Beruflich Dokumente

Kultur Dokumente

2005 Honda Odyssey - TSB 06-083

Hochgeladen von

Cmore MoreOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2005 Honda Odyssey - TSB 06-083

Hochgeladen von

Cmore MoreCopyright:

Verfügbare Formate

TSB 06-083 covers the 2005-2006 EX-L and TOURING models only: Service Bulletin 06-083 December 1, 2006

Applies To: 200506 Odyssey EX-L ALL 200506 Odyssey Touring ALL Excessive Engine Vibration at Idle or Below 2,100 RPM

SYMPTOM The engine vibrates excessively at idle or, under load, up to about 2,100 rpm. PROBABLE CAUSE The rubber inside the rear engine mount is torn. CORRECTIVE ACTION Replace the rear engine mount and its mounting bolts. PARTS INFORMATION Rear Engine Mount: P/N 50810-SHJ-A62, H/C 8485906 Rear Engine Mount Bolt, 10 x 35: P/N 90163-SDA-A01, H/C 7151350 Rear Engine Mount Bolt, 10 x 20 (four required):P/N 90163-S5A-000, H/C 6462931 WARRANTY CLAIM INFORMATION In warranty: The normal warranty applies. Operation Number: 1121C3 Flat Rate Time: 1.0 hour Failed Part: P/N 50810-SHJ-A61 H/C 7813967 Defect Code: 02101 Symptom Code: 04505 Template ID: 06-083A Skill Level: Repair Technician Out of warranty: Any repair performed after warranty expiration may be eligible for goodwill consideration by the District Parts and Service Manager or your Zone Office. You must request consideration, and get a decision, before starting work. DIAGNOSIS 1. Raise the vehicle on a lift. 2. Using a .610 mm (.024 inch) feeler gauge, check for clearance between the rear engine mounts rubber bumper and its bracket. Also check the shape of the rear engine mount. If you cant get the feeler gauge to slide through the entire length of the rubber bumper and

the engine mount bulges out (is shaped like a donut), go to REPAIR PROCEDURE. If the feeler gauge slides through the entire length of the rubber bumper and the engine mount look slightly deflated, this service bulletin does not apply. Continue with normal troubleshooting to find the cause of the engine vibration. Engine mount bulges out. Feeler gauge will not slide between the bumper and bracket. REPAIR PROCEDURE 1. Take weight off the rear engine mount by supporting the transmission with a screw jack. 2. Disconnect the connector from the rear ACM (active control engine mount) actuator. 3. Remove the rear engine mount stop (two nuts) and the rear engine mount (five bolts). 4. Using five new bolts, install a new rear engine mount in the reverse order of removal. NOTE: Torque the new rear engine mount bolts to 54 N.m (40 lb-ft). Torque the engine mount stop nuts to 73 N.m (54 lb-ft). 5. With the screw jack removed, make sure the exhaust pipe A bracket is centered in its rubber mount. If needed, center the bracket by tapping it with a hammer.

Das könnte Ihnen auch gefallen

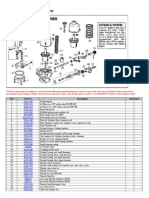

- Engine Identification: Removal (Carbureted Models)Dokument18 SeitenEngine Identification: Removal (Carbureted Models)(Obr-Bto) Francisco Antonio Lizardo SalasNoch keine Bewertungen

- Crime Against PropertyDokument2 SeitenCrime Against PropertyRic John Naquila CabilanNoch keine Bewertungen

- 4 Gauge Diesel Set InstructionsDokument5 Seiten4 Gauge Diesel Set InstructionsEd ZacharyNoch keine Bewertungen

- GM 1968 1982 Cruisemaster Cruise ControlDokument61 SeitenGM 1968 1982 Cruisemaster Cruise Controlralleman1100% (1)

- Honda Element LX 2009 Sistema de Carga (Charging System) Completo PDFDokument28 SeitenHonda Element LX 2009 Sistema de Carga (Charging System) Completo PDFRubenNoch keine Bewertungen

- FordDokument5 SeitenFordmiguelNoch keine Bewertungen

- AutoEnginuity Scantool User GuideDokument121 SeitenAutoEnginuity Scantool User GuideRob ChampionNoch keine Bewertungen

- 4R70W/4R75W 4R70E/4R75E Ford Aod (Fiod) Aod-E (Electronic) : All TransmissionsDokument12 Seiten4R70W/4R75W 4R70E/4R75E Ford Aod (Fiod) Aod-E (Electronic) : All TransmissionsarctNoch keine Bewertungen

- 30-Indoor Air QualityDokument12 Seiten30-Indoor Air Qualityvenka07100% (1)

- Celestron c10 N Users Manual 393252Dokument71 SeitenCelestron c10 N Users Manual 393252TestNoch keine Bewertungen

- Disk Brakes 2001-2003Dokument65 SeitenDisk Brakes 2001-2003dickenszzNoch keine Bewertungen

- A540 ToyotaDokument7 SeitenA540 ToyotaporkfaceNoch keine Bewertungen

- Specifications: Application Specification Metric EnglishDokument59 SeitenSpecifications: Application Specification Metric EnglishMauricio Casanova100% (1)

- 199r10487 1rev6Dokument12 Seiten199r10487 1rev6Alfonso JaureguiNoch keine Bewertungen

- 2005 Ford Mustang BrochureDokument28 Seiten2005 Ford Mustang BrochureBrandon McCombsNoch keine Bewertungen

- Dyno Test VariablesDokument7 SeitenDyno Test VariablesArto LehikoinenNoch keine Bewertungen

- Vats Sell SheetDokument2 SeitenVats Sell SheetJesus Gonzalez AndradeNoch keine Bewertungen

- Dual ClutchDokument19 SeitenDual ClutchZachary HuffmanNoch keine Bewertungen

- x100 Pad 2 User Manual PDFDokument29 Seitenx100 Pad 2 User Manual PDFSelva Prem KumarNoch keine Bewertungen

- AMC IgnitiionModificationDokument5 SeitenAMC IgnitiionModificationFred DeRoosNoch keine Bewertungen

- Brake Shoes Removal and Installation PDFDokument6 SeitenBrake Shoes Removal and Installation PDFMichael HernandezNoch keine Bewertungen

- Wotbox Instructions 2010mustangDokument14 SeitenWotbox Instructions 2010mustangAlejandro Da CostaNoch keine Bewertungen

- CruzeDokument13 SeitenCruzeShubham GhoshNoch keine Bewertungen

- 2w900fmr 2wshlcd ManualDokument22 Seiten2w900fmr 2wshlcd ManualLance FreesemanNoch keine Bewertungen

- Banshee Electrical FAQDokument29 SeitenBanshee Electrical FAQCristian VarelaNoch keine Bewertungen

- 2000-01 MT SERVICE Chevy TrackerDokument6 Seiten2000-01 MT SERVICE Chevy Trackerandres german romeroNoch keine Bewertungen

- About CJDokument15 SeitenAbout CJDicky Aryo100% (1)

- 2005tC Tech PDFDokument27 Seiten2005tC Tech PDFdeanewing11Noch keine Bewertungen

- MDX Suspension NoisesDokument2 SeitenMDX Suspension NoisesScotty MacNoch keine Bewertungen

- Jetting Mikuni CarburetorsDokument1 SeiteJetting Mikuni CarburetorstcmotorcycleNoch keine Bewertungen

- Ford Eectch98Dokument79 SeitenFord Eectch98jockerNoch keine Bewertungen

- Manual Trans ServiceDokument3 SeitenManual Trans ServiceGeraldo Pozos VazquezNoch keine Bewertungen

- 2005 Chevrolet Tahoe/Suburban Owner ManualDokument530 Seiten2005 Chevrolet Tahoe/Suburban Owner ManualClaudio Hernández PobleteNoch keine Bewertungen

- Specification Application Metric English: Engine Mechanical Specifications Y Car - LS1Dokument6 SeitenSpecification Application Metric English: Engine Mechanical Specifications Y Car - LS1Jean Paul BésNoch keine Bewertungen

- 500 518 618 No ReverseDokument1 Seite500 518 618 No Reverseeurospeed2Noch keine Bewertungen

- Hemi EngineDokument23 SeitenHemi Enginesurendrabarwar7Noch keine Bewertungen

- Tundra Transmission Fluid Check and Flush InstructionsDokument7 SeitenTundra Transmission Fluid Check and Flush InstructionsJason Lancaster100% (4)

- Accel Fuel Injectors TableDokument8 SeitenAccel Fuel Injectors Tablerizki hidayat100% (1)

- Steering Column SwitchesDokument9 SeitenSteering Column SwitchesAnimemanuel MuñozNoch keine Bewertungen

- HIF Carburetor Diagram and Parts ListDokument2 SeitenHIF Carburetor Diagram and Parts Listbhanuka2009Noch keine Bewertungen

- 1964 Supplement - Chevrolet Corvair Shop Manual - Section 6e - Automatic Transmission PDFDokument5 Seiten1964 Supplement - Chevrolet Corvair Shop Manual - Section 6e - Automatic Transmission PDFbelchior alvaroNoch keine Bewertungen

- BCM Controls EverythingDokument6 SeitenBCM Controls EverythingMichael Ainsworth0% (1)

- Detailed guide to coil-on-plug wiring install with photosDokument11 SeitenDetailed guide to coil-on-plug wiring install with photosEmilio J PardoNoch keine Bewertungen

- DR-Z400SM L0: Parts CatalogueDokument87 SeitenDR-Z400SM L0: Parts CataloguejuanjoserodriguezalzNoch keine Bewertungen

- Decline of MaterialismDokument3 SeitenDecline of Materialismyasminbahat80% (5)

- 300m PDFDokument1.649 Seiten300m PDFCarlos enriquezNoch keine Bewertungen

- Coil On Plug IgnitionDokument2 SeitenCoil On Plug IgnitionMedula OblongataNoch keine Bewertungen

- 97jamopar PDFDokument743 Seiten97jamopar PDFAngel MorenoNoch keine Bewertungen

- Civilian Control and The ConstitutionDokument29 SeitenCivilian Control and The ConstitutionVirginia LemusNoch keine Bewertungen

- T CASE App Chart NPDokument2 SeitenT CASE App Chart NPKyle BillingsleyNoch keine Bewertungen

- 2001 Camaro 3800 PCM Pin OutsDokument5 Seiten2001 Camaro 3800 PCM Pin OutsRashid JuarezNoch keine Bewertungen

- Lunati CatalogDokument340 SeitenLunati Catalogfreek76Noch keine Bewertungen

- Unit - 1: Automotive FundamentalsDokument26 SeitenUnit - 1: Automotive FundamentalsvedhhNoch keine Bewertungen

- Rolls Royce and Bentley Production MilestonesDokument2 SeitenRolls Royce and Bentley Production MilestonesBentley SpottingNoch keine Bewertungen

- Homepage Provides VIN Help for Holden OwnersDokument933 SeitenHomepage Provides VIN Help for Holden OwnersSanket KareNoch keine Bewertungen

- Whitney Family History Volume 3 Part 1Dokument626 SeitenWhitney Family History Volume 3 Part 1Karisa WalkerNoch keine Bewertungen

- SB1208 - ZF As Tronic - Clutch Component LubricationDokument12 SeitenSB1208 - ZF As Tronic - Clutch Component LubricationCarlos José FariaNoch keine Bewertungen

- 2012 Arctic Cat Service Updates and BulletinsDokument470 Seiten2012 Arctic Cat Service Updates and BulletinsJuan Carlos SuarezNoch keine Bewertungen

- FZR400MANUALDokument385 SeitenFZR400MANUALcoccaro88Noch keine Bewertungen

- Caterpillar forklift manual guideDokument3 SeitenCaterpillar forklift manual guidemuhammad ali9% (22)

- Alfa Romeo Brand Book FINALDokument10 SeitenAlfa Romeo Brand Book FINALlinein_lineoutNoch keine Bewertungen

- Toyota U660E: Fill and Overflow Plug LocationsDokument8 SeitenToyota U660E: Fill and Overflow Plug LocationsAlex Maceira Graterol100% (1)

- Allison 3000 Automatic Transmission Driver InstructionsDokument2 SeitenAllison 3000 Automatic Transmission Driver InstructionsLinzaw WinNoch keine Bewertungen

- M&M - How M&M Made Thar A Product, Price and Branding Combo, and Drove Beyond Off-Road Purists - The Economic Times HLDokument7 SeitenM&M - How M&M Made Thar A Product, Price and Branding Combo, and Drove Beyond Off-Road Purists - The Economic Times HLShubhangi KesharwaniNoch keine Bewertungen

- System Wiring Diagrams 2.3L Turbo, Engine Performance Circuits (1 of 2)Dokument29 SeitenSystem Wiring Diagrams 2.3L Turbo, Engine Performance Circuits (1 of 2)Karlis VilcinsNoch keine Bewertungen

- Ancap BMW x2Dokument6 SeitenAncap BMW x2carbasemyNoch keine Bewertungen

- 08-Toyota 6FBREDokument8 Seiten08-Toyota 6FBREEdwin Ng67% (3)

- Electrical High-Speed Multiple Unit (MU) EC250: For The Swiss Federal Railways (SBB), SwitzerlandDokument2 SeitenElectrical High-Speed Multiple Unit (MU) EC250: For The Swiss Federal Railways (SBB), SwitzerlandRodrigo Sampaio100% (1)

- Cover LetterDokument3 SeitenCover Letterapi-273214049Noch keine Bewertungen

- RTG Lista de Precios PDFDokument125 SeitenRTG Lista de Precios PDFAUTOMOCION SAC50% (2)

- Sunray Hybrid Light Tower Product InformationDokument2 SeitenSunray Hybrid Light Tower Product InformationnecrofunkNoch keine Bewertungen

- Dodge ChryslerDokument59 SeitenDodge ChryslerFrancisco Lagos50% (2)

- Timing Belt, Gear and Pulleys Opel Zafira-BDokument4 SeitenTiming Belt, Gear and Pulleys Opel Zafira-Bmr & mrsNoch keine Bewertungen

- Subaru Warning Lights and MeaningDokument17 SeitenSubaru Warning Lights and MeaningJa Phe TiNoch keine Bewertungen

- Machine Identification Plate DetailsDokument12 SeitenMachine Identification Plate Detailsניקולאי איןNoch keine Bewertungen

- Range Rover Classic Parts Manual 1986 - 1991Dokument724 SeitenRange Rover Classic Parts Manual 1986 - 1991Rio D CaraeffNoch keine Bewertungen

- OM - Kubota M100GX, M110GX, M126GX, M135GX PDFDokument178 SeitenOM - Kubota M100GX, M110GX, M126GX, M135GX PDFtgit28Noch keine Bewertungen

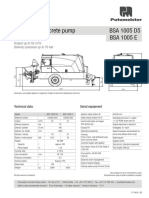

- BSA 1005 D5 - E Data Sheet ENDokument1 SeiteBSA 1005 D5 - E Data Sheet ENlukama constructNoch keine Bewertungen

- Four Wheel SteeringDokument5 SeitenFour Wheel SteeringMectrosoft Creative technologyNoch keine Bewertungen

- Chrysler Corporation: Service Manual 1994 JEEP Grand CherokeeDokument50 SeitenChrysler Corporation: Service Manual 1994 JEEP Grand CherokeeAlbert LewisNoch keine Bewertungen

- Lighting Systems Location Index: Ac5uuw00005411Dokument79 SeitenLighting Systems Location Index: Ac5uuw00005411chí công lêNoch keine Bewertungen

- Luis Carlos Galan Sarmiento 2018Dokument6 SeitenLuis Carlos Galan Sarmiento 2018eliana andrea cogolloNoch keine Bewertungen

- SEM655D Wheel Loader Weichai - TSUDokument2 SeitenSEM655D Wheel Loader Weichai - TSURivandho Anang100% (1)

- Daily Mis, Security DepartmentDokument12 SeitenDaily Mis, Security DepartmentMLastTryNoch keine Bewertungen

- W213 FusesDokument2 SeitenW213 Fusesdan.gutulescuNoch keine Bewertungen

- ANSI Inspection Form Boom Truck Cranes Fillable Template Loadking UPDATEDDokument4 SeitenANSI Inspection Form Boom Truck Cranes Fillable Template Loadking UPDATEDDaiver Lopez PadillaNoch keine Bewertungen

- Case Study - Indian Luxury Car MarketDokument5 SeitenCase Study - Indian Luxury Car MarketSatyam GambhirNoch keine Bewertungen

- LG Refrig - SB0805015 Change Door Switch (Prevents Freezing)Dokument9 SeitenLG Refrig - SB0805015 Change Door Switch (Prevents Freezing)Raul LopezNoch keine Bewertungen

- Service Report Monark: Dealer Process 0 1 11 4Dokument8 SeitenService Report Monark: Dealer Process 0 1 11 4Naser GulaidNoch keine Bewertungen