Beruflich Dokumente

Kultur Dokumente

An Kebutuhan Bahan Dan

Hochgeladen von

aldilamOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

An Kebutuhan Bahan Dan

Hochgeladen von

aldilamCopyright:

Verfügbare Formate

4/15/2009

PERENCANAAN KEBUTUHAN BAHAN DAN MANUFAKTUR JUST IN TIME

Dr. Mohammad Abdul Mukhyi, SE., MM

Resource Requirements Planning

Aggregate Planning

Master Production Scheduling (MPS)

Resource Requirements Planning

Material Requirements Planning (MRP)

Capacity Requirements Planning (CRP)

4/15/2009

4/15/2009

Material Requirements Planning (MRP)

4/15/2009

Materials Requirements Planning (MRP)

Computer based system Explodes Master Schedule (MPS) into required amounts of raw materials and subassemblies to support MPS Nets against current orders and inventories to develop production and purchased material ordering schedules

4/15/2009

4/15/2009

Objectives of MRP

Improve customer service Reduce inventory investment Improve plant operating efficiency

4/15/2009

Elements of MRP

Inputs ServiceService-Parts Orders and Forecasts Outputs Inventory Transaction Data

Inventory Status File MRP System

Order Changes Order Planned Order Schedule

Master Production Schedule

Planning Report Performance Exception Reports

6

Bill of Materials File

4/15/2009

4/15/2009

MRP Computer Program

Begins with number of end items needed Add service parts not included in MPS Explode MPS into gross requirements by consulting bill of materials file Modify gross requirements to get net requirements: Net Requirements = Gross Requirements + Allocated Inventory + Safety Stock - Inventory On Hand Offset orders to allow for lead time

4/15/2009 7

Outputs of MRP

Planned order schedule - quantity of material to be ordered in each time period Changes to planned orders - modifications to previous planned orders8 Secondary outputs:

Exception reports Performance reports Planning reports

4/15/2009

4/15/2009

Lot-Sizing in MRP

Lot-size is the quantity ordered/produced at one time Large lots are preferred because:

Changeovers cost less and capacity greater Annual cost of purchase orders less Price breaks and transportation breaks can be utilized

Small lots are preferred because:

Lower inventory carrying cost Reduced risk of obsolescence Shorter cycle time to produce customer order

4/15/2009 9

Lot-Sizing Methods

Economic Order Quantity (EOQ)

does not consider quantity discounts does not always provide the most economical approach with lumpy demands

Lot-for-Lot (LFL)

accommodates lumpy demand

Period Order Quantity (POQ)

The best method, resulting in least cost, depends on cost and demand patterns.

4/15/2009 10

4/15/2009

Issues in MRP

Lot-Sizing

Useful at lower levels but may drive excess inventory when applied at higher levels

Net Change versus Regenerative MRP

Net change may generate too many action notices Regenerative more costly to run but appears to be easier to manage

. . . more

4/15/2009 11

Issues in MRP

Safety Stock

Use depends on uncertainty of demand..... more uncertain the greater the need for safety stock

Assemble-to-Order Firms

MPS and MRP treated separately from Final Assembly Schedule(FAS) Use Modular Bill of Material

4/15/2009

12

4/15/2009

MRP I to MRP II

MRP I simply exploded demand (MPS) into required materials MRP II became Manufacturing Resource Planning which provides a closed-loop business management system

Financial management Shop floor control Operations management Simulation capability

4/15/2009 13

Evaluation of MRP

Most beneficial to process-focused systems that have long processing times and complex multistage production steps Lead times must be reliable Must freeze MPS for some time before actual production... certain demand Difficult to implement

4/15/2009

14

4/15/2009

Capacity Requirements Planning (CRP)

4/15/2009

15

Capacity Requirements Planning (CRP)

Tests MPS for feasibility Utilizes routings to determine labor/machine loads If schedule feasible, recommends freezing If schedule overloads resources, points out processes that are overscheduled

4/15/2009

16

4/15/2009

Load Schedules

Compares actual labor and machine hours against available hours Offsets schedules between successive stages of production by lead times Provides feasible MPS and economically loaded work centers Promotes system operating efficiency ... lowers costs!

4/15/2009 17

Das könnte Ihnen auch gefallen

- Material Requirements PlanningDokument5 SeitenMaterial Requirements PlanningNiño Rey LopezNoch keine Bewertungen

- L7 Material Requirement Planning (MRP)Dokument4 SeitenL7 Material Requirement Planning (MRP)COCONUTNoch keine Bewertungen

- 5th Unit SlidesDokument24 Seiten5th Unit Slidesgayatrimeghana32516Noch keine Bewertungen

- Introduction To: MRP & ErpDokument42 SeitenIntroduction To: MRP & ErpAnupama P Shankar100% (1)

- Chap012-Key Points 1Dokument6 SeitenChap012-Key Points 1Ace ChianNoch keine Bewertungen

- Material Requirement Plannin1Dokument4 SeitenMaterial Requirement Plannin1Shikha ThapaNoch keine Bewertungen

- Material Requirements PlanningDokument18 SeitenMaterial Requirements Planningamalroy1986Noch keine Bewertungen

- Benefits of MRP 001Dokument4 SeitenBenefits of MRP 001lynnthuNoch keine Bewertungen

- CH 5 MRPDokument20 SeitenCH 5 MRPahsanzia62Noch keine Bewertungen

- Chapter 4: Material Requirements Planning (MRP)Dokument14 SeitenChapter 4: Material Requirements Planning (MRP)Ethiopian Ayele SeyfeNoch keine Bewertungen

- ERP Assignment 1Dokument10 SeitenERP Assignment 1Ankit SinghNoch keine Bewertungen

- Material Requirements Planning (MRP) : By: K.N.D.Gopal Krishna 18HP5A0326Dokument14 SeitenMaterial Requirements Planning (MRP) : By: K.N.D.Gopal Krishna 18HP5A0326Roopasri BattulaNoch keine Bewertungen

- Material Requirements Planning FinalDokument16 SeitenMaterial Requirements Planning Finalniharika95323100% (2)

- Types of DemandDokument31 SeitenTypes of DemandVeera MuthuNoch keine Bewertungen

- Computer Aided Production Planning and Control JomyDokument32 SeitenComputer Aided Production Planning and Control JomyJo100% (2)

- Chapter 9 課本練習解答Dokument30 SeitenChapter 9 課本練習解答keshiangeltaslimNoch keine Bewertungen

- Production Planning & MRPDokument11 SeitenProduction Planning & MRPmuhammad_huzaifa2008Noch keine Bewertungen

- MRP Production Planning PresentationDokument22 SeitenMRP Production Planning Presentationvjeevan5Noch keine Bewertungen

- Inventory MNGMNT (MRP)Dokument11 SeitenInventory MNGMNT (MRP)Syed Waqas BukhariNoch keine Bewertungen

- Assignment # 3: Material Requirement PlanningDokument4 SeitenAssignment # 3: Material Requirement PlanningSabaNoch keine Bewertungen

- Materials Requirement PlanningDokument5 SeitenMaterials Requirement PlanningJohn Yaoto100% (1)

- Materials Requirement PlanningDokument8 SeitenMaterials Requirement PlanningdivyasahalNoch keine Bewertungen

- MODULE 3 - OM CombinedDokument18 SeitenMODULE 3 - OM Combinedchristy bijuNoch keine Bewertungen

- 01 Introduction OPSC or MPC SystemDokument31 Seiten01 Introduction OPSC or MPC SystemPrincess Marshalee FosterNoch keine Bewertungen

- Production PlanningDokument6 SeitenProduction Planningwiln89Noch keine Bewertungen

- MRP MaterialDokument1 SeiteMRP Materialsudhasweety19Noch keine Bewertungen

- Materials Requirements PlanningDokument20 SeitenMaterials Requirements PlanningMohamad FakihNoch keine Bewertungen

- 20 - Material Requirement PlanningDokument83 Seiten20 - Material Requirement Planning7708624402Noch keine Bewertungen

- Understanding Materials Requirement Planning (MRP) : Gul FarazDokument5 SeitenUnderstanding Materials Requirement Planning (MRP) : Gul FarazIqra MaroofNoch keine Bewertungen

- Unit III ErpDokument16 SeitenUnit III ErpSûrèndhár ChîYān RàsígânNoch keine Bewertungen

- An MRP Model For Supply Chains: ISSN 1913-9004 E-ISSN 1913-9012Dokument8 SeitenAn MRP Model For Supply Chains: ISSN 1913-9004 E-ISSN 1913-9012kurt_karunNoch keine Bewertungen

- Case 14 - MODokument8 SeitenCase 14 - MOMuthia Rahma Herdiyati0% (1)

- CH 14Dokument50 SeitenCH 14urvisuchakNoch keine Bewertungen

- Learn SAP PP in 1 Day: ALL RIGHTS RESERVED. No Part of This Publication May Be Reproduced orDokument23 SeitenLearn SAP PP in 1 Day: ALL RIGHTS RESERVED. No Part of This Publication May Be Reproduced orAmr ShararaNoch keine Bewertungen

- MRP & ErpDokument7 SeitenMRP & ErpAbdAllah KhodaryNoch keine Bewertungen

- Chap 5 - MRPDokument75 SeitenChap 5 - MRPladdooparmarNoch keine Bewertungen

- MRP & ErpDokument7 SeitenMRP & ErpAbdAllah KhodaryNoch keine Bewertungen

- Material Requirements PlanningDokument1 SeiteMaterial Requirements Planningflor gamboaNoch keine Bewertungen

- Material Requirement Planning (MRP)Dokument21 SeitenMaterial Requirement Planning (MRP)naveenNoch keine Bewertungen

- ERP - Past Present and FutureDokument17 SeitenERP - Past Present and Futurekrati12Noch keine Bewertungen

- MRP and ERP ModelDokument12 SeitenMRP and ERP ModelAmandeep SinghNoch keine Bewertungen

- "Implementation of MRP": School of Mechanical and Building SciencesDokument13 Seiten"Implementation of MRP": School of Mechanical and Building SciencesxyzNoch keine Bewertungen

- Material Requirements Planning: Submited byDokument5 SeitenMaterial Requirements Planning: Submited bynaveenNoch keine Bewertungen

- Supply Chain ManagementDokument4 SeitenSupply Chain ManagementEmelieKatharineNoch keine Bewertungen

- Assignment: Course: TopicDokument13 SeitenAssignment: Course: TopicjpearlNoch keine Bewertungen

- Module 8-MRP and ErpDokument25 SeitenModule 8-MRP and ErpDeryl GalveNoch keine Bewertungen

- A Study On Manufacturing Resources Planning of Tamilnadu Cement Corportation Limited at AriyalurDokument25 SeitenA Study On Manufacturing Resources Planning of Tamilnadu Cement Corportation Limited at Ariyalurk eswariNoch keine Bewertungen

- Odoo MRPDokument31 SeitenOdoo MRPTauseef Ahmed100% (1)

- BME1 Operations MGT Chapter 7Dokument8 SeitenBME1 Operations MGT Chapter 7Cristina maeNoch keine Bewertungen

- MRP and ERPDokument6 SeitenMRP and ERPAshley LumbaoNoch keine Bewertungen

- Aterial Equirement Lanning: Research Paper OnDokument21 SeitenAterial Equirement Lanning: Research Paper Onjain8687Noch keine Bewertungen

- ALR PresDokument30 SeitenALR PresArfe Lanhac RaganasNoch keine Bewertungen

- Cp-4 Erp A Manufacturing PerspectiveDokument32 SeitenCp-4 Erp A Manufacturing PerspectiveMinu SahNoch keine Bewertungen

- Unit 9 - Pull vs. Push System: StructureDokument69 SeitenUnit 9 - Pull vs. Push System: StructuresreerajNoch keine Bewertungen

- MPC BlockdiagramDokument15 SeitenMPC BlockdiagramKalpesh BardeNoch keine Bewertungen

- Student Slides Chapter 14Dokument15 SeitenStudent Slides Chapter 14Anthony RoyupaNoch keine Bewertungen

- Objective of MRP and MRP2 in Computer StudyDokument14 SeitenObjective of MRP and MRP2 in Computer StudyMostafa FawzyNoch keine Bewertungen

- Ch9 QUIZ ANWERS-Material Req PlanningDokument46 SeitenCh9 QUIZ ANWERS-Material Req Planningparatroop6662000Noch keine Bewertungen

- Enterprise Resource Planning (Erp) the Great Gamble: An Executive’S Guide to Understanding an Erp ProjectVon EverandEnterprise Resource Planning (Erp) the Great Gamble: An Executive’S Guide to Understanding an Erp ProjectBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Basic Accounting Equation Exercises 2Dokument2 SeitenBasic Accounting Equation Exercises 2Ace Joseph TabaderoNoch keine Bewertungen

- 05 Vision IAS CSP21 Test 5Q HIS AM ACDokument17 Seiten05 Vision IAS CSP21 Test 5Q HIS AM ACAvanishNoch keine Bewertungen

- ThesisDokument44 SeitenThesisjagritiNoch keine Bewertungen

- The Key To The Magic of The Psalms by Pater Amadeus 2.0Dokument16 SeitenThe Key To The Magic of The Psalms by Pater Amadeus 2.0evitaveigasNoch keine Bewertungen

- The Lure of The Exotic Gauguin in New York CollectionsDokument258 SeitenThe Lure of The Exotic Gauguin in New York CollectionsFábia Pereira100% (1)

- Jurisdiction and Kinds of JurisdictionDokument3 SeitenJurisdiction and Kinds of JurisdictionANUKULNoch keine Bewertungen

- EvaluationDokument4 SeitenEvaluationArjay Gabriel DudoNoch keine Bewertungen

- Sharmeen Obaid ChinoyDokument5 SeitenSharmeen Obaid ChinoyFarhan AliNoch keine Bewertungen

- NIST SP 800-53ar5-1Dokument5 SeitenNIST SP 800-53ar5-1Guillermo Valdès100% (1)

- Philippine ConstitutionDokument17 SeitenPhilippine ConstitutionLovelyn B. OliverosNoch keine Bewertungen

- Double Tax Avoidance Agreement ModelsDokument39 SeitenDouble Tax Avoidance Agreement ModelsReubenPhilipNoch keine Bewertungen

- ERRC Grid and Blue Ocean StrategyDokument2 SeitenERRC Grid and Blue Ocean StrategyfereNoch keine Bewertungen

- Series I: Episode OneDokument4 SeitenSeries I: Episode OnesireeshrajuNoch keine Bewertungen

- Covid-19: Researcher Blows The Whistle On Data Integrity Issues in Pfizer's Vaccine TrialDokument3 SeitenCovid-19: Researcher Blows The Whistle On Data Integrity Issues in Pfizer's Vaccine TrialLuxNoch keine Bewertungen

- Letter To Singaravelu by M N Roy 1925Dokument1 SeiteLetter To Singaravelu by M N Roy 1925Avinash BhaleNoch keine Bewertungen

- D Matei About The Castra in Dacia and THDokument22 SeitenD Matei About The Castra in Dacia and THBritta BurkhardtNoch keine Bewertungen

- Kesari Tours and Travel: A Service Project Report OnDokument15 SeitenKesari Tours and Travel: A Service Project Report OnShivam Jadhav100% (3)

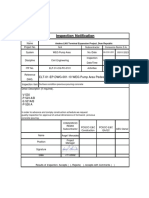

- In-CIV-201 INSPECTION NOTIFICATION Pre-Pouring Concrete WEG Pump Area PedestalsDokument5 SeitenIn-CIV-201 INSPECTION NOTIFICATION Pre-Pouring Concrete WEG Pump Area PedestalsPedro PaulinoNoch keine Bewertungen

- Trade Promotion Optimization - MarketelligentDokument12 SeitenTrade Promotion Optimization - MarketelligentMarketelligentNoch keine Bewertungen

- Printed by SYSUSER: Dial Toll Free 1912 For Bill & Supply ComplaintsDokument1 SeitePrinted by SYSUSER: Dial Toll Free 1912 For Bill & Supply ComplaintsRISHABH YADAVNoch keine Bewertungen

- Pulse of The Profession 2013Dokument14 SeitenPulse of The Profession 2013Andy UgohNoch keine Bewertungen

- Travisa India ETA v5Dokument4 SeitenTravisa India ETA v5Chamith KarunadharaNoch keine Bewertungen

- Chapter 11: Re-Situating ConstructionismDokument2 SeitenChapter 11: Re-Situating ConstructionismEmilio GuerreroNoch keine Bewertungen

- The Approach of Nigerian Courts To InterDokument19 SeitenThe Approach of Nigerian Courts To InterMak YabuNoch keine Bewertungen

- "Working Capital Management": Master of CommerceDokument4 Seiten"Working Capital Management": Master of Commercekunal bankheleNoch keine Bewertungen

- EIB Pan-European Guarantee Fund - Methodological NoteDokument6 SeitenEIB Pan-European Guarantee Fund - Methodological NoteJimmy SisaNoch keine Bewertungen

- Budo Hard Style WushuDokument29 SeitenBudo Hard Style Wushusabaraceifador0% (1)

- Times Leader 03-16-2013Dokument61 SeitenTimes Leader 03-16-2013The Times LeaderNoch keine Bewertungen

- SiswaDokument5 SeitenSiswaNurkholis MajidNoch keine Bewertungen

- Q1Dokument16 SeitenQ1satyamNoch keine Bewertungen