Beruflich Dokumente

Kultur Dokumente

Projmat For 2009-2010 v2

Hochgeladen von

Mohammed ZiadOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Projmat For 2009-2010 v2

Hochgeladen von

Mohammed ZiadCopyright:

Verfügbare Formate

Engineering World Health Senior Design Projects That Matter

2009/10

New for 2009/2010: Field Testing: This is a project where we have a design for a working prototype, but we need a team to reproduce the bench tests, potentially fix any problems, and ideally test the device in the developing world. If the team is not able to travel to the developing world, it may be possible to generate useful results from bench tests in lab (i.e. testing the device under different conditions, using the device to take measurements from multiple people, etc.).

Engineering World Health is an extraordinary fusion of engineers, scientists and physicians who donate their time and talents to positively impact the quality of healthcare in disadvantaged areas around the world. Our vision is embodied in the Cycle of Caring, which begins with donated medical equipment and parts and relies on professional expertise to recycle and restore the technology for reuse. We then deliver and install the refurbished machinery for a community in need. Our commitment does not end there. Unlike any other organization in the world, volunteer engineers and students return to that same equipment year after year to ensure that it remains in good working order. Our ultimate goal is to train local engineers and technicians to maintain their own equipment. However, this ultimate goal is constantly frustrated by the lack of adequate testing equipment. Even where the staff is adequately trained, they lack testing equipment which Biomedical Engineers in the developed world take for granted. The objective of these projects is to design testing equipment that can be provided as kits and built by engineers in the developing world. Individuals, groups of students, senior design teams, BMES or IEEE chapters or just a bunch of friends can submit designs. Designs are generally accepted in December or January, but can be submitted at any time. If your design meets the design criteria, you will receive up to $150 to build a prototype. If your prototype works, it may be selected to be produced. If you wish, in the summer following the production of your design, you, or your team, can travel to the developing world to distribute the product by participating in the EWH summer program. EWH chapters may also be interested in participating in the EWH

Design Competition. Winning chapters will receive cash prizes, and participating design teams will be invited to present their work at an international conference. Check out the website (www.ewh.org) or email info@ewh.org for more information.

In order to participate, you must meet several criteria: A) Your design must be documented, including 1) a description of the theory of the device (approximately two pages) including the specific specifications (accuracy and such) that your device will meet, 2) a detailed parts list, including source, quantity, part number, price (in quantities of 1 and 5) and anything else that would be required for one to order the parts. Your design can be kit-able (requiring no custom parts). Some projects require kit-ability. 3) engineering drawings including construction drawings for the enclosure, if there is one, top and side views of the completed item (multiple if required), 4) a requested amount (up to $150) for the prototype with the detailed budget to support the request, and 5) a cover letter stating your team members (name, address, telephone and e-mail for each) and to whom the prototype check should be made and sent. Additional documentation may be provided, if you deem it necessary. Your cover letter must state if you are designing a locally produced item (all parts on the parts list are from a developing world country of origin) or a kit (some parts must be ordered singly from a US distributor and shipped to the developing world) or a typical product (all components purchased and assembled in the US and then shipped to the developing world). Preference is often given to locally produced items. B) The cashing of the payment you receive constitutes a license to Engineering World Health to freely produce the final design non-exclusively, for donation to hospitals anywhere in the world in kit, documentation or final form. Engineering World Health is also licensed to publish all technical specifications on its web site for general use. C) All submissions must be made electronically in Word format. When your design is complete, you will also need the following documentation for the design to enter production: A) Updated documentation of anything that has changed. Be sure to update the kit/locally produced status of your design. B) New diagrams which include: 1) detailed construction instructions. If a kit, instructions for assembly of the kit of parts in the developing world with no special or custom parts. No special tools must be required. Assume a high school student or person in the developing world could construct your device from, typically, a sequence of photographs. For local construction, use mostly pictures of each stage of construction. For traditional products, assembly diagrams are usually sufficient. 2) testing instructions so that the builder can confirm that it is working. 3) operating instructions (must be in pictorial form, not words). C) Calibration data and testing data to show that your design works.

We prefer that you write us before beginning the design (info@ewh.org). That way, we can give you any updates or clarifications on the design criteria. If you decide to send a letter ahead of time, please include your projected date for the submission of the design and documentation and your mentors name and title. However, it is not necessary to write ahead of time. Any design which meets the published specifications and the criteria set out above receives the $150 to construct the prototype. If the criteria are met on your first submission, you will typically receive the $150 within four weeks or less. If you have written ahead of time, you may be able to receive the $150 sooner. We may select your design if 1) it the final prototype testing data shows that it meets the specifications, and if 2) its performance exceeds (lower cost, more features, higher reliability, etc.) any item which we are currently producing in that category and any other designs submitted that year of the same type. If you write ahead of time, we can inform you of what other teams have selected the same item, and what items we are currently producing in the selected category. Dont hesitate to write an e-mail to info@ewh.org if you have any questions. Your efforts can have a tremendous impact on the developing world.

Projects: These items have been requested by personnel working with Engineering World Health in developing world hospitals. These project specifications are intended to be used as guidelines. You should design your device to deliver the maximum possible performance while still staying within the cost specification. Some deviation from the cost specification may be tolerable if the benefits in performance warrant. Where superior performance specifications are given, they need not be followed for the design to be acceptable. Be sure to note if the design is for a kit, local production or traditional production. We cannot accept designs which are not on this list. However, we can accept suggestions for items to be added to the list. Feel free to suggest a new design project. If the project is accepted, it will be added to the list for everyone to see, and you will be able to submit your design as well. Write an e-mail describing your idea in one paragraph to info@ewh.org to find out if it is a project that we can support. In the following paragraphs, all costs are for parts only (no labor costs) and include all the costs of production, even costs that you may not encounter in the prototype, like the box or printed circuit boards. You can assume that the parts are purchased in the developing world or the US, as appropriate.

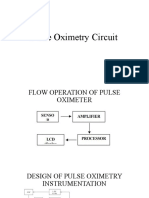

FIELD TESTING: Non-electronic Oxygen Concentration Test Engineers are often faced with oxygen concentrators of unknown quality. A team has now designed a device that allows an engineer in the developing world to quickly determine if the device is producing concentrated oxygen without using electricity (batteries, etc). It uses a candle, match, water, soap, bubble gum (or clay) and a calibration table that depends on a found bottle size. It claims to be accurate to within a few percent. There has been secondary confirmation that the device operates as designed. There have been some preliminary field trials. The early field tests are promising. A team is needed that can take this project and thoroughly field and bench test its operation under as wide a range of environmental conditions and expected uses as possible. Pulse Oximeter for Heart Rate The pulse oximeter is one of the most common medical instruments, and is the most frequently requested piece of medical equipment in our partner hospitals in the developing world. Prices have dropped for this product to the point where nearly every patient in a US hospital will be connected to such a device. However, in the developing world, pulse oximeters are still difficult to find and those that are found often require disposable probes that are not available. The most important function is to display heart rate. A team has developed a simple pulse ox device capable of reporting that heart rate. There has been no secondary confirmation that the device works. The design does not have a housing or instructions. No manufacturing stream has been suggested (kit or traditional or local). No field tests have been attempted. PIC programming is a necessary skill to replicate the prior work on this project. Universal Surgery Light Bulb Replacement Approximately 80% of the surgery lights that are found unused by Engineering World Health are sidelined by the lack of light bulbs. TWhile the replacement is simple, the bulbs are expensive, not available in many developing world countries, and in some cases not available anywhere due to the age of the surgery lamp. A team has developed an LED, universal replacement bulb system for multi-bulb surgery lamps. Hospitals with broken bulbs attach this replacement to the bulb stem and reinsert the stem+LED+circuit into the former housing. Bench testing indicates that the light output is sufficient. A team needs to thoroughly test the device under as wide a range of environmental conditions as possible. No field testing has been conducted, especially for compatibility with as wide a range of multi-bulb surgery lamps as possible.

Spectrophotometer Spectrophotometers provide a light source with a given wavelength for clinical laboratory tests. The expensive ones use gratings and filters to insure the proper wavelength. They are heavy and cannot be jarred. In third world countries there is a lack of power or an improper power source. Yet, clinical laboratory is one of the most requested areas of medical instrumentation for the developing world. A volunteer has developed a spectrophotometer that uses three colored LEDs in one convenient package that provides blue, red, and green wavelengths. They have sharp cutoffs of 470-nm, 574-nm and 636-nm respectively. These three wavelengths are sufficient for measuring hundreds of different compounds. The photo detector used is a silicon blue enhanced photodiode photoconductive type. An analog to digital 8-bit microprocessor (PIC) uses a lookup table to convert the percent transmission to optical density which in turn can be converted to concentration. No secondary testing has been done. Some field testing has been done on the original prototype and it is promising. We are looking for a team to build the device and provide procedures for the most commonly requested and possible clinical laboratory tests, considering that reagents must be obtainable in the developing world. Pulse Ox Phantom Pulse oximeters are common pieces of medical equipment. However, testing them can be difficult, as healthy people always read about 99% Spo2. A volunteer has developed an electronic phantom that provides a low heart rate and low Sp02 reading. However, no secondary confirmation has been done. No field testing has been completed. This is an excellent project for those with electronics background and access to a pulse ox, either purchased or used (only about $100 to get one on-line). Semi-Permanent ECG Pads Disposable, or single-use, ECG pads (electrodes) have replaced permanent ECG pads in the US for all cardiac monitoring and diagnosis. However, they are relatively expensive and difficult to find in the developing world. During the summer of 2008, one team in Tanzania had to drive to Nairobi, Kenya to purchase ECG pads! The majority of patients in the developing world can be measured nonambulatory. This greatly simplifies the design of the electrode, as an interface sponge is not necessary. A previous effort (Samaddar, Mahapatra, Ray, Indian J Anaesth, 2002 46(6), 437-440) has developed a potential alternative for nonambulatory patients in India. This effort was refined by an EWH team to be

usable with materials commonly found in Africa. There has been some field testing with very promising results. However, the early work suggests that a gel may be required. Saline evaporates too quickly. Preliminary work with common substances has been completed. The team needs to test this with the widest range of people and environmental conditions possible.

LEGACY PROJECTS: Defibrillator Tester EWH has a defibrillator tester product. However, it is designed to be used with monophasic defibrillators. Most hospitals defibrillators, even in the developing world, are now biphasic defibrillators. We wish to have a defibrillator tester that meets at least the performance specifications of the current device (providing a go/no-go test for a non-automatic, transthoracic defibrillator) but will be able to handle both biphasic and monophasic devices well. We would prefer a device that exceeds the performance of the current device, by for example, providing current, voltage or energy readings and indicating waveform shape. The device should be kitable (therefore requiring only simple soldering skills), but could use a PIC processor, where EWH would burn the PIC before sending out the kit. Teams will have access to the current design and the design of a general purpose PIC platform. It is ideal if the device takes its power from the defibrillator (by, for example, requiring two shocks to be delivered at one strength), however, battery powered devices are acceptable. Temperature Monitor Control Alarm A common set of problems seen in the developing world is measuring temperature, alarming when the temperature exceeds some threshold and turning on or off a device when the temperature reaches a threshold. This is most pressing when primitive incubators overheat, killing their occupants, or when primitive baby warmers fail to provide enough heat (perhaps out of fear of overheating), also killing their occupants. In fact, all of these functions should be provided by a single device, a temperature control system. A previous team has produced a design for a temperature control system. However, the design is not quite complete (it does not include the control of an outside device) and did not meet the battery specs (it consumed too much power when sleeping). This is potentially a very high impact project, as the low-cost but versatile sensor/processing/display platform can be used for a wide variety of designs for the developing world.

Non-Legacy PROJECTS: Non-electronic BP Assist Device While many philanthropic studies focus on high-profile killers such as HIV and malaria, the primary cause of death throughout the developing world still stems from issues related to the heart. The WHO has begun to seriously consider the growing number of hypertensive patients throughout the world, and as a result we are focusing specifically on improving the diagnostic capabilities of hospitals throughout developing countries. This project will develop a low cost, easy-to-use device to assist a minimallytrained person in taking the blood pressure using a sphygnomanometer. The device should be a mechanical adjunct to the existing device (clamp around the manometer tubing, for example) that amplifies the AC (or oscillatory) pressure signal. With the AC signal now visable, the oscillatory BP method is possible with a standard sphygmomanometer. This eliminates the need to be trained to identify Korotkoff sounds (the oscillatory use of a sphygmomanometer does not require a stethoscope). The user should be able to identify at least systolic pressure without training (only picture instructions). Ideally the user should be able to identify diastolic pressure with minimal training. Relevant additional specifications Only available for traditional production Cost: <$5 in quantities of 2000 or more Liquid Medication Delivery System The number of children infected by HIV continues to grow. There may be as many as 2.1 million children worldwide infected with HIV. Over the past 15 years, several options have become available for treating children and preventing the transmission of HIV from mother to child, including zidovudine (AZT), didanosine (ddl) and nevirapine. However, infants are unable to swallow pills, and so the drugs are donated to developing world pharmacies in 20-200 ml bottles. The problem is that a single, small dose of 0.5 ml must be provided to a mother so that when she gives birth, some number of months later and many miles away, she can deliver the dose to her newborn. In poor countries, liquid medications are now given in plastic bags, open syringes or recycled plastic bottles, all of which lead to medication spoilage and loss. For the poor pharmacy, extracting the correct dose from the bottle without contaminating the bottle and presenting it to the mother in a form she can transport home and use safely and effectively has presented serious challenges.

A team has now developed a simple package that can receive a small dose of a liquid medication. Now what is needed is a bottle topper capable of resealing the bottle and measuring the correct dose and delivering it to the packaging. Special care should be made to test the device with liquid medicine, as it is considerably more viscous than water. Relevant additional specifications Only available for traditional production Cost: <$2 in quantities of 2000 or more Universal ECG Connecting Cable Because most US hospitals replaced all of their bedside monitors every few years over the last decade, most developing world hospitals now have bedside monitoring capabilities. However, few of them are in use. The most common two problems are the lack of ECG pads (see field test problem above) and the lack of a cable to connect the machine to the ECG pads. ECG machines lack a cable because some donors do not know that this is required, or assume that the manufacturer or provider of the ECG pads can provide a new one, as they do in the US. This project is to develop a universal cable so that bedside monitoring machines, including those that are no longer manufactured or were manufactured by companies that no longer exist, can be used in the developing world. The universal cable would have non-connector, male terminators (like posts). These color-coded, male terminators would then be plugged into the female connector of the donated ECG machine in a prescribed fashion. The project team must design the cable and identify a scheme whereby the colorcode can be communicated. Ideally the design team would also devise a method for determining the appropriate code for a previously undocumented ECG machine in a developing world setting. Relevant additional specifications Ideal if manufacturable from locally available materials Cost: <$50 in quantities of 1

Research Projects Non-Invasive Blood Pressure Machine Failure Modes Non-invasive blood pressure machines are now available for about $25 at some drug stores and on-line shops. The expectation is that they would be used once or twice per day at home (about 300-600 cycles per year). These devices will last many years when used according to expectations. However, when these are donated to the developing world, they are used 24 hours per day, seven days per week (about 5000-10,000 cycles per day). What is unknown is why they fail. In this project, we anticipate the team will purchase several devices, modify them for continuous use, and then document their failure modes. Medical Waste Incineration This plea came to our attention: It seems that our hospital in Congo is forever plagued with waste, bandages, and other things that need to be incinerated. But most of it just gets buried in a hole and then we find children and others climbing down into the hole to get stuff which is usually quite contaminated. The problem of medical waste incineration plagues hospital far beyond Africa. We find this problem in hospitals throughout the world. The project here is to research all the work that has been done on medical waste incinerators for the developing world. There are several plans available. Also, there may be some products that can be adapted. The successful project will also document the engineering constraints of the problem, including performance and cost specifications.

Frequently Asked Questions The device has to be very simple to use, right? No. Clinical engineers and doctors in the developing world are just as capable as you and I to learn how to use a device. If you can figure it out, they can too. The device has to be really quick to use, right? No. The concept of time is different in the developing world. It is quite an acceptable design to require a significant amount of man-hours (minutes?) to operate your device. The device has to be maintenance free, right? Pretty much. If any maintenance is required, it must be something that itself does not require a specialized tool or part. If your design requires maintenance, you probably should write to us first (info@ewh.org). What environmental conditions must the device meet? Your design must not be destroyed even with extended exposure to temperatures down to -10 degrees centigrade and temperatures up to 40 degrees centigrade. It should be useable in environmental temperatures ranging from 20 degrees centigrade to 40 degrees centigrade. My design doesnt meet all the specifications, but it exceeds some. Should I send it in? If your design doesnt meet all the specifications, you are not guaranteed to receive the $150. However, you may be able to make an argument that the added performance in one area is worth the missed specification in another. Make sure to include a cover letter of one page or less which describes your argument. How do I know what is locally available for production? You must contact a clinical engineer and talk with them about this. There is no substitute for a conversation with the clinical engineer that will use your design.

I have just one custom part. Surely that wont affect your consideration of my design. Assuming the question is for a project that is designated for local construction, yes it will! If you have one custom component, and that component cannot be manufactured in the developing world in single quantities (and those costs are included in your cost estimates), then your design will be rejected. What if a part is not locally available? If you really need a component that you cant find locally (a capacitor or fuse, or a special plastic), then you should consider making your design a kit, not local construction. Many of the projects dont specify and you can choose. What if the component requires programming or burning? Most PICS and FPLA and such devices require burning or programming. Most clinical engineers in the developing world do not have access to a computer or a programmer. Therefore, your project requires a special tool that is not available in the developing world. It is a conventional design and could perhaps be a kit, but it could not be locally produced. The project I picked doesnt specify kit, local or conventional. What do I do? You have the choice. We prefer local construction, then kits and finally conventional construction. If we receive multiple submissions, well choose the preferred design.

Das könnte Ihnen auch gefallen

- 09-10 EWH Projects That MatterDokument13 Seiten09-10 EWH Projects That MatteroiboriowoNoch keine Bewertungen

- 2013 EWH Projects That MatterDokument12 Seiten2013 EWH Projects That MatterVer BautistaNoch keine Bewertungen

- Index: 2. Objectives of The Project 3. Problem Statement 4. Deliverables 5. Hardware/ Software RequirementsDokument11 SeitenIndex: 2. Objectives of The Project 3. Problem Statement 4. Deliverables 5. Hardware/ Software RequirementsAli UddinNoch keine Bewertungen

- Uta Thesis Mechanical CheckDokument4 SeitenUta Thesis Mechanical Checkkimberlybergermurrieta100% (2)

- Research Paper EeeDokument6 SeitenResearch Paper Eeeafedsxmai100% (1)

- Viability of The Proposed SolutionDokument3 SeitenViability of The Proposed Solutionapi-242778836Noch keine Bewertungen

- 4 3 3 Reverse Engineering Design BriefDokument6 Seiten4 3 3 Reverse Engineering Design Briefapi-2720552020% (1)

- Research Papers On Ieee StandardDokument5 SeitenResearch Papers On Ieee Standardtwfmadsif100% (1)

- Research Paper Download From IeeeDokument5 SeitenResearch Paper Download From Ieeefys374dr100% (1)

- Electronics Design ProcessDokument14 SeitenElectronics Design Processvenkata naga YasawiniNoch keine Bewertungen

- Thesis Ece ProjectsDokument4 SeitenThesis Ece ProjectsBuyCollegePapersOnlineMilwaukee100% (2)

- Ieee Research Papers For FreeDokument7 SeitenIeee Research Papers For Freecammtpw6100% (1)

- 2 4 3 Pringles Experiment FolioDokument7 Seiten2 4 3 Pringles Experiment Folioapi-308013039Noch keine Bewertungen

- Unsw Submit ThesisDokument4 SeitenUnsw Submit Thesishollyschulzgilbert100% (2)

- Lifting Platform Design BriefDokument20 SeitenLifting Platform Design Brieftony makNoch keine Bewertungen

- Test Bank For Modern Dental Assisting 10th Edition BirdDokument13 SeitenTest Bank For Modern Dental Assisting 10th Edition Birdalveusvotingy4ims100% (27)

- Electronics Thesis PrototypeDokument5 SeitenElectronics Thesis Prototypeleslieleebatonrouge100% (2)

- MIAE 380-Project GuidelinesDokument2 SeitenMIAE 380-Project GuidelinesDion BrownNoch keine Bewertungen

- Uq Mechanical Engineering ThesisDokument7 SeitenUq Mechanical Engineering Thesisheidibrowneverett100% (2)

- Academic Proposal Template - Draft 1.2Dokument4 SeitenAcademic Proposal Template - Draft 1.2Nancy NgNoch keine Bewertungen

- Hku Thesis SubmitDokument7 SeitenHku Thesis Submitbk1hxs86100% (1)

- Main Project-6 OctDokument13 SeitenMain Project-6 OctrathanyaNoch keine Bewertungen

- The Engineering Design ProcessDokument5 SeitenThe Engineering Design ProcessfendytoiliNoch keine Bewertungen

- INDU 440 Course Outline 2017Dokument3 SeitenINDU 440 Course Outline 2017JohnNoch keine Bewertungen

- MECH 3064 Design Project Guideline Course ProjectsDokument7 SeitenMECH 3064 Design Project Guideline Course ProjectsMozammeer DeenmahomedNoch keine Bewertungen

- Project Selection and Needs IdentificationDokument12 SeitenProject Selection and Needs IdentificationchinchucbNoch keine Bewertungen

- Project Selection and Needs IdentificationDokument12 SeitenProject Selection and Needs IdentificationDeepankumar AthiyannanNoch keine Bewertungen

- Engineering Design Process Explained in 40 CharactersDokument4 SeitenEngineering Design Process Explained in 40 CharactersMurphy JoeNoch keine Bewertungen

- 7cc003 Assignment DetailsDokument3 Seiten7cc003 Assignment Detailsgeek 6489Noch keine Bewertungen

- 3155 Project DescriptionDokument6 Seiten3155 Project Descriptionअजय ढकालNoch keine Bewertungen

- Technical Documentation in Software DevelopmentDokument37 SeitenTechnical Documentation in Software DevelopmentmleighravenNoch keine Bewertungen

- Year 4 Design Brief TemplateDokument7 SeitenYear 4 Design Brief Templateapi-491920750Noch keine Bewertungen

- Guide Questions For The Mock Oral ProposalDokument2 SeitenGuide Questions For The Mock Oral Proposalhadukenryu9761Noch keine Bewertungen

- Assignment 4: Master of TechnologyDokument5 SeitenAssignment 4: Master of TechnologyHrithik DalalNoch keine Bewertungen

- 2 4 3 Pringles Experiment FolioDokument8 Seiten2 4 3 Pringles Experiment Folioapi-308013008Noch keine Bewertungen

- 4 1 3 Rube Goldberg Design Brief FolioDokument9 Seiten4 1 3 Rube Goldberg Design Brief Folioapi-308013553Noch keine Bewertungen

- Engineering Desgin Process Pringle ProjectDokument7 SeitenEngineering Desgin Process Pringle Projectapi-310020492Noch keine Bewertungen

- Engineering Project Research PlanDokument2 SeitenEngineering Project Research PlanFaizan TahirNoch keine Bewertungen

- f1 1 Design ViablityDokument3 Seitenf1 1 Design Viablityapi-301407444Noch keine Bewertungen

- Thesis B UnswDokument8 SeitenThesis B Unswbsk561ek100% (2)

- New Product Development Process: Source 1Dokument3 SeitenNew Product Development Process: Source 1Nimal Jose KureekattilNoch keine Bewertungen

- Bu Thesis GuidelinesDokument4 SeitenBu Thesis GuidelinesSarah Pollard100% (3)

- MKTG2505 Group Project Pitch GuideDokument5 SeitenMKTG2505 Group Project Pitch GuideharkiesvfNoch keine Bewertungen

- Research Paper in Computer Science TopicsDokument4 SeitenResearch Paper in Computer Science Topicsh015trrr100% (1)

- Design of Technology - NotesDokument7 SeitenDesign of Technology - Notesfreesia.09876Noch keine Bewertungen

- Project SpecificationDokument8 SeitenProject SpecificationNa DeemNoch keine Bewertungen

- Research Papers in Engineering DesignDokument6 SeitenResearch Papers in Engineering Designfvdh47rr100% (1)

- 2 4 3 Pringles Experiment FolioDokument6 Seiten2 4 3 Pringles Experiment Folioapi-308013378Noch keine Bewertungen

- FinalDokument26 SeitenFinalapi-324383351Noch keine Bewertungen

- Thesis Engineering TopicsDokument8 SeitenThesis Engineering Topicsbk4p4b1c100% (2)

- Design and Fabrication of Ramjet Using CFDDokument9 SeitenDesign and Fabrication of Ramjet Using CFDHusein BhinderwalaNoch keine Bewertungen

- Coursework Assignment - Individual - 1CWK50: LinksDokument7 SeitenCoursework Assignment - Individual - 1CWK50: Linksameer hamzaNoch keine Bewertungen

- Product Design Thesis PDFDokument8 SeitenProduct Design Thesis PDFDaphne Smith100% (2)

- KLU Design Thinking For Innovation Project Title: Work in Progress Submission 2Dokument11 SeitenKLU Design Thinking For Innovation Project Title: Work in Progress Submission 2Kota Harsha VardhanNoch keine Bewertungen

- Thesis Project Sample For Computer ScienceDokument8 SeitenThesis Project Sample For Computer SciencePayToWritePaperSingapore100% (1)

- ME170 Term Design Project - Details-Fa2019Dokument6 SeitenME170 Term Design Project - Details-Fa2019Atthapol YuyaNoch keine Bewertungen

- Product Design-0 PDFDokument14 SeitenProduct Design-0 PDFteknikpembakaran2013Noch keine Bewertungen

- As Product Design Coursework OcrDokument5 SeitenAs Product Design Coursework Ocrafiwhwlwx100% (2)

- Product Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesVon EverandProduct Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesBewertung: 4 von 5 Sternen4/5 (4)

- Product Performance Evaluation using CAD/CAE: The Computer Aided Engineering Design SeriesVon EverandProduct Performance Evaluation using CAD/CAE: The Computer Aided Engineering Design SeriesNoch keine Bewertungen

- Concept Map - Abby !Dokument2 SeitenConcept Map - Abby !Abegail Abaygar100% (3)

- Nursing Care Plan!! #1Dokument2 SeitenNursing Care Plan!! #1Gloria GonzalezNoch keine Bewertungen

- Pulse Oximetry CircuitDokument19 SeitenPulse Oximetry Circuitنواف الجهنيNoch keine Bewertungen

- Power Point Pulse OximetryDokument11 SeitenPower Point Pulse Oximetryanon_47299004Noch keine Bewertungen

- Brochure Oximetro de Pulso MD300C21 PDFDokument1 SeiteBrochure Oximetro de Pulso MD300C21 PDFVERONICA LUGONoch keine Bewertungen

- Ecg Spo Nibp Temp: Multiparameter Patient Monitoring ModuleDokument1 SeiteEcg Spo Nibp Temp: Multiparameter Patient Monitoring ModuleRaden Ayu Nurfadhillah RifqahNoch keine Bewertungen

- Volume/Fluid Responsiveness in The ICUDokument42 SeitenVolume/Fluid Responsiveness in The ICUchadchimaNoch keine Bewertungen

- Communication Protocol of Contec Pulse Oximeter V7.0Dokument8 SeitenCommunication Protocol of Contec Pulse Oximeter V7.0Mike KlopferNoch keine Bewertungen

- Venous Oxygen Saturation in Critical Illness: Clinical Practice ReviewDokument11 SeitenVenous Oxygen Saturation in Critical Illness: Clinical Practice ReviewYudha AldiNoch keine Bewertungen

- Biology Dot Point SummaryDokument91 SeitenBiology Dot Point Summaryjulz230100% (4)

- 1 - 爱度AD805规格及资质 高清 0611Dokument20 Seiten1 - 爱度AD805规格及资质 高清 0611Anupam JainNoch keine Bewertungen

- GE Dinamap Pro 100-400 - Service ManualDokument31 SeitenGE Dinamap Pro 100-400 - Service Manualhector perla100% (1)

- Group 9 - Icp MonitoringDokument25 SeitenGroup 9 - Icp MonitoringKimberly Abella CabreraNoch keine Bewertungen

- Masimo Katalog 2018 PDFDokument112 SeitenMasimo Katalog 2018 PDFNandhini SivakumarNoch keine Bewertungen

- 2500 Nonin Oximeter TroubleshootingDokument2 Seiten2500 Nonin Oximeter TroubleshootingHector LopezNoch keine Bewertungen

- Manual EDAN h100bDokument99 SeitenManual EDAN h100blexor2010Noch keine Bewertungen

- Docshare - Tips - DNB Question Paper System Wise DNB Anaesthesia PDFDokument88 SeitenDocshare - Tips - DNB Question Paper System Wise DNB Anaesthesia PDFMuthuNoch keine Bewertungen

- Ghadeer Haider - Finger Heart Rate and Pulse Oximeter Smart SensorDokument14 SeitenGhadeer Haider - Finger Heart Rate and Pulse Oximeter Smart SensorGhadeer HaiderNoch keine Bewertungen

- Guidelines For Sedation and Anesthesia in GI Endos PDFDokument11 SeitenGuidelines For Sedation and Anesthesia in GI Endos PDFHernan RuedaNoch keine Bewertungen

- 301.885.000 02 en Bellavista Product Catalog WebDokument54 Seiten301.885.000 02 en Bellavista Product Catalog WebJossue LopezNoch keine Bewertungen

- Real-Time Health Care Monitoring System Using Iot: International Journal of Engineering & TechnologyDokument5 SeitenReal-Time Health Care Monitoring System Using Iot: International Journal of Engineering & TechnologyShaik JunaidNoch keine Bewertungen

- Oxygen QuizDokument22 SeitenOxygen Quizracalsarahjane50% (2)

- Spirometer MIR Spirolab3Dokument4 SeitenSpirometer MIR Spirolab3Dicky Budi Sugiarto100% (1)

- Fetal MonitorsDokument37 SeitenFetal MonitorsEngy ElmahdyNoch keine Bewertungen

- Cas Medical 750 Service Manual PDFDokument145 SeitenCas Medical 750 Service Manual PDFEdgar OsorioNoch keine Bewertungen

- Manual de Servicio de N3000Dokument110 SeitenManual de Servicio de N3000Mauricio FloresNoch keine Bewertungen

- Endodontic DIAGNOSTIC METHODSDokument34 SeitenEndodontic DIAGNOSTIC METHODSMereesha K MoideenNoch keine Bewertungen

- Cardiocap 5 User Manual PDFDokument242 SeitenCardiocap 5 User Manual PDFAlma ZepedaNoch keine Bewertungen

- Veterinary CatalogueDokument28 SeitenVeterinary Catalogueelectronico1000Noch keine Bewertungen

- 113003.en v5.1.x 2019 Fabian Hfo Ifu PDFDokument178 Seiten113003.en v5.1.x 2019 Fabian Hfo Ifu PDFLeevan BauNoch keine Bewertungen