Beruflich Dokumente

Kultur Dokumente

Annexure I A

Hochgeladen von

samirjoshi73Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Annexure I A

Hochgeladen von

samirjoshi73Copyright:

Verfügbare Formate

Annexure-I A

Project Cycle - All Activities

Sr. Activity No. 1 Circulation of contracts and complete scope to Design and Projects. 2 Creation of Single line Sales order in SAP 3 Kick off Meeting (Handing over of contracts to Design and Projects with scope and technical specification) Assignment of Design Team, Assignment of Projects Manager 4 Creation of Project Structure (header Level) 5 6 Assignment of WBS element in Sales Preparation of vertical list consisting of - List of assemblies, Major Bought outs, Scope and Planned assembly drawing completion dates (including components drawings) Preparation and Issue of detailed Bought out list to Projects Attachment of materials for advance procurement as per Bought out list. Dept. Capacity Responsible Sales NA Sales NA Sales / Design NA / Projects Remarks IBM's Scope Not Applicable Not Applicable Not Applicable

Annexure-I A

CMI FPE's Response

Projects Sales Design

NA NA NA

This is required to link Sales Order.

APS and SAP Integration APS and SAP Integration Prepared in MS Excel and to be integrated to APS Planner

Vertical List (with forecasted drawing issue dates) to be uploaded in APS Planner Tracking outside SAP i.e. in APS Planner. No MRP required for advanced procurement. In this case materials are attached to Project structure as advance procurement and PR are created as soon as we save project structure. This needs to be updated inSolution Should be treated as a Work center (engineers and draftsmen) in APS Work Centre (material master data team) in APS Work Centre (material master data team) in APS

Design

Design Hours

Projects

NA

Design task will brought in with SAP Planner Integration (transmittal Note + report) MRP to be run in APS Planner to generate Planned Purchase Recommendations. These will be updated to SAP

Detailed Engineering - Assembly and component level, Design No. of drawings in assembly and total design hours to complete drawings - assembly level 10 Creation of Material Master in SAP. Materials will be created by default for 3200 (Taloja) Plant and extended to others) 11 Creation and Release of Bill of material in SAP (by Design default after creation of BOM in SAP it is inactive. Based on confirmation from Design engineer the BOM will be activated in SAP). 12 Issue of drawings to manufacturing - Here the delay can Design be calculated based on planned completion date in vertical list - as Vertical list is out side SAP, there has to be facility of uploading it to APS software.

Design Hours

Not Applicable

Design Hours SAP Team Design Hours SAP Team

Not Applicable

Not Applicable

NA

Not Applicable

Actual drawing issue dates to be picked up from SAP

Annexure-I A

Sr. Activity Dept. Capacity No. Responsible 13 Attachment of material to Project structure as per billing Projects NA schedule finalised with Customer. Reference documents: *MPS (Master Production Schedule) *Type of despatched (Despatch through Plant or Third party despatch directly from Vendor to customer)

Remarks Material to be attached in SAP project structure thereby creating requirement. This requirement will be transferred to APS planner and MRP to be run in APS planner to generate plan order / purchase requisition. This will be updated in SAP.

IBM's Scope MRP to be run in APS to generate Planned order/ Purchase requisitions Recommendations. These will be updated to SAP

CMI FPE's Response To be Updated in APS Planner

14 Amending of Sale order as per billing schedule & creation of new sale order for Third Party despatches. 15 Creation of Second Level bill of materials (Process BOMs such as Fabrication , Sandblasting etc.) 16 Preparation of rough cut MPS based on the vertical list (allocation to Workshops)

Projects

To be updated in APS Planner

Planning

Planning

Central Planning

NA

(Planned Orders + Open Rough cut planning will be done production orders ) X Cycle inSolution time as defined in routing to be matched with capacity (available machines hours and assembly hours) to derive MPS fromSolution SAP will do the Procurement and feedback to be given to APSSolution The Planned Delivery dates will be updated from SAP toSolution The Planned Delivery dates will be updated from SAP toSolution -

Bill of material will be created in SAP only. MRP to be run in APS Planner on daily basis MPS will be generated fromSolution

17 Procurement of Raw materials. 18 QA Inspection (Raw material source Inspection) - UD1 (inspection type ZS / ZR) 19 Incoming QA - UD2 (inspection type 01) 20 Procurement Bought outs.

Purchase Quality Quality Purchase

PO Delivery date Man Hours Man Hours PO Delivery date Man Hours Man Hours PO Delivery date Man Hours Man Hours

Part of purchase order external lead time To be added in GR processing time in material master

21 QA Inspection (Bought out source Inspection) - UD1 Quality (inspection type ZS / ZR) 22 Incoming QA - UD2 (inspection type 01) Quality 23 Outsourcing of whole equipment (Machining, Assembly) Purchase 24 QA Inspection (Source Inspection) - UD1 (inspection type Quality ZS / ZR) 25 Incoming QA - UD2 (inspection type 01) Quality

Part of purchase order external lead time GR processing time

Part of purchase order external lead time To be added in GR processing time in material master

Annexure-I A

Sr. Activity Dept. Capacity Remarks No. Responsible Outsourcing of equipment (Make - Buy Decision of Manufacturing Item based on Machine Shop Load - Planning Dept.) 26 Procurement of Component Planning PO Delivery date Man Hours 27 QA Inspection (Source Inspection) - UD1 (inspection type Quality ZS / ZR) 28 Incoming QA - UD2 (inspection type 01) Quality Man Hours 29 Subcontracting Planning PO Delivery date Man Hours Man Hours Machine Hours Man Hours Man Hours

IBM's Scope

CMI FPE's Response

SAP - APS Solution. Supply Web will be integrated with SAP and these dates will be brought in APS Solution SAP Integration with APS Solution. Should be a part of Routing in SAP Part of purchase order external lead time To be added in GR processing time in material master

30 QA Inspection (Source Inspection) - UD1 31 Incoming QA - UD2 (inspection type 01) 32 Machining of components 33 In process inspection (inspection type 03)

Quality Quality Mshop Quality

Should be a part of external lead time in PO To be added in GR processing time in material master

34 Quality inspection against Production Order (inspection Quality type 04)

Quality Check will be defined as a Agreed Routing Operation and Work Center in SAP and integrated with APS Solution.

35 Assembling of components 36 In process inspection (inspection type 03)

Assembly by Assembly Dept. Assembly Man Hours Quality Man Hours Man Hours

APS solution -

Should be a part of Routing in SAP Should be a part of Routing in SAP

37 Quality inspection against Production Order (inspection Quality type 04)

Quality Check will be defined as a Agreed Routing Operation and Work Center in SAP and integrated with APS Solution. Man hours to be considered as it is outsourced. Tracking outside SAP i.e. in APS Solution. Tracking outside SAP i.e. in APS Solution Tracking outside SAP i.e. in APS Solution. Despatch intimation to be triggered by application and confirmed by E& C on site team on actual receipt of goods.

38 Third Party inspection 39 Despatch Clearance 40 Packing

Quality Projects Despatch

Man Hours NA

41 Despatch

Despatch

NA

Annexure-I A

Sr. No. 42 Transportation time

Activity

Dept. Capacity Responsible Despatch NA

Remarks This will differ from customer to customer (based on geographical location). -

IBM's Scope

CMI FPE's Response Despatch intimation to be triggered by application and confirmed by E& C on site team on actual receipt of goods. Confirmation (partial/complete as applicable)against activities(% completion based on elapsed time /site status reports) in Project strucutre will be carried out by Project department. Key stages of E & C activites are 1. E& C of Mechanical Equip 2. E&C of Hydraulic System. 3. E &C of Electrical sytem. 4. PAT 5. FAT This date will be pushed into APS application.

43 E & C - Foundation (if in our scope), arrangement of equipments, alignment of equipments, piping, instrumentation, final automation, cold run, PAT and FAT.

E&C

Man Hours

Project Scheduling Package

End Notes 1 - Production Order will continue to be made in SAP and TECO etc. performed with no change in cost capture process in SAP. 2 - Engineering efforts for assemblies will be aggregated as 'activities' for each week and will have to be confirm in SAP. Hence if engineering takes say 3 months, there will be 12 confirmation required. 3 - All Master data such as Material master, Bill of material, Routing (Including Multiple routing ) will continue to be created in SAP only. 4- All APS standard objects will have Project & WBS element field and selection criteria.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Aluminum Brazing PresentationDokument5 SeitenAluminum Brazing Presentationatul_sanghaviNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Authorisation Object ListDokument37 SeitenAuthorisation Object Listsamirjoshi73Noch keine Bewertungen

- Modified Vol I of Feasibility ReportDokument212 SeitenModified Vol I of Feasibility ReportDeepak_pethkarNoch keine Bewertungen

- Construction Guideline 2 For Export Abattoir PDFDokument41 SeitenConstruction Guideline 2 For Export Abattoir PDFKarthikeyan Balakrishnan100% (4)

- SHIPOWNERS Sampling Procedures For TankersDokument5 SeitenSHIPOWNERS Sampling Procedures For TankersErsin SaltNoch keine Bewertungen

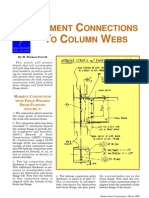

- Moment Connections To Column WebsDokument3 SeitenMoment Connections To Column WebsAmro Ahmad AliNoch keine Bewertungen

- Incline Caving As A Massive Mining MethodDokument9 SeitenIncline Caving As A Massive Mining MethodwalterloliNoch keine Bewertungen

- Scheduling AgreementDokument29 SeitenScheduling Agreementsamirjoshi73Noch keine Bewertungen

- Aluminum: Aluminum Extrusion Machine Aluminum SectionsDokument15 SeitenAluminum: Aluminum Extrusion Machine Aluminum Sectionsedbern20005873Noch keine Bewertungen

- Business BluePrint PS1 Version2.1Dokument80 SeitenBusiness BluePrint PS1 Version2.1samirjoshi73Noch keine Bewertungen

- Final List of All MFG Unit 15122018Dokument75 SeitenFinal List of All MFG Unit 15122018shiva lakshmiNoch keine Bewertungen

- Lecture 3. Matching Supply With DemandDokument42 SeitenLecture 3. Matching Supply With DemandSamantha SiauNoch keine Bewertungen

- Shirataka Chefknives MakingDokument16 SeitenShirataka Chefknives MakingAvraham Eisenberg100% (1)

- SAP MM Presentstion-FinalDokument80 SeitenSAP MM Presentstion-Finalsamirjoshi73100% (2)

- Organizational ChartDokument1 SeiteOrganizational Chartkaye=)25% (8)

- Planvisage EnhancementsDokument2 SeitenPlanvisage Enhancementssamirjoshi73Noch keine Bewertungen

- Mass Creation of PR in SAPDokument3 SeitenMass Creation of PR in SAPsamirjoshi730% (1)

- Authorisation Object ListDokument70 SeitenAuthorisation Object Listsamirjoshi73Noch keine Bewertungen

- Unit Testing ScriptDokument3 SeitenUnit Testing Scriptsamirjoshi73Noch keine Bewertungen

- Cadre Annual Appraisal Form 13 14Dokument5 SeitenCadre Annual Appraisal Form 13 14samirjoshi73Noch keine Bewertungen

- Qa High Level Process MapDokument1 SeiteQa High Level Process Mapsamirjoshi73Noch keine Bewertungen

- Processing Logic RM BOM Component CosumedDokument2 SeitenProcessing Logic RM BOM Component Cosumedsamirjoshi73Noch keine Bewertungen

- Key Processes Impacting PlanningDokument2 SeitenKey Processes Impacting Planningsamirjoshi73Noch keine Bewertungen

- MC Shop Process FlowDokument1 SeiteMC Shop Process Flowsamirjoshi73Noch keine Bewertungen

- SAP Functional Controls-: Production PlanningDokument2 SeitenSAP Functional Controls-: Production Planningsamirjoshi73Noch keine Bewertungen

- CMI FPE - Project Issues and ResolutionDokument11 SeitenCMI FPE - Project Issues and Resolutionsamirjoshi73Noch keine Bewertungen

- India Localization With Respect To SD: T.MuthyalappaDokument77 SeitenIndia Localization With Respect To SD: T.MuthyalappadavinkuNoch keine Bewertungen

- Validations in Project SystemDokument17 SeitenValidations in Project Systemsamirjoshi73Noch keine Bewertungen

- Format For Write OffDokument4 SeitenFormat For Write Offsamirjoshi73Noch keine Bewertungen

- P A V E: Ilot Ircraft EN Ironment Xternal PressuresDokument1 SeiteP A V E: Ilot Ircraft EN Ironment Xternal PressuresSohailArdeshiriNoch keine Bewertungen

- 7 11 JapanDokument27 Seiten7 11 JapanMuhammad Mazhar HussainNoch keine Bewertungen

- Buildex: Product Technical Data SheetDokument2 SeitenBuildex: Product Technical Data Sheetandrewb2005Noch keine Bewertungen

- LM25 Aluminium Casting Alloy (Al - Si7Mg) : Chemical CompositionDokument3 SeitenLM25 Aluminium Casting Alloy (Al - Si7Mg) : Chemical Compositiondaniel_sasikumarNoch keine Bewertungen

- Pilipinas Shell Petroleum Corporation: SHLPHDokument17 SeitenPilipinas Shell Petroleum Corporation: SHLPHIsis Normagne PascualNoch keine Bewertungen

- Electrical Wiring Interconnection SystemDokument1 SeiteElectrical Wiring Interconnection SystemSiva ViswaNoch keine Bewertungen

- Colloquium Paper - Shreya BangardDokument25 SeitenColloquium Paper - Shreya BangardShreya BangardNoch keine Bewertungen

- ASTM A27 Spec For General Steel CastingsDokument4 SeitenASTM A27 Spec For General Steel CastingsKarthik Nagendra0% (1)

- Env Impact Assessment KelticPetroDokument249 SeitenEnv Impact Assessment KelticPetrorome_n21Noch keine Bewertungen

- Brick CladdingDokument36 SeitenBrick CladdingManish ChauhanNoch keine Bewertungen

- Specification For Installation of Underground Conduit SystemsDokument60 SeitenSpecification For Installation of Underground Conduit SystemsMarkusMakuAldoNoch keine Bewertungen

- Rigid PavementDokument2 SeitenRigid Pavementanatoink2Noch keine Bewertungen

- Tamil Nadu Public Trusts (Regulation of Administration of Agricultural PDFDokument58 SeitenTamil Nadu Public Trusts (Regulation of Administration of Agricultural PDFLatest Laws TeamNoch keine Bewertungen

- GACUTAN & TAN - CE 190 Manuscript - Transportation Engg PDFDokument2 SeitenGACUTAN & TAN - CE 190 Manuscript - Transportation Engg PDFAngel Umali GacutanNoch keine Bewertungen

- Mahindra Gears Transmiision Training ReportDokument32 SeitenMahindra Gears Transmiision Training Reportbestmadeeasy50% (2)

- SpaceX Boosts Classified U.SDokument2 SeitenSpaceX Boosts Classified U.SDarrek F CrisslerNoch keine Bewertungen

- Fines For The Most Common Traffic Violations in The Slovak RepublicDokument3 SeitenFines For The Most Common Traffic Violations in The Slovak RepublickhaireddinNoch keine Bewertungen

- Mall and Event ManagementDokument5 SeitenMall and Event ManagementNik GuptaNoch keine Bewertungen

- Citgo Pocket GuideDokument288 SeitenCitgo Pocket GuideJavier Alejandro Muralles ReyesNoch keine Bewertungen