Beruflich Dokumente

Kultur Dokumente

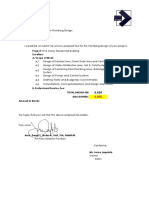

Final Hamilton StGeorge

Hochgeladen von

Danso Appiah LarryOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Final Hamilton StGeorge

Hochgeladen von

Danso Appiah LarryCopyright:

Verfügbare Formate

Session 36 H.R.

Hamilton

University of Florida

St George Island Pile Testing

Topic Description

In 2004 the Bryant Patton Bridge over Apalachicola Bay in the Florida panhandle was replaced. During demolition, twelve prestressed concrete piles with varying levels of corrosion damage were recovered. Two of the selected piles were equipped with a cathodic protection that had been installed in 1994 as part of a repair project involving most of the piles supporting the bridge. REsults of flexural and material testing that were conducted on the recovered piles will be presented.

Speaker Biography

H. R. (Trey) Hamilton III, P.E., PhD is an Associate Professor of Civil Engineering at the University of Florida in the Department of Civil & Coastal Engineering. His research and teaching interests include reinforced and prestressed concrete.

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

St George Island Bridge Pile Testing

Trey Hamilton, P.E., Ph.D.

University of Florida

Acknowledgements

FDOT Research Center Mr. Marc Ansley, Project Manager Eric Cannon, Claire Lewinger and Laz Alfonso, Caesar Abi, UF Graduate Students Frank Cobb, Tony Johnston, David Allen, Paul Tighe, and Steve Eudy of the FDOT Structures Research Center Mr. Scott Gros of Boh Bros. Construction

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Acknowledgements

Mr. Richard Delorenzo, FDOT State Materials Office (strand testing) Mr. Don Buwalda and the inspection team from FDOT District Two Mr. Ivan Lasa from the Corrosion Group of the FDOT State Materials Office Mr. William Scannell of Concorr, Florida, Inc.

Outline

Introduction Pile Recovery Testing Results Conclusions

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Bryant Grady Patton Bridge Apalachicola Bay

Location

St. George Island

History Bryant Grady Patton Bridge

Constructed in 1965. Carries SR 300 over Apalachicola Bay Pile repair in 1994

Patch Concrete jacketing Cathodic protection

Removed from service 2004

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

1994 Repair Program

Cathodic Protection System

Sprayed Zinc Splash Zone

Zinc Mesh

Bulk Anode

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Objectives

Evaluate remaining flexural capacity of piles

Why? Resistance to lateral loads such as barge impact. Why? Most inspections are visual with ratings used to classify state of bridge.

Compare tested capacity to visual rating

Tasks

Select piles Visual inspection and corrosion potentials in place Sample dissolved hydrogen in CP pile Sample chloride content of concrete Structural testing Post-test evaluation Materials testing

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Recovery Selection

FDOT D2 Inspection

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Recovery Cap Beam Removal

Recovery Pile Removal

12 piles recovered and tested

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Recovery Pile Removal

On site sampling of prestressing strands for dissolved hydrogen

Recovery Pile Preparation

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Specimen Details

(20) 7/16-in. diameter stress relieved 7-wire prestressing strands Average tested tensile strength of strands = 261 ksi Core concrete strength = 6200 psi

Flexural Test Set-up

LOAD CELL 42" TRANSFER BEAM CENTERED BETWEEN WATER MARKS PLATE 9" x 18" x 2" (TYP.) HIGH/LOW WATER MARK 9" x 18" x 1 1/2" NEOPRENE BEARING PAD (TYP.) HIGH/LOW WATER MARK 9" x 18" x 2" NEOPRENE BEARING PAD (TYP.) CLEVIS LOAD CELLS

36"

SPLASH ZONE PLACE SUPPORT INBOARD FROM DAMAGE (TYP.) SUPPORT SCALE: NTS

MOST HEAVILY DAMAGED FACE PLACED DOWN

SUPPORT

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Flexural Test Set-up

Typical Flexural Behavior

10

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Typical Flexural Behavior

40 35 30 Load (kips) 25 20 15 10 5 0 0.0 0.5 1.0 1.5 2.0 2.5 Displacements (in)

Corrosion Damage

11

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Flexural Test Results

Normalized Moment Capacity

1.2 1 0.8 0.6 0.4 0.2 0 40-3 J 32-3 J 44-3 CP 44-1 CP 33-4 J

8 7 6 5 4 3 2 1 0 -700 -600 -500 -400 -300 -200 -100 Corrosion Potentials (mVCSE) 0

Elevation (ft) Above MHW

39-2

40-2

31-1

44-4

44-2

29-2

Pile

Corrosion Potentials

40-3 32-3 40-4 39-2 44-2 29-2

350 mVCSE

40-4

12

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Corrosion Potentials

6 Distance above MHW where Corrosion Potential < -350mVCSE (ft.) 5 4 3 2 1 0 0 20 40 60 80 100 120 Remaining Flexural Capacity (%)

Visual Rating

Conducted by graduate student unfamiliar with flexural test results (no previous inspection training) Used photos and notes taken by D2 inspection team Ratings based on FDOT inspection guidelines for Commonly Recognized Structural Elements (CoRe) Normalized capacity based on rating

13

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Visual Rating

1.2

Moment Capacity

Normalized Rating

1 0.8 0.6 0.4 0.2 0 39-2

Visual

40-2

31-1

44-4

44-2

29-2

40-3 J

32-3 J

44-3 CP

Pile

Typical Flexural Behavior

44-1 CP

33-4 J

40-4

14

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Lifting Loops

Middle strand "M"

EQ

AM AC

3'-0"

Strand Sampling Hydrogen Charging for Hydrogen

Corner strand "C"

20 in.

3'-0"

Titanium mesh jacket saw cut (typ)

EQ

BM BC

3'-0"

CM CC

20 in.

3'-0"

DM DC

Saw-cut

Pile Section

10"

EM EC Saw-cut Corner strand "C" Middle strand "M"

Pile Section Pile Elevation

20 in.

Corner strand "C" Middle strand "M"

20 in.

15

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Results - Hydrogen Sampling

Average of pile with CP:

Outer wire: 2.0 ppm Inner wire: 1.4 ppm

Average of pile without CP:

Outer wire: 0.92 ppm

Expected background level: 0.6 to 0.7 ppm Appears that some charging had occurred

Effect of Hydrogen?

3

Normalized Ductility

2.5 2 1.5 1 0.5 0 39-2 40-2 31-1 44-4 44-2 29-2 40-3 J 32-3 J 44-3 CP 44-1 CP 33-4 J 40-4

N/A

Pile

16

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Conclusions Hydrogen

Elevated levels of hydrogen detected in CP piles Outer wires appeared to have higher levels of dissolved hydrogen No clear indication of a loss in ductility due to charging (based on flexural testing)

Conclusions Pile Capacity

8 out of the 12 piles tested below the calculated flexural capacity. Reduced capacity ranged from ~30 to 80% of full capacity. Both CP piles tested below 80% of original capacity. Appeared to be loss of section before CP installation.

17

Use of FRP Composites to Repair and Strengthen Concrete Bridges

October 5, 2005

Conclusions Visual Rating

7 of the 12 piles (58%) the normalized visual rating was within 10% of the normalized moment capacity One pile (8%) capacity was overestimated The remainder of the pile (34%) capacities were underestimated

18

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Boundary Layer Theory ExplainedDokument52 SeitenBoundary Layer Theory ExplainedPratham GargNoch keine Bewertungen

- Effect of Compression On T H E Shear Modulus of Rubber: of of of of of of ofDokument3 SeitenEffect of Compression On T H E Shear Modulus of Rubber: of of of of of of ofstefan.vince536Noch keine Bewertungen

- Wall-top units provide compact air conditioning solutionsDokument2 SeitenWall-top units provide compact air conditioning solutionsLiviu ConstantinNoch keine Bewertungen

- Piping Fabrication, Installation, Flushing and TestingDokument29 SeitenPiping Fabrication, Installation, Flushing and Testingiskricaman783% (6)

- Wood Joists PDFDokument27 SeitenWood Joists PDFRicaRDONoch keine Bewertungen

- Designing Fire Escape Routes and Pressurization in BuildingsDokument20 SeitenDesigning Fire Escape Routes and Pressurization in BuildingsRájDèép TrìpâţhíNoch keine Bewertungen

- Planning and Preliminary Design of BridgeDokument22 SeitenPlanning and Preliminary Design of BridgeBCE 2074 B Teacher0% (1)

- Plumbing ProposalDokument3 SeitenPlumbing ProposalDarryl GelacioNoch keine Bewertungen

- Modelling of Dynamic Stability Derivatives Using CFD: Sean Tuling Csir KeywordsDokument9 SeitenModelling of Dynamic Stability Derivatives Using CFD: Sean Tuling Csir KeywordsconqurerNoch keine Bewertungen

- Ed C 01.00 I 02Dokument38 SeitenEd C 01.00 I 02Enrique BlancoNoch keine Bewertungen

- Simple and Multiple Regression Models For Relationship Between Electrical Resistivity and Various Soil Properties For Soil Characterization PDFDokument10 SeitenSimple and Multiple Regression Models For Relationship Between Electrical Resistivity and Various Soil Properties For Soil Characterization PDFPato MeraNoch keine Bewertungen

- Upgrading Rural Road Project ReportDokument249 SeitenUpgrading Rural Road Project Reportamit singhNoch keine Bewertungen

- RCD Beam Analysis and DesignDokument33 SeitenRCD Beam Analysis and DesignLynx101Noch keine Bewertungen

- Technical Schedule A To D & H Pkg-2Dokument69 SeitenTechnical Schedule A To D & H Pkg-2vinodNoch keine Bewertungen

- Mill Housings Mangal SinghDokument5 SeitenMill Housings Mangal SinghGun SmithNoch keine Bewertungen

- Leaflet - IDEA StatiCa ConcreteDokument2 SeitenLeaflet - IDEA StatiCa ConcretepgyzNoch keine Bewertungen

- Bamboo Crete HouseDokument2 SeitenBamboo Crete HouseChandan Bose100% (1)

- Working Stress Design Method 1Dokument23 SeitenWorking Stress Design Method 1kumaravajiraNoch keine Bewertungen

- Calculating Wind Loads on a Steel Mill BuildingDokument135 SeitenCalculating Wind Loads on a Steel Mill BuildingKaraline MarcesNoch keine Bewertungen

- SS012-22-FAB-007-Rev CDokument1 SeiteSS012-22-FAB-007-Rev Cayman sharafNoch keine Bewertungen

- Engineering Utilities 2: A History of Plumbing SystemsDokument23 SeitenEngineering Utilities 2: A History of Plumbing SystemsRadie ArnaldoNoch keine Bewertungen

- NCh2369-2003 Seismic Design of Industrial Facilities and StructuresDokument75 SeitenNCh2369-2003 Seismic Design of Industrial Facilities and StructuresypuifoongNoch keine Bewertungen

- BMC-3.Ferrous&Non-Ferrous MaterialsDokument20 SeitenBMC-3.Ferrous&Non-Ferrous MaterialsMeenu Priya100% (1)

- Bafu Khola MHP Final ReportDokument8 SeitenBafu Khola MHP Final ReportBISHAL AdhikariNoch keine Bewertungen

- Frictional Losses in Pipe Flow ExperimentDokument38 SeitenFrictional Losses in Pipe Flow ExperimentAinur NasuhaNoch keine Bewertungen

- Staad Pro-RCC Open ChannelDokument7 SeitenStaad Pro-RCC Open ChannelV.m. RajanNoch keine Bewertungen

- DIVISION 03 | CONCRETE BUILDING TECHNOLOGYDokument32 SeitenDIVISION 03 | CONCRETE BUILDING TECHNOLOGYRicaBalbarosaNoch keine Bewertungen

- Eminent Structural Engineer: Julius Natterer: Brief CVDokument3 SeitenEminent Structural Engineer: Julius Natterer: Brief CVDesign explorer olomizanaNoch keine Bewertungen

- Asme Codes and Standard A SummaryDokument20 SeitenAsme Codes and Standard A Summarymawatwalharsh549Noch keine Bewertungen

- Drilling Programme - Preparation and ContentDokument2 SeitenDrilling Programme - Preparation and ContentYougchu LuanNoch keine Bewertungen