Beruflich Dokumente

Kultur Dokumente

Series 2000

Hochgeladen von

j_saucedaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Series 2000

Hochgeladen von

j_saucedaCopyright:

Verfügbare Formate

A TOGNUM GROUP BRAND

Oil & Gas

Series 2000-06

for Oil & Gas Mechanical Drive Applications

Dimensions and Masses Engine 12V 16V Dimensions (LxWxH) mm (in) 1830x1280x1430 (72x50x56) 2173x1280x1445 (86x50x57) Mass, dry kg (lbs) 2950 (6503) 3350 (7385)

All dimensions are approximate, for complete information refer to the installation drawing.

Engine Model Bore/stroke Cylinder conguration Displacement/cylinder Displacement, total Fuel specication l (cu in) l (cu in) mm (in) 135/156 (5.3/6.15) 90 V 2.23 (136) 12V: 26.76 (1633); 16V: 35.68 (2177) Diesel fuel in accordance with DIN EN 590, ASTM D 975, BS 2869, US DF # 1-Off Highway and US DF # 2-Off Highway Engine Type Model Application 12V 2000 S56 16V 2000 S56 Application 12V 2000 S96 16V 2000 S96

Exhaust emission: EPA Tier 4i

Rated Power ICFN kW bhp rpm

Peak Torque Nm lb-ft rpm

Optimization

Medium duty operation (4B) 783 970 1050 1300 2100 2100 4640 5471 3423 4035 1100-1500 1300

Short time / Frac operation (4D) 858 1163 1150 1560 2100 2100 4911 6582 3622 4854 1300-1600 1300

Power. Passion. Partnership.

Application 4B 4D

Power denition Continuous operation w/variable load Standby operation w/variable load Load factor: < 60 %, Operating hours: unrestricted, Overload: Fuel stop (ICFN) Load factor: < 40 %, Operating hours: max. 2000 h/year, Overload: Fuel stop (ICFN)

Power output within 5% tolerance at standard conditions. Power denition according to ISO 3046 (ratings also correspond to SAE J 1995 and SAE J 1349 standard conditions) Consult your MTU Detroit Diesel or MTU distributor/dealer for the rating that will apply to your specic application.

Standard Equipment Starting System Fuel System Electrical starter 24 VDC Electronically controlled common-rail injection system, dual engine mounted fuel lters, double-walled high pressure fuel lines Lube Oil System Forced feed lubricating system with piston cooling, lube oil circulating pump, multi stage oil lter, lube oil heat exchanger, 15 oil pan Combustion Air System Two-stage turbocharging, intercooling and charge air cooling, cooled exhaust gas recirculation, turbocharger air intake from free end (front side) Coolant System SCCC Flywheel/Housing Engine Mounting Electronics and Instrumentation Optional Equipment Starting System Oil System Combustion Air System Coolant System Redundant starting systems electric (dual); air Remote mounted oil lters, 22/30 oil pans Air shut-off Flaps, turbocharger air intake from driving end (rear side) Coolant heater, front crank PTO for fan drive (various ratios), connections for transmission heat exchanger (partial ow/full ow) Flywheel/Housing Accessory Drives Flywheel housing with aux. PTO`s Battery charging alternator, 28VDC, aux. PTOs for hydr. pump drives and compressors HT (JW) and LT (CAC) separate coolant circuits with coolant pumps and thermostats Flexplate, SAE 0 ywheel housing, suitable for wet and dry drive solutions 3-point or 4-point mounting Latest ADEC engine control and management system

Reference conditions: > Intake-air temperature: 25C (77F) > Ambient air pressure: 1000 mbar > Altitude above sea level: 100 m (328 ft) Subject to change without notice. Customization possible. Engines illustrated in this document may feature options not tted as standard.

Europe I Middle East I Africa, MTU Friedrichshafen GmbH, 88040 Friedrichshafen, Germany, T +49 7541 90 2998, F +49 7541 90 7776, oil_gasregion1@mtu-online.com, www.mtu-online.com I Asia I Australia I Pacic, MTU Asia Pte. Ltd., 1 Benoi Place, Singapore 629923, Republic of Singapore, T +65 6861 5922, F +65 6861 3615, oil_gasregion2@mtu-online.com, www.mtu-online.com I USA I Canada I Mexico I Latin America, MTU Detroit Diesel, Inc., 13400 Outer Drive West, Detroit, Michigan 48239, USA, T +1 313 592 7000 , F +1 313 592 5158, oil_gasregion3@mtu-online.com, www.mtu-online.com

Subject to change. | 3235191 | 1/11 | VMC 2011-05.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- MRT Technical Turbocharger Compressor CalculationsDokument6 SeitenMRT Technical Turbocharger Compressor Calculationsgeorgemesfin@gmail100% (1)

- SSP 495 3.0L V6 TDI Engine 2 GenerationDokument48 SeitenSSP 495 3.0L V6 TDI Engine 2 GenerationFabio Garzena100% (3)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Workshop Manual: Technical DataDokument40 SeitenWorkshop Manual: Technical DataGORD100% (1)

- Motor Iveco F5C PDFDokument290 SeitenMotor Iveco F5C PDFChristopher Jesus Reàtegui Olivares88% (8)

- List of Toyota engine codes under 40 charactersDokument39 SeitenList of Toyota engine codes under 40 charactersMwima Dafsow100% (1)

- Takeuchi Track Loader P Tl230eba Engine Parts ManualDokument10 SeitenTakeuchi Track Loader P Tl230eba Engine Parts Manuallouis100% (40)

- EPA07-10 Engine ManualDokument125 SeitenEPA07-10 Engine ManualRamon Pujol PerramonNoch keine Bewertungen

- Coach & Bus EngineDokument2 SeitenCoach & Bus EngineClegivaldoNoch keine Bewertungen

- PEUGEOT 307 407 607 806 807 406 306 106 107 FaultCodes 0586 PDFDokument1 SeitePEUGEOT 307 407 607 806 807 406 306 106 107 FaultCodes 0586 PDFRacu Cristian100% (1)

- 360 Modena ECU Error CodesDokument21 Seiten360 Modena ECU Error CodesDamien Jorgensen100% (2)

- Catalogo Motor DFAC 2.5 TDokument78 SeitenCatalogo Motor DFAC 2.5 Tjimmorse100% (1)

- Compass - Serial Catalogue For 350 KVA - 900 KVA DieselDokument807 SeitenCompass - Serial Catalogue For 350 KVA - 900 KVA DieselCesar CovaNoch keine Bewertungen

- D3E8001FB4E-Engine Mechanical PDFDokument142 SeitenD3E8001FB4E-Engine Mechanical PDFMartin VelikovNoch keine Bewertungen

- Parts Spare Ju4-6r c137060Dokument2 SeitenParts Spare Ju4-6r c137060Carlos salazarNoch keine Bewertungen

- PDF BMW R850 Shop Manual PDF 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 DownloadDokument1 SeitePDF BMW R850 Shop Manual PDF 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 DownloadMarian StroiaNoch keine Bewertungen

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 09D902-1607-E1Dokument25 SeitenParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 09D902-1607-E1maximchacaNoch keine Bewertungen

- SECTION 1.15: General InformationDokument18 SeitenSECTION 1.15: General InformationLUISA FERNANDA TORRES MANOSALVANoch keine Bewertungen

- 97 f150 PinoutDokument4 Seiten97 f150 PinoutUlises AlfaroNoch keine Bewertungen

- Air Inlet and Exhaust Valve Lash AdjustmentDokument3 SeitenAir Inlet and Exhaust Valve Lash Adjustmentnolram23Noch keine Bewertungen

- D 0836 RadilicaDokument12 SeitenD 0836 Radilicadzadza2Noch keine Bewertungen

- Study of AMSOIL Interceptor 2 Cycle Oil in Ski-DooRotax EnginesDokument20 SeitenStudy of AMSOIL Interceptor 2 Cycle Oil in Ski-DooRotax EnginesBruce WappmanNoch keine Bewertungen

- MAN Marine Diesel Engine - enDokument1.566 SeitenMAN Marine Diesel Engine - enYacine GhanemiNoch keine Bewertungen

- Compression Ratio Calculator cells accept data entriesDokument9 SeitenCompression Ratio Calculator cells accept data entriesetamil87Noch keine Bewertungen

- Cam TerminologyDokument8 SeitenCam TerminologychasestarNoch keine Bewertungen

- Exhaust Manifold: Vessel: M/V: KENZ Date: .22/02/2022 SO No. KENZ 1/22Dokument2 SeitenExhaust Manifold: Vessel: M/V: KENZ Date: .22/02/2022 SO No. KENZ 1/22amr allamNoch keine Bewertungen

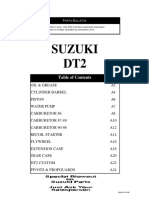

- Suzuki Parts - DT2Dokument25 SeitenSuzuki Parts - DT2Guillaume TremblayNoch keine Bewertungen

- Diesel Engines 16V 4000 M93/M93L: For Fast Vessels With Low Load Factors (1DS)Dokument2 SeitenDiesel Engines 16V 4000 M93/M93L: For Fast Vessels With Low Load Factors (1DS)julioNoch keine Bewertungen

- Test and Adjustment Data Engine M104Dokument4 SeitenTest and Adjustment Data Engine M104EvaristoEulalioNoch keine Bewertungen

- Four Stroke EngineDokument5 SeitenFour Stroke Enginemnoorulain80Noch keine Bewertungen

- Performance Analysis of An Engine by Fabricating An Air Pre PDFDokument7 SeitenPerformance Analysis of An Engine by Fabricating An Air Pre PDFhridoy bosuniaNoch keine Bewertungen