Beruflich Dokumente

Kultur Dokumente

Electronic Magnetic Ballasts

Hochgeladen von

charlnnmdOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Electronic Magnetic Ballasts

Hochgeladen von

charlnnmdCopyright:

Verfügbare Formate

Electronic v Magnetic Ballasts

Many comparisons unfairly hobble magnetic ballast fluorescent lighting by comparing old inefficient class C and D ballasts (removed from sale in Australia in March 2003 by MEPS1). Added to that comparisons also often use glow-starters rather than the modern electronic starter which gets rid of flicker on startup and improves lamp life. Many will compare old tubes or cheap tubes that have a shorter life and more mercury than regular lamps. Electronic Ballasts have their advantages. First they are half the price of magnetic ballasts. Second intelligent electronic ballasts can dim lamps to fraction of their full light output which can be very handy but is not needed in most applications.

Light Power Density or Lumens per Watt and voltage reduction

A low-loss magnetic ballast (Class B1) with voltage reduction can achieve similar or greater lumens per watt than an electronic ballast. Even the old inefficient class C and D magnetic ballasts produce only 2% and 5% less lumens/watt than an electronic ballast when driven at low voltages while consuming 10 % less power.

Reliability

One maker speaks of a failure rate below 2% per 1000 hours operation with their electronic ballast. That sounds quite nice, but for an average supermarket with 3000 hours p.a. of operation this amounts to 6% dropouts per year. Under constant duty, such as in a car park, it means replacing more than 1 of every 6 ballasts annually. Magnetic ballasts are very bullet proof. Michael Lane, Lighting Design Lab .3

EcoSpecifier independent Conclusion

There is a seemingly strong case to review the single emphasis on the use of electronic ballasts only, to achieve optimum energy efficiency and environmental outcomes. This review should include the assessment of HP magnetic ballasts, used in conjunction with voltage reduction power saving units, electronic starters, and innovative new technologies in project analyses and Green Star credits, to take energy efficiency in lighting to yet a new level of saving.2

Disposal

The iron and copper in a magnetic ballast is readily and easily recyclable (having different melting temperatures). Theoretically there is no limit to the number of times a magnetic ballast can be recycled. Electronic ballasts are a different matter. In Australia most go to landfill while some are burnt in high temperature incinerators and the pollutants released into the atmosphere (our food chain). Source: CMA Eco Cycle, a division of CMA Recycling.

Energy Efficiency and voltage reduction

At normal voltage a good magnetic ballast consumes only 3 watts more than an electronic ballast.1 The lower the voltage the more efficient a magnetic ballast becomes, especially the modern ones. Comparing the worst-case old style magnetic ballast and a new high-efficiency electronic ballast (Class A3) the magnetic ballast will actually consume less power if driven at 190 volts and produce only 4.7% less light per watt. More efficient class B1 or B2 magnetic ballast will consume less power than the electronic ballast when driven at 210 volts (Power Saver drives lamps at 206 volts) than the same electronic ballast and produce only 2.7% less light per watt. The magnetic ballast would then consume less power for a tiny loss in light.

Ballast upgrade cost savings

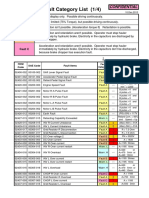

Payback Periods for replacing magnetic ballasts with electronic ballasts Intensity of use 3000h/a Electricity price 0.08/kWh Replacing a conventional class C magnetic ballast with a class B1 3.5 years low-loss magnetic ballast Replacing a conventional class C magnetic ballast with a class A2 13.1 years electronic ballast Replacing a class B1 low-loss magnetic ballast with a class A2 19.4 years electronic ballast

Electronic ballast case studies:

University, Hospital, Institute of Technology, Airport and Manufacturer.

Victoria University, Flinders, Street Melbourne Installed ceiling fittings with two fluorescent lamps and electronic ballasts. Two years on they were all removed and refurbished due to the high failure rate of the electronic ballasts.

Swiss Federal Institute of Technology Zurich found a very high failure rate with new ballasts. Following customer complaints the contractor contacted the manufacturer to be told that an initial failure rate of 17% was absolutely normal for electronic ballasts.

Paderborn-Lippstadt airport, Germany, found that out of about 80 electronic ballasts no less than 30 had failed within 4 months in one part of the installation. Investigation of the cause suggested that the ballasts kill each other, unless other loads absorb their electronic litter. About half a year later the same problem occurred in another location of the same airport, but with different ballasts from a different producer.

Image: Changeover fittings at Victoria University.

Kaufbeuren hospital in Germany4 installed about 480 luminaires into the ceiling, each fitted with 2 fluorescent lamps, rated 2*13 W, with 1 common electronic ballast. By end of 2004, some 800 lamps had to be replaced. Upon examination it appeared the ballast misinterpreted a voltage dip as an instance of switch-off and switch-on again and started to heat the filaments, waiting for the lamp current to rise as a signal of successful start, to shut off the heating current. But the lamp current did not rise because the lamp was already in operation, so the pre-heat current remained on and overloaded the filaments.

Image: Electronic ballast failures at Swiss Federal Institute of Technology, Zurich within one year.

A Lamp Manufacturer that didnt want to be named needed a reliable way of testing T5 80 watt lamps and found that failures of electronic ballasts caused frequent and expensive production stoppages. Magnetic ballasts were substituted (using 400 volts instead of 320) and have ensured smooth production testing of the lamps. www.powersaver.net.au info@powersaver.net.au Phone +61 3 9563 3300 Fax +61 3 9563 3221

1 2

MEPS http://www.energyrating.gov.au/ballasts2.html Ecospecifier http://www.ecospecifier.org/knowledge_base/technical_guides/high_performance_fluorescent_lighting 3 http://www.lightingdesignlab.com/articles/delamping/delamping.htm 4 http://www.baubiologie.net/docs/elektrosmog-Ballasts-for-fluorescent-lamps.pdf (P 27-29, 42)

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Parenting EducationDokument40 SeitenParenting Educationcharlnnmd100% (1)

- ParentingDokument28 SeitenParentingcharlnnmdNoch keine Bewertungen

- ParentingDokument28 SeitenParentingcharlnnmdNoch keine Bewertungen

- The Rewards of Fasting - Mike BickleDokument160 SeitenThe Rewards of Fasting - Mike Bickleclayton.shepherd94% (17)

- Cmos Sequential CircuitsDokument33 SeitenCmos Sequential Circuitslachuns123Noch keine Bewertungen

- Chalmit Lighting 2010Dokument172 SeitenChalmit Lighting 2010charlnnmd0% (2)

- Philips Tube CodesDokument14 SeitenPhilips Tube CodesTortie-BoyNoch keine Bewertungen

- Lightning Protection BS 6651Dokument5 SeitenLightning Protection BS 6651Isz Nia100% (1)

- Mega Himel Pricelist 2021Dokument38 SeitenMega Himel Pricelist 2021Fritz NatividadNoch keine Bewertungen

- Earthing RequirementDokument7 SeitenEarthing RequirementSandy ChoudhariNoch keine Bewertungen

- The Ten Commandments PlainDokument1 SeiteThe Ten Commandments Plainscorpionsting2500Noch keine Bewertungen

- How To Change Bearing.Dokument5 SeitenHow To Change Bearing.charlnnmdNoch keine Bewertungen

- Ats 101e1Dokument8 SeitenAts 101e1charlnnmdNoch keine Bewertungen

- Axial Lock Nuts PDFDokument3 SeitenAxial Lock Nuts PDFcharlnnmdNoch keine Bewertungen

- Prayer and FaithDokument51 SeitenPrayer and FaithcharlnnmdNoch keine Bewertungen

- A New On-Line Partial Discharge Test For Turbine GeneratorsDokument6 SeitenA New On-Line Partial Discharge Test For Turbine Generatorsarun_adventureNoch keine Bewertungen

- Parenting OutcomesDokument58 SeitenParenting OutcomescharlnnmdNoch keine Bewertungen

- Logic Symbols Truth Tables and Equivalent Ladder Logic DiagrDokument2 SeitenLogic Symbols Truth Tables and Equivalent Ladder Logic DiagrSteve LisleNoch keine Bewertungen

- HVAC ControlsDokument6 SeitenHVAC ControlscharlnnmdNoch keine Bewertungen

- Child DevelopmentDokument19 SeitenChild DevelopmentcharlnnmdNoch keine Bewertungen

- Attention Deficit DisorderDokument5 SeitenAttention Deficit DisordercharlnnmdNoch keine Bewertungen

- PDA How ToDokument94 SeitenPDA How TocharlnnmdNoch keine Bewertungen

- Correspondence Lesson 10: Home Controls: Electrical Construction and MaintenanceDokument4 SeitenCorrespondence Lesson 10: Home Controls: Electrical Construction and MaintenancecharlnnmdNoch keine Bewertungen

- Correspondence Lesson 7: Motor Controls: Electrical Construction and MaintenanceDokument6 SeitenCorrespondence Lesson 7: Motor Controls: Electrical Construction and MaintenancecharlnnmdNoch keine Bewertungen

- A New On-Line Partial Discharge Test For Turbine GeneratorsDokument6 SeitenA New On-Line Partial Discharge Test For Turbine Generatorsarun_adventureNoch keine Bewertungen

- REF542plus Om 755869 ENgDokument144 SeitenREF542plus Om 755869 ENgcharlnnmdNoch keine Bewertungen

- Protecta: Normal and Emergency LightingDokument4 SeitenProtecta: Normal and Emergency LightingcharlnnmdNoch keine Bewertungen

- Instructions For Installation & Use For The Aquarius Range WF445, WF440, WF430, WF250, WF240, WF225, WF220, WF215, WF210 and WF000Dokument11 SeitenInstructions For Installation & Use For The Aquarius Range WF445, WF440, WF430, WF250, WF240, WF225, WF220, WF215, WF210 and WF000charlnnmdNoch keine Bewertungen

- Differentiating Between NEMA Vs IECDokument5 SeitenDifferentiating Between NEMA Vs IECbyanggoNoch keine Bewertungen

- Industrial Relays: WorkshopDokument20 SeitenIndustrial Relays: WorkshopruthNoch keine Bewertungen

- 15-28 SUPPLEMENT FOR 1989: Wiring Diagram KX80-L3, N3, KX100-A2 (UK)Dokument1 Seite15-28 SUPPLEMENT FOR 1989: Wiring Diagram KX80-L3, N3, KX100-A2 (UK)PabloNoch keine Bewertungen

- Group 5 Connectors: 1. Connector DestinationDokument17 SeitenGroup 5 Connectors: 1. Connector DestinationREMZONANoch keine Bewertungen

- Alcan Cable: A Growing TrendDokument3 SeitenAlcan Cable: A Growing TrendCarlos Lino Rojas AgüeroNoch keine Bewertungen

- DCB Flyer Engelsk 2013-09 Ed2Dokument2 SeitenDCB Flyer Engelsk 2013-09 Ed2Han HuangNoch keine Bewertungen

- Eee 2164Dokument4 SeitenEee 2164Mani MalNoch keine Bewertungen

- HV Breaker Details Alastom PDFDokument39 SeitenHV Breaker Details Alastom PDFSanjeev DhariwalNoch keine Bewertungen

- (VOLKSWAGEN) Manual de Taller Volkswagen Jetta 1999 2006 PDFDokument4 Seiten(VOLKSWAGEN) Manual de Taller Volkswagen Jetta 1999 2006 PDFSergio IslasNoch keine Bewertungen

- Transformer Protection: 2 Winding Auto Transformer Earthing Transformer ReactorDokument18 SeitenTransformer Protection: 2 Winding Auto Transformer Earthing Transformer ReactorGnanavel GNoch keine Bewertungen

- Dwell Calibration PDFDokument16 SeitenDwell Calibration PDFpmanguareNoch keine Bewertungen

- 08 Fault Code Category List (EH4000AC ) 131210Dokument5 Seiten08 Fault Code Category List (EH4000AC ) 131210willy torresNoch keine Bewertungen

- Catalog Accessories Dust Collector Series 909 Asco en 4278956Dokument4 SeitenCatalog Accessories Dust Collector Series 909 Asco en 4278956ChangHuiChuanNoch keine Bewertungen

- Vector Control of Induction Motor Without Shaft EncoderDokument8 SeitenVector Control of Induction Motor Without Shaft Encoderapi-3826450Noch keine Bewertungen

- OSM & RC Testing Summary 0260119070398 + VT 509190132Dokument3 SeitenOSM & RC Testing Summary 0260119070398 + VT 509190132Mohammed MaherNoch keine Bewertungen

- TT 1392Dokument4 SeitenTT 1392rickNoch keine Bewertungen

- Charging & Discharging of Capacitor PDFDokument4 SeitenCharging & Discharging of Capacitor PDFHemanth GedelaNoch keine Bewertungen

- UntitledDokument91 SeitenUntitledLiza Mae BalboaNoch keine Bewertungen

- Section R Alarms Messages Powervalue v5 7 TEXTDokument19 SeitenSection R Alarms Messages Powervalue v5 7 TEXTzakattsh4345Noch keine Bewertungen

- CH 4 Asynchronous Motor Speed VariationDokument79 SeitenCH 4 Asynchronous Motor Speed VariationMAHMOUD MOHAMEDNoch keine Bewertungen

- Unisonic Technologies Co., LTD: 14.7A, 100V (D-S) N-CHANNEL Power MosfetDokument5 SeitenUnisonic Technologies Co., LTD: 14.7A, 100V (D-S) N-CHANNEL Power MosfetEnrique LandraNoch keine Bewertungen

- Alarms Ericsson BtsDokument15 SeitenAlarms Ericsson BtsMaicl PuriciNoch keine Bewertungen

- Experiment No10 Simulation of Photodiode Using MATLAB SIMULINKDokument3 SeitenExperiment No10 Simulation of Photodiode Using MATLAB SIMULINKVaishnavi muralliNoch keine Bewertungen

- Physics Investigatory ProjectDokument19 SeitenPhysics Investigatory ProjectKrish KaushikNoch keine Bewertungen

- PR G61CP DatasheetDokument2 SeitenPR G61CP DatasheetvidotrNoch keine Bewertungen

- Lecture 03 - Diode Applications (Rectification)Dokument16 SeitenLecture 03 - Diode Applications (Rectification)Joseph NgowiNoch keine Bewertungen