. Commercial Building (Outlet Layout) Engr. Jike AlcainDokument1 SeiteLighting Layout Power Layout: Carza, Ma. Jenselle D. Commercial Building (Outlet Layout) Engr. Jike AlcainJenselle CarzaNoch keine Bewertungen

- Apply for Fire Safety Evaluation Clearance in 40 CharactersDokument1 SeiteApply for Fire Safety Evaluation Clearance in 40 CharactersMacabebe Fire StationNoch keine Bewertungen

- Product Catalog Update1Dokument70 SeitenProduct Catalog Update1ayebless100% (1)

- Rawr Company ProfileDokument22 SeitenRawr Company ProfileAinaa BohrNoch keine Bewertungen

- Land Market, Consolidation and Readjustment ComponentDokument71 SeitenLand Market, Consolidation and Readjustment ComponentMufid MuyassarNoch keine Bewertungen

- PHALTRA 87th NCSW Program of ActivitiesDokument7 SeitenPHALTRA 87th NCSW Program of Activitiesvin1925Noch keine Bewertungen

- Bank Guarantee Format for Construction PerformanceDokument1 SeiteBank Guarantee Format for Construction PerformanceMSEB JVNoch keine Bewertungen

- BT3 COMPILATION Viktoria Allona M.yumangDokument33 SeitenBT3 COMPILATION Viktoria Allona M.yumangViktoria YumangNoch keine Bewertungen

- An Overview of The Cadastral System in TanzaniaDokument17 SeitenAn Overview of The Cadastral System in TanzaniasiwalazeNoch keine Bewertungen

- Standard of Architectural Services and Scale of ChargesDokument10 SeitenStandard of Architectural Services and Scale of ChargesamlaNoch keine Bewertungen

- A.01.5 SectionDokument1 SeiteA.01.5 SectionevanzflorenceNoch keine Bewertungen

- Stair Detail PDFDokument1 SeiteStair Detail PDFManish AgrawalNoch keine Bewertungen

- Lightweight Concrete 16 PagesDokument16 SeitenLightweight Concrete 16 Pageschris lee50% (2)

- Residential Mechanical DrawingsDokument12 SeitenResidential Mechanical DrawingsfebousNoch keine Bewertungen

- Purlin Blow Up: Footing ScheduleDokument1 SeitePurlin Blow Up: Footing ScheduleRenvil PedernalNoch keine Bewertungen

- Positioning and Its Strategic Relevance For Charitable OrganisationsDokument18 SeitenPositioning and Its Strategic Relevance For Charitable OrganisationsDr Celine ChewNoch keine Bewertungen

- Vishranti Greens BrochureDokument14 SeitenVishranti Greens BrochuretechkasambaNoch keine Bewertungen

- Construction/Rehabilitation of Rainwater Collector System for Palabotan Elementary SchoolDokument8 SeitenConstruction/Rehabilitation of Rainwater Collector System for Palabotan Elementary SchoolJervin BragadoNoch keine Bewertungen

- 01-MAIN-VILLA-END UNIT (Aseel) (REVISED-final Price-19-12-2019-1Dokument3 Seiten01-MAIN-VILLA-END UNIT (Aseel) (REVISED-final Price-19-12-2019-1jatinNoch keine Bewertungen

- Building Specification ProposalDokument9 SeitenBuilding Specification ProposalEngr SwapanNoch keine Bewertungen

- Agnes Vo2 Furniture QuoteDokument18 SeitenAgnes Vo2 Furniture QuoteChai Yew Hin HinNoch keine Bewertungen

- Letter of AcceptanceDokument5 SeitenLetter of AcceptanceTender TenderNoch keine Bewertungen

- Mbe Pcab 2023 To 2024Dokument2 SeitenMbe Pcab 2023 To 2024Dirky TemNoch keine Bewertungen

- Eco-Friendly School ElevationsDokument1 SeiteEco-Friendly School ElevationsAndrew AmedaNoch keine Bewertungen

- 18KO-0200 Official Statement of Work AccomplishmentDokument4 Seiten18KO-0200 Official Statement of Work AccomplishmentJohn Regulacion IINoch keine Bewertungen

- Terrace (RCC Slab) +9150 SSL: General NotesDokument1 SeiteTerrace (RCC Slab) +9150 SSL: General Notescheligp1981Noch keine Bewertungen

- Pag Asa Steel - ReinforcementDokument2 SeitenPag Asa Steel - Reinforcementjremptymak100% (1)

- Roof BOQDokument9 SeitenRoof BOQOscarKonzultNoch keine Bewertungen

- Subcontract Standard Form of Agreement Between: RequestDokument1 SeiteSubcontract Standard Form of Agreement Between: Requestjherna215Noch keine Bewertungen

- Glazing and Curtain Wall Prices Philippines - PHILCON PRICESDokument1 SeiteGlazing and Curtain Wall Prices Philippines - PHILCON PRICESjohn reyesNoch keine Bewertungen

- Front Elevation Right Side Elevation: A B C D E 5 4 3 2 1Dokument1 SeiteFront Elevation Right Side Elevation: A B C D E 5 4 3 2 1ArjelyNoch keine Bewertungen

- QUOTATIONDokument3 SeitenQUOTATIONMiguel Taleon100% (1)

- Rainwater and Domestic Water Storage Tank DetailsDokument1 SeiteRainwater and Domestic Water Storage Tank DetailsGarduque AngreysNoch keine Bewertungen

- Weekly Report TemplateDokument2 SeitenWeekly Report TemplateJames Alvin NealegaNoch keine Bewertungen

- Proposal of Building MaterialsDokument40 SeitenProposal of Building MaterialsErnane RitaNoch keine Bewertungen

- Wilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetDokument2 SeitenWilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetTrung Trần MinhNoch keine Bewertungen

- Nodelman 1992Dokument8 SeitenNodelman 1992Ana Luiza RochaNoch keine Bewertungen

- The Teacher and The LearnerDokument23 SeitenThe Teacher and The LearnerUnique Alegarbes Labra-SajolNoch keine Bewertungen

- 3.5 Lonaphala S A3.99 PiyaDokument9 Seiten3.5 Lonaphala S A3.99 PiyaPiya_TanNoch keine Bewertungen

- Case Study On Global Branding - DuluxDokument18 SeitenCase Study On Global Branding - DuluxAakriti NegiNoch keine Bewertungen

- Communication & Collaboration: Lucy Borrego Leidy Hinojosa Scarlett DragustinovisDokument44 SeitenCommunication & Collaboration: Lucy Borrego Leidy Hinojosa Scarlett DragustinovisTeacherlucy BorregoNoch keine Bewertungen

- Booklet English 2016Dokument17 SeitenBooklet English 2016Noranita ZakariaNoch keine Bewertungen

- 1ST Periodical Test ReviewDokument16 Seiten1ST Periodical Test Reviewkaren rose maximoNoch keine Bewertungen

- Nurses Week Program InvitationDokument2 SeitenNurses Week Program InvitationBenilda TuanoNoch keine Bewertungen

- Fixed Prosthodontics Provisional Materials: Making The Right Selection.Dokument7 SeitenFixed Prosthodontics Provisional Materials: Making The Right Selection.veloso.rossana0% (1)

- 11.trouble Shooting For TMDokument9 Seiten11.trouble Shooting For TMfrezgi birhanuNoch keine Bewertungen

- Analog Communication Interview Questions and AnswersDokument34 SeitenAnalog Communication Interview Questions and AnswerssarveshNoch keine Bewertungen

- Conditional Sentences in NT Greek Ruben VideiraDokument62 SeitenConditional Sentences in NT Greek Ruben Videiraruviso100% (1)

- Rise of NationalismDokument19 SeitenRise of NationalismlolaNoch keine Bewertungen

- Manage a micro business with BSB30315Dokument3 SeitenManage a micro business with BSB30315Theo A W JacksonNoch keine Bewertungen

- MUM202001007 - 300 TR Price BOQ ChillerDokument4 SeitenMUM202001007 - 300 TR Price BOQ ChillerB DASNoch keine Bewertungen

- Cbydp Draft SK BaracbacDokument13 SeitenCbydp Draft SK BaracbacLikey PromiseNoch keine Bewertungen

- Specification: F.V/Tim e 3min 5min 8min 10MIN 15MIN 20MIN 30MIN 60MIN 90MIN 1.60V 1.67V 1.70V 1.75V 1.80V 1.85VDokument2 SeitenSpecification: F.V/Tim e 3min 5min 8min 10MIN 15MIN 20MIN 30MIN 60MIN 90MIN 1.60V 1.67V 1.70V 1.75V 1.80V 1.85VJavierNoch keine Bewertungen

- PremiumpaymentReceipt 10663358Dokument1 SeitePremiumpaymentReceipt 10663358Kartheek ChandraNoch keine Bewertungen

- Thesis PromptsDokument7 SeitenThesis Promptsauroratuckernewyork100% (2)

- Goldenberg and Reddy (2017)Dokument10 SeitenGoldenberg and Reddy (2017)Mariana ToniniNoch keine Bewertungen

- Ti 1000 0200 - enDokument2 SeitenTi 1000 0200 - enJamil AhmedNoch keine Bewertungen

- IRC-114-2013 Use of Silica Fume in Rigid PavementDokument14 SeitenIRC-114-2013 Use of Silica Fume in Rigid PavementZakee MohamedNoch keine Bewertungen

- Iwwusa Final Report IdsDokument216 SeitenIwwusa Final Report IdsRituNoch keine Bewertungen

- Atlanta Pipes and FittingsDokument2 SeitenAtlanta Pipes and Fittingsotadoyreychie31Noch keine Bewertungen

- Henderson PresentationDokument17 SeitenHenderson Presentationapi-577539297Noch keine Bewertungen

- Advantages of Computerizing and Networking ComputersDokument5 SeitenAdvantages of Computerizing and Networking ComputersIn BioNoch keine Bewertungen

- Vijay Solvex PROJECT "Retention Strategy"Dokument110 SeitenVijay Solvex PROJECT "Retention Strategy"Jayesh SinghNoch keine Bewertungen

- ICO Basic SyllabusDokument11 SeitenICO Basic SyllabusRaúl Plasencia Salini100% (1)

- Sequence TransformationDokument2 SeitenSequence Transformationbrown222Noch keine Bewertungen