Beruflich Dokumente

Kultur Dokumente

Lection 1

Hochgeladen von

Jason RossOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lection 1

Hochgeladen von

Jason RossCopyright:

Verfügbare Formate

1

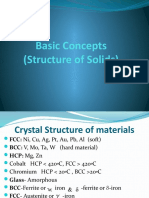

Theme 1. Fundamentals of metals and alloys theory Crystalline structure of metals and alloys All metals are crystalline substances having a particular system of ions arrangement in space, which is characterized by a crystal lattice. The majority of metals used in engineering, has a lattice of one of following types: space-centered cubic, face-centered cubic and close-packed hexagonal (fig. 1.1). a a a

Fig. 1.1. Types of crystal lattices: a space-centered cubic; b - face-centered cubic; c - close-packed hexagonal. The crystal lattice is characterized not only by the type of a low level cell, but also by sizes or parameters (in a fig. 1.1 - sizes a and c). The lattice parameters are measured in angstroms: 1=10-10 m. Some metals, for example, titanium, iron, stannum can have different crystalline structure at miscellaneous temperatures. Each modification of crystalline structure is stable in particular temperature range and is marked by small characters of the Greek alphabet ( , , , , etc.), for example: -titanium, -titanium, -iron. The transferring of one crystalline structure in another is called as polymorphism or allotropy (the polymorphic transformation takes place). The pure metal does not satisfy the requirements to construction materials. Therefore not pure metals, but their alloys are mainly applied in engineering. The concepts of alloy and phase are used at alloys composition research. Alloy is a composition obtained by alloying or sintering of two or more substances. The substances that are included in compound structure, called as components. A phase is a part of alloy with fixed chemical structure, with the same modular condition, identical type of a crystal lattice and interface with other parts of alloy. The atoms of two or more elements participate in alloy formation. At their

interaction can arise following component: liquid solutions, solid solutions, chemical compounds, intermediate phases and mechanical mixtures. Overwhelming number of metals unrestrictedly dissolve in each other in liquid state. Solid solution - single-phase structure with a crystal lattice formed by atoms of alloy components. Component, which crystal lattice is saved, called as a solvent. Component, that does not save own crystal lattice, but returns the atoms in a solvent lattice, is called as miscible. The main types of solid solutions: substitutional solid solutions (SSS) and interstitial solid solution (ISS). SSS can be of restricted and unlimited oxygen solubility. SSS are formed by replacement of solvent crystal lattice atoms with the atoms of dissolved component (fig. 1.2, a, b). ISS are formed by arranging of dissolving component atoms in free interspaces between atoms of solvent crystal lattice (fig. 1.2, c).

Fig. 1.2. Lattice distortion at solid solutions formation: a - atomic radius of dissolving metal is greater than atomic radius of a solvent in SSS; b - atomic radius of dissolving metal is less than atomic radius of a solvent in SSS; c - formation of ISS. Principles of crystallization Crystallization is a metal and alloy conversion from liquid to solid state. This transformation is accompanied by formation of certain crystal lattice. The beginning of crystallization is accompanied by occurring of nucleus center in a melt. The further increase of crystals quantity and their sizes begins from these centers. The crystallization process is quantitatively characterized by nuclei generation rate Vcc (measured in mm-3s-1) and solidification rate Vcg (measured in mm/s) - the fig. 1.3.

Fig. 1.3. Model of crystallization process At cooling of alloy up to chilling point a nuclei generation rate Vcc and solidification rate Vcg grow up. At certain degree of a supercooling they reach maxima, after that reduce to zero. Thus a nuclei generation rate Vcc and the number of nucleus centers grows faster, than solidification rate Vcg (fig. 1.4). The greater the nuclei generation rate and the less the solidification rate, the less is the size of a crystal. In this case the structure of metal will be more fine-grained. The size of metal grain greatly influences on viscosity and toughness of metal. Heating temperature of molten metal, its chemical composition and presence at metal of ectogenic admixtures cause large effect on a grain size.

V VC C Vg C T

Fig. 1.4. Relationship between nuclei generation rate Vcc , solidification rate Vcg and degree of alloy supercooling The equilibrium diagrams It is necessary to know structure of alloy in a stable condition and during heat and cooling for definition of alloys properties and their melting temperatures, for selection of methods and conditions of heat treatment. In this case equilibrium diagrams in

coordinates "temperature - density" of alloy can be defined experimentally. With the help of the thermal analysis can be received the alloy cooling curves in coordinates "temperature of alloy - time of cooling" (fig. 1.5, b). Inflection points and horizontal sections, which characterize critical temperatures of alloys, can be discovered on these curves. Critical points of alloys transformation then must be plotted in coordinates "temperature density" and smoothly connected with one another. There are some techniques of equilibrium diagrams plotting for multicomponent alloys. Let's consider for simplicity two-component systems. The equilibrium diagram of the first kind This diagram describes crystallization of alloys with components, dissolved unlimitedly in each other only in liquid state. Components cannot dissolve in each other and do not form chemical combinations in solid state. During process of crystallization alloy components form mechanical mixture called as eutectic. Examples of such components: lead-stibium, tin-zinc, lead-silver etc. General view of the first kind equilibrium diagram for components A and B is shown in a fig. 1.5, a.

I 1 C A L D A + A 0 + t2 ( A + B ) A C L m L + B B to C

1 2 2

t1

2 B + 3

E ( A + B ) 3

B 1 0 2 0 3 0 4 0 5 0 6 0 7 0 8 0 9 01 0 0

Fig. 1.5. The equilibrium diagram of the first kind (a) with relevant cooling curve (b) The line ACB is called as a liquidus line. It is a geometrical place of points where alloys crystallization begins. The crystals of component A crystallize from a liquid melt L on a line AC. Crystallization of component A finishes on a line ADC. The crystals of component B crystallize from a liquid melt L on a line BC. Crystallization of component B finishes on a line DCE. The line DCE is called as a solidus line. The

eutectic mixture of crystals (A+B) is formed on a line DCE in any point at constant temperature. A point C corresponds to alloy of eutectic composition. In this point the eutectic mixture (A+B) crystallizes only. Alloys with components concentration more to the left of a point C are called as hypoeutectic. Alloys with components concentration relevant to point C are called as eutectic. Alloys with components concentration more to the right of a point C are called as hypereutectic. The amount and composition of phases in alloy is determined by a rule of cuts. This rule can be used only in two-phase area of the diagram. Conode (horizontal line) is carried out up to intersection with liquidus and solidus lines at temperature t1 for alloy of I-concentration in area BCE of diagram. The cut nt1 is taking as 100 %. According to the rule of cuts for definition of the fluid phase amount qlp in percentage it is necessary: to relate a cut mt1, opposite to a liquidus line, to all length of a cut and multiplicate it on 100%, i.e. qp = mt 1 100% . nt 1

Similarly the solid phase amount qsp can be determined in percentage by the ratio of cuts mn and nt1: q sp = mn 100% . nt 1

The second part of cuts rule consists in following: the projections of conode intersection points with liquidus and solidus lines on concentration axis give necessary values of liquid phases and solid phases densities. The equilibrium diagram of the second kind This diagram describes crystallization of alloys with components, dissolved unlimitedly in each other both in solid and in liquid state. Examples of such alloys: iron - nickel, iron - chrome, copper - nickel. The equilibrium diagram of the second kind is shown in fig. 1.6. Let's consider a crystallization of alloy I. Point C marks the moment of appearing of solid solution crystals in a fluid phase L with density of point 1. Solid solution crystals having density of point 2 appear at temperature t. In a point D solid solution

crystals of point E density will conform to the density of alloy I. Thus, during crystallization from a fluid phase the crystals of variable composition may originate.

I t o, C C 3 t 2 A D 1 L B

E 0 1 0 2 0 3 0 4 0 5 0 B , % 6 0 7 0 8 0 9 0 1 0 0

Fig. 1.6. The equilibrium diagram of the second kind. Line ACB - a liquidus, line ABD - a solidus. The equilibrium diagram of the third kind This diagram describes crystallization of alloys with components, dissolved unlimitedly in each other in liquid state. In a solid state they are dissolved limitedly and form a eutectic at crystallization. Figure 1.7 illustrates the equilibrium diagram of the second kind. In this diagram the pure components A and B cant crystallize. Solid solution of component A is called . Solid solution of component B is called . Line DCE shows the moment when mechanical mixture of solid solutions crystals is formed during crystallization of fluid phase with point C density. As solubility B in A can vary, line DK reflects temperature dependence of abundant crystals extraction. II - phase enriched with a component B.

A t o , C L + C D 1 2 I

B L + E

+1 1 K 0 1 0 2 0

+ ( + )

+ ( + ) 3 F 8 0 9 0 1 0 0

3 0 4 0

5 0 6 0 B , %

7 0

Fig. 1.7. The equilibrium diagram of the third kind. Line ACB - a liquidus, line ADCEB- a solidus. DCE- a line of eutectic transformation. DK- a line of a limited solubility of component B in component A. EF- a line of a marginal solubility of component A in a component B. The equilibrium diagram of the fourth kind The equilibrium diagram of the fourth kind characterizes alloys, which components A and B can resolve unlimitedly in each other in liquid state. Those components are insoluble in a solid state and form steady chemical combinations. The equilibrium diagram of the fourth kind is shown in a fig. 1.8. The line CE in a fig. 1.8 refers to chemical compound AnBm. A point C corresponds to melting point of chemical compound AnBm. The diagram has 2 eutectic points D and D . The constant melting point and fixed components ratio are typical to chemical compound AnBm.

t o,

A n Bm C D

1 0 0 %

1 0 0 %

Fig. 1.8. The equilibrium diagram of the fourth kind The diagram composition of property The analysis of the equilibrium diagrams allows studying dependence of alloys properties from their structure. N.S. Kurnakov designed the method of the diagram composition of property ploting. On these diagrams on a horizontal the composition of alloy, and on verticals - amount of components A and B in alloys varies. With the help of these diagrams the alloys for particular purpose are selected. For example, the alloys with large electrical resistance belong to solid solutions. The alloys for a casting should be selected among eutectic alloys. The alloys of high hardness should be selected among alloys forming chemical compounds.

Das könnte Ihnen auch gefallen

- Mce 203. Phase Equilibrium.Dokument7 SeitenMce 203. Phase Equilibrium.samuelodeyemi3000Noch keine Bewertungen

- FL&O Section 10Dokument24 SeitenFL&O Section 10Muhammad FaizNoch keine Bewertungen

- Terminology For Mechanical PropertiesDokument75 SeitenTerminology For Mechanical PropertiesibrahimNoch keine Bewertungen

- Lesson 5 PDFDokument32 SeitenLesson 5 PDFMajak MarialNoch keine Bewertungen

- Unit - III: Me432P: Material EnggDokument37 SeitenUnit - III: Me432P: Material Engghans groupNoch keine Bewertungen

- Metallurgical EngineeringDokument49 SeitenMetallurgical EngineeringMatab ThamerNoch keine Bewertungen

- Met 01 Metals Structure - Steel MakingDokument22 SeitenMet 01 Metals Structure - Steel MakingRaghu vamshiNoch keine Bewertungen

- CHE 414 PPTDokument21 SeitenCHE 414 PPTLooking forwardNoch keine Bewertungen

- Assignment WEEK 5 SolutionsDokument5 SeitenAssignment WEEK 5 SolutionsPeeka Prabhakara RaoNoch keine Bewertungen

- Cooling Curve Diagrams ExplainedDokument6 SeitenCooling Curve Diagrams Explainedحسين كاظم ياسينNoch keine Bewertungen

- Material Engineering QUESTION BANKDokument13 SeitenMaterial Engineering QUESTION BANKFUNTUBENoch keine Bewertungen

- Solidification of Single-Phase Alloys - 2007Dokument12 SeitenSolidification of Single-Phase Alloys - 2007pkn_pnt9950Noch keine Bewertungen

- 2_5391019718461098174Dokument7 Seiten2_5391019718461098174Motaz TharwatNoch keine Bewertungen

- Alloy Systems and Phase DiagramsDokument11 SeitenAlloy Systems and Phase DiagramsarugeetNoch keine Bewertungen

- Emm HandoutsDokument58 SeitenEmm HandoutsDr.A.Maniram KumarNoch keine Bewertungen

- 2-Alloy SystemsDokument23 Seiten2-Alloy SystemsHussein SaeedNoch keine Bewertungen

- Chapter 2 - TTA - TTT - DiagramsDokument13 SeitenChapter 2 - TTA - TTT - DiagramsPrasad Mhatre100% (1)

- Interstitial Solid Solution L.C. H.L.Dokument14 SeitenInterstitial Solid Solution L.C. H.L.ombuilder92Noch keine Bewertungen

- Question BankDokument4 SeitenQuestion BankParameswara RajaNoch keine Bewertungen

- Chapter 9 ReportDokument16 SeitenChapter 9 ReportG. Dancer GhNoch keine Bewertungen

- Binary Alloy Phase DiagramsDokument12 SeitenBinary Alloy Phase Diagramseeng.ali651550% (2)

- Materials Phase DiagramsDokument23 SeitenMaterials Phase DiagramsKandasamy VenkatachalamNoch keine Bewertungen

- Structure of Engineering MaterialsDokument12 SeitenStructure of Engineering Materialsjust_killing_pplNoch keine Bewertungen

- IPM Note CompressedDokument59 SeitenIPM Note CompressedNouhaila HajjoumNoch keine Bewertungen

- Phase Diagram ExDokument23 SeitenPhase Diagram ExTey KaijingNoch keine Bewertungen

- Slides - 4Dokument55 SeitenSlides - 4Rahul PandeyNoch keine Bewertungen

- Unit-2: Phase DiagramDokument37 SeitenUnit-2: Phase DiagramPrasad Govind KumbharNoch keine Bewertungen

- EM Five Units Notes PDFDokument85 SeitenEM Five Units Notes PDFRajesh ChidambaramNoch keine Bewertungen

- Phase DiagramsDokument50 SeitenPhase DiagramsIbrahim MalikNoch keine Bewertungen

- Material Engineering AssignmentDokument60 SeitenMaterial Engineering Assignmentjunaid hassanNoch keine Bewertungen

- Monotectic AlloysDokument8 SeitenMonotectic Alloysandrea usugaNoch keine Bewertungen

- Biomaterials II Lec 5Dokument13 SeitenBiomaterials II Lec 5m9trdk92ksNoch keine Bewertungen

- Actividad Fundametal 2Dokument10 SeitenActividad Fundametal 2Altsuki SKNoch keine Bewertungen

- Mechanical Properties 4Dokument12 SeitenMechanical Properties 4FrancisNoch keine Bewertungen

- Point Defects and Imperfections in SolidsDokument46 SeitenPoint Defects and Imperfections in SolidsJesse De LeonNoch keine Bewertungen

- 9A03301 Materials Science and EngineeringDokument4 Seiten9A03301 Materials Science and EngineeringsivabharathamurthyNoch keine Bewertungen

- Lecture2-Structure of Materials & Influence On PropertiesDokument50 SeitenLecture2-Structure of Materials & Influence On PropertiesKamal SurenNoch keine Bewertungen

- Crystal Imperfection CH 4Dokument44 SeitenCrystal Imperfection CH 4anapguerraNoch keine Bewertungen

- Engineering Metallurgy NotesDokument89 SeitenEngineering Metallurgy NotesYuvaraja Yuva100% (1)

- Phase Diagrams - Equilibrium Microstructural Development: 38 WT % PBDokument45 SeitenPhase Diagrams - Equilibrium Microstructural Development: 38 WT % PBpetember100% (1)

- Capili Jefferson 9Dokument13 SeitenCapili Jefferson 9Christian Al EncarnacionNoch keine Bewertungen

- Eng Mat Chapter 4Dokument126 SeitenEng Mat Chapter 4VC Chua Yee LeongNoch keine Bewertungen

- Edge Dislocation Means That One of The Atoms in A Unit Cell Is Absent or Replaced or Added As An Extra ThatDokument4 SeitenEdge Dislocation Means That One of The Atoms in A Unit Cell Is Absent or Replaced or Added As An Extra ThatAshok PradhanNoch keine Bewertungen

- Basic Metallurgy - Chap2Dokument117 SeitenBasic Metallurgy - Chap2AhmedNoch keine Bewertungen

- Phase Diagrams & Heat Treatment of Carbon SteelDokument84 SeitenPhase Diagrams & Heat Treatment of Carbon SteelTanmay DuttaNoch keine Bewertungen

- PhaseDokument6 SeitenPhasefarooq_bagbanNoch keine Bewertungen

- MM Question BankDokument22 SeitenMM Question BankDr.A.Maniram KumarNoch keine Bewertungen

- The Iron Iron Carbide Phase Diagram A Practical GuDokument6 SeitenThe Iron Iron Carbide Phase Diagram A Practical GuMuhammad Irfan SalahuddinNoch keine Bewertungen

- Two Marks With AnswersDokument19 SeitenTwo Marks With AnswersNallappan Rajj ANoch keine Bewertungen

- Ch-27.1 Basic Concepts On Structure of SolidsDokument45 SeitenCh-27.1 Basic Concepts On Structure of SolidsdSGDASUDNoch keine Bewertungen

- Solidification, Phase Diagrams and Phase TransformationDokument35 SeitenSolidification, Phase Diagrams and Phase TransformationkrishnasaiNoch keine Bewertungen

- Handbook No.1Dokument125 SeitenHandbook No.1Dhinakar AnnaduraiNoch keine Bewertungen

- Chem 1Dokument23 SeitenChem 1Adi SoNoch keine Bewertungen

- Note CHP 2-Material Science 281 Uitm Em110Dokument74 SeitenNote CHP 2-Material Science 281 Uitm Em110bino_rye100% (1)

- Phase DiagramsDokument80 SeitenPhase DiagramsWilliams AkandiNoch keine Bewertungen

- Infrared Spectroscopy of Triatomics for Space ObservationVon EverandInfrared Spectroscopy of Triatomics for Space ObservationNoch keine Bewertungen

- Introduction. External Forces Acting On An AircraftDokument9 SeitenIntroduction. External Forces Acting On An AircraftMelvin PhilipNoch keine Bewertungen

- Section 3. Aerodynamics of An AirplaneDokument13 SeitenSection 3. Aerodynamics of An AirplaneJason RossNoch keine Bewertungen

- Mutual Influence of LiftingDokument15 SeitenMutual Influence of LiftingJason RossNoch keine Bewertungen

- Razdel 7 Eng ReviewedDokument24 SeitenRazdel 7 Eng ReviewedJason RossNoch keine Bewertungen

- Landing of An Airplane PDFDokument11 SeitenLanding of An Airplane PDFJason RossNoch keine Bewertungen

- Fuselage Geometrical ParametersDokument10 SeitenFuselage Geometrical ParametersJason RossNoch keine Bewertungen

- Mutual Influence of LiftingDokument15 SeitenMutual Influence of LiftingJason RossNoch keine Bewertungen

- Section 3. Aerodynamics of An AirplaneDokument13 SeitenSection 3. Aerodynamics of An AirplaneJason RossNoch keine Bewertungen

- Aerodynamics of Wings Flow FeaturesDokument10 SeitenAerodynamics of Wings Flow FeaturesJason RossNoch keine Bewertungen

- The Aerodynamic Characteristics of Wings in A Flow of Incompressible FluidDokument17 SeitenThe Aerodynamic Characteristics of Wings in A Flow of Incompressible FluidJason RossNoch keine Bewertungen

- Aerodynamics of Wings Flow FeaturesDokument10 SeitenAerodynamics of Wings Flow FeaturesJason RossNoch keine Bewertungen

- Chapter1 Properties of FluidsDokument17 SeitenChapter1 Properties of FluidsХардип ЗинтаNoch keine Bewertungen

- Multiple Pipe Flow SystemsDokument10 SeitenMultiple Pipe Flow SystemsJason Ross0% (1)

- The Polar DiagramDokument7 SeitenThe Polar DiagramJason RossNoch keine Bewertungen

- Take-Off and Landing Characteristics of AirplanesDokument13 SeitenTake-Off and Landing Characteristics of AirplanesJason RossNoch keine Bewertungen

- Equations of Airplane Motion in Trajectory Coordinate System in Particular Cases. Aerodynamic Calculation of An Aircraft. Zhukovsky Method of ThrustsDokument10 SeitenEquations of Airplane Motion in Trajectory Coordinate System in Particular Cases. Aerodynamic Calculation of An Aircraft. Zhukovsky Method of ThrustsJason RossNoch keine Bewertungen

- Theme 1Dokument10 SeitenTheme 1Jason RossNoch keine Bewertungen

- Airplane Descent. GlidingDokument7 SeitenAirplane Descent. GlidingJason RossNoch keine Bewertungen

- Theme 1Dokument10 SeitenTheme 1Jason RossNoch keine Bewertungen

- Turbomachinery 1Dokument19 SeitenTurbomachinery 1Jason RossNoch keine Bewertungen

- LathesDokument59 SeitenLathesSami ZamaNoch keine Bewertungen

- Landing of An Airplane PDFDokument11 SeitenLanding of An Airplane PDFJason RossNoch keine Bewertungen

- Chapter2 Kinematics of FluidsDokument43 SeitenChapter2 Kinematics of FluidsJason RossNoch keine Bewertungen

- Screw NutDokument37 SeitenScrew NutJason RossNoch keine Bewertungen

- Theme 1Dokument10 SeitenTheme 1Jason RossNoch keine Bewertungen

- Coordinate Systems Used in Flight DynamicsDokument9 SeitenCoordinate Systems Used in Flight DynamicsJason RossNoch keine Bewertungen

- Theme 15 PDFDokument17 SeitenTheme 15 PDFJason RossNoch keine Bewertungen

- Aerodynamics of Lifting SurfacesDokument8 SeitenAerodynamics of Lifting SurfacesJason RossNoch keine Bewertungen

- Theme 1Dokument10 SeitenTheme 1Jason RossNoch keine Bewertungen

- Introduction. External Forces Acting On An AircraftDokument9 SeitenIntroduction. External Forces Acting On An AircraftMelvin PhilipNoch keine Bewertungen